Professional Documents

Culture Documents

Tank Emission Calculation Form

Uploaded by

OmarTraficanteDelacasitosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tank Emission Calculation Form

Uploaded by

OmarTraficanteDelacasitosCopyright:

Available Formats

Table 1

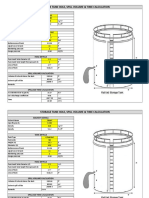

TANK EMISSION CALCULATION FORM1

( Note - Cells in pink are input cells. All other cells are calculated cells. )

Fill in pink input cells with specific tank description, dimensions, throughput and paint absorpta

DIRECTIONS: absorptance factor included in Table 1a below.

Tank No. T-501 Tank type Vertical fixed roof

Material stored Residual Fuel Oil No. 6 Company

City Newark State NJ

Description Outdoor storage tank

INPUT DATA

Symbol Units

Breathing losses

Molecular Weight Tank vapor space volume

Molecular weight Mv 190.00 Lb/lb-mole Vapor density

Tank design data Vapor space expansion factor

Shell height Hs 40.00 Vented vapor saturation factor

Diameter D 20.00 ft

Liquid height Hl 40.00 ft Breathing losses

Avg. Liquid height Hl 20.00 ft

vapor space outage Hvo 20.21 ft Working losses

Tank volume 94,003 gallons

Turnovers N 10 TOTAL LOSSES

Net throughput Q 940,033 gallons/yr

Tunover factor KN 1.000

Working loss product factor Kp 1.00

Meteorological data

Daily ave. ambient temp. TAA 54.75 °F

Daily max. ambient temp. TAX 63.38 °F

Daily min. ambient temp. TAN 46.11 °F

Daily ambient temp. range DTA 17.28 °F

Tank paint solar absorptance (see adjacent table) a 0.68

Daily total insolation factor I 1,236 Btu/ft2-day

Liquid bulk temperature TB 57.83 °F

Daily vapor temp. range DTv 35.96 °F

Daily ave. liquid surface temp. TLA 63.11 °F

Daily max. liquid surface temp. TLX 72.10 °F

Daily min. liquid surface temp. TlN 54.12 °F

VP @ daily ave. liquid surf. temp. PvA 0.00 mm Hg

VP @ daily max. liquid surf. temp. PvX 0.01 mm Hg

VP @ daily min. liquid surf. temp. PvN 0.00 mm Hg

Daily vapor pressure range DPv 0.00 mm Hg

Breather vent pressure setting range DPB 0.06 psia

Breather vent pressure setting range DPB 3.10 mm Hg

1

Calculations performed on this spreadsheet are taken from the USEPA AP-

42- Section 7.1 Organic Liquid Storage Tanks - January 1996. This

spreadsheet is derived from materials provided by Jimmy Peress, PE,

Tritech Consulting Engineers, 85-93 Chevy Chase Street, Jamaica, NY 11432

USA, Tel - 718-454-3920, Fax - 718-454-6330, e-mail - PeressJ@nyc.rr.com.

FORM1

s are calculated cells. )

ns, throughput and paint absorptance factor. For paint

Date 11/27/18

Performed by Jimmy Peress

CALCULATIONS

Symbol Units

athing losses

Tank vapor space volume Vv 6,217.75 ft3

Vapor density Wv 1.929E-6 lb/ft3

Vapor space expansion factor KE 0.06467

Vented vapor saturation factor Ks 0.9999 ft2

athing losses LB 0.28 lb/yr

Lw 0.24 lb/yr

AL LOSSES LT 0.53 lb/yr

Table 1a

Tank Paint Solar Absorptance

Tank Paint Solar Absorptance

white/white 0.17

Aluminum/Specular 0.39

gray/light 0.54

Aluminum/Diffuse 0.6

grey/medium 0.68

Table 1

TANK EMISSION CALCULATION FORM1

( Note - Cells in pink are input cells. All other cells are calculated cells. )

Fill in pink input cells with specific tank description, dimensions, throughput and paint absorpta

DIRECTIONS: absorptance factor included in Table 1a below.

Tank No. T-501 Tank type Vertical fixed roof

Material stored Distilllate Fuel Oil NO. 2 Company

City Newark State NJ

Description Outdoor storage tank

INPUT DATA

Symbol Units

Breathing losses

Molecular Weight Tank vapor space volume

Molecular weight Mv 130 Lb/lb-mole Vapor density

Tank design data Vapor space expansion factor

Shell height Hs 40.00 Vented vapor saturation factor

Diameter D 20.00 ft

Liquid height Hl 40.00 ft Breathing losses

Avg. Liquid height Hl 20.00 ft

vapor space outage Hvo 20.21 ft Working losses

Tank volume 94,003 gallons

Turnovers N 10 TOTAL LOSSES

Net throughput Q 940,033 gallons/yr

Tunover factor KN 1.000

Working loss product factor Kp 1.00

Meteorological data

Daily ave. ambient temp. TAA 54.75 °F

Daily max. ambient temp. TAX 63.38 °F

Daily min. ambient temp. TAN 46.11 °F

Daily ambient temp. range DTA 17.28 °F

Tank paint solar absorptance (see adjacent table) a 0.68

Daily total insolation factor I 1,236 Btu/ft2-day

Liquid bulk temperature TB 57.83 °F

Daily vapor temp. range DTv 35.96 °F

Daily ave. liquid surface temp. TLA 63.11 °F

Daily max. liquid surface temp. TLX 72.10 °F

Daily min. liquid surface temp. TlN 54.12 °F

VP @ daily ave. liquid surf. temp. PvA 0.37 mm Hg

VP @ daily max. liquid surf. temp. PvX 0.50 mm Hg

VP @ daily min. liquid surf. temp. PvN 0.27 mm Hg

Daily vapor pressure range DPv 0.22 mm Hg

Breather vent pressure setting range DPB 0.06 psia

Breather vent pressure setting range DPB 3.10 mm Hg

1

Calculations performed on this spreadsheet are taken from the USEPA AP-

42- Section 7.1 Organic Liquid Storage Tanks - January 1996. This

spreadsheet is derived from materials provided by Jimmy Peress, PE,

Tritech Consulting Engineers, 85-93 Chevy Chase Street, Jamaica, NY 11432

USA, Tel - 718-454-3920, Fax - 718-454-6330, e-mail - PeressJ@nyc.rr.com.

FORM1

s are calculated cells. )

ns, throughput and paint absorptance factor. For paint

Date 11/27/18

Performed by Jimmy Peress

CALCULATIONS

Symbol Units

athing losses

Tank vapor space volume Vv 6,217.75 ft3

Vapor density Wv 1.667E-4 lb/ft3

Vapor space expansion factor KE 0.06496

Vented vapor saturation factor Ks 0.9925 ft2

athing losses LB 24.40 lb/yr

Lw 20.95 lb/yr

AL LOSSES LT 45.35 lb/yr

Table 1a

Tank Paint Solar Absorptance

Tank Paint Solar Absorptance

white/white 0.17

Aluminum/Specular 0.39

gray/light 0.54

Aluminum/Diffuse 0.6

grey/medium 0.68

Table 1

TANK EMISSION CALCULATION FORM1

( Note - Cells in pink are input cells. All other cells are calculated cells. )

Fill in pink input cells with specific tank description, dimensions, throughput and paint absorpta

DIRECTIONS: absorptance factor included in Table 1a below.

Tank No. T-501 Tank type Vertical fixed roof

Material stored Gasoline (RVP 9) Company

City Newark State NJ

Description Outdoor storage tank

INPUT DATA

Symbol Units

Breathing losses

Molecular Weight Tank vapor space volume

Molecular weight Mv 67 Lb/lb-mole Vapor density

Tank design data Vapor space expansion factor

Shell height Hs 40.00 Vented vapor saturation factor

Diameter D 20.00 ft

Liquid height Hl 40.00 ft Breathing losses

Avg. Liquid height Hl 20.00 ft

vapor space outage Hvo 20.21 ft Working losses

Tank volume 94,003 gallons

Turnovers N 10 TOTAL LOSSES

Net throughput Q 940,033 gallons/yr

Tunover factor KN 1.000

Working loss product factor Kp 1.00

Meteorological data

Daily ave. ambient temp. TAA 54.75 °F

Daily max. ambient temp. TAX 63.38 °F

Daily min. ambient temp. TAN 46.11 °F

Daily ambient temp. range DTA 17.28 °F

Tank paint solar absorptance (see adjacent table) a 0.68

Daily total insolation factor I 1,236 Btu/ft2-day

Liquid bulk temperature TB 57.83 °F

Daily vapor temp. range DTv 35.96 °F

Daily ave. liquid surface temp. TLA 63.11 °F

Daily max. liquid surface temp. TLX 72.10 °F

Daily min. liquid surface temp. TlN 54.12 °F

VP @ daily ave. liquid surf. temp. PvA 253.42 mm Hg

VP @ daily max. liquid surf. temp. PvX 300.94 mm Hg

VP @ daily min. liquid surf. temp. PvN 212.11 mm Hg

Daily vapor pressure range DPv 88.83 mm Hg

Breather vent pressure setting range DPB 0.06 psia

Breather vent pressure setting range DPB 3.10 mm Hg

1

Calculations performed on this spreadsheet are taken from the USEPA AP-

42- Section 7.1 Organic Liquid Storage Tanks - January 1996. This

spreadsheet is derived from materials provided by Jimmy Peress, PE,

Tritech Consulting Engineers, 85-93 Chevy Chase Street, Jamaica, NY 11432

USA, Tel - 718-454-3920, Fax - 718-454-6330, e-mail - PeressJ@nyc.rr.com.

FORM1

s are calculated cells. )

ns, throughput and paint absorptance factor. For paint

Date 11/27/18

Performed by Jimmy Peress

CALCULATIONS

Symbol Units

athing losses

Tank vapor space volume Vv 6,217.75 ft3

Vapor density Wv 5.849E-2 lb/ft3

Vapor space expansion factor KE 0.23798

Vented vapor saturation factor Ks 0.1629 ft2

athing losses LB 5,144.50 lb/yr

Lw 7,348.37 lb/yr

AL LOSSES LT 12,492.88 lb/yr

Table 1a

Tank Paint Solar Absorptance

Tank Paint Solar Absorptance

white/white 0.17

Aluminum/Specular 0.39

gray/light 0.54

Aluminum/Diffuse 0.6

grey/medium 0.68

Table 1

TANK EMISSION CALCULATION FORM1

( Note - Cells in pink are input cells. All other cells are calculated cells. )

Fill in pink input cells with specific tank description, dimensions, throughput and paint absorpta

DIRECTIONS: absorptance factor included in Table 1a below.

Tank No. T-501 Tank type Vertical fixed roof

Material stored Gasoline (RVP 13) Company

City Newark State NJ

Description Outdoor storage tank

INPUT DATA

Symbol Units

Breathing losses

Molecular Weight Tank vapor space volume

Molecular weight Mv 62 Lb/lb-mole Vapor density

Tank design data Vapor space expansion factor

Shell height Hs 20.00 Vented vapor saturation factor

Diameter D 5.00 ft

Liquid height Hl 20.00 ft Breathing losses

Avg. Liquid height Hl 10.00 ft

vapor space outage Hvo 10.05 ft Working losses

Tank volume 2,938 gallons

Turnovers N 7 TOTAL LOSSES

Net throughput Q 20,000 gallons/yr

Tunover factor KN 1.000

Working loss product factor Kp 1.00

Meteorological data

Daily ave. ambient temp. TAA 54.75 °F

Daily max. ambient temp. TAX 63.38 °F

Daily min. ambient temp. TAN 46.11 °F

Daily ambient temp. range DTA 17.28 °F

Tank paint solar absorptance (see adjacent table) a 0.68

Daily total insolation factor I 1,236 Btu/ft2-day

Liquid bulk temperature TB 57.83 °F

Daily vapor temp. range DTv 35.96 °F

Daily ave. liquid surface temp. TLA 63.11 °F

Daily max. liquid surface temp. TLX 72.10 °F

Daily min. liquid surface temp. TlN 54.12 °F

VP @ daily ave. liquid surf. temp. PvA 380.61 mm Hg

VP @ daily max. liquid surf. temp. PvX 448.05 mm Hg

VP @ daily min. liquid surf. temp. PvN 321.48 mm Hg

Daily vapor pressure range DPv 126.56 mm Hg

Breather vent pressure setting range DPB 0.06 psia

Breather vent pressure setting range DPB 3.10 mm Hg

1

Calculations performed on this spreadsheet are taken from the USEPA AP-

42- Section 7.1 Organic Liquid Storage Tanks - January 1996. This

spreadsheet is derived from materials provided by Jimmy Peress, PE,

Tritech Consulting Engineers, 85-93 Chevy Chase Street, Jamaica, NY 11432

USA, Tel - 718-454-3920, Fax - 718-454-6330, e-mail - PeressJ@nyc.rr.com.

FORM1

s are calculated cells. )

ns, throughput and paint absorptance factor. For paint

Date 11/27/18

Performed by Jimmy Peress

CALCULATIONS

Symbol Units

athing losses

Tank vapor space volume Vv 195.33 ft3

Vapor density Wv 8.129E-2 lb/ft3

Vapor space expansion factor KE 0.39416

Vented vapor saturation factor Ks 0.2049 ft2

athing losses LB 468.06 lb/yr

Lw 217.29 lb/yr

AL LOSSES LT 685.35 lb/yr

Table 1a

Tank Paint Solar Absorptance

Tank Paint Solar Absorptance

white/white 0.17

Aluminum/Specular 0.39

gray/light 0.54

Aluminum/Diffuse 0.6

grey/medium 0.68

You might also like

- Directions:: T-501 Vertical Fixed Roof Residual Fuel Oil No. 6 Jimmy Peress Newark NJ Outdoor Storage TankDocument8 pagesDirections:: T-501 Vertical Fixed Roof Residual Fuel Oil No. 6 Jimmy Peress Newark NJ Outdoor Storage TankAnonymous K3FaYFlNo ratings yet

- Tank Emission Calculation FormDocument4 pagesTank Emission Calculation FormgenergiaNo ratings yet

- Tank Pressure During Pump OutDocument1 pageTank Pressure During Pump OutRexx MexxNo ratings yet

- Storage Tank Hole, Spill Volume & Time Calculation: Solvent DetailsDocument3 pagesStorage Tank Hole, Spill Volume & Time Calculation: Solvent Detailstribhuvan ShankarNo ratings yet

- Vessel Volume Calculation ReceiverDocument17 pagesVessel Volume Calculation ReceiverDHAVALESH AM100% (1)

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- Liquid Pipe Sizing: Group Technology SolutionsDocument1 pageLiquid Pipe Sizing: Group Technology SolutionsAhmad SiddiqNo ratings yet

- Heat Exchanger Specification Sheet Us Units: C:/Htri/Xchangersuite5/Samples/Xist - Shellsinseries - HtriDocument1 pageHeat Exchanger Specification Sheet Us Units: C:/Htri/Xchangersuite5/Samples/Xist - Shellsinseries - HtriNatarajan RavisankarNo ratings yet

- Vessel Sizing SpreadsheetDocument28 pagesVessel Sizing SpreadsheetEmamokeNo ratings yet

- Calculo Dimensional de Un FlareDocument2 pagesCalculo Dimensional de Un FlareFREDYTOAPANTANo ratings yet

- Ducted Air Conditioning Unit Performance SpecificationsDocument6 pagesDucted Air Conditioning Unit Performance Specificationsbasheer9No ratings yet

- TankJkt ExampleDocument16 pagesTankJkt ExamplesioanniNo ratings yet

- Heat Exchanger Plate TypeDocument1 pageHeat Exchanger Plate TypeDeepak jainNo ratings yet

- RTHD - RTHD AFD 87-99 - Consolidated Customer PackageDocument13 pagesRTHD - RTHD AFD 87-99 - Consolidated Customer Packageimecc ingenieriaNo ratings yet

- VG 320 Oil CoolerDocument32 pagesVG 320 Oil CoolergsdaundhNo ratings yet

- Liquid - Gas Phase SizingDocument12 pagesLiquid - Gas Phase Sizingeke23No ratings yet

- Fcu RDocument1 pageFcu RFareethAbdullahNo ratings yet

- SizingDocument3 pagesSizingheinfongNo ratings yet

- 5TR CondenserDocument1 page5TR CondenserbevarsiNo ratings yet

- PSV Calculation Report - Gas / Vapor Relief Sizing Case: Const. VarDocument4 pagesPSV Calculation Report - Gas / Vapor Relief Sizing Case: Const. VarfarshadNo ratings yet

- Chapter 1Document4 pagesChapter 1Aiman HazimNo ratings yet

- PSV Calculation Report - Gas Relief SizingDocument1 pagePSV Calculation Report - Gas Relief Sizingsugeng wahyudiNo ratings yet

- DJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADocument3 pagesDJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADIANTORONo ratings yet

- High Speed Small Direct Drive Water-Cooled Chillers - China Product Report PDFDocument3 pagesHigh Speed Small Direct Drive Water-Cooled Chillers - China Product Report PDFKhải The MonkNo ratings yet

- Master Flo Choke Control Valve Sizing - Version 7.1.0.0046I CV Sizing Calculation - Surface ValvesDocument2 pagesMaster Flo Choke Control Valve Sizing - Version 7.1.0.0046I CV Sizing Calculation - Surface ValvesFabian Solano100% (1)

- Tank Emisiion CalcDocument16 pagesTank Emisiion CalcAdhe GedeNo ratings yet

- 50KL Tank - API CalcDocument1 page50KL Tank - API CalcRathikaNo ratings yet

- PSV 1433Document1 pagePSV 1433Besan LaduNo ratings yet

- SCL ETP VOC Emission 2020Document3 pagesSCL ETP VOC Emission 2020shubhamNo ratings yet

- PROYEK MINI LPG PLANT LAPANGAN JATA CALCULATIONDocument6 pagesPROYEK MINI LPG PLANT LAPANGAN JATA CALCULATIONDIANTORONo ratings yet

- M=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dDocument23 pagesM=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dHoa NguyenNo ratings yet

- PLN CNG Process CalculationDocument14 pagesPLN CNG Process CalculationViqiNo ratings yet

- Diesel oil storage tank calculation data sheetDocument2 pagesDiesel oil storage tank calculation data sheetbagus handoko0% (1)

- New Heat Exchaner Design - 5mwDocument20 pagesNew Heat Exchaner Design - 5mwDaniel Perez0% (1)

- Pr-2 Teknik Produksi I: Catur Kristiawan 124.16.021Document8 pagesPr-2 Teknik Produksi I: Catur Kristiawan 124.16.021Reynold AvgNo ratings yet

- MC Fe-88115spiDocument1 pageMC Fe-88115spigallegos70No ratings yet

- The Production of Syrene From Methanol and TolueneDocument261 pagesThe Production of Syrene From Methanol and TolueneNizar MousaNo ratings yet

- DJM-MBA-PCS-CA-005 De-Etanizer Accumulator REV-1Document6 pagesDJM-MBA-PCS-CA-005 De-Etanizer Accumulator REV-1DIANTORONo ratings yet

- Fcu - 1Document1 pageFcu - 1basheer ahmedNo ratings yet

- Burner specification document summaryDocument6 pagesBurner specification document summaryHafiz Muhammad AbubakarNo ratings yet

- Oily Water Separator Calculation ParametersDocument2 pagesOily Water Separator Calculation ParametersTun Naing WinNo ratings yet

- Consequence AnalyserDocument23 pagesConsequence AnalyserGlacier RamkissoonNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- B41OA Datasheet 2017-2018Document7 pagesB41OA Datasheet 2017-2018Turkan AliyevaNo ratings yet

- Horizontal KO Pot V1.2Document6 pagesHorizontal KO Pot V1.2hk168No ratings yet

- SCL ETP VOC Emission 2021Document3 pagesSCL ETP VOC Emission 2021shubhamNo ratings yet

- Well Completions QuestionaireDocument27 pagesWell Completions QuestionaireashwaniNo ratings yet

- 1X660 MW WBPDCL Sagardighi TPP Etn. UNIT-5: Condenser Data SheetDocument2 pages1X660 MW WBPDCL Sagardighi TPP Etn. UNIT-5: Condenser Data SheetAyush ChoudharyNo ratings yet

- Fire Fighting CO2-CalcDocument8 pagesFire Fighting CO2-Calcjhaamit4No ratings yet

- 20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFDocument7 pages20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFahmedNo ratings yet

- Customer: Project Name: Ref. No: Date: Project Details - : Mekar Fcselect V4.220.021Document1 pageCustomer: Project Name: Ref. No: Date: Project Details - : Mekar Fcselect V4.220.021AL RawaqNo ratings yet

- VSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)Document7 pagesVSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)rudi 010% (1)

- Lats RS. Sardjito (R0)Document18 pagesLats RS. Sardjito (R0)agus abonNo ratings yet

- Thermal Design Well Head Natural GasDocument3 pagesThermal Design Well Head Natural GaskodeesNo ratings yet

- Calculation Header: Rtkcalc Powered by Conval® Version 2.0 (Build 2.0.2)Document3 pagesCalculation Header: Rtkcalc Powered by Conval® Version 2.0 (Build 2.0.2)Ahmed KhairiNo ratings yet

- STEAMcalc 12.8 RupiahDocument1,009 pagesSTEAMcalc 12.8 RupiahlightsonsNo ratings yet

- Hot Gas Recuperator Specification SheetDocument1 pageHot Gas Recuperator Specification Sheetmjaric81No ratings yet

- Cálculo de Diseño de SeparadoresDocument4 pagesCálculo de Diseño de SeparadoresEdwardNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Time History Analysis of Circular and Rectangular Elevated Water Storage Tank Using Baffle WallDocument5 pagesTime History Analysis of Circular and Rectangular Elevated Water Storage Tank Using Baffle WallIJEMR JournalNo ratings yet

- AFR Process Presentation - 22.11.2016Document34 pagesAFR Process Presentation - 22.11.2016Rohit SolomonNo ratings yet

- Construction Method Jack UpDocument23 pagesConstruction Method Jack UpMikiRoniWijaya100% (1)

- API 650 Storage Tank Data Sheet March 2017Document3 pagesAPI 650 Storage Tank Data Sheet March 2017Nasi GorengNo ratings yet

- Article Floating Roof Design Volume Emissions MaintenanceDocument3 pagesArticle Floating Roof Design Volume Emissions MaintenanceSara NunesNo ratings yet

- Cálculo de Volume em TanquesDocument7 pagesCálculo de Volume em TanquesMaurícioNo ratings yet

- Hot Tap Procedures ExonDocument17 pagesHot Tap Procedures ExonDian Ardiansyah67% (3)

- EEMUA 159 Reading ChecklistDocument3 pagesEEMUA 159 Reading ChecklistbacabacabacaNo ratings yet

- Storage Tanks: Building Services Submitted To: Meet Fatewar Ankita GaurDocument21 pagesStorage Tanks: Building Services Submitted To: Meet Fatewar Ankita GaurKhalida ParveenNo ratings yet

- GB50160 99Document45 pagesGB50160 99Anonymous YjKZdJTNo ratings yet

- Chapter 4-Taller 4Document56 pagesChapter 4-Taller 4Héctor F BonillaNo ratings yet

- Section 3: Desalters: Reduced Crude Unit Corrosion. at The High Temperatures Found in Crude UnitDocument48 pagesSection 3: Desalters: Reduced Crude Unit Corrosion. at The High Temperatures Found in Crude Unitrvkumar61No ratings yet

- Process Equipment DesignDocument418 pagesProcess Equipment DesignMoch Rokhmat Taufiq HidayatNo ratings yet

- Mothballing Guidelines For Plant EquipmentDocument11 pagesMothballing Guidelines For Plant EquipmentthawatchaiNo ratings yet

- BP Process Safety Series - Safe Ups and Downs For Process Units (7th Edition)Document71 pagesBP Process Safety Series - Safe Ups and Downs For Process Units (7th Edition)anhchangleloi88% (8)

- Oil Tank InstallationDocument16 pagesOil Tank InstallationGabriel MontaniNo ratings yet

- MDNDFHDocument31 pagesMDNDFHsreenathsNo ratings yet

- Horizontal Tank Calibration Using ExcelDocument8 pagesHorizontal Tank Calibration Using ExcelBhanwraa AawaraNo ratings yet

- Vapor RecoveryDocument12 pagesVapor RecoveryJasmine SalmassiNo ratings yet

- Vedlegg 17 Kvantitativ RisikovurderingDocument164 pagesVedlegg 17 Kvantitativ RisikovurderingGuillermo GonsalesNo ratings yet

- Oisd 116 Fire Protection Facilities Petroleum RefineriesDocument52 pagesOisd 116 Fire Protection Facilities Petroleum Refineriesdeua200483% (12)

- PT GoLNG Indonesia PDFDocument24 pagesPT GoLNG Indonesia PDFSutomo RochmandaNo ratings yet

- CG 2015148 00 - 2016Document2 pagesCG 2015148 00 - 2016Siles LimberdsNo ratings yet

- CS Raw Water Storage TankDocument18 pagesCS Raw Water Storage Tankmuchamad yasinNo ratings yet

- API Codes and SectionsDocument35 pagesAPI Codes and Sectionspattersondxb100% (4)

- Field and Range of Inspection Regulations, Standards, Specifications and Inspection ProceduresDocument5 pagesField and Range of Inspection Regulations, Standards, Specifications and Inspection ProceduresHazimNo ratings yet

- STORAGE TANK DESIGNDocument7 pagesSTORAGE TANK DESIGNMichael Robert Gatdula SamarNo ratings yet

- Design Transfer and StorageDocument46 pagesDesign Transfer and StorageMinh Tuấn NguyễnNo ratings yet

- Tank Lifting CalculationsDocument71 pagesTank Lifting Calculationsdownlaod06100% (2)

- CBI LNG Journal JanFeb05-LoresDocument3 pagesCBI LNG Journal JanFeb05-Loresaby_abraham5005No ratings yet