Professional Documents

Culture Documents

VDZVFVFDSVFSDVFS PDF

Uploaded by

SS31685Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VDZVFVFDSVFSDVFS PDF

Uploaded by

SS31685Copyright:

Available Formats

1 2 3 4 5 6

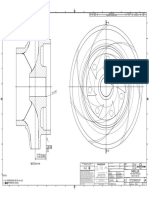

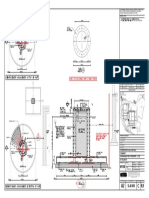

NOTE:

A SHOULD BE CONSTRUCTED FROM 2 PARTS: A

A MACHINED FLANGE PLATE, AND A LENGTH OF

STOCK TUBE.

THE TUBE SHOULD BE FITTED THROUGH

THE FLANGE (NOT JUST UP TO IT), AND SHOULD BE

WELDED IN PLACE SO THAT THE TUBE IS PERPENDICULAR

TO THE FLANGE FACE 0.1 .

4

4x 16 THRU 250

EQUISPACED ON PCD

127

B AS SHOWN 10 B

51

PCD 98.43

45

MA

X TH

ICKN

ES S3

C WELDED SEAM ALL THE WAY C

ROUND, THIS SIDE ONLY

CHAMFER 2 x 2

SIGNATURE: UNLESS OTHERWISE SPECIFIED: DIMENSIONS ARE IN MILLIMETERS AND AFTER FINISHING;

LINEAR TOLERANCE: +/-0.1; ANGULAR TOLERANCE: +/-0.1; THIRD ANGLE PROJECTION

REV. DESCRIPTION DATE PDF ARCHIVED [ ] DRAWING RELEASED TO PRODUCTION [ ] STOCK RECORD UPDATED [ ]

2 ORIGINAL 13/02/2009 MATERIAL: TITLE:

3 FINISH CHANGED TO RED OXIDE PRIMER 17/04/2009

MILD STEEL

D

4 INCREASED LENGTH TO 250MM 02/10/2009

DynOptic Systems Ltd

1.5" ANSI FLANGE EXTENSION

(incorporating Tunnel SensorsLtd)

Furlong House, Crowfield,

Brackley, Northants. NN13 5TW WEIGHT:

United Kingdom FINISH: DWG NO:

MTL-006-04

www.dynoptic.com

www.tunnelsensors.com WELD THRU RED OXIDE PRIMER

A4

**

CONFIDENTIAL!

All intellectual property rights reserved by

DynOptic Systems Ltd. This document is SHEET 1 OF 1

transmitted to you in confidence and its contents

may not be disclosed, or used for any purpose

1 2 other than that supplied, without written consent. STATE: CLEAN, DRY,AND DEBURRED DATE: 17/04/2009 DO NOT SCALE DRAWING SCALE: 1:3

You might also like

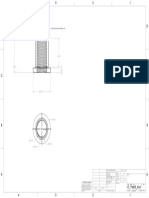

- Impeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLDocument1 pageImpeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLSenthilkumar RamalingamNo ratings yet

- Nozzle Orientation Drawing: Reference Drawings & SpecificationDocument1 pageNozzle Orientation Drawing: Reference Drawings & SpecificationjalNo ratings yet

- Planet CarrierDocument1 pagePlanet Carrierapi-439460086No ratings yet

- Shaft Main MTRDocument1 pageShaft Main MTRRizal MochammadNo ratings yet

- 00-00 BTDocument1 page00-00 BTSeptianNo ratings yet

- Sun GearDocument1 pageSun Gearapi-439460086No ratings yet

- mp2 Dean Johnson Full PDF With All Drawing Files 2Document6 pagesmp2 Dean Johnson Full PDF With All Drawing Files 2api-534483767No ratings yet

- Part3 NutDocument1 pagePart3 NutSaYed RaDyNo ratings yet

- E12004180 - Light Weight Lub Lower AssyDocument1 pageE12004180 - Light Weight Lub Lower Assysachin kadamNo ratings yet

- Strctl. Plans (As-Built) - S-3Document1 pageStrctl. Plans (As-Built) - S-3Raul DiazNo ratings yet

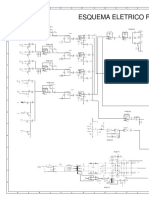

- Destroyer SoundTech S375WR & PSM1200 IC8 M65831 PDFDocument2 pagesDestroyer SoundTech S375WR & PSM1200 IC8 M65831 PDFSandro José100% (1)

- Biljax Error CodesDocument30 pagesBiljax Error CodesFauziah100% (1)

- PTF T2-Asse 00Document1 pagePTF T2-Asse 00ZERINA ŠKULJNo ratings yet

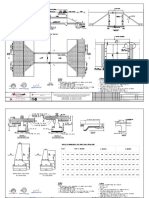

- Bill of Materials For Dimensional Reference Only: Do Not Scale If in Doubt, AskDocument1 pageBill of Materials For Dimensional Reference Only: Do Not Scale If in Doubt, AskJuan Andres RacinesNo ratings yet

- S4103 - R1 - Foundation Plan & Details For ChimneyDocument1 pageS4103 - R1 - Foundation Plan & Details For Chimneybhavin_civilNo ratings yet

- SCC TC e 1001Document1 pageSCC TC e 1001SaeidKHOKHANo ratings yet

- 30M Span 14.5 M Width - 1Document1 page30M Span 14.5 M Width - 1manupriyaNo ratings yet

- A&h Custom: For FabricationDocument1 pageA&h Custom: For FabricationReuben MuriguNo ratings yet

- TF 000070Document1 pageTF 000070api-299556237No ratings yet

- Va536 3Document1 pageVa536 3陆军No ratings yet

- SLD Softstarter Dol ModelDocument1 pageSLD Softstarter Dol ModelsihamuNo ratings yet

- NHD C12864LZ FSW FBW 3V3Document13 pagesNHD C12864LZ FSW FBW 3V3christjjonesNo ratings yet

- BG6944 6 PDFDocument1 pageBG6944 6 PDFArmando De la TorreNo ratings yet

- Planet GearDocument1 pagePlanet Gearapi-439460086No ratings yet

- E12001948 - Light Weight Lub Upper AssyDocument1 pageE12001948 - Light Weight Lub Upper Assysachin kadamNo ratings yet

- Asy13144Document87 pagesAsy13144Oz DemonNo ratings yet

- Part4 - Locking NutDocument1 pagePart4 - Locking NutSaYed RaDyNo ratings yet

- SHIBATA Donut Rubber FenderDocument1 pageSHIBATA Donut Rubber FenderJose LugardoNo ratings yet

- Schematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byDocument1 pageSchematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byTaufiq HidayatNo ratings yet

- Parafuso: Revision Do Not Scale Drawing Debur and Break Sharp Edges FinishDocument1 pageParafuso: Revision Do Not Scale Drawing Debur and Break Sharp Edges FinishAntonio MarinhoNo ratings yet

- Parafuso PDFDocument1 pageParafuso PDFAntonio MarinhoNo ratings yet

- E2 MinglaDocument1 pageE2 MinglaEricka Jane V. CeballosNo ratings yet

- Structure WoodenDocument14 pagesStructure WoodenAngélica María González FlórezNo ratings yet

- Truss T4 PDFDocument15 pagesTruss T4 PDFquocphong199No ratings yet

- 181004-GNFC-NEEM-220V-160A-As BuiltDocument28 pages181004-GNFC-NEEM-220V-160A-As BuiltPranav PatelNo ratings yet

- Planet GearDocument1 pagePlanet Gearapi-439358555No ratings yet

- SCC TC e 1003Document1 pageSCC TC e 1003SaeidKHOKHANo ratings yet

- Seci-Dvc-Ktps6mw-Dwg-Civ-34 - MCR - Foundation General Arrangement and Reinforcement Details - R02 - Cat-IDocument2 pagesSeci-Dvc-Ktps6mw-Dwg-Civ-34 - MCR - Foundation General Arrangement and Reinforcement Details - R02 - Cat-Ipravin singhNo ratings yet

- Habshan SS-1 MV Cable SizeDocument12 pagesHabshan SS-1 MV Cable SizeAbdul RahmanNo ratings yet

- AE - GASCO HABSHAN SS1 - 1VL8471424 - SLD - RevA1 - CTVT - UpdDocument12 pagesAE - GASCO HABSHAN SS1 - 1VL8471424 - SLD - RevA1 - CTVT - UpdAbdul RahmanNo ratings yet

- Board Formation & Panel Construction - Rev-A - 03.06.2013Document7 pagesBoard Formation & Panel Construction - Rev-A - 03.06.2013ADE mrtNo ratings yet

- P - EA5101E00QCCT00050141 SR Pref Tip 2, H 1.60m Ad 0.40mDocument1 pageP - EA5101E00QCCT00050141 SR Pref Tip 2, H 1.60m Ad 0.40mAlinNo ratings yet

- Gad Ad2 J10k1020c27a 200a201Document1 pageGad Ad2 J10k1020c27a 200a201AbdulNo ratings yet

- Jsfa FNHD16G08 TNDocument1 pageJsfa FNHD16G08 TNLuong LeNo ratings yet

- Agv Autocharger V2Document2 pagesAgv Autocharger V2Azhar AzmiNo ratings yet

- 1X1.5x1.5 BOX CULVERT FOR-2 - LANE PDFDocument3 pages1X1.5x1.5 BOX CULVERT FOR-2 - LANE PDFbakhteyar shaikhNo ratings yet

- Revisions C: REVISED PER ECO-11-005150 RK HMR New Creo Drawing BV GBDocument1 pageRevisions C: REVISED PER ECO-11-005150 RK HMR New Creo Drawing BV GBhulaneNo ratings yet

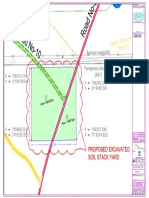

- 01 - Proposed Excavated Soil Stack Yard-Layout1Document1 page01 - Proposed Excavated Soil Stack Yard-Layout1Ramesh BabuNo ratings yet

- Pile Cap DesignDocument1 pagePile Cap DesignMaitrayee AdityaNo ratings yet

- SWSP-715-20 7 1 16in 15ksi SwivelSpool Flange Assembly MarketingDocument1 pageSWSP-715-20 7 1 16in 15ksi SwivelSpool Flange Assembly MarketingJitendra BhosaleNo ratings yet

- Ecu Chevrolet S10 1998 2.2Document4 pagesEcu Chevrolet S10 1998 2.2AUTOMOTRIZ TIPO SPCA100% (2)

- J3B-AM-08-D-00001-0-Sludge Treatment BuildingDocument8 pagesJ3B-AM-08-D-00001-0-Sludge Treatment BuildingNaheed AkhtarNo ratings yet

- A1 BOIVIN - Apr29.21 ImplantationDocument1 pageA1 BOIVIN - Apr29.21 Implantationserge BoivinNo ratings yet

- Supe St.-Span23.2m-Width-16.5m-401 - (Dim Details) - SH 1Document1 pageSupe St.-Span23.2m-Width-16.5m-401 - (Dim Details) - SH 1Engineering CivilMantraNo ratings yet

- Combustion Control Construction Drawings Internal Wiring/ControlDocument14 pagesCombustion Control Construction Drawings Internal Wiring/ControlJosh ScherdnikNo ratings yet

- MC-MNT-TOP-2 Line DrawingDocument2 pagesMC-MNT-TOP-2 Line Drawing208.nampa.idNo ratings yet

- 60kld ZLD Flow Diagram-10.11.18-ModelDocument1 page60kld ZLD Flow Diagram-10.11.18-ModelkezaihrajNo ratings yet

- 8.environmental - Engineering (CE)Document1 page8.environmental - Engineering (CE)ZaidNo ratings yet

- Differential Pressure Gauge Double Diaphragm Type: Special FeaturesDocument4 pagesDifferential Pressure Gauge Double Diaphragm Type: Special FeaturesSS31685No ratings yet

- MTL-006-04 - Sheet1Document1 pageMTL-006-04 - Sheet1SS31685No ratings yet

- MTL-006-04 - Sheet1Document1 pageMTL-006-04 - Sheet1SS31685No ratings yet

- Annexure ADocument2 pagesAnnexure ARajesh LingamalluNo ratings yet

- 全新全真题库一 PDFDocument36 pages全新全真题库一 PDFTzarlene100% (1)

- The Other Twelve Part 1Document5 pagesThe Other Twelve Part 1vv380100% (2)

- An Introduction To Routine and Special StainingDocument13 pagesAn Introduction To Routine and Special StainingBadiu ElenaNo ratings yet

- Operation and Maintenance Manual Compressor Models: P105WJD, P130DWJD, P160DWJD, P175DWJDDocument70 pagesOperation and Maintenance Manual Compressor Models: P105WJD, P130DWJD, P160DWJD, P175DWJDManuel ParreñoNo ratings yet

- Handout Waste Catch BasinDocument2 pagesHandout Waste Catch BasinJonniel De GuzmanNo ratings yet

- PretestDocument8 pagesPretestAlmonte Aira LynNo ratings yet

- 1.classification of Reciprocating PumpsDocument8 pages1.classification of Reciprocating Pumpsgonri lynnNo ratings yet

- What Is Urban PlanningDocument33 pagesWhat Is Urban PlanningDivine Grace FernandoNo ratings yet

- 1id Abstracts Season 2 Episode 6Document406 pages1id Abstracts Season 2 Episode 6Jennifer BrownNo ratings yet

- Adigwe J. C.: ATBU, Journal of Science, Technology & Education (JOSTE) Vol. 3 (1), January, 2015 ISSN: 2277-0011Document16 pagesAdigwe J. C.: ATBU, Journal of Science, Technology & Education (JOSTE) Vol. 3 (1), January, 2015 ISSN: 2277-0011AnnyNo ratings yet

- Industrial Motor Control Part IDocument38 pagesIndustrial Motor Control Part Ikibrom atsbha100% (2)

- RESEARCHDocument5 pagesRESEARCHroseve cabalunaNo ratings yet

- Penelitian Tindakan Kelas - Alberta Asti Intan Sherliana 20220049Document25 pagesPenelitian Tindakan Kelas - Alberta Asti Intan Sherliana 20220049Asti SherlyanaNo ratings yet

- Unit 20: TroubleshootingDocument12 pagesUnit 20: TroubleshootingDongjin LeeNo ratings yet

- Nbme NotesDocument3 pagesNbme NotesShariq AkramNo ratings yet

- Performance Task 2Document3 pagesPerformance Task 2Edrose WycocoNo ratings yet

- Baby DedicationDocument3 pagesBaby DedicationLouriel Nopal100% (3)

- ENSC1001 Unit Outline 2014Document12 pagesENSC1001 Unit Outline 2014TheColonel999No ratings yet

- LT3845ADocument26 pagesLT3845Asoft4gsmNo ratings yet

- Effects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionDocument5 pagesEffects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionJasmine EffendiNo ratings yet

- 2023 2024 Syllabus PDFDocument23 pages2023 2024 Syllabus PDFRika DianaNo ratings yet

- Uniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFDocument64 pagesUniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFtradosevic4091No ratings yet

- Mossbauer SpectrosDocument7 pagesMossbauer SpectroscyrimathewNo ratings yet

- 3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation GuideDocument6 pages3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation GuideYuukinoriNo ratings yet

- 12 Logarithm Approximate FloatingDocument6 pages12 Logarithm Approximate FloatingPhilippe Englert VelhaNo ratings yet

- RS-All Digital PET 2022 FlyerDocument25 pagesRS-All Digital PET 2022 FlyerromanNo ratings yet

- Charles Zastrow, Karen K. Kirst-Ashman-Understanding Human Behavior and The Social Environment-Thomson Brooks - Cole (2007)Document441 pagesCharles Zastrow, Karen K. Kirst-Ashman-Understanding Human Behavior and The Social Environment-Thomson Brooks - Cole (2007)joan82% (17)

- V13 D03 1 PDFDocument45 pagesV13 D03 1 PDFFredy Camayo De La CruzNo ratings yet

- DADTCO Presentation PDFDocument34 pagesDADTCO Presentation PDFIngeniería Industrias Alimentarias Itsm100% (1)

- 8 Adam AmuraroDocument28 pages8 Adam Amurarokmeena73No ratings yet