Professional Documents

Culture Documents

Stainless Selector Guide

Uploaded by

josel2130 ratings0% found this document useful (0 votes)

6 views1 pageok

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentok

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageStainless Selector Guide

Uploaded by

josel213ok

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

SFAS.4/SFAS4M ASME BPVCILC-2015

A7.6 E308H. ‘These electrodes are the same as E308 except that the allowable weld metal carbon content has been

restricted to eliminate the lowest carbon levels. Carbon content inthe range of 0.04 to 0.08 percent provides higher tensile

and creep strengths at elevated temperatures. These electrodes are used for welding Type 304H base metal. Weld metal

ferrite content is normally targeted for 5 EN to minimize the effect of sigma embrittlement in high-temperature service.

7.7 E3081. The composition of the weld metal is the same as E308, except for the carbon content, The 0.04 percent

‘maximum carbon content of weld metal deposited by these electrodes reduces the possibility of intergranular carbide

precipitation and thereby increases the resistance to intergranular corrosion without the use of stabilizers such as niobium.

or titanium. A carbon content of 0.04 percent maximum has been shown to be adequate in weld metal, even though itis

recognized that similar base metal specifications require a 0.03 percent limitation, This low-carbon alloy, however, is not

as strong at elevated temperature as E308H or E347.

AT. E308Mo, These electrodes are the same as E308, except for the addition of molybdenum, E308Mo electrodes are

recommended for welding ASTM CF8M stainless steel castings, as they match the base metal with regard to chromium,

nickel, and molybdenum. They may also be used for welding wrought materials such as Type 316 stainless when

increased ferrite is desired beyond that attainable with E316 electrodes.

A7.9 E308LMo. These electrodes are recommended for welding ASTM CF3M stainless steel castings, as they match the

base metal with regard (0 chromium, nickel, and molybdenum. E308LMo electrodes may also be used for welding,

wrought materials such as Type 316L. stainless when increased ferrite is desired beyond that attainable with E316L

electrodes,

AT.L1 E309H. These clectrodes are the same as E309, except that the allowable weld metal carbon content has been

restricted to eliminate the lowest carbon levels. The carbon restriction will provide higher tensile and creep strengths at

elevated temperatures. This together with a typical ferrite content of about 6 FN make these electrodes suitable for the

welding of 24 Cr 12.Ni wrought and cast steels designed for corrosion and oxidation resistance. High-carbon castings to

ACT's HHT grade should be welded with an electrode that is similar to the easting composition

A7.13 E309ND. The composition of this weld metal is the same as Type 309, except for the addition of niobium and a

reduction in the carbon limit, The niobium provides resistance to carbide precipitation and thus inereases intergranular

corrosion resistance, and also provides higher strength in elevated-temperature service. E309Nb electrodes are used also

for welding Type 347 clad steels or for the overlay of earbon steel

A7.14 E309Mo. The composition of this weld metal is the same as that deposited by E309 electrodes, except for the

addition of molybdenum and a small reduction in the carbon limit. These electrodes are used for welding Type 316 clad

steels or for the overlay of carbon steels,

128

ervares pewudtufidog

Wwar2s vosuoy, fq owUovoL Jo AiTsuentun cy pesuaD

oon

You might also like

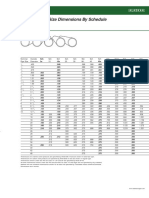

- Nominal Pipe Size DimensionsDocument1 pageNominal Pipe Size Dimensionsjosel213No ratings yet

- STAINLESS Filler Selector Guide PDFDocument1 pageSTAINLESS Filler Selector Guide PDFArul Edwin VijayNo ratings yet

- Carbon Structural Steel: Standardspecification ForDocument4 pagesCarbon Structural Steel: Standardspecification ForlinaNo ratings yet

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocument1 pageTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014No ratings yet

- P Number Soldadores (Welder)Document1 pageP Number Soldadores (Welder)josel213No ratings yet

- ASME B16.48-2010 Line BlanksDocument56 pagesASME B16.48-2010 Line Blanksjosel213No ratings yet

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocument1 pageTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014No ratings yet

- Welding StainlessSteel LincolnDocument40 pagesWelding StainlessSteel Lincolnjosel213No ratings yet

- 1169 2014-BOK Rev-071014Document9 pages1169 2014-BOK Rev-071014Siva KumarNo ratings yet

- Concept Shot BlastingDocument16 pagesConcept Shot Blastingjosel213No ratings yet

- F Number ER70S 6Document1 pageF Number ER70S 6josel213No ratings yet

- Thermal Efficiency and Arc Energy FEM ModelDocument5 pagesThermal Efficiency and Arc Energy FEM ModelWilly Villa SalsavilcaNo ratings yet

- ISO 10816 - Severidad en Vibracion PDFDocument2 pagesISO 10816 - Severidad en Vibracion PDFJuan Carlos Bonifacio BricenoNo ratings yet

- F Number ER70S 6Document1 pageF Number ER70S 6josel213No ratings yet

- Al Flhakj Halhfakg Lkahf LKJHG Agas GaDocument1 pageAl Flhakj Halhfakg Lkahf LKJHG Agas Gaabidaliabid1No ratings yet

- Test TensileDocument31 pagesTest Tensilejosel213No ratings yet

- Test TensileDocument31 pagesTest Tensilejosel213No ratings yet

- A36 23793-1 PDFDocument1 pageA36 23793-1 PDFjosel213No ratings yet

- Naxtra-Xabo 2010 GBDocument6 pagesNaxtra-Xabo 2010 GBjosel213No ratings yet

- A572 15056-1Document1 pageA572 15056-1josel213No ratings yet

- b31.4 Contenido PDFDocument6 pagesb31.4 Contenido PDFEliezerlunaNo ratings yet

- XAR 400 (WB 703) EnglischDocument3 pagesXAR 400 (WB 703) Englischgheoda8926No ratings yet

- M1 121 221 2011Document1 pageM1 121 221 2011josel213No ratings yet

- This documentDocument44 pagesThis documentTran Thanh HaoNo ratings yet

- A36 23793-1 PDFDocument1 pageA36 23793-1 PDFjosel213No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)