Professional Documents

Culture Documents

Oxygen Enrichment Process

Uploaded by

Azrul Ikhwan Azhar0 ratings0% found this document useful (0 votes)

8 views6 pagesoxygen enrichment process

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentoxygen enrichment process

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views6 pagesOxygen Enrichment Process

Uploaded by

Azrul Ikhwan Azharoxygen enrichment process

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

United States Patent (19) 11, 3,957,463

Drissel et al. (45) May 18, 1976

54) OXYGEN ENRICHMENT PROCESS Primary Examiner-John Adee

75 Inventors: Gerald M. Drissel; Shivaji Sircar, Attorney, Agent, or Firm-Harold A. Hormann; Barry

both of Allentown, Pa. Moyerman

73) Assignee: Air Products and Chemicals, Inc., 57 ABSTRACT

Allentown, Pa.

22) Filed: Dec. 12, 1973 Ambient air, during an on-stream period, is passed

through a first adsorbent bed removing moisture and

21 Appl. No.: 423,995 carbon dioxide and then through a second bed of ad

sorbent selective for retention of nitrogen, the oxygen

52 U.S. Cl......................................... 55/25; 55/58; rich effluent being collected in an expandable re

55/68 ceiver. Desorption of both beds is effected by reduc

51 Int. Cl”.......................................... B01D 53/02 ing the pressure at the inlet end of the first bed caus

58 Field of Search............... 55/25, 31, 32, 58, 62, ing desorbed nitrogen from the second bed to pass

55/75, 389, 179, 68 through the first bed, desorbing moisture and CO,

therefrom. Further removal of moisture and CO2 from

(56) References Cited the first bed is then effected by lowering the pressure

UNITED STATES PATENTS of that bed further, while the second bed is restored to

its on-stream pressure by admission of enriched oxy

3,533,221 10/1970 Tamura................................... 55162 gen thereto from the expandable receiver.

3,719,025 3/1973 Heinze et al............................ 55/31

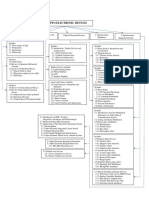

7 Claims, 1 Drawing Figure

U.S. Patent May 18, 1976 3,957,463

3,957,463

2

column and its associated fractionation column, while

OXYGEN ENRICHMENT PROCESS continuing vacuum application to the pretreatment

BACKGROUND OF THE INVENTION column alone, thus regenerating the water-CO2 adsorp.

tion column during each cycle. During the further ap

Numerous and diverse systems are described in the 5 plication of vacuum to the pretreatment column, the

patent literature for separation of gases by preferential fractionation column is repressured with product gas

adsorption. Typical among these, particularly designed before returning on stream for repetition of the adsorp

for or asserted to be useful in the recovery of an en tion-desorption sequence.

riched oxygen product stream from air, are the pres DETAILED DESCRIPTION

sure swing adsorption systems described in U.S. pat. ()

Nos. 2,944,627; 3,564,816; 3,636,679; and in pub The invention will be understood and its several ad

lished German patent application OLS No. 2,153,807. vantages appreciated from the detailed description

The systems described in these patents utilize zeolite which follows, read in connection with the Schematic

molecular sieves as adsorbents and involve intricate flow diagram shown in the accompanying drawings.

cycle time operational sequences necessitating com 5 While not limited thereto, the system of the present

plex valve arrangements for their operation. invention is particularly advantageous in the produc

In U.S. pat. No. 3,533,221, a system is described for tion of an enriched and purified oxygen product stream

recovery of an enriched oxygen stream from air from atmospheric air or from other oxygen-nitrogen

wherein the air charged to the system is initially passed gas mixtures containing water and/or carbon dioxide as

through an adsorption column to remove carbon diox an impurity. The particular embodiment hereinafter

ide and moisture therefrom and then into a nitrogen described in detail is accordingly directed to purifica

adsorption column, recovering therefrom a product tion and separation of atmospheric air as the charge gas

stream enriched in oxygen. When the effluent from the which ordinarily contains minor amounts of water and

nitrogen adsorber contains nitrogen in excess of the carbon dioxide.

desired maximum level, the air supply is discontinued 25 The incoming air is compressed slightly above atmo

and vacuum applied at the air inlet end to desorb the spheric pressure to accomodate the pressure drop

nitrogen column, the desorbed gas being passed through the adsorption columns and transfer lines. In

through the water-CO adsorption column enroute to general, a pressure of 0.5 to 5 pounds per square inch

discharge. The water-CO adsorption column in the gauge will be sufficient for this purpose. With valve

described system needs to be periodically regenerated. 30 being open and valves 1 and 2 closed, the compressed

For this purpose two such water-CO pretreatment air enters the pretreatment column A which contains

columns are provided for each nitrogen adsorption adsorbent suitable for selective removal of moisture

column, being alternately connected to the nitrogen and carbon dioxide. Column A has previously been

column so that one of these is in adsorptive opertion purged, as will hereinafter appear, and regenerated by

while the other is being regenerated. Regeneration of 35 evacuation to lowest pressure, preferably below 50

the water-CO adsorption column is effected by heating mm. Hg. After passing through column A, the thus

the adsorbent therein to drive off water and carbon pretreated air passes through open valve 3 into frac

dioxide. tionating column B containing an adsorbent preferen

While the gas separation and purification system of tially adsorbing and retaining nitrogen while permitting

the present invention utilizes a pretreatment column 40 oxygen to pass through. Adsorber column B prior to

for removal of water and carbon dioxide from the feed receiving the air charge, has been brought to about

gas prior to its separation by selective adsorption of one atmospheric pressure by introduction of an oxygen gas

or more components in a subsequent adsorption col stream of high purity obtained from a source hereinaf

umn, the operation is carried out under conditions such ter described. The effluent from column B including a

that isolation of the pretreatment column from the portion of the oxygen which had been adsorbed in the

system for its separate regeneration need not be prac bed by the repressuring step hereinafter described, is

ticed. eluted and passes out of the bed with the unadsorbed

BRIEF DESCRIPTION OF THE INVENTON oxygen. This effluent is discharged through open valve

4 into a so-called 'rinse bag' for temporary storage.

In accordance with the present invention, a simpli 50 The rinse bag is a vessel of expandable volume which is

fied and efficient vacuum swing gas separation and maintained at about atmospheric pressure. This vessel

purification system is provided wherein a pretreatment provides for product surge capacity during operation of

adsorption column is utilized for removal of water and the system, from which high purity oxygen product can

carbon dioxide from the charge gas prior to further 55 be withdrawn for desired use or further storage. The

adsorptive fractionation of such gas. The system prefer rinse bag also serves as the supply source for high pu

entially employs two or more fractionation columns in rity oxygen gas used in repressuring the fractionation

parallel alternately operated in timed sequence through vessels at the conclusion of the desorption step to be

successive steps of adsorption and desorption. Each of described.

the fractionation columns is connected in series with a Flow of air through valve 1 and continuous with

pretreatment adsorber column. During desorption of 60 drawal of product gas through valve 4 and into the rinse

the fractionating column under reduced pressure, the bag is continued until there is a breakthrough of nitro

desorbed gas from such column is passed serially gen in the effluent from adsorber B or just short of that

through the associated pretreatment column purging point which may be designated as the point of incipient

such column of a portion of its contained moisture and 65 nitrogen breakthrough. The breakthrough point may

carbon dioxide while under the applied suction. Fur be defined as that at which the effluent from an ad

ther removal of moisture and carbon dioxide from the sorber B or B' contains substantially the amount of

pretreatment column is then effected by shutting off nitrogen as that contained in the charge gas or at a

the flow communication between the pretreatment predetermined level short of that amount depending

3,957,463

3 4.

upon desired product quality. the equal pressure of column B (about atmospheric).

When the desired termination of the adsorption step At this point, the cycle of operation already described

is reached, further supply of air to columns A and B is may be resumed by suitable valve changes, placing

discontinued. This is accomplished by closing valves 1 columns A and B on stream to receive the air charge,

and 4 and switching the flow of the air charge to com while columns A" and B' which were on adsorption

panion columns A" and B', with the opening of valve 3' during the desorption of columns A and B, undergo the

and subsequent opening of valves 1' and 4" as hereinaf desorption sequence and repressuring as already de

ter described. Thus, the operation heretofore con scribed for companion columns A and B.

ducted in columns A and B is continued in correspond 10 Table I below illustrates a time program for the vari

ing columns A" and B" with the flow of oxygen ous steps in the sequence of operations based on an

enriched product gas into the rinse bag. embodiment employing a suggested 4 minute cycle,

Columns A and B are now ready for desorption and and indicating the valve positions during the sequence.

regeneration. After closing valve 1, valve 2 is now It will be understood, however, that the 4 minute cycle

opened, permitting flow of residual unadsorbed and described is merely illustrative and other time cycles

adsorbed gases into line 6. Suction is applied through 15 may be employed in practice of the invention.

TABLE I

VcsSc, Pressures

Timc Valve Positions - (mm Hg) Process

(Sec.) 2' 3 3' 4 4' 5 5 A A" B B' A A' B B'

() - 5 C C C () () () C C () C 10-760 76() 760 760 R D S D

5 - 75 O C C O O O O C C C 76() 76() 5() 760 7605() A D A D

75 - 20 O C C O O C O C C O 76() 5()-1() 76) 50-760 A D A R

120 - 125 C C O C O O C C C O 760 ()-76() 760 760 D R D S

125 - 195 C O O C O O C O C C 760 50 76() 760.50 760 D A D A

195 - 24() C O O C C O C O O. C. 5()-() 76() 50-760 76() D A R A

() - 5 C C C () O O C C O C 10-760 760 760 760 R D S D

Notes:

A -- in adsorption

D = on desorption

R = repressuring with product gas from rinse hag

S = equalization by flow of rinse gas from B to A or from B to A

line 6 to withdraw any remaining unadsorbed gas and

to desorb the respective adsorbents contained in col It will be apparent from the foregoing that during the

umns A and B. With valve 3 remaining open, desorp on-stream adsorption period gas flow into and through

tion of columns A and B is thus continued for a period columns A and B is by way of open valves 1, 3 and 4;

during which these vessels are brought to an intermedi during which period, valves 1' and 4' are closed. While

ate pressure below atmospheric. For example, these columns A and B are on adsorption companion col

vessels may be brought to a pressure of below 60 mm. umns A" and B' are being countercurrently desorbed of

Hg or preferably to below about 50 mm. Hg. Valve 3 is previously adsorbed gas. The desorption of columns A"

then closed while the application of suction through and B' is begun during flow of rinse gas from B to A and

line 6 is continued thus further evacuating column A continued during the next period that columns A and B

and thereby regenerating that column by further re are receiving charge gas. The desorption of A' and B' is

moval of adsorbed moisture and carbon dioxide from accomplished by opening valve 2" leading into suction

that column. Such further evacuation of column A is line 6, while valve 3' remains open and valves 4' and 5'

continued for a period until the column is brought to closed. Suction on column A' is thereafter continued

the lowest pressure designed for the cycle of opera with valve 3' being closed to further evacuate column

tions; for example, evacuation of column A is contin A to lowest pressure in the operation cycle, while

ued to an attained pressure of at least 10 mm. Hg below column B' is repressured with high purity oxygen ad

the intermediate pressure and preferably to an ultimate mitted thereto by opening valve 5' in the line leading

50 from the rinse bag. In the presently described embodi

pressure of about 30 to 10 mm Hg. The ultimate lowest

desorption pressure to be employed is dictated largely ment countercurrent flow of rinse gas from B' to A' to

by the quality of the ambient air and the properties of equalize the pressure therebetween, is effected by re

the adsorbent being used. During this period of further opening valve 3' while flow of gas through open valve

evacuation of column A, with valve 3 closed, column B 5'' is continued.

is repressured with high purity oxygen gas from the 55 In columns A and A' any solid adsorbent suitable for

rinse bag, bringing that column back to about atmo retaining moisture and CO may be employed such as

spheric pressure. This is accomplished by opening silica gel, alumina, activated carbon or a zeolitic molec

valve 5 permitting flow of collected oxygen product gas ular sieve of natural or synthetic origin, such as mor

from the rinse bag into column B until these vessels are denite or molecular sieve SA. In columns B and B' the

at equal pressure (atmospheric), the rinse bag con 60 adsorbent may be any molecular sieve material having

tracting to lower volume while remaining at atmo preferential affinity for adsorption of nitrogen from its

spheric pressure. admixture with oxygen under the process conditions

As a final step in the sequence, valve 2 is now closed, employed. For this purpose known commercial adsor

discontinuing evacuation of column A, and, in accor bents may be utilized such as 5A molecular sieve (cal

dance with the presently described embodiment, valve 65 cium zeolite A) or a synthetic mordenite having pore

3 is reopened, permitting flow of the rinse gas from the openings of about 5 to 10 angstrom size, preferably

rinse bag through column B into column A until col Norton Zeolon 900-Na, which is purported to have

umn A is brought from the lowest attained pressure to pore openings in about the 7 angstrom range. The ad

3,957,463

S 6

sorbents recommended for use in columns B and B' The described embodiments are predicated on a

may also be used, if desired, in columns A and A'. practical system employing two parallel trains of ad

In the particular embodiment above described, the sorbers operated in a programmed time schedule of

repressuring of the water-carbon dioxide adsorption one-half cycle out of phase. This insures a continuous

beds A and A' is effected by flow of oxygen rich gas flow of product gas and maximizes utilization of the

thereinto from their associated fractionating columns B gas-handling equipment. It will be appreciated that a

and B' respectively through opened valves 3 and 3'. In single train comprising a water-CO, adsorber and a

an alternative embodiment the watercarbon dioxide nitrogen selective adsorber in series could be utilized

adsorption beds A and A' may be repressured by gases 0 without departing from the essential features of the

other than the previously indicated oxygen rich gas. invention; however, this would be at the sacrifice of

Typically, there may be utilized for such repressuring: desirable continuous adsorber product flow and utiliza

air, nitrogen, oxygen or other suitable gas or gas mix tion of gas-handling equipment. In some instances it

ture from any source. During such repressuring, of may be found desirable to employ a time schedule

course, valves 3 and 3' in turn, will be closed. If the gas wherein the period employed for the on-stream blow

used to repressure beds A and A' contains water or 15 (adsorption) and repressuring and that needed for de

CO, the repressuring gas will be introduced to flow in sorption are not equal. In such instance three or more

a direction cocurrent to that of the gas stream charged parallel trains of adsorbers may be employed in appro

during the adsorption step. If the repressuring gas is priate timed sequence. The valve changes during the

substantially free of water and CO, repressuring of 20 cycle of operations in any such modification, are pro

beds A and A' may be carried out in either direction; grammed in well known manner and are automatically

that is cocurrent or countercurrent to the flow of gas carried out under control of a cycle timer device.

charged during the adsorption step. While the several described embodiments are con

Table 2 below illustrates a time program for the vari cerned with the recovery of an oxygen-enriched prod

ous steps in the sequence of operations based on a uct stream from atmospheric air, it will be understood

suggested 4 minute cycle using ambient air for repres 25 that other gas mixtures comprising oxygen and nitrogen

suring beds A and A'; and indicating the respective could be similarly treated. For example, oxygen-con

valve positions during the sequence. taining waste gas recovered from treatment of scwage

TABLE II

Time Valve Positions Vesse Pressures (mm Hg) Process

(sec.) 1' 2 2 3 3' 4 4' 5 5' A A" B B' A A' B B'

0-5 O C C O C O C C O C ()-760 760 760 76() P D S D

5-75 O C C O O O O C C C 760 760 50 76) 760 5() A D A D

75-20 O C. C. O O C O C C O 760 S0-10 760 S()-76() A D A R

20-125 C O O C O C C C C O 760 ()-76) 760 760 D P D S

25-195 C O O C O O C O C C 760 - 50 760 760 50 760 D. A D A

95-240 C O O C C O C O O C 50-0 760 50-760 76() D A R A

0-5 O C C O C O C C O C ()-760 76() 760 76() P D S D

Notcs:

A = on adsorption

D = on desorption

R = repressuring at bed B or B with product gas from rinse bag

S = static condition for hed B or B' during repressuring of A or A"

P = repressuring of bed A or A" to adsorption pressure

or sludge with oxygen-rich gases, may be purified and

In the illustrative embodiment above described the 45 reconcentrated in oxygen by the described system of

intermediate pressure achieved during vacuum desorp the invention.

tion of the nitrogen adsorbers and of the water-CO. EXAMPLE

pretreating adsorbers, is designated as being below 60

mm. Hg or at about 50 mm. Hg. The intermediate Experimental test runs were conducted in a single

pressure level (or the final pressure with respect to the 50 column using 5A molecular sieve (Ca aluminosilicate)

nitrogen adsorbers) will be determined by the desired for adsorption of water and CO, in advance of a bed of

oxygen purity required. With lower pressure utilized Norton Zeolon 900 Na (mordenite molecular sieve), in

during desorption, the purity of the obtained oxygen the form of 1/6 inch pellets. The packed column was

product is enhanced. Such enhancement of purity, employed in treatment of ambient air passed serially

however, results in reduced yield of product gas. 55 downward through the beds of 5A sieve and Zeolon

The final pressure or lowest pressure attained by the sieve respectively, at the rate of 6 to 6.5 liters/min., for

further evacuation of the water-CO adsorbers alone, is a period of 90 seconds. During this period, the effluent,

dictated by the equilibrium vapor pressure of water which consisted of high purity oxygen product, was

over the adsorbent selected for use in these adsorbers. collected in an expandable receiver (rinse bag) main

60 tained under atmospheric pressure, part of which efflu

In all instances, however, the final pressure attained on

desorption of the water-CO, adsorber beds will be sub ent was subsequently employed for repressuring the

stantially lower than the final vacuum pressure in the beds. At the end of the air blow (adsorption) period the

nitrogen adsorber beds. column was a few seconds short of breakthrough.

Also, the cycle time periods indicated in the de Charging of air was discontinued at this point and vac

scribed embodiment are illustrative and may be varied 65 uum applied at the top of the column, removing first

as required in actual operation depending upon the unadsorbed voids gas then desorbing part of the ad

product purity required and the particular adsorbent sorbed nitrogen, water and CO. In several runs the

materials employed. final desorption pressure was varied as shown in Table

3,957,463

7 8

III below. Evacuation was continued in each instance a. applying a vacuum to the inlet end of said first bed

for 120 seconds. The vacuum was then broken by intro while maintaining flow communication between

ducing high purity oxygen into the column from the said first bed and said second bed,

rinse bag at the rate of 8 to 9 liters per minute, for 30 b. continuing application of said vacuum to said beds

seconds. At the end of this period of repressuring with and attaining a reduced intermediate pressure of

oxygen the column was again at about atmospheric less than 60 mm. Hg, thereby desorbing gases from

pressure, and the cycle again repeated with introduc said beds including substantially all of the nitrogen

from said second bed,

tion of atmospheric air. c. discontinuing flow communication between said

It was found that the quality and quantity of the prod () second and said first beds while continuing vacuum

uct gas depended upon the final desorption pressure in application to said first bed to a lower terminal

the nitrogen adsorber. Evacuation of the nitrogen pressure at least 10mm. Hg below said intermedi

selective adsorbent bed to 30 torr achieves the produc ate pressure thereby desorbing any residual mois

tion of a product stream having 90% oxygen (by vol ture and carbon dioxide from said first bed,

ume) from atmospheric air. d. repressuring said second bed with product gas to

The effect of final desorption pressure in the nitrogen about sorption cycle pressure during said continu

adsorber on oxygen purity and on product volume is ing vacuum application to said first bed,

shown in Table III below: e. discontinuing vacuum application to said first bed

TABLE II and repressuring said first bed to about sorptive

cycle pressure,

Final Desorption

Pressure (orr) in

% O. In

Product

Relative Vol.

product Gas

f. re-establishing flow communication between said

the Nitrogen Adsorher Gas Vol.1Vol. Adsorbent first bed and said second bed and resuming the

charge gas flow for sorbtive gas separation and

48

72

67

8()

1.9

1.68 purification.

55 84 1.6 2. The method as defined in claim 1 wherein the

2-4

()

91

95*

5

... 4

defined cycle of operation is carried out in parallel in at

least two series connected trains of first and second

*extrapolated beds, so that during a period that at least one such train

of beds is on stream another parallel train is being

The experimental value shown above when plotted as desorbed.

3. The method as defined in claim 1 wherein said

Cartesian coordinates, with pressure as abscissa, show charge gas is ambient air.

substantially a simple straight line relation over the 4. The method as defined in claim 1 wherein said

range covered. terminal bed pressure is in the range of from about 30

What is claimed is: to about 10 mm. Hg.

1. In a method for regenerating adsorbents reduced 5. The method as defined in claim 1 wherein said first

in sorbent capacity during use in an oxygen enrichment bed is restored to about atmospheric pressure by flow

vacuum swing gas separation and purification system of gas thereinto from said second bed.

utilizing a first bed of absorbent effective in adsorption 6. The method as defined in claim 1 wherein said first

of carbon dioxide and water and a second bed of adsor 40 bed is restored to about atmospheric pressure by flow

bent selective in retention of nitrogen as opposed to of gas thereinto in a direction concurrent to that em

oxygen, said system operating on a cycle including a ployed during on-stream adsorption.

sorbtive gas separation and purification period and a 7. The method as defined in claim 1 wherein said first

regeneration period during which charge gas flow is bed is restored to about atmospheric pressure by flow

discontinued, the improvement in regeneration which of ambient air thereinto.

ck sk. k sk sk

comprises.

55

60

65

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Unit 1 Module 3 Period 3 and Group II Elements WorksheetDocument2 pagesUnit 1 Module 3 Period 3 and Group II Elements WorksheetFrank MassiahNo ratings yet

- CHE Perlis Modul Juss ADocument162 pagesCHE Perlis Modul Juss ALim Wai Wai SmktpNo ratings yet

- Chemistry 203 Pre-Lab Assignment: Determining The Hardness of Different Water SampleDocument2 pagesChemistry 203 Pre-Lab Assignment: Determining The Hardness of Different Water SampleCarl-Etienne ChaayaNo ratings yet

- Product Name: Amphetane Phosphate Chemical PropertiesDocument1 pageProduct Name: Amphetane Phosphate Chemical PropertiesMarkoNo ratings yet

- Thermodynamic Steady States in Simple Electrical CircuitsDocument19 pagesThermodynamic Steady States in Simple Electrical Circuitspomon666No ratings yet

- Chem Topic 1 QuestionsDocument27 pagesChem Topic 1 QuestionsOscarHigson-SpenceNo ratings yet

- An Inherently Safer Process ChecklistDocument6 pagesAn Inherently Safer Process ChecklistJosé LuísNo ratings yet

- Heat Transfer ConvectionDocument23 pagesHeat Transfer ConvectionDilaFirizqinaNo ratings yet

- Corrosion in Oil and Gas IndustryDocument41 pagesCorrosion in Oil and Gas IndustryRoyan Arabzz100% (1)

- Atoms PyqDocument26 pagesAtoms PyqAditya Singh PatelNo ratings yet

- Coulomb Gap and Low-Temperature Conductivity of Disordered SystemsDocument3 pagesCoulomb Gap and Low-Temperature Conductivity of Disordered SystemsSergey KopylovNo ratings yet

- Periodic Table of ElementsDocument22 pagesPeriodic Table of ElementsZennith Orions100% (1)

- Technical Report Zhelius ZapplinDocument10 pagesTechnical Report Zhelius ZapplinZhelius ZapplinNo ratings yet

- ElectrochemistryDocument16 pagesElectrochemistryapi-223462153No ratings yet

- U5 Org q5Document2 pagesU5 Org q5Mohamed MuhajireenNo ratings yet

- GC Methode Development RestekDocument71 pagesGC Methode Development RestekbenyNo ratings yet

- Engineering Cocrystals of Poorly Water-Soluble Drugs To Enhance Dissolution in Aqueous MediumDocument74 pagesEngineering Cocrystals of Poorly Water-Soluble Drugs To Enhance Dissolution in Aqueous MediumAndrea GomezNo ratings yet

- Temperature CH 10 8thDocument12 pagesTemperature CH 10 8ththegedusNo ratings yet

- Concept Map For OEDDocument2 pagesConcept Map For OEDDr. P. KannanNo ratings yet

- 11 Chemistry Impq States of Matter KvsDocument7 pages11 Chemistry Impq States of Matter KvsAnant MadhavNo ratings yet

- Light and Optic NotesDocument18 pagesLight and Optic NotesNuan Ting NgNo ratings yet

- AnaChem Conjugate Acid Base Pairs 3Document3 pagesAnaChem Conjugate Acid Base Pairs 3Jei HernandezNo ratings yet

- Detergent Polymers, Other Ingredients, Basics, Tests, Assessment of Sustainability Und Environmental EvaluationDocument17 pagesDetergent Polymers, Other Ingredients, Basics, Tests, Assessment of Sustainability Und Environmental EvaluationGhufron A. AzisNo ratings yet

- Water Research: Xiangling Zhang, Lu Guo, Hualing Huang, Yinghe Jiang, Meng Li, Yujie LengDocument12 pagesWater Research: Xiangling Zhang, Lu Guo, Hualing Huang, Yinghe Jiang, Meng Li, Yujie LengmaizansofiaNo ratings yet

- Heat Conduction Nuclear Heat SourceDocument18 pagesHeat Conduction Nuclear Heat SourceChaudhry ZaidNo ratings yet

- Oil Wetting AgentDocument2 pagesOil Wetting AgentBhoomi KapadiaNo ratings yet

- Advanced Practical Organic Chemistry - Purification and Drying of Solvents (1990)Document15 pagesAdvanced Practical Organic Chemistry - Purification and Drying of Solvents (1990)سید حسین عارفیNo ratings yet

- Electronics Cooling Final PresentationDocument37 pagesElectronics Cooling Final PresentationManoj KumarNo ratings yet

- Atomic Structure _ DPP 02 (of Lec 04) __ Arjuna JEE 2025Document3 pagesAtomic Structure _ DPP 02 (of Lec 04) __ Arjuna JEE 2025ishanttanwar12345No ratings yet

- Temp Faculty Shortlisted Canditates v6Document51 pagesTemp Faculty Shortlisted Canditates v6Lakshmi Priya SubburajanNo ratings yet