Professional Documents

Culture Documents

Optimum Design of EOT Crane Bridge Girder Using C Program

Uploaded by

Konserve TechOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimum Design of EOT Crane Bridge Girder Using C Program

Uploaded by

Konserve TechCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/260197309

Optimum Design of Bridge Girder of an EOT Crane Structure

Conference Paper · November 2009

CITATIONS READS

0 1,699

1 author:

Ashish Gohil

Nirma University

13 PUBLICATIONS 60 CITATIONS

SEE PROFILE

All content following this page was uploaded by Ashish Gohil on 26 February 2014.

The user has requested enhancement of the downloaded file.

INSITIUTE OF TECHNOLOGY, NIRMA UNIVERSITY, AHMEDABAD-382481, 25–27, NOVEMBER, 2009

Optimum Design of Bridge Girder of an EOT

Crane Structure

A. M. Gohil, Lecturer in Mechanical Engg. Dept., Institute of Technology, Nirma University

Alkin [3]. Design evaluation of Overhead Traveling crane was

Abstract--Bridge Girder which carries various dead loads and carried out by Mahanty [4] to validate the design.

live load is heavily stressed part of Crane structure. Along with In this paper Optimization program is prepared in C

the strength it should provide sufficient rigidity to maintain the language. The Program prepared gives optimum values of the

proper and safe movement of the load. Failure to sustain the design variables while checking all the possible modes of

load while in operation could lead to loss of material and in

failures and meeting the stringent requirement imposed by

worst case persons working nearby the crane. It is also the need

of the Industry to reduce the weight of the structure thereby various Indian Standards. Optimized girder design is verified

reducing the cost of fabrication and also the running cost of the using ANSYS software. Analysis of the Bridge Girder is

crane. In this paper weight optimization of the crane girder is carried out in two different positions:

carried out using a custom made C program based on the 1. Crab position is at the center

Davidon-Fletcher-Powell (DFP) method and the solution is 2. Crab position is at the corner

verified using ANSYS software. The C program and finite

element results also meet the stringent requirements stipulated II. ANALYTICAL SOLUTION

by Indian Standard IS: 807.

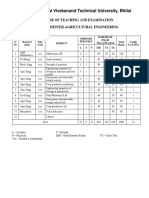

TABLE 1

Keywords-- bridge girder, Design variables, Objective

NOMENCLATURE

function, Constraints.

I. INTRODUCTION

E lectrically-Operated Overhead Traveling (EOT) cranes

are widely used to transport objects in many factories,

ports, and work places[1].

Crane structure is made up of bridge girder and end-

truck[2]. Bridge girder is that component of a crane structure

on which trolley travels to provide the traversing motion.

Box girders are widely used because of it design efficiency in

providing strength and stiffness. To provide rigidity to the

structure Full depth stiffeners and additional partial depth

stiffeners are used.

Before putting the crane into operation Testing is carried

out to check the operational performance of the crane.

Standard weights are attached to the crane and the deflection

of the Bridge Girder is checked when the crab position is at

the centre. The deflection should be below the permissible

value which is given by the equation, 1) Objective function chosen here is to reduce the weight of

the girder which can be formulated as below in terms of

δ p = span/900 (1) design variables.

Hence during the test if the Bridge Girder fails to meet the f ( X ) = ( B × H − b × h) × l × ρ kg (2)

requirements than it cost time and resources in rework. To As span and density are constant for a particular crane above

avoid this sort of problems and to improve the design of the objective function can be simplified as

Bridge Girder analysis can be carried out which will ensure

the validity of the analytical solution before starting to f ( X ) = ( B × H − b × h) , mm 2 (3)

fabricate the Bridge Girder. Problem consists of four design variables: Outer width of

There are many published studies on solid modeling and box, Overall height of Box, Inner width of box and Inner

Finite Element Analysis of Crane structure. Solid modeling height of box.

of bridge structures and finite element analysis to find the

displacements and stress values have been investigated by

NATIONAL CONFERENCE ON CURRENT TRENDS IN TECHNOLOGY, ‘NUCONE–2009’ CCME–07 ♦ 29

2) Height of web is calculated from the following empirical hW 3

relation to ensure adequate stiffness at midspan. g3 ( X ) = −1 ≤ 0 (20)

l l wF

hW = to , mm (4) w

15 10 g4 ( X ) = F − 1 ≤ 0 (21)

3) Width of flange is calculated from the following hW 2

empirical relation to ensure transverse stiffness of the girder. 6

hW hW g5 ( X ) = − 1 ≤ 0 (22)

wF = to , mm (5) tF

3 2

t

4) Thickness of Flange and Thickness of Web can be g6 ( X ) = F − 1 ≤ 0 (23)

selected from available standard sizes of 6 to 63 mm. 63

5) As per IS: 807[5] ratio of equivalent length of girder to the 6

width of flange should be less than 60. g7 ( X ) = − 1 ≤ 0 (24)

tW

lE

rLEWT = (6) t

tW g8 ( X ) = W − 1 ≤ 0 (25)

[6]

6) As per IS: 800 ratio of Height of web to thickness of 63

web should be less than 200 when vertical stiffeners are used. r

g9 ( X ) = LEFW − 1 ≤ 0 (26)

h 60

rWHWT = w (7)

tW r

g10 ( X ) = WHWT − 1 ≤ 0 (27)

7) As per IS: 807 Slenderness ratio of the girder should be 200

less than 300. r

lE g11 ( X ) = S − 1 ≤ 0 (28)

rs = (8) 180

rY f

g12 ( X ) = bt − 1 ≤ 0 (29)

8) Designed stresses should be less than permissible stresses fbtp

given in IS: 800.

fbc

g13 ( X ) = −1 ≤ 0

2

Bending Tensile: f bt ≤ f btp , N / mm (9) (30)

2

f bcp

Bending Compressive: f bc ≤ f bcp , N / mm (10)

fs

Shear Stress: f s ≤ f sp , N / mm

2

(11) g14 ( X ) = −1 ≤ 0 (31)

f sp

Bearing Stress: f b≤ f bp , N / mm 2 (12) fb

2 g15 ( X ) = −1 ≤ 0 (32)

Equivalent Stress: f e≤ f ep , N / mm (13) fbp

Torsional Shear: τ s ≤ f sp , N / mm 2 (14) fe

g16 ( X ) = −1 ≤ 0 (33)

Longitudinal : f l ≤ f lp , N / mm 2

(15) f ep

τS

9) As per IS: 807 deflection should be less than permissible g17 ( X ) = −1 ≤ 0 (34)

value. f sp

δ T ≤ δ p , mm (16)

fl

10) With the above information optimization problem can g18 ( X ) = −1 ≤ 0 (35)

be formulated as minimize,

f lp

f ( X ) = ( B × H − b × h) , mm 2 δT

(17)

g19 ( X ) = −1 ≤ 0 (36)

Subject to the following constraints: δP

hWL The Problem consists of four design variables and nineteen

g1 ( X ) = −1 ≤ 0 (18) constraints. As the constraints are of nonlinear type it is a

hW

nonlinear constrained optimization problem. To solve the

h above problem Davidon-Fletcher-Powel (DFP) method is

g2 (X ) = W −1 ≤ 0 (19) selected which is one of the nonlinear constrained

hWU

optimization methods. The choice is made on DFP method

30 ♦ CCME–07 NATIONAL CONFERENCE ON CURRENT TRENDS IN TECHNOLOGY, ‘NUCONE–2009’

because it is sequential in its solution, reliable and always

search point remains within the feasible region [7].

III. VERIFICATION OF THE ANALYTICAL SOLUTION USING

ANSYS

CASE I: ANALYSIS WHEN CRAB AT CENTRE

1. SHELL63 element is selected for the analysis because it

has both bending and membrane capabilities. Both in-

plane and normal loads are permitted. The element has

six degrees of freedom at each node [8].

2. Values of various forces acting and other parameters

required for the solution of analysis is shown in Table-II.

3. Deflection of the Bridge Girder & Von Mises stress

induced is shown in Fig. 1 & Fig. 2 respectively.

TABLE II

INPUTS TO ANALYSIS WHEN CRAB AT CENTRE Fig. 1. Deflection of bridge girder when crab at center

Fig. 2. Von-Mises stress on bridge girder when crab at center

TABLE III

INPUTS TO ANALYSIS WHEN CRAB AT CORNER

CASE II: ANALYSIS WHEN CRAB AT CORNER

1. Values of various forces acting and other parameters

required for the analysis are shown in Table-III.

2. Deflection of the Bridge Girder & Von Mises stress

induced is shown in Fig. 3 & Fig. 4 respectively.

Deflection of the Bridge Girder is less when the crab is

positioned at the corner compared with that of the crab at

the central position. Because of the same reason it is

recommended that when crane is not operative crab

should be positioned at the corner to avoid permanent set

in the Bridge Girder.

NATIONAL CONFERENCE ON CURRENT TRENDS IN TECHNOLOGY, ‘NUCONE–2009’ CCME–07 ♦ 31

The Von-Mises stress is safe within limits analytically as

well as by ANSYS. Von-Mises stress calculated by ANSYS

is on higher side than analytical method because of the effect

of stress concentration at the corner where the Bridge Girder

is connected to the End Truck. However the effect of stress

concentration and possible danger of failure of Bridge Girder

at the corner can be avoided by welding thick plate at the

corner.

TABLE V

COMPARISON OF WEIGHT

Fig. 3. Deflection of bridge girder when crab at corner

The cross-sectional area given by the optimization program is

less compared with the existing design of the company.

Reduction in weight obtained is 12.29%. This reduction in

weight will lead to the low weight design of End truck on

which bridge girder is mounted. Also pressure on the wheels

will reduce and low weight section of rail can be selected.

Thus overall reduction in weight of crane will be much more,

which will reduce the initial cost of crane. At the same time

the running cost of the crane will reduce because low weight

crane will accelerate and decelerate faster reducing the power

consumption.

V. REFERENCES

[1] Rudenko N., Materials handling equipment, Envee publishers, New

Delhi, 1979, pp. 20-23

[2] Alexandrov M. P., Materials handling equipment, Mir publishers,

Fig. 4. Von-Mises stress on bridge girder when crab at corner Moscow, 1981, pp. 59-77, pp. 253-261, pp. 357-385

[3] C. Alkin, C. E. Imrak, H. Kocabas, Solid Modeling and Finite Element

IV. RESULTS & DISCUSSION Analysis of an Overhead Crane Bridge, Acta Polytechnica Vol. 45 No.

3/2005, Prague

[4] Dilip K Mahanty, Satish Iyer, Vikas Manohar, Design Evaluation of the

TABLE IV

375 T Electric Overhead Traveling Crane

COMPARISON OF ANALYTICAL AND ANSYS RESULTS

[5] IS: 807, Code of Practice for Design, Manufacture, Erection and

Testing (Structural portion) Of Cranes and Hoists, Bureau of Indian

Standards, New Delhi, 1992, pp. 9-24

[6] IS: 800, Code of Practice for Use of Structural Steel in General

Building Construction, Bureau of Indian Standards, New Delhi, 1984,

pp. 19-22, pp. 29-35, pp. 44-47, 67-73

[7] Rao S. S., Engineering optimization: Theory and Practice, New age

international (P) limited, New Delhi, 2001, pp. 5-6, pp. 399-405, pp.

The stresses and deflection given by analytical and 487-501

ANSYS are well within limits specified as shown in Table [8] ANSYS Documentation, ANSYS Element Reference.

IV. The deflection given by the analytical formulae dose not

take into account the effect of Stiffener plate and that of

intermediate and bearing stiffener. However the ANSYS

does take into account, hence the deflection is quite lower

than the analytical value and that of permissible value.

Camber which is provided in opposite direction to deflection

of the Bridge Girder reduces this value considerably.

View publication stats

You might also like

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Optimization of hanger arrangementDocument13 pagesOptimization of hanger arrangementAndrius TNo ratings yet

- 13107-Article Text PDF-45335-4-10-20190228Document10 pages13107-Article Text PDF-45335-4-10-20190228mohammed nafethNo ratings yet

- Idges PDFDocument14 pagesIdges PDFBarış ÖzcanNo ratings yet

- Numerical Simulation of Flow Around The Ship Using CFD MethodDocument12 pagesNumerical Simulation of Flow Around The Ship Using CFD MethodNguyen Van QuyenNo ratings yet

- Design Standard and SpecificationDocument8 pagesDesign Standard and SpecificationRiot AyaseNo ratings yet

- Sorrentino 2014Document18 pagesSorrentino 2014Hiến Đinh VănNo ratings yet

- 3 Basinc Ve Akiskan StatigiDocument7 pages3 Basinc Ve Akiskan Statigiizzet9696No ratings yet

- H. Veladi PaperDocument11 pagesH. Veladi PaperbortehNo ratings yet

- Examples of Various Formulations of Optimization ProblemsDocument23 pagesExamples of Various Formulations of Optimization ProblemsPanosNo ratings yet

- Failure Probability Analysis of Overhead Crane Bridge Girders Within Uncertain Design ParametersDocument11 pagesFailure Probability Analysis of Overhead Crane Bridge Girders Within Uncertain Design ParametersRABAH MESLOUBNo ratings yet

- Finite Element Analysis and Calculation of HTC15J01 Petrochemical Industry Crane Pulley DesignDocument6 pagesFinite Element Analysis and Calculation of HTC15J01 Petrochemical Industry Crane Pulley DesignFrancisco Raro AlmuzaraNo ratings yet

- Simplified Methods of Analysis for Bridge Load DistributionDocument69 pagesSimplified Methods of Analysis for Bridge Load Distributionolimpiu_muresanNo ratings yet

- Genetic Algorithm Optimization of Steel Frame DesignDocument35 pagesGenetic Algorithm Optimization of Steel Frame DesignCesar ManNo ratings yet

- Optimization of The Box Section of The Main Girders of The BridgeDocument9 pagesOptimization of The Box Section of The Main Girders of The BridgeramiNo ratings yet

- Bridge Girder Design of An EOT Crane Structure - A CAD ApproachDocument5 pagesBridge Girder Design of An EOT Crane Structure - A CAD ApproachChristian Oribe CastilloNo ratings yet

- Modernising Steel Gantry Beam for Transport WorkDocument14 pagesModernising Steel Gantry Beam for Transport WorkRABAH MESLOUBNo ratings yet

- Design and Analysis For CraneDocument10 pagesDesign and Analysis For CraneOmar WardehNo ratings yet

- Column Size For R.C. Frames With High Drift: Sunil S. Mayengbam and S. ChoudhuryDocument7 pagesColumn Size For R.C. Frames With High Drift: Sunil S. Mayengbam and S. Choudhurysachin9984No ratings yet

- Solanki (2015) - Weight Optimization in Crane HookDocument5 pagesSolanki (2015) - Weight Optimization in Crane HookGogyNo ratings yet

- Spi Santy 1972Document7 pagesSpi Santy 1972albertoxinaNo ratings yet

- Analysis of Long Span Roof TrussDocument6 pagesAnalysis of Long Span Roof Trussአድሜ ልስልሱNo ratings yet

- Design and dynamic analysis of 70T overhead crane girderDocument8 pagesDesign and dynamic analysis of 70T overhead crane girderGogyNo ratings yet

- Trans Design - Catalog Hughes BrothersDocument27 pagesTrans Design - Catalog Hughes BrothersgilbertomjcNo ratings yet

- Shape Optimization of An Autonomous Underwater Vehicle With A Ducted Propeller Using Computational Fluid Dynamics AnalysisDocument13 pagesShape Optimization of An Autonomous Underwater Vehicle With A Ducted Propeller Using Computational Fluid Dynamics AnalysishanstiwariNo ratings yet

- Ductility of Confined Bridge Piers in The Seismic Region: August 2013Document9 pagesDuctility of Confined Bridge Piers in The Seismic Region: August 2013Raghava KumarNo ratings yet

- Comparison of Wind Loads On Buildings Using Computational Fluid Dynamics, Design Codes, and Wind Tunnel TestsDocument11 pagesComparison of Wind Loads On Buildings Using Computational Fluid Dynamics, Design Codes, and Wind Tunnel TestsLille Douai IMTNo ratings yet

- An Integrated Tool For Concept and FinalDocument15 pagesAn Integrated Tool For Concept and FinaljasserjederNo ratings yet

- Analysis Report of Residential BuildingDocument41 pagesAnalysis Report of Residential BuildingSudip Ghimire50% (2)

- Preliminary Static Analysis of Suspension Bridges PDFDocument8 pagesPreliminary Static Analysis of Suspension Bridges PDFp rNo ratings yet

- Design and Construction of Steel Diagrid Structures: School of Architecture, Yale University, New Haven, USADocument8 pagesDesign and Construction of Steel Diagrid Structures: School of Architecture, Yale University, New Haven, USApuppyarav2726No ratings yet

- Bridge-Ch-5-Example On Slab Bridge EDITEDFINALDocument15 pagesBridge-Ch-5-Example On Slab Bridge EDITEDFINALkassahun kebede100% (1)

- The Design and Analysis On Intensity of Anti-Roll Bar On 100% Low-Floor Light Rail VehicleDocument5 pagesThe Design and Analysis On Intensity of Anti-Roll Bar On 100% Low-Floor Light Rail VehicleCarlos AlonsoNo ratings yet

- Optimizations of Air-Lubricated Slider Bearings by Usnig Reduced Basis ConceptDocument1 pageOptimizations of Air-Lubricated Slider Bearings by Usnig Reduced Basis ConceptParsaNo ratings yet

- Design 12.9 X 22 MDocument214 pagesDesign 12.9 X 22 MBilal Ahmed BarbhuiyaNo ratings yet

- Defence Presentation-Ma HtetDocument64 pagesDefence Presentation-Ma HtetYoonNadi KyawNo ratings yet

- Major Design Project Brief 2017Document6 pagesMajor Design Project Brief 2017Dilshan JayasuriyaNo ratings yet

- Calcul de Alpha CritiqueDocument20 pagesCalcul de Alpha Critiquelahlou_d9216No ratings yet

- Design and Analysis of Eot Crane Hook For Various Cross SectionsDocument6 pagesDesign and Analysis of Eot Crane Hook For Various Cross SectionsFiroz PawaskarNo ratings yet

- Calculo Soil Nail FHWADocument91 pagesCalculo Soil Nail FHWAdiana cristina arias aldanaNo ratings yet

- Texas A&M University MEEN 683 Multidisciplinary System Design Optimization (MSADO) Spring 2021 Assignment 5, Part ADocument5 pagesTexas A&M University MEEN 683 Multidisciplinary System Design Optimization (MSADO) Spring 2021 Assignment 5, Part ABobaNo ratings yet

- Multi-Objective Optimization of Automotive Front Rail Based On Surrogate Model and NSGA-IIDocument10 pagesMulti-Objective Optimization of Automotive Front Rail Based On Surrogate Model and NSGA-IIhaceneNo ratings yet

- Reliability Analysis-PbDocument8 pagesReliability Analysis-Pbmsn sastryNo ratings yet

- Swing Bolt Closure Design - Pressure VesselDocument12 pagesSwing Bolt Closure Design - Pressure VesselRasatja Yongskulrote100% (2)

- Design of Deep BeamDocument29 pagesDesign of Deep BeamHuzaifa zafer100% (1)

- Haunch EquationsDocument8 pagesHaunch EquationsJacques Ontal0% (1)

- DesignDocument84 pagesDesignbijendraNo ratings yet

- BindDocument21 pagesBindHenry MarcellaNo ratings yet

- 2 Vikky Kumhar VSRDIJMCAPE 5555 Research Paper 5 5 May 2015Document7 pages2 Vikky Kumhar VSRDIJMCAPE 5555 Research Paper 5 5 May 2015Kiet Truong AnhNo ratings yet

- Built-Up CFS Column With Lacings and BattensDocument10 pagesBuilt-Up CFS Column With Lacings and BattensMD Sameer HussainNo ratings yet

- NCHRP RPT AppendixbDocument150 pagesNCHRP RPT Appendixboabrown4No ratings yet

- Indrumator Metal - EGDocument37 pagesIndrumator Metal - EGhooky1100% (1)

- Automatic Verified Shear Force Design of Reinforced Concrete BeamsDocument14 pagesAutomatic Verified Shear Force Design of Reinforced Concrete BeamsMyron OikonomakisNo ratings yet

- Wind Turbines, EurocodeDocument9 pagesWind Turbines, EurocodeIvan JovanovicNo ratings yet

- BDM Example 6 - 20180101Document23 pagesBDM Example 6 - 20180101mustafurade1No ratings yet

- Vibration Characteristics of A Suspension FootbridgeDocument18 pagesVibration Characteristics of A Suspension Footbridgeahagen00No ratings yet

- Minimum Weight Optimization of Materials and High Strength For Spur Gear DesignDocument14 pagesMinimum Weight Optimization of Materials and High Strength For Spur Gear DesignTJPRC PublicationsNo ratings yet

- PSC I-Girder Bridge Design in AASHTO-LRFDDocument99 pagesPSC I-Girder Bridge Design in AASHTO-LRFDSANDIPNo ratings yet

- Comparison of Moments For Pile-Cap Design: Soil Mechanics and Foundation Engineering February 2020Document7 pagesComparison of Moments For Pile-Cap Design: Soil Mechanics and Foundation Engineering February 2020BogdanBNo ratings yet

- ACSIR KineticsDocument12 pagesACSIR KineticsKonserve TechNo ratings yet

- Life Cycle Assessment of Cu & Zinc Cathode Production From Sulfide OresDocument17 pagesLife Cycle Assessment of Cu & Zinc Cathode Production From Sulfide OresKonserve TechNo ratings yet

- Salome & Code_Aster linear statics piston analysisDocument23 pagesSalome & Code_Aster linear statics piston analysisjarbas.otoniNo ratings yet

- FEA Best PracticesDocument105 pagesFEA Best Practicesalfonxxl0% (1)

- Agricultural Engineering Syllabus 3rd Sem NitinDocument12 pagesAgricultural Engineering Syllabus 3rd Sem NitinKonserve TechNo ratings yet

- Object Oriented Assignment GuideDocument10 pagesObject Oriented Assignment GuideThiviyaa DarshiniNo ratings yet

- Project SELF Work Plan and BudgetDocument3 pagesProject SELF Work Plan and BudgetCharede BantilanNo ratings yet

- Vocabulary and grammar practice for future technologyDocument4 pagesVocabulary and grammar practice for future technologyRosa MartinezNo ratings yet

- Pineapple Peel Extract vs Calamansi Extract Stain RemoverDocument13 pagesPineapple Peel Extract vs Calamansi Extract Stain RemoverShebbah MadronaNo ratings yet

- RSBACDocument166 pagesRSBACtradersanNo ratings yet

- Reasoning Olympiads Mind Map Class 3Document7 pagesReasoning Olympiads Mind Map Class 3vikasNo ratings yet

- Galletto 1250 User GuideDocument9 pagesGalletto 1250 User Guidesimcsimc1No ratings yet

- K-12 Grade 9 Science Roll Roll AwayDocument20 pagesK-12 Grade 9 Science Roll Roll AwayMeya Jhana Navidad75% (8)

- SEM GuideDocument98 pagesSEM GuideMustaque AliNo ratings yet

- 3rd Year-Industrial Training Letter SampleDocument3 pages3rd Year-Industrial Training Letter SampleSai GowthamNo ratings yet

- Learning OrganizationDocument104 pagesLearning Organizationanandita28100% (2)

- Data Pre Processing in WEKADocument5 pagesData Pre Processing in WEKAPrashant SunejaNo ratings yet

- Bus210 Week5 Reading1Document33 pagesBus210 Week5 Reading1eadyden330% (1)

- Cbcs Syllabus 2016-17 Admn Batch 30.07.16Document23 pagesCbcs Syllabus 2016-17 Admn Batch 30.07.16Sushree sonali NayakNo ratings yet

- ASVAB Arithmetic Reasoning Practice Test 1Document7 pagesASVAB Arithmetic Reasoning Practice Test 1ASVABTestBank100% (2)

- Blueprint 7 Student Book Teachers GuideDocument128 pagesBlueprint 7 Student Book Teachers GuideYo Rk87% (38)

- Sony Kdl-42w654a rb1g PDFDocument100 pagesSony Kdl-42w654a rb1g PDFMihaela CaciumarciucNo ratings yet

- WBI06 01 Rms 20190124Document17 pagesWBI06 01 Rms 20190124Imran MushtaqNo ratings yet

- Impact of Social Media in Tourism MarketingDocument16 pagesImpact of Social Media in Tourism MarketingvidhyabalajiNo ratings yet

- Construction Vibrations and Their Impact On Vibration-Sensitive FacilitiesDocument10 pagesConstruction Vibrations and Their Impact On Vibration-Sensitive FacilitiesKwan Hau LeeNo ratings yet

- Escaping The Digital Dark AgeDocument5 pagesEscaping The Digital Dark AgeKarlos lacalleNo ratings yet

- The Cultural Diversity Phenomenon in Organisations and Different Approaches For Effective Cultural Diversity Management - A Literary Review PDFDocument21 pagesThe Cultural Diversity Phenomenon in Organisations and Different Approaches For Effective Cultural Diversity Management - A Literary Review PDFeugene123No ratings yet

- 015-Using Tables in ANSYSDocument4 pages015-Using Tables in ANSYSmerlin1112255No ratings yet

- Synthesis and Characterization of Nanoparticles of Iron OxideDocument8 pagesSynthesis and Characterization of Nanoparticles of Iron OxideDipteemaya BiswalNo ratings yet

- Validating and Using The Career Beliefs Inventory: Johns Hopkins UniversityDocument12 pagesValidating and Using The Career Beliefs Inventory: Johns Hopkins Universityyinyang_trNo ratings yet

- Seminar Report On Satellite CommunicationDocument17 pagesSeminar Report On Satellite CommunicationHapi ER67% (6)

- LCCC Campus MapDocument1 pageLCCC Campus MapmatsciNo ratings yet

- Accomplishment in ScinceDocument21 pagesAccomplishment in ScinceChristine CanoyNo ratings yet

- Dry Docking Ships Training Course for DockmastersDocument7 pagesDry Docking Ships Training Course for DockmastersSunil Kumar P GNo ratings yet

- Herschel 10027757Document83 pagesHerschel 10027757jurebieNo ratings yet