Professional Documents

Culture Documents

Soap and Lime Soap Dispersants

Uploaded by

ראול אפונטהCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Soap and Lime Soap Dispersants

Uploaded by

ראול אפונטהCopyright:

Available Formats

Soap and Lime Soap Dispersants

W.M. LINFIELD. Eastern Regional Reasearch Center

ARS, USDA, Philadelphia, Pennsylvania, USA

ABSTRACT greatly increased.

In the engineering area substantial advances have been

In recent decades, soap has largely been replaced

made in continuous saponification or continuous fat split-

by petrochemicals and polyphosphates as the major

ting followed by neutralization. Vacuum drying and plod-

components of laundry detergents in the U.S. Cur-

ding have largely replaced mills for the finishing of toilet

rently, the use of soap is primarily confined to the

bars. Striated or marbleized bars have achieved some popu-

toilet soap bar field, and technological advances here

larity in the U.S. and elsewhere and are an example of what

have been mainly in processing. In view of the rising

costs and increasing scarcity of petrochemicals and effects can be achieved with modern soapmaking equip-

polyphosphates, tallow, a replenishable, inexpensive ment.

agricultural by-product, was examined as an alter-

nate raw material. Tallow soap has a long history of DETERGENTS FROM SOAP

efficacy and safety but suffers from poor perfor- During the past 7 years a substantial a m o u n t of research

mance in hard water and insolubility in cold water. It has been carried out at the Eastern Regional Research Cen-

has now been shown that the performance of soaps ter of the U.S. Department of Agriculture on the use of

can be drastically improved in cold water solubility soap as the major ingredient in laundry detergents. Factors

and in hard water detergency by the addition to the leading to the initiation of this research included water pol-

soap of lime soap dispersing agents (LSDA). These are lution due to phosphate builders, dwindling petroleum re-

anionic or amphoteric surfactants possessing one or sources, and the abundance of inedible tallow, a replenish-

more bulky polar groups. These soap-LSDA combina- able agricultural by-product.

tions form mixed micelles in water and essentially The basic concept of soap modification is the addition

take on the surface active characteristics of a single of a lime soap dispersant to tallow soap. This enables the

anionic surfactant. Soap-LSDA combinations wash soap to act as an efficient detergent in hard or soft water

well in hard water without curd formation; they can without deposition of soap scum during the wash cycle or

be "built" with various materials such as phosphates during rinsing. About 20 different classes of surfactants

and trisodium nitrilotriacetate (NTA) to enhance de- were synthesized and evaluated for their lime soap dis-

tergency. Soap-LSDA combinations equal the conven- persing ability at ERRC. It was found that anionic or

tional detergents in every performance respect and amphoteric surfactants could be lime soap dispersants. Non-

undergo biodegradation more readily and completely. ionics, although effective dispersants, were not usable. For

reasons not clearly understood, nonionic surfactants are an-

INTRODUCTION tagonistic to the washing action of soap. Cationic surfac-

rants, of course, are not suitable since they form precipi-

Although soap is the world's oldest and probably safest

tates with soap.

surfactant, its use dwindled rapidly in most developed

For a surfactant molecule to function as a lime soap

countries after World War II. The major reasons for this

dispersing agent (LSDA), it must possess a bulky polar

decline were the rapid advances in surfactant technology,

group. It is visualized that soap and the LSDA form a

the relative abundance and low cost of petrochemicals, and

mixed micelle in which the LSDA, due to its bulky nature,

the unpredictable price fluctuation of natural fats and oils.

acts as a wedge. In hard water the LSDA wedge forces the

The increasing cost, scarcity, and price fluctuation of petro-

particle to retain its curvature with the polar groups on the

chemicals coupled with recent advances in soap technology

and relative abundance and low cost of fats and oils, such as periphery, whereas soap micelles by themseNes invert in

tallow and palm oil, now make soap look more attractive. hard water with the nonpolar long alkyl chains turned out-

Soap, i.e., the alkali metal salts of fatty acids, has retained ward, thus producing the familiar lime soap curds and scum

its position as the major component of toilet bars, although (2).

soap-syndet combination bars have made some inroads, par-

ticularly in the U.S. On the other hand, soap has all but CHEMISTRY OF THE LSDA

disappeared as a component of detergent products. This In general, bulk can be introduced into the LSDA surfac-

presentation is a summary of recent developments in soap tant molecule in the form of one or more ester or amido

technology as applied to the toilet bar and detergent fields. groups, ether linkages, or by inclusion of b o t h an anionic

and cationic group. Introduction of a second anionic group

such as -CO0- or -SO3- into an anionic LSDA molecule

TOI LET BARS

does not enhance lime soap dispersing properties. The lime

The technological advances in the toilet bar field as sum- soap dispersing ability of a given compound is conveniently

marized by Jungermann (1) have been largely in the me- measured by a test developed by Borghetty and Bergman

chanical and engineering fields. Although there has been (3) that measures the minimum lime soap dispersant re-

some research activity in soap germicides and lime soap quirement (LSDR) in grams to keep 100 g of sodium oleate

dispersants, the chemical nature of these additives to bar from precipitating in hard water (333 ppm as CaCO3).

soaps has not been changed greatly during the past 20 Table I shows a summary of all major classes of LSDA

years. However, during that period the popularity of bars investigated in this laboratory together with the appropriate

containing deodorants and those containing surfactants has literature references. The key surface-active properties of

J. AM. OIL CHEMISTS' SOC., January 1978 (VOL. 55) 87

TABLE I

Lime Soap Dispersing Properties and Detergency of Various Lime Soap Dispersants

Formulation detergency a

(percent of control)b

C o m p o u n d no. Structure Reference no. LSDR EMPAC TFd

1 R C H ( S O 3 N a ) C O 2 CeH 3 8, 9 9 95 70

2 RCH(SO3Na)CON(CH2CH2OH)2 24 8 97 79

3 RCO2(CH2)3SO3Na 25 7 87 78

4 RCON(CH3)(CH2)2SO3Na 18 5 95 65

5 RCON[ CH2CO2(CH2)3SO3Na ] 2 26 5 85 48

6 RCONHCH2CH(OSO3Na)CH3 6 5 97 64

7 RCONHCH2CH2OCH2CH2OSO3Na 6 4 97 66

8 RO(CH2CH20)3OSO3Na 17, 27 4

9 arSO2NHCH2CH20SO3Na f 7 7 94 90

10 RCONH(CH2CH2O) 11 H 28 3 53 69

11 RCON(CH2CH20)7H2 28 2 50 95

12 RO(CH2)3SO3Na 25 9 75 73

13 RNHCOCH2CH(SO3Na)CO2CH3 29 7 90 86

/CO~CH2

14 R-N~ | 30 9 100 68

xCO--CHSO3Na

1$ arCOCH2CH(SO3Na)CO2CH 3 3 l, 32 8 87 100

+

16 RN(CH3)2CH2CO2" 10 12 65 46

+

17 RN (CH3)2 (CH2)3SO3" 11 3 92 108

+

18 RCONH(CH2)3N(CH3)2(CH2)3SO 3- 11, 13 2 89 91

+

19 RN(CH3)2(CH2)3OSO3" 13 4 102 92

+

20 RCONH(CH2)3N(CH3)2 (CH2)3OSO3" 13 3 91 96

aDetergency of 0.2% of solution of formulation containing 64% tallow soap, 19% LSDA, 14% glossy silicate, 1% GMC, and 2% impurities

in 300 ppm hard water.

b50% Tripolyphosphate built commercial control detergent.

CEMPA 101 presoiled cotton cloth.

dTestfabrics presofled 65% polyester - 35% cotton blend.

eR refers to a tallow derived alkyl group.

far refers to a dodecylphenyl group derived from a commercial detergent alkylate.

LSDR and detergency are given for the tallow derivative of since they are prepared from commercial detergent alkylate

each class, except compounds no. 9 and no. 13, which are or from alkylbenzene sulfonic acids (LAS acid).

derived from a commercial detergent alkylate. Another type of LSDA which was thoroughly investi-

Among the anionic LSDA types the best known one is gated was that of the 0~-sulfo fatty esters (no. 1, Table I).

probably the fatty acid amide of N-methyltaurine or Igepon From a raw materials point of view, the methyl ester of a-sul-

T type (no. 4 in Table I). While it is a very good detergent fotallow fatty acid is probably the least expensive anionic

by itself and an excellent lime soap dispersant with an LSDA of all the compounds studied. It is prepared from

LSDR of 5, the commercial product has the disadvantage of hydrogenated tallow by transesterification and subsequent

high cost and a high sodium chloride content. Some sul- sulfonation with SO3, followed by neutralization (8,9).

fated alkanolamides such as no. 6 and no.7 (Table I) provide This type of product is produced most adviantageously by

a less expensive alternative and provide the same good sur- continuous SO3 sulfonation. The ct-sulfonated methyl

face-active properties. Such materials are synthesized by esters are less stable to hydrolysis than the sulfated fatty

amidation of tallow fatty acid followed by sulfation and acid alkanolamides no. 6 and no. 7. Furthermore, as Table I

neutralization. Although sulfated fatty acid alkanolamides shows, they are poorer detergents and lime soap dispersants

were first synthesized in 1933 (4), the development of a (LSDR = 9) than the sulfated alkanolamides.

practical sulfation method is quite recent. Neat sulfation of Amphoteric surfactants are the most efficient LSDA

fatty alkanolamides in high yields is nearly impossible be- studied, and they offer better detergency than the anionics.

cause of the high viscosity of the reaction mixture which However, they are inherently more expensive because of

makes efficient agitation, and hence good contact between costlier starting materials, and some of the reaction steps by

sulfating agent and amide, very difficult. In the past, chlori- which they are made have not been fully investigated.

nated solvents were usually added to alleviate this problem. The simplest members of this group are the betaines

However, current environmental considerations make this obtained via the reaction of an alkyldimethylamine with

approach unattractive. It was now found that cosulfation of sodium chloroacetate to give compound no. 16 (Table I).

a mixture of the monoisopropanolamide (no. 6) and digiy- The analogous amidoamino amphoteric is prepared in

colamide (no. 7) of tallow fatty acid with n-butanol elimi- two steps starting with amidation of a fatty acid and sub-

nated the viscosity problem (5). The resulting mixture of sequent reaction with sodium chloroacetate to give a be-

sulfates, subsequently referred to as TAM, was obtained in taine of the structure:

a high yield and possessed excellent surface-active proper- +

ties. These products have somewhat limited hydrolytic sta- RCONHCH2CH2CH2N(CH3)2CH2COO"

bility (6); however, in the presence of soap the sulfated

amides are quite stable because of the higher pH. Both betaines are produced commercially in the U.S. and

The analogous alkylarylsulfonamides (no. 9, Table I) pos- abroad. The lime soap dispersing (LSDR = 12) and deter-

sess similar surface-active properties but are somewhat less gency properties of compound no. 16 (10) are slightly in-

stable to alkaline hydrolysis than the sulfated fatty alkanol- ferior to those of anionic LSDA such as sodium methyl

amides (7). These sulfonamide derivatives are of interest, ct-sulfotallowate as is shown in Table I.

88 J. AM. OIL CHEMISTS' SOC., January 1978 (VOL. 55)

~Oggg~

=o o ~=oo= DO ~OOOO ~OOO

<

m

O

v- ._=

e~

6

,d

d

ex

_o

< w

e~

ct~

: e~'_ to= , a

go=..

4gd~gd~4r

J. AM. OIL CHEMISTS' SOC., January 1978 (VOL. 55) 89

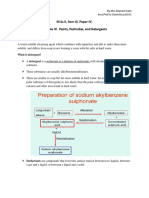

FIG. 1. Photomicrographs of cotton (C) and polyester-cotton FIG. 3. Photomicrographs of fabrics washed in 0.2% of tallow

blend (PC) fabrics washed 25 times in hard water containing 0.2% soap.

of soap-LSDA type detergent.

The exact position of the sulfo group is not known.

The other synthetic route involves reaction between epi-

chlorohydrin and sodium bisulfite to give the sodium salt of

1-chloro-2-hydroxy-3-propanesulfonic acid, and subsequent

reaction with a tertiary amine yields a sulfobetaine ac-

cording to the following scheme:

RN(CH3)2 + C 1CH2CHOHCH2SO3Na---~

+

RN(CH3)2CH2CHOHCH2SO 3 + NaC1

This type of product is commercially available in the

U.S. The surface-active properties of the sulfobetaines ob-

tained via these two alternative routes are the same as that

of the sulfobetaine prepared from propane sultone.

The spacing between the anionic and cationic sites of the

sulfobetaine molecule effects water solubility and surface

FIG. 2. Photomicrographs of fabrics washed in 0.2% of a high activity. The Krafft point is lowered by 50 C or more, and

phosphate built control detergent, detergency is slightly improved as the bridge between the

two sites is increased from C2 to C3. Replacement of the

Superior LSDA are produced when the anionic group in sulfo group by sulfate tends to decrease solubility but does

the molecule is a sulfo -SO 3- or sulfato -OSO3" group. The not change surface activity (13).

sulfo compounds are readily prepared by the reaction of a Introduction of an amido group into the sulfobetaine

tertiary amine with propane sultone to give compound molecule usually improves the LSDR, as stated above, and

no. 17. These sulfobetaines have an LSDR of 4-5, depending water solubility is also improved. Introduction of a second

on the alkyl chain length, and exhibit good detergency amido group does not cause further improvement in the

(1 1). When an amido group is introduced into the molecule LSDR but increases solubility in water, i.e., lowers the

to form compounds of the structure no. 18 (Table I), the Krafft point (14,15).

lime soap dispersing power is usually greatly enhanced, and The relative positions of the anionic and cationic sites in

the LSDR drops to 2. These types of compounds are the the molecule are very important. When the quaternary

most potent lime soap dispersants we have encountered so ammonium group is placed at the terminal position of the

far. The synthetic scheme is as follows: molecule and the sulfo group is placed away from the end

position, the surface-active properties show remarkable de-

RCOOH + H2 NCH2CH2CH2N(CH3)2 - RCONHCH2CH2CH2N(CH3)2 cline (16).

+ . PropaneI

RCONHCH2CH2CH2N(CH3)2CH2CH2CH2SO3

Sultone

FORMULATIONS WITH SOAP-LSDA BLENDS

The detergency of soap is potentiated by addition of an

Because of the carcinogenic nature and high cost of pro-

LSDA, and vice versa. Maximum detergency is usually at-

pane sultone, its use for commercial syntheses is no longer

feasible, and consequently two alternative synthetic routes tamed when the ratio of soap to LSDA is 80:20, and such a

were developed which lead to closely related compounds. blend washes better than either compound by itself. Fur-

Both involve a two-step reaction scheme (12). In the first ther enhancement of detergency is achieved by the addition

synthesis the tertiary amine is first quaternized with aUyl of builders such as glassy silicates, sodium tripolyphos-

chloride, and the resulting quaternary a m m o n i u m salt is phate, or sequestering agents like trisodium nitrilotriacetate

then treated with sodium bisulfite in the presence of a free (NTA) and other organic chelating agents (17). A relatively

radical initiator such as t-butyl perbenzoate to give the sul- simple formulation, used in evaluation tests of all LSDA's,

fobetaine. The overall scheme is as follows. consists of the following (18):

+ 64% tallow soap

RN(CH3)2 + CH2 = CHCH2CL--~RN(CH3)2CH2CH = CH2.C 1

19% LSDA

+ H <NaHSO3 I 14% silicate builder

RN(CH3)2CH2CH--I--CH2

SO3- peroxide 1% sodium carboxymethylcellulose (CMC)

catalyst 2% impurities and minor additives

90 J. AM. OIL CHEMISTS' SOC., January 1978 (VOL. 5S)

Formulations o f this type, in which the LSDA was sodium blends is that soap and LSDA solubilize each other. For

methyl a-tallowate (no. 1), Igepon T (no. 4), a mixture of example, a blend of an insoluble LSDA and sodium palmi-

the two sulfated alkanolamides no. 6 and no. 7 called TAM, tate, a high Krafft point soap, is more water soluble than

or a tallow derived sulfobetaine no. 17 called TSB, were either component (22). Since poor solubility of soap, and

spray dried successfully on a pilot plant scale. In addition, hence poor detergency in cold water, has been a serious

formulations containing no. 1 or TAM were also dried in a drawback to the use of soap as a detergent, this difficulty

conventional hot air dryer to form flakes. These formula- can now be overcome by the addition o f an LSDA to the

tions were evaluated in a Tergometer (18) and the formula- soap.

tion containing no. 1 was also evaluated in several bundle

tests. The results indicated that such formulations perform BIOLOGICAL BEHAVIOR

as well in hard (300 ppm) or soft (50 ppm) water as does a

high quality commercial detergent built with 50% sodium The acute oral toxicity, skin and eye irritation, sensitiza-

tripolyphosphate (STPP). The choice of silicate builder is tion and toxicity to fish were determined for three high

not too critical, and sodium metasilicate performs about as soap content detergent formulations containing compounds

well as a glossy silicate (SiO2 :Na 2 0 = 1.6:1). 1, 4, and 6 as the LSDA. It was found that the soap-based

Table II shows detergency data for detergents containing detergents are as safe as a high phosphate commercial con-

the soap-LSDA blend as a major ingredient according to the trol detergent (23). With regards to ease and completeness

above formulations as well as for highly built formulations. of biodegradation, it was determined that these three soap-

If desired (and legally permissible), the soap-LSDA blend LSDA formulations degrade more rapidly and completely

may be formulated with tripolyphosphate or organic than the control. Since these detergents are phosphate-free,

builders in a manner analogous to formulations with linear it is obvious that they are less objectionable from an envi-

alkylbenzene sulfonates (LAS). Table II shows the compo- ronmental point of view than present day commercial de-

sition of the formulations and their detergency as a percen- tergents.

tage of the performance of a commercial detergent con- This new concept of a laundry detergent offers a simple

taining 50% STPP. The anionic sulfated mixed tallow fatty solution to the quest for phosphate-free detergents. It is as

acid alkanolamide (TAM), and the amphoteric tallow de- safe and effective as a high phosphate built detergent but

rived sulfobetaine (no. 17, TSB) were used as LSDA, and without the environmentally objectionable features of the

the builders were STPP and NTA. The table clearly shows latter. Since the present worldwide price trends for petro-

the superiority of the high soap-TAM blend formulation leum and petrochemicals are expected to continue as crude

over the highly built soap-TAM detergents. While the TAM- petroleum becomes scarcer, the use of tallow, a replenish-

containing formulations are adversely affected by the ad- able agricultural by-product, should b e c o m e very attractive

dition of sodium sulfate, the sulfate-free formulations give as a raw material for use in built and unbuilt detergents. It

acceptable detergency although poorer than that of either is significant that several Japanese firms already are manu-

the control or the high soap-LSDA formulation. On the facturing and successfully marketing such products. The

other hand, formulations containing the amphoteric TSB as only imminent problem encountered in the U.S. and several

the LSDA are essentially unaffected by the addition of so- European countries is that there is a shortage of soap-

dium sulfate, and differences between the high soap-TSB making facilities. However, just as the detergent industry a

and the highly built soap-TSB formulations are small. NTA generation ago decided to scrap their obsolete soap plants

appears to be a better builder than STPP for the soap-LSDA in favor of facilities to produce the so-called "synthetic

formulations shown in Table II. detergents," there is no reason why present worn out deter-

gent-making facilities cannot be replaced gradually by mo-

MODE OF ACTION OF SOAP-LSDA MIXTURES dern efficient soapmaking facilities.

It has been frequently assumed that the soap component

REFERENCES

in soap-LSDA blend acts as a scavenger for hard water ions,

whereas the LSDA is solely responsible for detergency. This 1. Jungermann, E., JAOCS 50:475 (1973).

view does not agree with the experimental findings. All 2. Stirton, A.J., F.D. Smith, and J.K. Well, Ibid. 42:114 (1965).

evidence obtained indicates that soap, LSDA, and calcium 3. Borgbetty, H.C., and C.A. Bergman, lbid. 27:88 (1950).

and magnesium ions are tightly bound together in a sus- 4. Guenther, F., F. Munz, and H. Haussmann (I.G. Farbenin-

pended particle. Thus fabric washed 25 consecutive times dustrie), U.S. Patent 1,932,180 (1933).

5o Bistline, R.G., Jr., W.R. Noble, F.D. Smith, and W.M. Linfield,

with soap-LSDA formulation in 300 ppm hard water shows JAOCS 54:371 (1977).

no buildup whatsoever of foreign matter when viewed un- 6. Weft, J.K., N. Parris, and A.J. Stirton, Ibid. 47:91 (1970).

der a scanning electron microscope (Fig. 1); neither does a 7. Bistline, R.G., Jr., W.R. Noble, and W.M. Linfield, Ibid. 51:126

high phosphate built commercial detergent (Fig. 2), where- (1974).

as a heavy buildup of soap scum occurs with soap alone 8. Stein, W., H. Weiss, O. Koch, P. Neuhausen, and H. Baumann,

Fette Seifen Anstrichm. 72:956 (1970).

(Fig. 3) (19). Analysis of the same fabrics shows very low 9. Stein, W., and H. Baumann, JAOCS 52:323 (1975).

Ca ++ and Mg++ for the high phosphate built detergent and 10. Linfield, W.M., W.R. Noble, and N. Parris, Proc. 59th Mid-Year

for the soap-LSDA detergent but a high Ca ++ and Mg++ Mtg., Chem. Specialties Manuf. Assoc., 1973, p. 85.

content for the soap alone. Even more convincing evidence 11. Parris, N., J.K. Well, and W.M. Linfield, JAOCS 50:$09 (1973).

was obtained when a soap-LSDA dispersion in hard water 12. Parris, N., J.K. Well, and W.M. Linfield, Ibid. $3:60 (1976).

was filtered on a small porosity polymer membrane and 13, Parris, N., J.K. Well, and W.M. Linfield, Ibid. $3:97 (1976).

14. Micich, T.J., W.M. Linfield, and J.K. Well, Ibid. 54:91 (1977).

analyzed. The filter residue contained all of the soap, all of

15. Micich, T.J., and W.M. Linfield, Ibid. 54:264 (1977).

the LSDA, all of the Ca ++ , most of the Mg§ but no Na § 16. Smith, F.D., M.K. Sucharski, and W.M. Linfield, Ibido 53:69

The filtered material could be redispersed in water, and the (1976).

resulting dispersion exhibited high surface activity including 17. Bistline, R.G., Jr., W.R. Noble, J.K. Well, and W.M. Linfield,

detergency, whereas the filtrate was essentially devoid of Ibid. 49:63 (1972).

18. Noble, W.R., R.G. Bistline, Jr., and W.M. Linfield, Soap Cos-

surface activity (20). The surface tension behavior o f soap- met. Chem. Spec. 48(7):38 (1972).

LSDA mixtures likewise indicated a mixed micelle, and the 19. Noble, W.R., J.K. Well, R.G. Bistline, Jr., S.B. Jones, and W.M.

mixture gave surface tension vs. log concentration curves Linfieid, JAOCS 52:1 (1975).

which are typical of single surfactants rather than of mix- 20. Well, J.K., C.J. Pierce, and W.M. Linfield, Ibid. 53:757 (1976).

21. Well, J.K., and W.M. Linfield, Ibid. 54:339 (1977).

tures (21 ). 22. Well, J.K., C.A. Schollenberger, and W.M. Linfieid, Ibid. 54:1

An interesting phenomenon observed with soap-LSDA (1977).

J. AM. OIL CHEMISTS' SOC., January 1978 (VOL. 55) 91

23. Maurer, E.W., T.C. Cordon, J.K. Weft, and W.M. Linfieid, Ibid. (1966).

51:287 (1974). 28. Weft, J.IC, F.D. Smith, and W.M. Linfield, Ibid. 4 9 : 3 8 3 (1972).

29. Micieh, T.J., W.M. Linfield, and J.K. Weft, Ibid. 51:297 (1974).

24. Smith, F.D., J.K. Weil, and W.M. Linfield, Ibid. 51:435 (1974).

30~ Micich, T.J., J.K. Weft, and W.M. Linfield, Ibid. 52:451 (1975).

25. Pards, N., J.K. Weft, and W.M. Linfield, Ibid. 4 9 : 6 4 9 (1972).

26. Micicb, T.J., M.K. Sucharski, J.K. Weft, and W.M. Linfield, Ibid. 31. Marmer, W.N., D.E. Van Horn, and W.M. Linfield, Ibid. 51:174

4 9 : 6 5 2 (1972). (1974).

27. Weft, J.K., A.J. Stirton, and M.V. Nun'ez-Ponzoa, Ibid. 4 3 : 6 0 3 32. Mariner, W.N., and W.M~ Linfield, Ibid. 5 2 : 3 3 0 (1975).

92 J. AM. OIL CHEMISTS' SOC., January 1978 (VOL. 55)

You might also like

- Solvent Extraction Principles and Practice 2nd Ed - Jan Rydberg Et Al. (Marcel Dekker, 2004)Document724 pagesSolvent Extraction Principles and Practice 2nd Ed - Jan Rydberg Et Al. (Marcel Dekker, 2004)Milena Katarina Stojiljkovic100% (6)

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- As 2278.1-2008 Aerosol Containers Metal Aerosol Dispensers of Capacity 50 ML To 1000 ML InclusiveDocument7 pagesAs 2278.1-2008 Aerosol Containers Metal Aerosol Dispensers of Capacity 50 ML To 1000 ML InclusiveSAI Global - APAC50% (2)

- How Does A Refrigerator WorkDocument5 pagesHow Does A Refrigerator WorkAlfis0% (1)

- Builder - PDF (China Substitution)Document11 pagesBuilder - PDF (China Substitution)Finsen SooNo ratings yet

- Development of Surfactants and Builders in Detergent FormulationsDocument11 pagesDevelopment of Surfactants and Builders in Detergent FormulationsAyukiyut KambaliNo ratings yet

- Laundry Detergents An Overview SynthesisDocument15 pagesLaundry Detergents An Overview SynthesisazertyNo ratings yet

- Laundry DetergentsDocument15 pagesLaundry DetergentsfarhadNo ratings yet

- 5.1 Analysing Soap and DetergentDocument28 pages5.1 Analysing Soap and DetergentNor HusseinNo ratings yet

- DETERGENTS ManualDocument7 pagesDETERGENTS Manualmeharitikue31No ratings yet

- Comparing Soap and Detergent PropertiesDocument19 pagesComparing Soap and Detergent PropertiesNajihah JaffarNo ratings yet

- Soap and Detergent IndustryDocument30 pagesSoap and Detergent IndustryJohn Morrel D. Miranda100% (1)

- Organic Soap Manufacturing Process by PRDocument90 pagesOrganic Soap Manufacturing Process by PRRengeline LucasNo ratings yet

- Soaps & Detergents NotesDocument3 pagesSoaps & Detergents NotesVina Kwan100% (1)

- The Performance Test of Fatty Acid Methyl Ester Sulfonates and Application in The Dishwashing Liquid DetergentDocument6 pagesThe Performance Test of Fatty Acid Methyl Ester Sulfonates and Application in The Dishwashing Liquid DetergentMuhammad HuseinNo ratings yet

- Detergent Industry Report - Onel IsraelDocument13 pagesDetergent Industry Report - Onel IsraelOnel Israel BadroNo ratings yet

- ReportDocument89 pagesReportDekabris Avogardo Gerald100% (1)

- Sulphonation Technology in The Detergent IndustryDocument5 pagesSulphonation Technology in The Detergent IndustryСергей КубахNo ratings yet

- Use of High-Active Alpha Olefin Sulfonates in Laundry PowdersDocument9 pagesUse of High-Active Alpha Olefin Sulfonates in Laundry PowdersJuan Camilo RodriguezNo ratings yet

- Liquid Laundry Detergents Based on Soap and Α-sulfo Methyl EstersDocument4 pagesLiquid Laundry Detergents Based on Soap and Α-sulfo Methyl Estersראול אפונטהNo ratings yet

- CHAPTER 3 Shreve Chemical Process Industries 5th Ed. OCRpdfDocument25 pagesCHAPTER 3 Shreve Chemical Process Industries 5th Ed. OCRpdfFellippe AmorNo ratings yet

- What Are The Raw Materials For The Production of SoapsDocument7 pagesWhat Are The Raw Materials For The Production of SoapsArslan ChatthaNo ratings yet

- Hostapur SAS A Traditional SpecialityDocument44 pagesHostapur SAS A Traditional SpecialityMehmet AydinNo ratings yet

- Detergent Formulations - Ion ExchangeDocument8 pagesDetergent Formulations - Ion ExchangeSaeid MirNo ratings yet

- Soap and Detergent: Production and Cleansing ActionsDocument8 pagesSoap and Detergent: Production and Cleansing ActionsAmeerul HazeeqNo ratings yet

- Soap and DetergentsDocument25 pagesSoap and DetergentsPaolo GochingcoNo ratings yet

- ChemDocument34 pagesChemAaghash A SNo ratings yet

- Us 2952639Document7 pagesUs 2952639khoiri 787No ratings yet

- Manufacturing of DetergentsDocument20 pagesManufacturing of Detergentsmohsin razaNo ratings yet

- Qualitative Analysis of Some Soap: January 2020Document12 pagesQualitative Analysis of Some Soap: January 2020Favour OgbonnaNo ratings yet

- Grade 11 Chemistry Week 9 Lesson 2Document4 pagesGrade 11 Chemistry Week 9 Lesson 2RealGenius (Carl)No ratings yet

- Detergents Heavy Duty PowderDocument9 pagesDetergents Heavy Duty PowderJohn Demson TapiaNo ratings yet

- Polymeric Materials PolycarboxylatesDocument2 pagesPolymeric Materials PolycarboxylatesSkolastika ErnaNo ratings yet

- Detergent ProductionDocument24 pagesDetergent ProductionAlo Peter taiwo100% (1)

- Chemistry Project Class 12thDocument17 pagesChemistry Project Class 12thshristhi79No ratings yet

- EXP6 Soap and DetergentheheDocument19 pagesEXP6 Soap and DetergenthehesamengNo ratings yet

- Detergents AcDocument8 pagesDetergents AcTaimoor Hassan KhanNo ratings yet

- Project ChemistryDocument14 pagesProject ChemistryLIYA ASKARNo ratings yet

- Rheological Characterization of Hair Shampoo in The Presence of Dead Sea SaltDocument11 pagesRheological Characterization of Hair Shampoo in The Presence of Dead Sea SaltJean RisquezNo ratings yet

- Soaps and detergents: How they clean and their ingredientsDocument8 pagesSoaps and detergents: How they clean and their ingredientsChristal Elaine CelestialNo ratings yet

- Foaming CapacityDocument12 pagesFoaming Capacitysachidanandas51No ratings yet

- Decolorizing and Detoxifying Textile Wastewater Using Anaerobic/Aerobic TreatmentDocument9 pagesDecolorizing and Detoxifying Textile Wastewater Using Anaerobic/Aerobic TreatmentShurooq TaibNo ratings yet

- Detergent Comp With Fun CTDocument5 pagesDetergent Comp With Fun CTayman1234567No ratings yet

- Chemistry Folio NotesDocument15 pagesChemistry Folio NotesElaine ChinNo ratings yet

- Soap and Detergent 2Document37 pagesSoap and Detergent 2Erviani RahmawatiNo ratings yet

- Investigation of Foaming Capacity of Different Washing Soap - Chemistry Science Fair ProjectDocument4 pagesInvestigation of Foaming Capacity of Different Washing Soap - Chemistry Science Fair ProjectSujay NirmaleNo ratings yet

- The Science of Cleansing: Soaps vs DetergentsDocument18 pagesThe Science of Cleansing: Soaps vs DetergentsGutium CristiNo ratings yet

- The Role of PAA Na With Different Weight-Average Molar Mass in Phosphate Free Laudry Detergent Builder SystemsDocument9 pagesThe Role of PAA Na With Different Weight-Average Molar Mass in Phosphate Free Laudry Detergent Builder SystemselisosbeNo ratings yet

- Sulfonation/Sulfation Processing Technology For Anionic Surfactant ManufactureDocument27 pagesSulfonation/Sulfation Processing Technology For Anionic Surfactant Manufactureumasankar.jNo ratings yet

- Soap and Detergent: Give The Definition of Soap and Some Examples of SoapDocument6 pagesSoap and Detergent: Give The Definition of Soap and Some Examples of SoapfanusNo ratings yet

- Effect of Sodium Carbonate On Forming Capacity of A SoapDocument6 pagesEffect of Sodium Carbonate On Forming Capacity of A SoapThiagarajan BaluNo ratings yet

- 0035 0045Document11 pages0035 0045Frank MtetwaNo ratings yet

- Patent US4081395 - Alkaline detergent compositions for cleaning polycarbonate surfacesDocument9 pagesPatent US4081395 - Alkaline detergent compositions for cleaning polycarbonate surfacesPeterNo ratings yet

- CH 1Document10 pagesCH 1Abdullah AliNo ratings yet

- Aatcc DetergentDocument2 pagesAatcc DetergentOliver Everett Espino100% (1)

- Soap and DetergentDocument16 pagesSoap and DetergentFarhan Anwer100% (2)

- Surfactant:: History of DetergentDocument9 pagesSurfactant:: History of DetergentSharaf NourNo ratings yet

- Foaming CapacityDocument12 pagesFoaming Capacityg8440512No ratings yet

- Effect of Sodium Carbonate on Soap FoamingDocument5 pagesEffect of Sodium Carbonate on Soap FoamingADITYA SAHUNo ratings yet

- Detergent Notes - MVM 2022Document8 pagesDetergent Notes - MVM 2022KulsumNo ratings yet

- CONSUMER CHEMISTRY 9 Q3 MODULE 2 SOAPS AND DETERGENTS Reviewed 2Document8 pagesCONSUMER CHEMISTRY 9 Q3 MODULE 2 SOAPS AND DETERGENTS Reviewed 2trixter jedd a laguatanNo ratings yet

- Chapter 5 Chemicals For Consumers: 5.1 Soap and Detergent (A) SoapDocument24 pagesChapter 5 Chemicals For Consumers: 5.1 Soap and Detergent (A) SoapLee Li JieNo ratings yet

- Structural Mimics of Acetylene HydrataseDocument7 pagesStructural Mimics of Acetylene Hydrataseראול אפונטהNo ratings yet

- Complexation of Procainamide With DextroseDocument3 pagesComplexation of Procainamide With Dextroseראול אפונטהNo ratings yet

- Reconstruction of Paleo-Fire Emissions Over The Past Millennium From MeasurementsDocument22 pagesReconstruction of Paleo-Fire Emissions Over The Past Millennium From Measurementsראול אפונטהNo ratings yet

- Co-Crystals With Acetylene - Small Is Not Simple!Document16 pagesCo-Crystals With Acetylene - Small Is Not Simple!ראול אפונטהNo ratings yet

- Transport Refusal by Hypoglycemic Patients After On-Scene Intravenous DextroseDocument3 pagesTransport Refusal by Hypoglycemic Patients After On-Scene Intravenous Dextroseראול אפונטהNo ratings yet

- A Sensitive Spectrophotometric Method For Lipid Hydroperoxide DeterminationDocument7 pagesA Sensitive Spectrophotometric Method For Lipid Hydroperoxide Determinationראול אפונטהNo ratings yet

- Storage and Sorption Properties of Acetylene in Jungle-Gym-LikeDocument7 pagesStorage and Sorption Properties of Acetylene in Jungle-Gym-Likeראול אפונטהNo ratings yet

- Acetylene Degradation by New Isolates of Aerobic Bacteria and Comparison of Acetylene Hydratase EnzymesDocument6 pagesAcetylene Degradation by New Isolates of Aerobic Bacteria and Comparison of Acetylene Hydratase Enzymesראול אפונטהNo ratings yet

- Quantum Chemical Exploration of Intermolecular Reactions of AcetyleneDocument11 pagesQuantum Chemical Exploration of Intermolecular Reactions of Acetyleneראול אפונטהNo ratings yet

- Life Cycle Assessment of BioethanolDocument10 pagesLife Cycle Assessment of Bioethanolראול אפונטהNo ratings yet

- Acetylene Degradation by New Isolates of Aerobic Bacteria and Comparison of Acetylene Hydratase EnzymesDocument6 pagesAcetylene Degradation by New Isolates of Aerobic Bacteria and Comparison of Acetylene Hydratase Enzymesראול אפונטהNo ratings yet

- Urea-Resorcinol-Formaldehyde Adhesives of Low Resorcinol ContentDocument12 pagesUrea-Resorcinol-Formaldehyde Adhesives of Low Resorcinol Contentראול אפונטהNo ratings yet

- Quantum Chemical Exploration of Intermolecular Reactions of AcetyleneDocument11 pagesQuantum Chemical Exploration of Intermolecular Reactions of Acetyleneראול אפונטהNo ratings yet

- Microporous Magnesium and Manganese Formates For Acetylene StorageDocument5 pagesMicroporous Magnesium and Manganese Formates For Acetylene Storageראול אפונטהNo ratings yet

- An Overview of Algae Bioethanol ProductionDocument13 pagesAn Overview of Algae Bioethanol Productionראול אפונטהNo ratings yet

- Current State of BioethanolDocument10 pagesCurrent State of Bioethanolראול אפונטהNo ratings yet

- Synthesis and Characterization of Lactose Based Resorcinol ResinDocument5 pagesSynthesis and Characterization of Lactose Based Resorcinol Resinראול אפונטהNo ratings yet

- The Interaction of Fructose, Dextrose and Ethanol On Human PerformanceDocument11 pagesThe Interaction of Fructose, Dextrose and Ethanol On Human Performanceראול אפונטהNo ratings yet

- Using Electric Power To Synthesize Resorcinol Formaldehyde Gels With Enhanced CharacteristicsDocument10 pagesUsing Electric Power To Synthesize Resorcinol Formaldehyde Gels With Enhanced Characteristicsראול אפונטהNo ratings yet

- Nitrite-Scavenging Properties of Catechol, Resorcinol, and HydroquinoneDocument5 pagesNitrite-Scavenging Properties of Catechol, Resorcinol, and Hydroquinoneראול אפונטהNo ratings yet

- Fabrication of Low Density Foam Shells From Resorcinol Formaldehyde AerogelDocument12 pagesFabrication of Low Density Foam Shells From Resorcinol Formaldehyde Aerogelראול אפונטהNo ratings yet

- Embryotoxic Effects of Acrolein, Methacrylates, Guanidines and Resorcinol On Three Day Chicken EmbryosDocument5 pagesEmbryotoxic Effects of Acrolein, Methacrylates, Guanidines and Resorcinol On Three Day Chicken Embryosראול אפונטהNo ratings yet

- Structure of Resorcinol, Phenol, and Furan Resins by MALDI TOF Mass Spectrometry and 13C NMRDocument10 pagesStructure of Resorcinol, Phenol, and Furan Resins by MALDI TOF Mass Spectrometry and 13C NMRראול אפונטהNo ratings yet

- The Influence of Hydrogen Peroxide On The Permeability of Protective Gloves To Resorcinol in HairdressingDocument7 pagesThe Influence of Hydrogen Peroxide On The Permeability of Protective Gloves To Resorcinol in Hairdressingראול אפונטהNo ratings yet

- Resorcinol Formaldehyde Resins and Hydroxymethyl Resorcinol (HMR and N HMR) PDFDocument22 pagesResorcinol Formaldehyde Resins and Hydroxymethyl Resorcinol (HMR and N HMR) PDFראול אפונטהNo ratings yet

- Aqueous Chlorination of ResorcinolDocument5 pagesAqueous Chlorination of Resorcinolראול אפונטהNo ratings yet

- Biodegradation of Resorcinol and Catechol by Denitrifying Enrichment CulturesDocument6 pagesBiodegradation of Resorcinol and Catechol by Denitrifying Enrichment Culturesראול אפונטהNo ratings yet

- Resorcinol skin sensitization potential identified by LLNADocument5 pagesResorcinol skin sensitization potential identified by LLNAראול אפונטהNo ratings yet

- The Synergistic Effect of Dicyandiamide and Resorcinol in The Curing of Epoxy ResinsDocument6 pagesThe Synergistic Effect of Dicyandiamide and Resorcinol in The Curing of Epoxy Resinsראול אפונטהNo ratings yet

- Treatment of Wastewater From Syngas Wet Scrubbing - Model Based Comparison of Phenol Biodegradation Basin ConfigurationsDocument26 pagesTreatment of Wastewater From Syngas Wet Scrubbing - Model Based Comparison of Phenol Biodegradation Basin Configurationsראול אפונטהNo ratings yet

- BenchTop Orbital Shakers GuideDocument8 pagesBenchTop Orbital Shakers Guidedéborah_rosales100% (1)

- BOF1Document3 pagesBOF1Skartini DayNo ratings yet

- Booher Chem Sketch Activity 1Document13 pagesBooher Chem Sketch Activity 1c_booher9561No ratings yet

- CAB Cable Rings and SaddlesDocument5 pagesCAB Cable Rings and SaddlesgoyalmanojNo ratings yet

- Waterproofing: Hydrostop 4 Py-SDocument2 pagesWaterproofing: Hydrostop 4 Py-SPrashantBaruaNo ratings yet

- Titrimetric Methods of AnalysisDocument28 pagesTitrimetric Methods of AnalysisPraveen Kumar Avvaru100% (2)

- 2 Basic Clinical Genetic - ppt-1Document24 pages2 Basic Clinical Genetic - ppt-1Najib M. NauvalNo ratings yet

- PK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory IiiDocument21 pagesPK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory Iiibedirtupak92% (12)

- AL REScheck CertificateDocument6 pagesAL REScheck Certificatebcap-oceanNo ratings yet

- Comparison of Triode and Diode Ion PumpDocument7 pagesComparison of Triode and Diode Ion PumpAarkayChandruNo ratings yet

- 1010750-Steam Quality TestingDocument11 pages1010750-Steam Quality TestingHendra Hadriansyah100% (1)

- High Performance Butterfly Valve HP 111Document4 pagesHigh Performance Butterfly Valve HP 111JOHNNo ratings yet

- BioreactorsDocument32 pagesBioreactorskhadeeja vjfndnNo ratings yet

- Chem 2 Course OutlineDocument15 pagesChem 2 Course Outlineapi-607966786No ratings yet

- Role of DSS in RefineryDocument24 pagesRole of DSS in Refineryramadoss_alwar7307100% (1)

- Warna Daun Padi LCCDocument12 pagesWarna Daun Padi LCCM Hisyam NasrullohNo ratings yet

- Food Chemistry: Miaomiao Shi, Zhiheng Zhang, Shujuan Yu, Kai Wang, Robert G. Gilbert, Qunyu GaoDocument7 pagesFood Chemistry: Miaomiao Shi, Zhiheng Zhang, Shujuan Yu, Kai Wang, Robert G. Gilbert, Qunyu GaoSNo ratings yet

- MScSYChem18 19Document40 pagesMScSYChem18 19kumarNo ratings yet

- FINALSDocument8 pagesFINALSSeenpai23No ratings yet

- ME6008 WELDING TECHNOLOGY Part B IQDocument1 pageME6008 WELDING TECHNOLOGY Part B IQVikram mNo ratings yet

- UNIT III TheoryDocument6 pagesUNIT III TheoryRanchuNo ratings yet

- SDS Asam SulfatDocument8 pagesSDS Asam SulfatQuality AssuranceNo ratings yet

- Rapid and Reliable HPLC Method For The Simultaneous Determination of Dihydroxyacetone, Methylglyoxal and 5-Hydroxymethylfurfural in Leptospermum HoneysDocument9 pagesRapid and Reliable HPLC Method For The Simultaneous Determination of Dihydroxyacetone, Methylglyoxal and 5-Hydroxymethylfurfural in Leptospermum Honeysasel ppNo ratings yet

- Astm D 2863Document13 pagesAstm D 2863Ma PonyNo ratings yet

- New Australian Curriculum Senior Secondary ChemistryDocument44 pagesNew Australian Curriculum Senior Secondary Chemistryapi-252350138No ratings yet