Professional Documents

Culture Documents

Road Reinstatement

Uploaded by

Bishop Ojonuguwa AmehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Road Reinstatement

Uploaded by

Bishop Ojonuguwa AmehCopyright:

Available Formats

INTER– DEPARTMENTAL PROCEDURE - OPERATIONS

JOB HAZARD ANALYSIS Procedure Ref: QP-STD-S-102-QP

________________________________________________________________________________________________________ Page 4 of 12_

`Risk Assessment Matrix (RAM)

INCREASING LIKELIHOOD/PROBABILITY

CONSEQUENCES A B C D E

Never heard of in Has occurred in Has occurred in Occurs several Occurs several

Potential Severity People Asset damage & Environment Reputation Impact industry industry QP times a year in QP times a year at

business losses effect this site

INCREASING SEVERITY

0 No Injury No Damage No Effect No Impact

1 Slight Injury or Slight damage. Slight Effect Slight Impact

Health effects (<QR 35000) Low Risk

2 Minor Injury or Minor damage Minor Effect Minor Impact

Health effects (between QR

35,000 and 350,000

3 Major Moderate damage Moderate Effect Moderate Impact

Injury or Health (between 350,000 Medium Risk

effects and 3.5 Million)

4 Single Fatality or Major damage Major Effect Major Impact

permanent Total (between 3.5 High Risk

Disability Million and 35

Million)

5 Multiple Fatalities Massive damage Massive Effect Massive Impact

(> QR 35 Million)

Emmanuel Ameh – HSE Supervisor

INTER– DEPARTMENTAL PROCEDURE - OPERATIONS

JOB HAZARD ANALYSIS Procedure Ref: QP-STD-S-102-QP

________________________________________________________________________________________________________ Page 4 of 12_

JHA No: 22 Revision No: 0 Area: QPA DUKHAN Job Location : Location 15 Date : 25/04/2018

Job Ref(Project No/Work Order No): Hazardous Area Classification: Zone 0 , , Zone 1 , Zone 2 , Non Hazardous

X

Job Description: Manual Road Excavation Permit Type & No :

SL Activity (Job Steps) Potential Hazard Risk Rating Control/Mitigation Measures SL Action Party/

No Before No Remark

Mitigation

2xB= Conform with the Company’s and QP’s Heat Stress 2xA= Supervisor /

Heat Stress

Low Management program Low Foreman

Equipment must be in good condition. Third party

Mobilization of Defective / incorrect 2xB= certificate of thorough inspection must be valid. 2xA= Supervisor /

01 personnel and equipment and tools Low Do not use defective tools Low Foreman

equipment at site

Ensure that equipment passed QP inspection

No awareness on the

2xB= Conduct ERP awareness training to personnel, include 2xA= Supervisor /

Emergency Response

Low periodic refresher trainings. Low Foreman

Procedures

Planning and Scope not included in PTW / Review / ensure that scope of work is included in the

2xB= 2xA= Supervisor /

02 preparation of task invalid PTW / Incorrect JSA PTW and PTW has current revalidation. JSA must be task

Low Low Foreman

execution specific.

03 Installation of Observe proper body positioning. Lift with your legs and

barricades/safety 2xB= not with your back. Maximum of 25 kg per person is 2XA= Supervisor /

Manual handling

cones and traffic Low allowed for manual lifting. Use hand protection when Low Foreman

signage handling materials.

Emmanuel Ameh – HSE Supervisor

INTER– DEPARTMENTAL PROCEDURE - OPERATIONS

JOB HAZARD ANALYSIS Procedure Ref: QP-STD-S-102-QP

________________________________________________________________________________________________________ Page 4 of 12_

SL Activity (Job Steps) Potential Hazard Risk Rating Control/Mitigation Measures Residual Action Party/

No Before Risk Rating Remark

Mitigation

2xB= Conform with the Company’s and QP’s Heat Stress 2xA= Supervisor /

Heat Stress

Low Management program Low Foreman

Reduce loads by making them smaller or lighter.

Ensure the working environment is suitable and free

from obstructions

Ensure that the individual is lifting correctly,

Fractures, , Sprains Cuts,

maintains good posture, and lifts with knees bent and

Lacerations, Abrasions

back kept straight.

Injury through 2xB= 2xA= Supervisor /

All loads should be assessed individually for size

aggravation of Low Low Foreman

and weight, but generally loads greater than 8kg

previous/existing medical

should be handled by more than one person.

condition

Operatives must wear appropriate gloves and other

clothing to reduce the risk of injury all appropriate

04 Manual Handling PPE shall be strictly adhered to before and during the

work

2xB= Conform with the Company’s and QP’s Heat Stress 2xA= Supervisor /

Heat Stress

Low Management program Low Foreman

2xB= 2XB= Supervisor /

Dust Wear respiratory protection

Low Low Foreman

Uneven work surface due to 2xB= Remove stones on the access way and provide a 2XB= Supervisor /

excavation Low standard access inside the excavated trench Low Foreman

Emmanuel Ameh – HSE Supervisor

INTER– DEPARTMENTAL PROCEDURE - OPERATIONS

JOB HAZARD ANALYSIS Procedure Ref: QP-STD-S-102-QP

________________________________________________________________________________________________________ Page 4 of 12_

2xB= 2XB= Supervisor /

Sharp objects Wear hand protection

Low Low Foreman

2xB= 2XB= Supervisor /

Ergonomics Observe proper body positioning

Low Low Foreman

Team Members & Endorsement:

S/N Name Position/Ref Indicator Sign S/N Name Position/Ref Indicator Sign

HSE SUPERVISOR

Emmanuel Ameh

HSE MANAGER

Ahsan Zamir

Safety Officer

Chiazota Adrian

JHA Team Leader Authorization: Ref Indicator: Sign :

JHA Approval (Permit Authority/Asset Holder): Ref Indicator: Sign:

Emmanuel Ameh – HSE Supervisor

You might also like

- Risk Assessment CleaningDocument7 pagesRisk Assessment Cleaningahmer09No ratings yet

- Protect Yourself from Moving Machine PartsDocument7 pagesProtect Yourself from Moving Machine PartsPedro ViegasNo ratings yet

- GEN-021 Fact FindingDocument3 pagesGEN-021 Fact Findingacanbasri1980No ratings yet

- Theme Based Safety Discussion - Gas Cylinder Storage & HandlingDocument2 pagesTheme Based Safety Discussion - Gas Cylinder Storage & HandlingMr. XNo ratings yet

- Fiberglass Cloth SdsDocument5 pagesFiberglass Cloth Sdslance boxNo ratings yet

- Toolbox Talk 12 Banks Men Lifting GearDocument2 pagesToolbox Talk 12 Banks Men Lifting GearSajid HussainNo ratings yet

- 9C - MSDS FiberglassDocument3 pages9C - MSDS FiberglassSon TranNo ratings yet

- Theme Based Safety Discussion (TBT) For Manual Grinding OperationDocument3 pagesTheme Based Safety Discussion (TBT) For Manual Grinding OperationMr. XNo ratings yet

- FiveSteps PDFDocument1 pageFiveSteps PDFMohamed FouadNo ratings yet

- k3 Bore Pile DenganBIMDocument6 pagesk3 Bore Pile DenganBIMrhoewiebNo ratings yet

- Theme Based Discussion (TBT) - Heat StressDocument2 pagesTheme Based Discussion (TBT) - Heat StressMr. XNo ratings yet

- SRA-GEN Risk Assessment for Turbine MaintenanceDocument3 pagesSRA-GEN Risk Assessment for Turbine Maintenanceacanbasri1980No ratings yet

- Warehouse Risk Assessment Aldir II IWPPDocument25 pagesWarehouse Risk Assessment Aldir II IWPPMadhu MohanNo ratings yet

- Loto VeneervisionDocument2 pagesLoto Veneervisionapi-362234935No ratings yet

- Operating in Confined SpacesDocument4 pagesOperating in Confined SpacesFaiqoh NahareyNo ratings yet

- Form Accident ReportDocument4 pagesForm Accident ReportKarthik SNo ratings yet

- Risk assessment for hanging doorsDocument11 pagesRisk assessment for hanging doorsMitchRappNo ratings yet

- TOPIC: Demolition SafetyDocument1 pageTOPIC: Demolition SafetyMohamed HamdallahNo ratings yet

- PTW/Hot Work 2/checklist 34 - Excavations and Work WithinDocument2 pagesPTW/Hot Work 2/checklist 34 - Excavations and Work WithinAli Shaikh AbdulNo ratings yet

- BOMMI-PRD-03.0008-Rev.00 - Personal Protective EquipmentDocument10 pagesBOMMI-PRD-03.0008-Rev.00 - Personal Protective Equipmentfundatia_gaudeamusNo ratings yet

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarNo ratings yet

- DT-1 Cleaning PTWDocument2 pagesDT-1 Cleaning PTWsubhashkpn86No ratings yet

- Log of Work-Related Injuries and Illnesses: OSHA's Form 300Document3 pagesLog of Work-Related Injuries and Illnesses: OSHA's Form 300bioarquitecturaNo ratings yet

- ARA - For Emergency Diesel GeneratorDocument4 pagesARA - For Emergency Diesel GeneratorShaikh AftabNo ratings yet

- Hand and Power Tools Safe WorkDocument11 pagesHand and Power Tools Safe WorkOkba TelNo ratings yet

- CL-07-02 Crane Lift Study ChecklistDocument7 pagesCL-07-02 Crane Lift Study Checklisthanes0% (1)

- Risk Management and AssessmentDocument50 pagesRisk Management and Assessmentfaik395No ratings yet

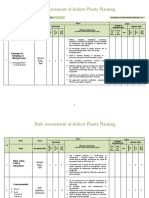

- Risk Assessment of Indoor Plants PlantingDocument5 pagesRisk Assessment of Indoor Plants Plantingطارق رضوانNo ratings yet

- OHS&W Plant Specific Hazard IdentificationDocument3 pagesOHS&W Plant Specific Hazard IdentificationJulio Best SetiyawanNo ratings yet

- Daily HSSE ReportDocument117 pagesDaily HSSE ReportMoaatazz NouisriNo ratings yet

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Document6 pagesCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- 003 SWMS - ExcavationDocument11 pages003 SWMS - Excavationsasi kumar50% (2)

- Coco Shell Base Course Preparation Safety ChecklistDocument2 pagesCoco Shell Base Course Preparation Safety ChecklistPaul TamayoNo ratings yet

- Sample-Risk Assessment & Safe Work Method StatementDocument4 pagesSample-Risk Assessment & Safe Work Method StatementioanchiNo ratings yet

- Safety Alert Safety Alert: BackgroundDocument1 pageSafety Alert Safety Alert: BackgroundAnonymous h0yGTDQWZNo ratings yet

- Safety Alert - Danger of Infection - January 2010Document1 pageSafety Alert - Danger of Infection - January 2010Meklo1No ratings yet

- Confined Space ENGDocument30 pagesConfined Space ENGfaik395No ratings yet

- Work Permit SystemDocument24 pagesWork Permit Systemsudeesh kumarNo ratings yet

- Unloading of EWPs From ContainersDocument10 pagesUnloading of EWPs From ContainersPirashanth SathananthanNo ratings yet

- Caramics LotoDocument7 pagesCaramics LotoAhmad MensaNo ratings yet

- Segregation of Paper and Cardboard Waste, Polymeric Materials Waste, Glass and TiresDocument10 pagesSegregation of Paper and Cardboard Waste, Polymeric Materials Waste, Glass and Tiresfaik395No ratings yet

- Welding and Cutting SafetyDocument22 pagesWelding and Cutting SafetyyawarhassanNo ratings yet

- Family Emergency Contact PlanDocument2 pagesFamily Emergency Contact PlanJeremy NashNo ratings yet

- Risk Ass. - AD 417 - Installation of SocketDocument6 pagesRisk Ass. - AD 417 - Installation of SocketnsadnanNo ratings yet

- Behavior Based Safety (BBS) : Emco QatarDocument29 pagesBehavior Based Safety (BBS) : Emco QatarparthaNo ratings yet

- TRA 58 Unloading and Rigging Up Test EquipmentDocument4 pagesTRA 58 Unloading and Rigging Up Test EquipmentPirlo PoloNo ratings yet

- Confined Space SapDocument2 pagesConfined Space SapfairusNo ratings yet

- Osha 3761Document1 pageOsha 3761api-301892310No ratings yet

- Cold Work PermitDocument1 pageCold Work PermitherdianNo ratings yet

- Assessment For CCTV System Testing & CommissioningDocument5 pagesAssessment For CCTV System Testing & CommissioningAnonymousNo ratings yet

- Disaster Management Safety OrientDocument55 pagesDisaster Management Safety OrientVishalNo ratings yet

- Hse-Swms-018-A - Traffic Signal Maintenance - NSWDocument12 pagesHse-Swms-018-A - Traffic Signal Maintenance - NSWapi-326016071No ratings yet

- Bidaa Tower Risk Assessment From CALISTO UpdatedDocument5 pagesBidaa Tower Risk Assessment From CALISTO Updatedirshad gNo ratings yet

- Risk Assessment For Coring WorksDocument5 pagesRisk Assessment For Coring WorksFaizan Tanveer100% (1)

- PPE Matrix AgrocelDocument2 pagesPPE Matrix AgrocelBhakti MahbubaniNo ratings yet

- Hse Plan 2012Document1 pageHse Plan 2012Arief FirmansyahNo ratings yet

- Health & Safety: Workplace Inspection Checklist - Workshop AreasDocument6 pagesHealth & Safety: Workplace Inspection Checklist - Workshop AreasMuhammad Alif ZauharNo ratings yet

- Cable PullingDocument10 pagesCable PullingnsadnanNo ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument13 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- 32 First Aid Kit Box Inspection ChecklistDocument1 page32 First Aid Kit Box Inspection ChecklistBishop Ojonuguwa Ameh67% (3)

- InstructionsDocument1 pageInstructionsBishop Ojonuguwa AmehNo ratings yet

- CydiaDocument2 pagesCydiaBishop Ojonuguwa AmehNo ratings yet

- WashingtonDocument2 pagesWashingtonBishop Ojonuguwa AmehNo ratings yet

- OSHA Issues Scaffold Fact SheetsDocument2 pagesOSHA Issues Scaffold Fact SheetsBishop Ojonuguwa AmehNo ratings yet

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- CydiaDocument2 pagesCydiaBishop Ojonuguwa AmehNo ratings yet

- Code For Instagram HackDocument1,766 pagesCode For Instagram HackBishop Ojonuguwa Ameh100% (1)

- KunuDocument3 pagesKunuBishop Ojonuguwa AmehNo ratings yet

- HazidDocument2 pagesHazidBishop Ojonuguwa Ameh100% (1)

- EbolaDocument2 pagesEbolaBishop Ojonuguwa AmehNo ratings yet

- New OSHA Fact Sheet Addresses Silica Rule For General Industry, MaritimeDocument3 pagesNew OSHA Fact Sheet Addresses Silica Rule For General Industry, MaritimeBishop Ojonuguwa AmehNo ratings yet

- Example 4 - Field Services Inspection ChecklistDocument4 pagesExample 4 - Field Services Inspection ChecklistfargoNo ratings yet

- Lawno1of2015amendinglabourlaw PDFDocument2 pagesLawno1of2015amendinglabourlaw PDFBishop Ojonuguwa AmehNo ratings yet

- Court upholds silica rule but asks OSHA to consider medical removalDocument3 pagesCourt upholds silica rule but asks OSHA to consider medical removalBishop Ojonuguwa AmehNo ratings yet

- Binomran Trdg. & Telecom WLL: Fuel Bill ClaimDocument2 pagesBinomran Trdg. & Telecom WLL: Fuel Bill ClaimBishop Ojonuguwa AmehNo ratings yet

- JHADocument6 pagesJHABishop Ojonuguwa AmehNo ratings yet

- BM15-SCCM N100824 Infoblad Wet - en Regelgeving ENG Versie10jul12 4Document2 pagesBM15-SCCM N100824 Infoblad Wet - en Regelgeving ENG Versie10jul12 4Bishop Ojonuguwa AmehNo ratings yet

- 1f. MS 06 Pavement - Method Statement RoadDocument16 pages1f. MS 06 Pavement - Method Statement RoadAnonymous 5omQ3lRNo ratings yet

- Site Inspection Record Template 1 of 2 Construction: Observations / Corrective ActionsDocument2 pagesSite Inspection Record Template 1 of 2 Construction: Observations / Corrective ActionsBishop Ojonuguwa AmehNo ratings yet

- Cis WSH Jobsite Safreview 146959 7Document4 pagesCis WSH Jobsite Safreview 146959 7Bishop Ojonuguwa AmehNo ratings yet

- BM15-SCCM N100824 Infoblad Wet - en Regelgeving ENG Versie10jul12 4 PDFDocument44 pagesBM15-SCCM N100824 Infoblad Wet - en Regelgeving ENG Versie10jul12 4 PDFPanos CayafasNo ratings yet

- 3150 FM Bwew0083Document2 pages3150 FM Bwew0083Bishop Ojonuguwa AmehNo ratings yet

- Fuel Bill Claim ReportDocument2 pagesFuel Bill Claim ReportBishop Ojonuguwa AmehNo ratings yet

- Portable Power Tool Safety ChecklistDocument3 pagesPortable Power Tool Safety ChecklistBishop Ojonuguwa AmehNo ratings yet

- 2018 06.02.2018 Bin Omran GC14113100 HSE WalkthroughDocument9 pages2018 06.02.2018 Bin Omran GC14113100 HSE WalkthroughBishop Ojonuguwa AmehNo ratings yet

- Relevance of Natural Law To Nigerian LegDocument43 pagesRelevance of Natural Law To Nigerian LegBishop Ojonuguwa AmehNo ratings yet

- Heat Stress First Aid ChartDocument2 pagesHeat Stress First Aid ChartBishop Ojonuguwa AmehNo ratings yet

- Technische Beschreibung BMSAGADocument28 pagesTechnische Beschreibung BMSAGABishop Ojonuguwa AmehNo ratings yet

- ABS Braking System ExplainedDocument7 pagesABS Braking System Explainedletter_ashish4444No ratings yet

- Resume of Promila - MattuDocument3 pagesResume of Promila - MattuKyle EmersonNo ratings yet

- Parts For DPI-2-HE (Tuneles de Colombia)Document474 pagesParts For DPI-2-HE (Tuneles de Colombia)Rodríguez y Londoño GarantiasNo ratings yet

- Identity Theft Prevention: Protect Yourself and OthersDocument4 pagesIdentity Theft Prevention: Protect Yourself and OtherscherryfooNo ratings yet

- Dynamic LogisticDocument15 pagesDynamic LogisticChamp MehtaNo ratings yet

- CMI Extractive Metallurgy ServicesDocument46 pagesCMI Extractive Metallurgy ServicesAbdullah SalemNo ratings yet

- Method StatementDocument82 pagesMethod StatementSrinidhi Kakarla83% (6)

- JJNDocument1 pageJJNiancuNo ratings yet

- Ae 3007a-72-299Document7 pagesAe 3007a-72-299turboshaftNo ratings yet

- Cement Grinding OptimizationDocument9 pagesCement Grinding OptimizationFran JimenezNo ratings yet

- Amstrad Action 001Document100 pagesAmstrad Action 001maddog571998No ratings yet

- B.O.Q of Electro-Mechanical Works 31Document1 pageB.O.Q of Electro-Mechanical Works 31asdsd dsdaNo ratings yet

- CM11 Nordics p22-23 Koenigsegg CATIA EN FINAL PDFDocument1 pageCM11 Nordics p22-23 Koenigsegg CATIA EN FINAL PDFsunilbholNo ratings yet

- Sathya Seelan resume for electrical engineerDocument4 pagesSathya Seelan resume for electrical engineerSathyaSeelan Veerasamy KumaresanNo ratings yet

- Project ReportDocument19 pagesProject ReportEr Nandkishor Prajapati86% (7)

- Eicher Motors Initiating CoverageDocument15 pagesEicher Motors Initiating CoverageNikhil SinghalNo ratings yet

- Doc13852681f290020160603122731 SKL User Guide V15 June 2016Document22 pagesDoc13852681f290020160603122731 SKL User Guide V15 June 2016Jose PulidoNo ratings yet

- Jawaban Sertifikasi SAPDocument4 pagesJawaban Sertifikasi SAPanggie100% (2)

- Final Report Part IIDocument127 pagesFinal Report Part IIPatrisonNo ratings yet

- Motorcycle Parts & Services OnlineDocument10 pagesMotorcycle Parts & Services OnlineJomar DimabuyuNo ratings yet

- My Classes - SkillshareDocument1 pageMy Classes - SkillsharekolakNo ratings yet

- Informatica HCLDocument221 pagesInformatica HCLminnusiri100% (1)

- Tec PecDocument23 pagesTec PecALI BEN AMORNo ratings yet

- Chaderton Barbara AS400Document3 pagesChaderton Barbara AS400Sivakumar RajuNo ratings yet

- ZF TrainnigDocument132 pagesZF TrainnigNuno Pires100% (4)

- Types Of Gearboxes: Bevel, Helical, Offset, Planetary & MoreDocument7 pagesTypes Of Gearboxes: Bevel, Helical, Offset, Planetary & MoreRavi ParkheNo ratings yet

- Aisi S220-11 PDFDocument0 pagesAisi S220-11 PDFLutfi VerdyNo ratings yet

- ORings-NOK S SS SeriesDocument2 pagesORings-NOK S SS SeriesKudanthai SenthilkumarNo ratings yet

- Jet Blue Airways Soft Core CompetenciesDocument47 pagesJet Blue Airways Soft Core CompetenciesFez Research Laboratory100% (1)