Professional Documents

Culture Documents

0 Coupled Horizontal and Torsional Vibrations of Container Ships PDF

Uploaded by

khabiranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0 Coupled Horizontal and Torsional Vibrations of Container Ships PDF

Uploaded by

khabiranCopyright:

Available Formats

UDC 629.5.015.5:629.

544

COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS... I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ

Ivo SENJANOVIĆ

Stipe TOMAŠEVIĆ Coupled Horizontal and Torsional

Rajko GRUBIŠIĆ

Vibrations of Container Ships

Original scientific paper

Necessity of performing hydroelasticity analysis of large container ships is pointed out. For

this purpose theory of coupled horizontal and torsional vibration is described. Beam finite ele-

ment for vibration analysis, with eight degrees of freedom, which includes bending, shear, tor-

sional and warping stiffness, is developed. Coupling between horizontal and torsional vibration is

realised through inertia forces. Application of the theory is illustrated in case of a large container

ship.

Authors’ address: Keywords: container ship, horizontal and torsional vibration, finite element method

Faculty of Mechanical Engineering

and Naval Architecture Spregnute horizontalne i torzijske vibracije kontejnerskih brodova

University of Zagreb Izvorni znanstveni rad

I. Lučića 5

HR-10000 Zagreb, Croatia Naglašena je potreba provođenja hidroelastične analize velikih kontejnerskih brodova. Radi

E-mail: ivo.senjanovic@fsb.hr toga prikazana je teorija spregnutih horizontalnih i torzijskih vibracija brodova sa širokim palub-

nim otvorima. Za analizu vibracija razvijen je gredni konačni element s osam stupnjeva slobode

Received (Primljeno): 2007-05-31 gibanja, koji uključuje krutost na savijanje, smicanje, uvijanje i iskrivljavanje. Sprega horizontalnih

i torzijskih vibracija ostvaruje se putem inercijskih sila. Primjena teorije ilustrirana je na primjeru

Accepted (Prihvaćeno): 2007-07-11

velikoga kontejnerskog broda.

Open for discussion (Otvoreno

za raspravu): 2008-12-24 Ključne riječi: kontejnerski brod, horizontalne i torzijske vibracije, metoda konačnih elemenata

1 Introduction i.e. below the keel, and therefore the coupling of horizontal and

torsional vibrations is extremely high.

Increased sea transport requires building of ultra large con- The above problem is rather complicated due to geometrical

tainer ships which are quite flexible [1]. Therefore, their strength discontinuity of the hull cross-section. Solution accuracy de-

has to be checked by hydroelastic analysis [2]. Methodology of pends on the reliability of stiffness parameters determination,

hydroelastic analysis is described in [3]. It includes definition i.e. of bending, shear, torsional and warping moduli. The finite

of the structural model, ship and cargo mass distributions, and element method is a powerful tool to solve the above problem

geometrical model of ship wetted surface. Hydroelastic analysis in a successful way.

is based on the modal superposition method. First, dry natural One of the first solutions for coupled horizontal and tor-

vibrations of ship hull are calculated. Then modal hydrostatic sional hull vibrations, dealing with the finite element technique,

stiffness, modal added mass, modal damping and modal wave is given in [6] and [7]. Generalised and improved solutions are

load are determined. Finally, calculation of wet natural vibra- presented in [8] and [9] respectively. In all these references de-

tions is performed and transfer functions for determining ship termination of hull stiffness is based on the classical thin-walled

structural response to wave excitation are obtained [4], [5]. girder theory, which does not give a satisfactory value for the

This paper deals with dry natural vibrations of container warping modulus of the open cross-section. Besides that, the

initial values of stiffness moduli are determined, so that the ap-

ships as an important step in their hydroelastic analysis. A ship

plication of the beam theory for hull vibration analysis is limited

hull, as an elastic nonprismatic thin-walled girder, performs lon-

to a few lowest natural modes.

gitudinal, vertical, horizontal and torsional vibrations. Since the The developed higher-order theory of thin-walled girders

cross-sectional centre of gravity and deformation centre posi- offers the opportunity to overcome the aforementioned defi-

tions are not identical, coupled longitudinal and vertical, as well ciencies [10]. Within this theory the energy approach is used to

as horizontal and torsional vibrations occur, respectively. Thus, define hull stiffness parameters as mode dependent quantities.

vibration coupling is realised through the mass only. In this way more accurate results for the uncoupled girder vibra-

Distance between the centre of gravity and the deformation tion are obtained.

centre is negligible for longitudinal and vertical vibration as well In this paper the beam finite element method is elaborated

as for horizontal and torsional vibration of conventional ships. for coupled horizontal and torsional vibration of ship hull with

Therefore, in the above cases ship hull vibrations are usually large hatch openings. For this purpose a beam finite element of

analysed separately. However, the deformation centre in ships eight degrees of freedom is developed. Application of the theory

with large hatch openings is located outside the cross-section, is illustrated in case of a large container ship.

58(2007)4, 365-379 365

I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS...

2 Differential equations of beam vibrations ∂ 2 wb

M = − EI b (4)

Referring to the flexural beam theory [11], the total beam ∂ x2

deflection, w, consists of the bending deflection, wb, and the

shear deflection, ws, i.e., Figure 1

and the shear force

w = wb + ws . (1)

∂ ws

Q = GAs . (5)

∂x

The inertia load consists of the distributed load, qi, and the

bending moment, μi, specified as

⎛ ∂2 w ∂2 ψ ⎞ (6)

qi = − m ⎜ 2 + c 2 ⎟

⎝ ∂t ∂t ⎠

∂ 3 wb ,

μi = − Jb (7)

∂ x ∂t2

where m is the distributed ship and added mass, Jb is the mo-

ment of inertia of ship mass about the centre line, and c is the

distance between the centre of gravity and the deformation cen-

tre, c = zG – zD, Figure 2. Deformation centre is a shear centre

i.e. torsional centre.

Figure 1 Beam bending and torsion

Slika 1 Savijanje i uvijanje grede

The shear deflection is a function of wb

EI b ∂ 2 wb

ws = − , (2)

Figure 2 Cross section of a thin-walled girder

GAs ∂ x 2

Slika 2 Poprečni presjek tankostijenog nosača

where E and G are the Young’s and shear modulus respective- Concerning torsion, the displacements are the twist angle ψ

ly, while Ib and As are the bending modulus and shear area re- and its variation

spectively. In (2) a term depending on mass rotation is ignored ∂ψ

because of low influence and for the reason of simplicity. The ϑ=

∂x (8)

angle of cross-section rotation also depends on wb

as a warping measure, Figure 1. The sectional forces include the

∂ wb . total torque, T, consisting of the pure torsional torque, Tt, and

ϕ= (3)

the warping torque Tw [12] i.e.

∂x

The cross-sectional forces include the bending moment T = Tt + Tw , (9)

366 58(2007)4, 365-379

COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS... I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ

where Since

∂ψ

Tt = GI t E

∂x (10) G=

2(1 + ν)

∂3 ψ

Tw = − EI w (11) the ratio E/G may be expressed by Poisson’s ratio ν.

∂ x3

and the bimoment given by

3 Beam finite element

The properties of a finite element for the coupled horizontal

∂ ψ .

2 and torsional vibration analysis may be derived from the ele-

Bw = EI w (12) ment total energy. The total energy consists of the deformation

∂ x2 energy, the inertia energy, the work of the external lateral load,

q, and the torque, μ, and the work of the boundary forces. Thus

The inertia load includes the distributed torque, μti, and the [14],

bimoment, μwi, presented in the following form:

∂2 ψ ∂2 w

μ ti = − J t − mc 2 (13) ⎡ 2 2

⎤

∂t 2

∂t ⎛ ∂ 2 wb ⎞ ⎛ ∂ ws ⎞

⎢ EI b ⎜ + GAs ⎜ +⎥

l

1 ⎢ ⎝ ∂ x 2 ⎟⎠ ⎝ ∂ x ⎟⎠ ⎥

Etot = ∫ ⎢ ⎥d x +

∂4 ψ , (14) 20⎢ ⎛ ∂2 ψ ⎞

2

⎛ ∂ψ⎞

2

⎥

μ wi = J w + E I + GI

w ⎜

⎝ ∂ x 2 ⎟⎠

t ⎜

∂ x2 ∂ t 2 ⎢

⎣ ⎝ ∂ x ⎟⎠ ⎥

⎦

where Jt is polar moment of inertia of ship and added mass ⎡ ⎛ ∂w⎞2 ⎛ ∂ 2 wb ⎞ ⎤

2

about the deformation centre and Jw is bimoment of inertia of ⎢m + J +⎥

⎢ ⎜⎝ ∂ t ⎟⎠

b ⎜

ship mass about the warping centre, Figure 2. ⎝ ∂ x ∂ t ⎟⎠ ⎥

l ⎢ ⎥ (17)

Considering the equilibrium of a differential element, one 1 ∂w ∂ψ

may write + ∫ ⎢ +2 mc + ⎥d x −

20⎢ ∂t ∂t ⎥

⎢ 2 2

⎥

∂M ⎢ ⎛ ∂ ψ⎞

2

⎛ ∂ψ⎞ ⎥

= Q + μi ⎢+ Jw ⎜ + Jt ⎜ ⎥

∂x ⎣ ⎝ ∂ x ∂ t ⎟⎠ ⎝ ∂ t ⎠⎟ ⎦

∂Q l

= − qi − q (15) − ∫ (qw + μψ )d x + (Qw − M ϕ + T ψ + Bw ϑ )l0 ,

∂x

0

∂T

= −μ ti − μ wi − μ .

∂x

Substituting corresponding sectional forces and distributed

loads into (15) and condensing the first two equations (15), the where l is the element length.

following system of differential equations is obtained for a pris- Since the beam has four displacements, ω, ϕ, ψ, ϑ, a two-

matic beam [13], [14]: nodded finite element has eight degrees of freedom, i.e. four

nodal shear-bending and torsion-warping displacements respec-

tively, Figure 3,

∂ 4 wb ⎛ EI b ⎞ ∂ 4 wb

EI b −⎜ m + Jb ⎟ +

∂x 4

⎝ GAs ⎠ ∂ x2 ∂ t 2

⎛ ∂ 2 wb J ∂ 4 wb ∂2 ψ ⎞

+m ⎜ + b +c 2 ⎟ =q (16) ⎧ w(0 )⎫ ⎧ ψ (0 )⎫

⎝ ∂t 2

GAs ∂ t 4

∂t ⎠

⎪ ϕ(0 ) ⎪ ⎪ ϑ (0 ) ⎪

EI w

∂4 ψ

− GI

∂2 ψ

+ J

∂2 ψ

− J

∂4 ψ

+ {U } = ⎪⎨ ⎪⎬ , {V } = ⎪⎨ ⎪

⎬ (18)

∂ x4

t

∂ x2

t

∂t2

w

∂ x2 ∂ t 2 ⎪ w(l ) ⎪ ⎪ ψ (l ) ⎪

⎪⎩ ϕ(l ) ⎪⎭ ⎪⎩ ϑ (l ) ⎪⎭

⎛ ∂ 2 wb EI b ∂ 4 wb ⎞

+ mc ⎜ − =μ.

⎝ ∂t2 GAs ∂ x 2 ∂ t 2 ⎟⎠

58(2007)4, 365-379 367

I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS...

⎡ 1 + 6β 0 −3 2⎤

⎢ −4β(1 + 3β)l (1 + 12β)l −2(1 + 3β)l l ⎥

1

[ aik ] = 1 + 12β ⎢⎢ 6β 0 3

⎥

−2 ⎥

(22)

⎢ ⎥

⎣ −2β(1 − 6β)l 0 −(1 − 6β)l l ⎦

⎡ 6β −12β 0 0⎤

⎢ 4β(1 + 3β)l −6β l 0 0⎥

1

[bik ] = 1 + 12β ⎢⎢ −6β 12β 0

⎥

0⎥

(23)

⎢ ⎥

⎣ 2β(1 − 6β)l −6β l 0 0⎦

EI b

[ cik ] = [ aik ] + [bik ] , β=

GAs l 2

(24)

Figure 3 Beam finite element ⎡ 1 0 −3 2⎤

Slika 3 Gredni konačni element ⎢ 0 l −2l l ⎥

[ dik ] = ⎢⎢ 0 0 3 ⎥

−2 ⎥

(25)

Therefore, the basic beam displacements, wb and ψ, may be ⎢ ⎥

presented by the third-order polynomials ⎣ 0 0 −l l ⎦

wb = ak {ξ } ,

k

ξ=

x

l Substituting Eqs. (20) into (17) one obtains

(19)

ψ = dk {ξ } ,

k

k = 0, 1, 2, 3 .

T T

1 ⎧U ⎫ ⎡ kbs 0 ⎤ ⎧U ⎫ 1 ⎧U ⎫ ⎡ msb mst ⎤

Etot = ⎨ ⎬ ⎨ ⎬+ ⎨ ⎬ i

Furthermore, satisfying alternately the unit value for one of 2 ⎩V ⎭ ⎢⎣ 0 kwt ⎥⎦ ⎩V ⎭ 2 ⎩V ⎭ ⎢⎣ mts mtw ⎥⎦

the nodal displacement {U} and zero values for the remaining T T

⎧U ⎫ ⎧ q ⎫ ⎧U ⎫ ⎧ P ⎫ ⎧U ⎫

displacements, and doing the same for {V}, it follows that: i⎨ ⎬ − ⎨ ⎬ ⎨ ⎬ − ⎨ ⎬ ⎨ ⎬ ,

⎩V ⎭ ⎩μ ⎭ ⎩V ⎭ ⎩ R ⎭ ⎩V ⎭ (26)

wb = wbi {U } , i = 1, 2, 3, 4

where, assuming constant values of the element properties,

ws = wsi {U } (20)

w = wi {U } , ⎡ l 2

d 2 wbi d wbj

l

d wsi d wsj ⎤

[ k ]bs = ⎢ EI b ∫ d x + GAs∫ d x⎥

ψ = ψ i {V } , ... = { ... } ,

T 2 2

⎣ 0

dx dx 0

dx dx ⎦

– bending-shear stiffness matrix,

where wbi, wsi, wi and ψi are the shape functions given below

⎡ l

d2 ψ i d ψ j

2 l

d ψi d ψ j ⎤

[ k ]wt = ⎢ EI w ∫ 2 2

d x + GI t ∫ d x⎥

⎣ dx dx dx dx ⎦

wbi = aik {ξ } k 0 0

wsi = bik {ξ }

k – warping-torsion stiffness matrix,

(21)

wi = cik {ξ }

k

⎡ l

[ m ]sb = ⎢ m ∫ wi w j d x + J b ∫

l

d wbi d wbj ⎤

d x⎥

ψ i = dik {ξ }

k

⎣ 0 0

dx dx ⎦

– shear-bending mass matrix,

368 58(2007)4, 365-379

COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS... I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ

⎡ ⎤ It is obvious that coupling between the bending and torsion

d ψi d ψ j

l l

[ m ]tw = ⎢ J t ∫ ψ i ψ j d x + J w ∫ d x⎥ occurs through the mass matrix only, by the coupling matrices

⎣ 0 0

dx dx ⎦ [m]st and [m]ts.

– torsion-warping mass matrix, 4 Finite element transformation

In the finite element equation (31) first the element prop-

⎡ l ⎤

[ m ]st = ⎢ mc ∫ wi ψ j d x ⎥ , [ m ]ts = [ m ]st

T

erties related to bending and then those related to torsion ap-

⎣ 0 ⎦ pear. To make a standard finite element assembling possible,

it is necessary to transform Eq. (31) in such a way that first all

– shear-torsion mass matrix, properties related to the first node and then those belonging to

the second one are specified. Thus, the nodal force and displace-

ment vectors read

⎧l ⎫

{q} = ⎨ ∫ q w j d x ⎬ − shear load vector,

⎩0 ⎭

⎧ −Q ( 0 ) ⎫ ⎧ w(0 ) ⎫

⎧ l

⎫ ⎪ M (0 ) ⎪ ⎪ ϕ(0 ) ⎪

{μ} = ⎨ ∫ μ ψ j d x ⎬ − torsion load vector, (27)

⎪ ⎪ ⎪ ⎪

⎩0 ⎭ ⎪ −T ( 0 ) ⎪ ⎪ ψ (0 )⎪

i, j = 1, 2, 3, 4 . ⎪ ⎪ ⎪ ⎪

⎪ − Bw (0 )⎪ ⎪ ϑ (0 ) ⎪

{}f =⎨ ⎬, {}

δ =⎨ ⎬. (33)

⎪ Q(l ) ⎪ ⎪ w(l ) ⎪

The vectors {P} and {R} represent the shear-bending and ⎪ − M (l ) ⎪ ⎪ ϕ(l ) ⎪

⎪ ⎪ ⎪ ⎪

⎪ ψ (l ) ⎪

torsion-warping nodal forces, respectively,

⎪ T (l ) ⎪

⎪⎩ Bw (l ) ⎪⎭ ⎪⎩ ϑ (l ) ⎪⎭

⎧ −Q ( 0 ) ⎫ ⎧ −T ( 0 ) ⎫

⎪ M (0 ) ⎪ ⎪ − B (0 )⎪

{P} = ⎪⎨ ⎪

⎬, { R} = ⎪⎨ w ⎪⎬ . (28) The same transformation has to be done for the load vector

⎪ Q(l ) ⎪ ⎪ T (l ) ⎪ {ƒ}qμ resulting in {ƒ˜}qμ. The above vector transformation implies

⎪⎩ − M (l )⎪⎭ ⎪⎩ Bw (l ) ⎪⎭ the row and column exchange in the stiffness and mass matrix

according to the following set form:

The above matrices are specified in Appendix A, as well as the

load vectors for loads linearly distributed along the element, i.e. 1 2 5 6 3 4 7 8

1 11 12 15 16 13 14 17 18

q = q0 + q1ξ, μ = μ 0 + μ1ξ . (29)

2 21 22 25 26 23 24 27 28

Also, shape functions of sectional forces are listed in Ap- 5 51 52 55 56 53 54 57 58

pendix B. 6 61 62 65 66 63 64 67 68 (34)

The total element energy has to be at its minimum. Satisfy-

ing the relevant conditions 3 31 32 35 36 33 34 37 38

4 41 42 45 46 43 44 47 48

∂ Etot ∂ Etot

= {0} , = {0} , (30)

7 71 72 75 76 73 74 77 78

∂ {U } ∂ {V } 8 81 82 85 86 83 84 87 88

and employing Lagrange equations of motion, the finite element

equation yields

The element deflection refers to the deformation centre as

{ f } = [ k ] {δ} + [ m ] {δ} − { f }qμ

the origin of a local coordinate system. Since the vertical posi-

(31)

tion of the deformation centre varies along the ship’s hull, it is

necessary to prescribe the element deflection for a common line,

where in order to be able to assemble the elements. Thus, choosing the

x-axis (base line) of the global coordinate system as the referent

⎧P⎫ ⎧q⎫ ⎧U ⎫

{f} = ⎨ ⎬, { f }qμ = ⎨ ⎬, {δ} = ⎨ ⎬ line, the following relation between the former and the latter

⎩ R⎭ ⎩μ ⎭ ⎩V ⎭ (32)

nodal deflections exists:

⎡k 0⎤ ⎡m mst ⎤

[ k ] = ⎢ 0bs kwt ⎥⎦

, [ m ] = ⎢ msb mtw ⎥⎦

. w(0 ) = w(0 ) + z D ψ (0 ) (35)

⎣ ⎣ ts w(l ) = w(l ) + zD ψ (l ),

58(2007)4, 365-379 369

I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS...

where zD is the coordinate of the deformation centre, Figure 2. In case of natural vibration {F(t)} = {0} and the influence

The other displacements are the same in both coordinate sys- of damping is rather low for ship structures so that the damping

tems. Twist angle ψ does not have influence on the cross-sec- forces may be ignored. Assuming

tion rotation angle ϕ. The local displacement vector may be

expressed as {Δ} = {φ} eiω t (42)

{δ} = ⎡⎣T ⎤⎦ {δ ] (36) where {φ} and ω are the mode vector and natural frequency

respectively, Eq. (41) leads to the eigenvalue problem

where [T˜ ] is the transformation matrix

([ K ] − ω [ M ]) {φ} = {0}

2

(43)

⎡1 0 zD 0⎤ which may be solved employing different numerical meth-

⎡[T ] ⎢0 0⎥

[0]⎤ 1 0 ods [15]. The basic one is the determinant search method in

⎡⎣T ⎤⎦ = ⎢ , [ T ] = ⎢ ⎥ (37)

⎣[0] [T ]⎥⎦ ⎢0 0 1 0⎥ which ω is found from the condition

⎢ ⎥

⎣0 0 0 1⎦ [K ] − ω2 [ M ] =0 (44)

Since the total element energy is not changed by the above by an iteration procedure. Afterwards, {φ} follows from (43)

transformations, a new element equation may be derived taking assuming unit value for one element in {φ}.

(36) into account. Thus, one obtains in the global coordinate The forced vibration analysis may be performed by direct

system integration of Eq. (41) or as well as by the modal superposition

method. In the latter case the displacement vector is presented

{ f } = ⎡⎣ k ⎤⎦ {δ} + ⎡⎣ m ⎤⎦ {δ} − { f }

in the form

qμ

, (38) {Δ} = [ φ ] { X } , (45)

where [φ] = [{φ}] is the undamped mode matrix and {X} is the

where generalised displacement vector. Substituting (45) into (41), the

modal equation yields

{ f } = ⎡⎣T ⎤⎦ { f }

T

[ k ] { X } + [ c ] { X } + [ m ] { X } = { f (t )} (46)

⎡ k ⎤ = ⎡T ⎤ ⎡ k ⎤ ⎡T ⎤

T

where

⎣ ⎦ ⎣ ⎦ ⎣ ⎦⎣ ⎦

⎡⎣ m ⎤⎦ = ⎡⎣T ⎤⎦

T

[ m ] ⎡⎣T ⎤⎦

(39) [ k ] = [φ]T [ K ][φ] - modal stiffness matrix

[ c ] = [φ]T [C ][φ] - modal damping matrix

{f} qμ

= ⎡⎣T ⎤⎦

T

{f} qμ

.

[ m ] = [φ]T [ M ][φ] - modal mass matrix

(47)

{ f (t )} = [φ]T {F (t )} - modal load vector.

The first of the above expressions transforms the nodal

torques into the form

The matrices [k] and [m] are diagonal, while [c] becomes di-

agonal only in a special case, for instance if [C] = α [M] + β [K],

−T ( 0 ) = −T ( 0 ) − z D Q ( 0 ) where α and β are coefficients [14].

(40)

T (l ) = T (l ) + zDQ(l ). Solving (46) for undamped natural vibration [k] = [ω2m] is

obtained, and by its backward substitution into (46) the final

form of the modal equation yields

5 Vibration analysis

A ship’s hull is modelled by a set of beam finite elements.

{ } { }

⎡⎣ω 2 ⎤⎦ { X } + 2 [ ω ] {ζ} X + X = {ϕ(t )} (48)

Their assemblage in the global coordinate system, performed where

in the standard way, results in the matrix equation of motion,

which may be extended by the damping forces

⎡ kii ⎤

[ω ] = ⎢ ⎥ - natural frequency matrix

⎣ mii ⎦

[ K ] {Δ} + [C ] {Δ} + [ M ] {Δ} = {F (t )} , (41) (49)

⎡ cij ⎤

[ζ ] = ⎢ ⎥ - relative damping matrix

where [K], [C] and [M] are the stiffness, damping and mass ⎢⎣ 2 ( kii mii ) ⎥⎦

matrices, respectively; {∆}, {∆̇} and {∆¨ } are the displacement, ⎧ fi (t ) ⎫

velocity and acceleration vectors, respectively; and {F(t)} is the {ϕ(t )} = ⎨ ⎬ - relative load vector.

load vector. ⎩ mii ⎭

370 58(2007)4, 365-379

COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS... I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ

If {ζ} is diagonal, the matrix Eq. (48) is split into a set of

uncoupled modal equations.

The ship vibration is caused by the engine and propeller ex-

citation forces, which are of the periodical nature and therefore

may be divided into harmonics. Thus, the ship’s hull response is

obtained solving either (41) or (46). In both cases the system of

differential equations is transformed into a system of algebraic

equations.

If hull vibration is induced by waves, the time integration

of (41) or (46) can be performed. A few numerical methods are

available for this purpose, as for instance the Houbolt, the New-

mark and the Wilson θ method [15], as well as the harmonic

acceleration method [16], [17].

6 Natural vibrations of container ship

The application of developed theory is illustrated in case of

a 7800 TEU VLCS (Very Large Container Ship), Figure 4. The

main vessel particulars are the following:

Length over all Loa = 334 m

Length between perpendiculars Lpp = 319 m

Breadth B = 42.8 m

Depth H = 24.6 m

Draught T = 14.5 m

Displacement, full load ∆f = 135336 t

Displacement, ballast ∆b = 68387 t

Engine power P = 69620 kW Figure 5 Midship section

Ship speed v = 25.4 kn Slika 5 Glavno rebro

The midship section, which shows a double skin structure

with the web frames and longitudinals, is presented in Figure 5.

Rows and tiers of containers at the midship section are indi-

cated in Figure 6. Vertical positions of the neutral line, deforma-

tion (shear, torsional) centre, and the centre of gravity are also

marked in the figure. A large distance between the gravity centre

and the deformation centre causes high coupling of horizontal

and torsional vibrations.

Figure 4 7800 TEU container ship Figure 6 Container distribution at midship section

Slika 4 Kontejnerski brod nosivosti 7800 TEU Slika 6 Raspored kontejnera na glavnom rebru

58(2007)4, 365-379 371

I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS...

Figure 7 Longitudinal distribution of ship cross-section

geometrical properties

Slika 7 Uzdužna raspodjela geometrijskih značajki poprečnog

presjeka brodskog trupa

372 58(2007)4, 365-379

COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS... I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ

Figure 8 Longitudinal distribution of ship mass properties, full

load

Slika 8 Uzdužna raspodjela masenih značajki potpuno

nakrcanog broda

58(2007)4, 365-379 373

I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS...

bending moment My and shear force Qz are presented in Fig-

ures 11 and 12 respectively.

Figure 10 Natural modes of vertical vibrations

Slika 10 Prirodni oblici vertikalnih vibracija

Figure 9 Longitudinal distribution of ship mass properties,

ballast condition

Slika 9 Uzdužna raspodjela masenih značajki broda u balastu

The ship hull stiffness properties are calculated by program

STIFF [18], based on the theory of thin-walled girders [10],

[19]. Their distributions along the ship are shown in Figure 7.

Figure 11 Vertical bending moment and shear force of the first

It is evident that geometrical properties rapidly change values natural mode

in the engine and superstructure area due to closed ship cross- Slika 11 Vertikalni moment savijanja i poprečna sila prvog

section. This is especially pronounced in the case of torsional oblika vibriranja

modulus, which takes quite small values for open cross-section

and rather high for closed one, Figure 7e.

Longitudinal distributions of ship mass properties for full

load and ballast conditions are shown in Figures 8 and 9 respec-

tively. The harmonic variation of diagrams in Figure 8 is a result

of container arrangement.

Dry natural vibrations are calculated by the modified and

improved program DYANA within [4]. The ship hull is divided

into 50 beam finite elements. Finite elements of closed cross-

section (6 d.o.f.) are used in the ship bow, ship aft and in the

engine room area. Dry natural frequencies for vertical vibra-

tions, and coupled horizontal and torsional vibrations for full

load and ballast conditions are listed in Table 1. Their values for

ballast condition are higher due to the lower mass. The lowest

frequency value, which plays the main role in wave excitation,

is detected for coupled vibrations. As a result of rather low tor-

sional stiffness it belongs to primarily torsional mode.

Figure 12 Vertical bending moment and shear force of the

The first two dry natural modes, i.e. total deflection w, of second natural mode

vertical vibrations for full load are shown in Figure 10. They Slika 12 Vertikalni moment savijanja i poprečna sila drugog

are of ordinary shape. The corresponding diagrams of vertical oblika vibriranja

374 58(2007)4, 365-379

COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS... I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ

Figure 13 The first natural modes of horizontal and torsional

vibrations

Slika 13 Prvi prirodni oblici horizontalnih i torzijskih vibracija Figure 16 Torque and warping bimoment of the first natural

mode

Slika 16 Moment uvijanja i bimoment vitoperenja prvog

prirodnog oblika

Figure 14 The second natural modes of horizontal and torsional

vibrations

Slika 14 Drugi prirodni oblici horizontalnih i torzijskih vibracija

The first two natural modes of coupled horizontal and tor- Figure 17 Horizontal bending moment and shear force of the

sional vibrations for full load are shown in Figures 13 and 14 re- second natural mode

spectively. Symbol wG denotes horizontal hull deflection at the Slika 17 Horizontalni moment savijanja i poprečna sila drugog

level of gravity centre, while ψ denotes torsional angle. The cor- oblika vibriranja

responding sectional forces, i.e. horizontal bending moment Mz,

shear force Qy, torque T and warping bimoment Bw, are shown in

Figures 15, 16, 17 and 18 respectively. Torque T is determined

with respect to the shear centre of corresponding finite element.

T and Bw show some discontinuity in the area of the engine room

due to different type of the hull cross-sections.

Figure 18 Torque and warping bimoment of the second natural

mode

Slika 18 Moment uvijanja i bimoment vitoperenja drugog

prirodnog oblika

Figure 15 Horizontal bending moment and shear force of the

first natural mode Once the dry natural modes of ship hull are determined, it

Slika 15 Horizontalni moment savijanja i poprečna sila prvog is possible to transfer the beam node displacements to the ship

oblika vibriranja wetted surface for the hydrodynamic calculation. The transfor-

58(2007)4, 365-379 375

I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS...

mation (spreading) functions for vertical and coupled horizontal

and torsional vibration yield respectively [3]

d wv

hv = − ( Z − zN ) i + wv k (50)

dx

⎛ d wh dψ ⎞

h ht = ⎜ − Y+ u i + [ wh + ψ ( Z − zS )] j − ψ Y k (51)

⎝ dx d x ⎟⎠

where w is hull deflection, ψ is twist angle, u = u ( x, Y , Z )

is the cross-section warping function reduced to the wetted

surface, zN and zS coordinate of neutral line and shear centre

respectively, and Y and Z are coordinates of the point on the

ship surface. The first two dry natural modes of the ship wetted

surface in case of vertical and coupled horizontal and torsional

vibrations are shown in Figures 19, 20, 21 and 22.

Figure 22 The second natural mode of coupled horizontal and

torsional vibrations, ω2 = 4.23 rad/s

Slika 22 Drugi prirodni oblik spregnutih horizontalnih

i torzijskih vibracija, ω2 = 4,23 rad/s

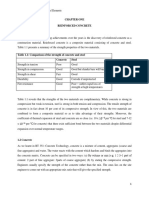

Figure 19 The first natural mode of vertical vibrations, Table 1 Dry natural frequencies, ωi [rad/s]

ω1 = 4 rad/s Tablica 1 Prirodne frekvencije za trup u zraku, ωi [rad/s]

Slika 19 Prvi prirodni oblik vertikalnih vibracija, ω1 = 4 rad/s

Full load Ballast

Mode

no. Vertical Horizontal + Vertical

Horizontal +

torsional torsional

1 4.00 2.18 5.59 3.98

2 8.41 4.23 11.60 6.79

3 13.22 7.08 17.85 11.55

Figure 20 The second natural mode of vertical vibrations, 4 18.07 9.23 25.02 14.90

ω2 = 8.41 rad/s 5 23.04 13.19 32.52 20.59

Slika 20 Drugi prirodni oblik vertikalnih vibracija, ω2 = 8,41 rad/s

6 28.09 15.37 39.21 23.03

7 32.77 18.22 46.29 27.98

8 37.22 22.65 53.25 32.64

9 41.73 23.75 60.40 36.33

10 42.27 28.38 66.96 40.38

7 Conclusion

Ultra large container ships are quite flexible and present

classification rules cannot be used for reliable structure design.

Therefore, hydroelastic analysis has to be performed. The meth-

odology of hydroelastic analysis is elaborated in [3]. One of the

basic steps is dry natural vibration analysis of ship hull. Vertical

vibration calculation is performed in a standard way, while the

coupled horizontal and torsional vibrations are rather complex

as it is evident from this article.

The theory of coupled horizontal and torsional vibrations of

ships with large deck openings is checked by analytical vibra-

Figure 21 The first natural mode of coupled horizontal and

tion solution for a prismatic pontoon [20], [21]. Furthermore, the

torsional vibrations, ω1 = 2.18 rad/s implementation of the structural model in hydroelastic analysis

Slika 21 Prvi prirodni oblik spregnutih horizontalnih i torzijskih is checked for the case of a flexible barge [3], [4], for which test

vibracija, ω1 = 2,18 rad/s results are available [22]. The influence of transverse bulkheads

376 58(2007)4, 365-379

COUPLED HORIZONTAL AND TORSIONAL VIBRATIONS... I. SENJANOVIĆ, S. TOMAŠEVIĆ, R. GRUBIŠIĆ

of container ships on hull stiffness is investigated in [23], where [7] SENJANOVIĆ, I., GRUBIŠIĆ, R.: “Coupled horizontal

an increase of torsional stiffness of 127% is determined, while and torsional vibration of a ship hull with large hatch open-

the influence on bending stiffness is almost negligible. Reper- ings”, Computers & Structures, Vol. 41, No. 2, 1991, p.

cussion on torsional natural frequencies is ca 6%. 213-226.

The reliability of the 1D FEM model and the software code [8] WU, J. S., HO, C. S.; “Analysis of wave-induced horizon-

is confirmed by 3D FEM analysis of dry vibrations for ship tal- and torsion-coupled vibrations of a ship hull”, Journal

lightweight with displacement of 33 692 t. Natural frequencies of Ship Research, Vol. 31, No. 4, 1987, p. 235-252.

of the basic modes are compared in Table 2 [5]. [9] PEDERSEN, P.T.: “Torsional response of container ships”

Journal of Ship Research, Vol. 29, 1985, p. 194-205.

Table 2 Natural frequencies of dry vibrations, ωi [rad/s] (T – tor-

sion, HB – horizontal bending) [10] SENJANOVIĆ, I., FAN, Y.: “A higher-order theory of

Tablica 2 Prirodne frekvencije za trup u zraku, ωi [rad/s] (T – uvi- thin-walled girders with application to ship structures”,

janje, HB – horizontalno savijanje) Computers & Structures, 43(1992) 1, p. 31-52.

[11] SENJANOVIĆ, I., FAN, Y.: “A higher-order flexural beam

Mode No. 1 (T) 2 (T+HB)

theory”, Computers & Structures, 32(1989) 5, p. 973-986.

1D FEM model 5.39 9.23 [12] SENJANOVIĆ, I., FAN, Y.: “A higher-order torsional

3D FEM model 5.41 9.42 beam theory”, Engineering Modelling, 10(1997) 1-4, p.

25-40.

The performed vibration analysis of the 7800 TEU contain- [13] TIMOSHENKO, S., YOUNG, D. H.: “Vibration Problems

er ship shows that the developed theory, utilising the 1D FEM in Engineering”, D. Van Nostrand, 1955.

model and the theory of thin-walled girders for determination of

[14] SENJANOVIĆ, I.: “Ship Vibration”, 2nd Part., University

hull stiffness parameters, is an efficient tool for application in

of Zagreb, Zagreb, (in Croatian), 1990.

ship hydroelastic analyses.

[15] BATHE, K.J.: “Finite Element Procedures”, Prentice Hall,

1996.

Acknowledgment [16] SENJANOVIĆ, I.: “Harmonic acceleration method for

The authors would like to express their gratitude to Ms. Es- dynamic structural analysis”, Computers & Structures,

telle Stumpf, research engineer at Bureau Veritas, Marine Divi- 18(1984) 1, p. 71-80.

sion - Research Department, for performing the 3D FEM vibra- [17] LOZINA, Ž.: “A comparison of harmonic acceleration

tion analysis of container ship and king permission to publish method with the other commonly used methods for calcu-

the valuable results. lation of dynamic transient response”, Computers & Struc-

tures, 29(1988) 2, p. 227-240.

References [18] FAN, Y., SENJANOVIĆ, I.: “STIFF User’s manual”,

FAMENA, Zagreb, 1990.

[1] MIKKELSEN, B.: “Emma Maersk - the world’s largest“, [19] SENJANOVIĆ, I., FAN, Y.: “A finite element formula-

The Scandinavian Shipping Gazette, 2006. tion of initial ship cross-section properties”, Brodogradnja

[2] BISHOP, R.E.D., PRICE, W.G.: “Hydroelasticity of 41(1993) 1, p. 27-36.

Ships”, Cambridge University Press, 1979. [20] SENJANOVIĆ, I., ĆATIPOVIĆ, I., TOMAŠEVIĆ, S.:

[3] SENJANOVIĆ, I., MALENICA, Š., TOMAŠEVIĆ, S.,

“Coupled horizontal and torsional vibrations of a flexible

RUDAN, S.: “Methodology of ship hydroelasticity inves-

barge, Engineering Structures 30(2008) 93-109.

tigation”, Brodogradnja 58 (2007)2, p.133-145..

[21] SENJANOVIĆ, I., ĆATIPOVIĆ, I., TOMAŠEVIĆ, S.:

[4] TOMAŠEVIĆ, S.: “Hydroelastic model of dynamic re-

sponse of container ships in waves”, Ph.D. Thesis, FSB, “Coupled flexural and torsional vibrations of ship-like

Zagreb, 2007. (in Croatian). girders, 45(2007) 1002-1021.

[5] MALENICA, Š., SENJANOVIĆ, I., TOMAŠEVIĆ, S., [22] REMY, F., MOLIN, B., LEDOUX, A.: “Experimental and

STUMPF, E.: “Some aspects of hydroelastic issues in the numerical study of the wave response of a flexible barge”,

design of ultra large container ships”, Proceedings of the Hydroelasticity in Marine Technology, Wuxi, China, 2006.,

22nd International Workshop on Water Waves and Floating p. 255-264.

Bodies, Plitvice, Croatia, 2007, p. 133-136. [23] SENJANOVIĆ, I., SENJANOVIĆ, T., TOMAŠEVIĆ, S.,

[6] KAWAI, T.: “The application of finite element methods RUDAN, S: “Contribution of transverse bulkheads to hull

to ship structures”, Computers & Structures, Vol. 3, 1973, stiffness of large container ships”, Brodogradnja (submit-

p. 1175-1194. ted).

58(2007)4, 365-379 377

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- CapmDocument3 pagesCapmkhabiranNo ratings yet

- Dio 22b. Sprečavanje Onečišćenja - Izmjene Jan 2021Document5 pagesDio 22b. Sprečavanje Onečišćenja - Izmjene Jan 2021Samo SpontanostNo ratings yet

- Ocean Internet-of-Things // Networked Blue Economy: C-Accel Track RecommendationDocument12 pagesOcean Internet-of-Things // Networked Blue Economy: C-Accel Track RecommendationkhabiranNo ratings yet

- DavorinDujmovic PaperDavorinDujmovicDocument10 pagesDavorinDujmovic PaperDavorinDujmovickhabiranNo ratings yet

- No. F-14-AAA-0000Document9 pagesNo. F-14-AAA-0000khabiranNo ratings yet

- Landmark Facility Solutions - QuestionsDocument1 pageLandmark Facility Solutions - QuestionsFaig0% (1)

- Quiz - Exercise - Mini-Case Instructions InstructionsDocument1 pageQuiz - Exercise - Mini-Case Instructions InstructionskhabiranNo ratings yet

- HjlinjftsaiDocument13 pagesHjlinjftsaikhabiranNo ratings yet

- Review of Charterer and Owner Relationship PDFDocument15 pagesReview of Charterer and Owner Relationship PDFShanti Prakhar AwasthiNo ratings yet

- ICS Rules & Regulations and GuidanceDocument2 pagesICS Rules & Regulations and GuidancekhabiranNo ratings yet

- Customer Value Chain Analysis For Sustainable Reverse Logistics Implementation: Indonesian Mobile Phone IndustryDocument4 pagesCustomer Value Chain Analysis For Sustainable Reverse Logistics Implementation: Indonesian Mobile Phone IndustrykhabiranNo ratings yet

- United Nations Industrial Development Organization: Single Workstation - Comfar Iii ExpertDocument1 pageUnited Nations Industrial Development Organization: Single Workstation - Comfar Iii ExpertkhabiranNo ratings yet

- Customer Value Chain Analysis For Sustainable Reverse Logistics Implementation: Indonesian Mobile Phone IndustryDocument4 pagesCustomer Value Chain Analysis For Sustainable Reverse Logistics Implementation: Indonesian Mobile Phone IndustrykhabiranNo ratings yet

- Overview of Health, Safety and Environmental Regulation Relating To The Offshore Oil and Gas IndustryDocument16 pagesOverview of Health, Safety and Environmental Regulation Relating To The Offshore Oil and Gas IndustrykhabiranNo ratings yet

- Shell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.EngDocument8 pagesShell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.Engkhabiran100% (1)

- 20120710ATT48612EN OriginalDocument16 pages20120710ATT48612EN OriginalkhabiranNo ratings yet

- Project Management & Engineering Services To The Submarine Power Cable MarketDocument2 pagesProject Management & Engineering Services To The Submarine Power Cable MarketkhabiranNo ratings yet

- Numerical Simulation of Fluid Added Mass Effect On A Kaplan Turbine Runner With Experimental ValidationDocument9 pagesNumerical Simulation of Fluid Added Mass Effect On A Kaplan Turbine Runner With Experimental ValidationkhabiranNo ratings yet

- DNV GL Adv DP Verfication BC 3 2017Document1 pageDNV GL Adv DP Verfication BC 3 2017khabiranNo ratings yet

- Marine Safety Management Plan: Kendall Bay Sediment Remediation ProjectDocument37 pagesMarine Safety Management Plan: Kendall Bay Sediment Remediation Projectkhabiran100% (1)

- A Brief Review On Ndt&E Methods For Structural Aircraft ComponentsDocument9 pagesA Brief Review On Ndt&E Methods For Structural Aircraft ComponentskhabiranNo ratings yet

- Shell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.EngDocument8 pagesShell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.Engkhabiran100% (1)

- A Brief Review On Ndt&E Methods For Structural Aircraft ComponentsDocument9 pagesA Brief Review On Ndt&E Methods For Structural Aircraft ComponentskhabiranNo ratings yet

- Nonlinear Analysis of Offshore Structures: Bjo RN Skallerud Jo Rgen AmdahlDocument1 pageNonlinear Analysis of Offshore Structures: Bjo RN Skallerud Jo Rgen AmdahlkhabiranNo ratings yet

- On Design, Modelling, and Analysis of A 10-MW Medium-Speed Drivetrain For Offshore Wind TurbinesDocument1 pageOn Design, Modelling, and Analysis of A 10-MW Medium-Speed Drivetrain For Offshore Wind TurbineskhabiranNo ratings yet

- Smallseotools 1617464053Document1 pageSmallseotools 1617464053khabiranNo ratings yet

- Service Note: ABB Solar Inverter Life Cycle ManagementDocument2 pagesService Note: ABB Solar Inverter Life Cycle ManagementkhabiranNo ratings yet

- Orcaflex Standard Training Course Syllabus: Line TypesDocument3 pagesOrcaflex Standard Training Course Syllabus: Line TypeskhabiranNo ratings yet

- Innovatum Tone GeneratorDocument8 pagesInnovatum Tone GeneratorGleison PrateadoNo ratings yet

- Average Fuel ConsumptionDocument1 pageAverage Fuel ConsumptionkhabiranNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Holeyman-Whenham2017 - Article - CriticalReviewOfTheHypervib1MoDocument19 pagesHoleyman-Whenham2017 - Article - CriticalReviewOfTheHypervib1MoJúlia Hein MazuttiNo ratings yet

- BS 5950-2000 Example 002Document5 pagesBS 5950-2000 Example 002Anitha Hassan KabeerNo ratings yet

- FMD GTU Study Material E-Notes Unit-4 06042020015456PMDocument5 pagesFMD GTU Study Material E-Notes Unit-4 06042020015456PMRaj PrajapatiNo ratings yet

- 6 Design of Constant Dia RCC Chimney and Foundation 23052014 PDFDocument16 pages6 Design of Constant Dia RCC Chimney and Foundation 23052014 PDFbhargavramudu 2019No ratings yet

- Lecture6 (CRACKED MOMENT OF INTERTIA)Document38 pagesLecture6 (CRACKED MOMENT OF INTERTIA)RajKumarNo ratings yet

- Introduction To R C Design..Document70 pagesIntroduction To R C Design..Eman EssamNo ratings yet

- Indeterminate StructureDocument82 pagesIndeterminate Structuresenthil.m3457100% (1)

- Reinforced Concrete Design by Professor Anthony Kwame DansoDocument131 pagesReinforced Concrete Design by Professor Anthony Kwame DansoBadu Evans NyiayeNo ratings yet

- One Way Simply-Supported and Continuous Solid SlabDocument39 pagesOne Way Simply-Supported and Continuous Solid Slabdixn__100% (13)

- Pipe Riser Support Systems: Mason Industries, IncDocument4 pagesPipe Riser Support Systems: Mason Industries, Incconstantin.iacomi3837No ratings yet

- Seismic Performance of Timber StructuresDocument3 pagesSeismic Performance of Timber StructuresAllan MarbaniangNo ratings yet

- 8b. Hibbeler - 8th - Double Integration TheoryDocument9 pages8b. Hibbeler - 8th - Double Integration TheoryMuhammad KaisarNo ratings yet

- Holding Down ArrangementsDocument3 pagesHolding Down ArrangementsJitendra KumarNo ratings yet

- 1.1 DefinitionsDocument75 pages1.1 Definitionsbalusharma1212No ratings yet

- Spread Footing DesignDocument9 pagesSpread Footing DesignLeonardo PimentelNo ratings yet

- S10 Rudders, Sole Pieces and Rudder Horns S10Document41 pagesS10 Rudders, Sole Pieces and Rudder Horns S10Giannis PanagiotopoulosNo ratings yet

- Design of Compliant TowerDocument50 pagesDesign of Compliant TowerEvi Susanti50% (2)

- Structural Soln Nov 2018 PDFDocument19 pagesStructural Soln Nov 2018 PDFrey martiNo ratings yet

- Automatic Pneumatic Braking With Dual Mode Operating System Using SensorsDocument34 pagesAutomatic Pneumatic Braking With Dual Mode Operating System Using SensorsRKPNo ratings yet

- Vertical Lift Hydraulic Gate DesignDocument40 pagesVertical Lift Hydraulic Gate Designmesam100% (3)

- 01 - Chapter 1Document37 pages01 - Chapter 1Eko Idris Hutagaol100% (1)

- Mackenzie PVP2017 Stress Linearization Concepts and Restrictions in Elastic Design by AnalysisDocument8 pagesMackenzie PVP2017 Stress Linearization Concepts and Restrictions in Elastic Design by Analysissvk_ntNo ratings yet

- Design of Sandwich StructuresDocument114 pagesDesign of Sandwich StructuresSuhas100% (1)

- Question Bank: Prist UniversityDocument12 pagesQuestion Bank: Prist Universityphillipe baillyNo ratings yet

- Design of Reinforced Concrete Floor Systems: Professional Development SeriesDocument7 pagesDesign of Reinforced Concrete Floor Systems: Professional Development SeriesJCS100% (1)

- Steps in Designing A Rectangular BeamDocument8 pagesSteps in Designing A Rectangular BeamIvan GonzalesNo ratings yet

- Nastran Verification Manual-5Document1 pageNastran Verification Manual-5DanNo ratings yet

- Sona College of Technology, Salem 636 005 (Autonomous)Document8 pagesSona College of Technology, Salem 636 005 (Autonomous)savithaNo ratings yet

- Design of Beams - PPT SONAMDocument111 pagesDesign of Beams - PPT SONAMLovely Mae Cruza GawinganNo ratings yet

- Gate Indiabix PDFDocument122 pagesGate Indiabix PDFRalph RebugioNo ratings yet