Professional Documents

Culture Documents

Use of Glass Powder As Fine Aggregate in High Strength Concrete

Uploaded by

Saqib ShaikhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Use of Glass Powder As Fine Aggregate in High Strength Concrete

Uploaded by

Saqib ShaikhCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/313471215

Use Of Glass Powder As Fine Aggregate In High Strength Concrete

Article · August 2014

CITATION READS

1 1,145

1 author:

Suganya Suganya

Sri Ramakrishna Institute of Technology

5 PUBLICATIONS 1 CITATION

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Experimental Investigation On Partial Replacement Of Cement With Artificial Pozzolanas Using Pva Binder View project

Application of Robotics in Construction Industry View project

All content following this page was uploaded by Suganya Suganya on 08 February 2017.

The user has requested enhancement of the downloaded file.

International Journal of Science and Engineering Research (IJ0SER),

Vol 2 Issue 7 july-2014

Use Of Glass Powder As Fine Aggregate In High

Strength Concrete

Jostin.P.jose*1 , S.suganya*2, Banu Priya#3

*1

lecturer/civil department “R.V.S Technical Campus”, Coimbatore, Tamilnadu, India.

*2&3

M.E Construction management and engineering “R.V.S Technical Campus ”Coimbatore, Tamilnadu,India.

Abstract— Glass powder (GP) used in concrete making leads to greener environment. In shops, damaged glass sheets & sheet glass

cuttings are go to waste, which are not recycled at present and usually delivered to landfills for disposal. Using GP in concrete is an

interesting possibility for economy on waste disposal sites and conservation of environment. This project examines the possibility of

using GP as fine aggregate replacement in concrete. Natural sand was partially replaced (0%-30%) with GP in concrete. Tensile

strength, Compressive strength (cubes and cylinders) and Flexural strength up to 28 days of age were compared with those of high

performance concrete made with natural sand.

Keywords—Glass powder, Natural sand Tensile strength, Compressive strength

I. INTRODUCTION increasing application of this industrial waste, the level of

Concrete is a widely used material in the world. Based on utilization of glass powder in the industrialized nations has

global usage it is placed at second position after water. River been reached more than 60% of its total production. The use

sand is one of the constituents used in the production of of manufactured sand in India has not been much popular,

conventional concrete has become highly expensive and also when compared to some advanced countries.

scare. In the backdrop of such a bleak atmosphere, there is a

large demand for alternative materials from industrial waste.

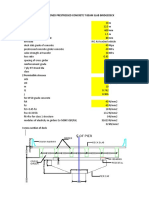

II. METHODOLOGY OF THE STUDY

Some alternative materials have already been used as a part of

natural sand. For example fly ash, slag, red mud, ponded ashes .

Collection of materials,

were used in concrete mixtures as a partial replacement of

Studyofphysicalpropertiesofmaterials,

natural sand.

mix design

Similarly the waste glass are collected from the shops

are used. The collected glasses are crushed to sand size and it

could be used an alternate material for natural sand as partial

Casting of specimens

replacement. In brief, successful utilization of glass as fine

Curing of specimens

aggregate will turn this waste material into a valuable resource.

Test on concrete

Hardened concrete

1. Compressive strength

2. Split tensile strength

3. Flexural strength

A. OBJECTIVE

Analysis and Discussion of Test Result

To evaluate the utility of glass powder as a partial

replacement of cement in concrete.

To study and compare the performance conventional Conclusion

concrete and glass powder concrete. Scope for future study

To understand the effectiveness of glass powder in

strength enhancement.

The utilization of glass powder which can be called as

manufactured sand has been accepted as a building material in A. MATERIAL TEST

the industrially advanced countries. As a result of sustained TABLE

research and developmental works undertaken with respect to PHYSICAL PROPERTIES OF THE MATERIALS

Jostin,.. . . (IJ0SER) July- 2014

International Journal of Science and Engineering Research (IJ0SER),

Vol 2 Issue 7 july-2014

In this thesis work M50 grade is being used. The design

Property Glass Natural procedure is detailed below. (Based on IS: 10262 – 1982)

powder sand

Specific gravity 2.4-2.8 2.60

Bulk density 2.53 1.46 Water Cement Fine aggregate Coarse aggregate

Moisture content (%) Nil 1.50 139.5 398.5 kg/m3 648 kg/m3 1267.25 kg/m3

Fine particles less than 12-15 0- 6 kg/m3

0.075mm (%) 0.35 1 1.626 3.10

Sieve analysis Zone Zone

The concrete samples are caste with mix 1: 1.626: 3.10 as per

design, with partial replacement of fine aggregate. The

numbers of concrete samples caste are laid down as per IS

code. The tests are carried out after 7 & 28 days of casting of

S.No Material concrete,

Property details

Grade 43-OPC a) Compressive strength (cube specimen)

Consistency 34% b) Tensile strength (cylinder specimen)

1. Cement

Specific gravity 3.15 c) Flexural strength or Modulus of rupture (beam

Fineness 2% specimen)

Modulus

Grading Zone Zone II

Natural

A. SAMPLES WITH GLASS POWDER

2. Specific gravity 2.70

sand

Fineness 2.43% Crushing of glass pieces is done by crusher. Glass

Modulus

Specific gravity 2.66

3.

Glass material is sieved in 2.36mm sieve. Then it is used by

powder Fineness 3.36% replacing fine aggregate in different percentages. Glass

Modulus

Specific gravity 2.60 powder is taken in, 10% weight of fine aggregate and 20%

Coarse

4. weight of fine aggregate and 30%weight of fine aggregate.

Aggregate Fineness 7.14%

Modulus

5. Water Type Potable

B. CURING

TABLE

PHYSICAL PROPERTIES OF GLASS POWDER AND NATURAL SAND

In all but the least critical applications, care needs to be

Constituent Glass powder Natural taken to properly cure concrete, to achieve best strength and

(%) sand (%) hardness. This happens after the concrete has been placed.

Silica (SiO2) 72.5 80.78 Cement requires a moist, controlled environment to gain

Alumina (Al2O3) 01.06 10.52 strength and harden fully. The cement paste hardens over time,

Iron Oxide (Fe2O3) 0.36 01.75 initially setting and becoming rigid though very weak and

Lime (CaO) 08 03.21 gaining in strength in the weeks following.

Magnesia (MgO) 4.18 00.77

Sodium Oxide (Na2O) 13.1 01.37

Potassium Oxide (K2O) 0.26 01.23

Sulphur Trioxide (SO3) 0.18 -

Fig. Curing Tank with Specimen

III. EXPERIMENTAL INVESTIGATION TABLE

The most common of all tests on hardened concrete is the

compressive strength test. This is partly because it is easy to DETAILS OF SPECIMEN FOR 7 & 28 DAYS (CUBE SIZE MM:

make, and partly because many through not all, of the 150X150X150),CYLINDERS SPECIMEN SIZE MM (300X150Ф), PCC

desirable characteristics of concrete are qualitatively related to PRISM SIZE MM (1000X150X150), REINFORCED BEAM SPECIMEN SIZE

MM (1200X150X150).

its strength, but mainly because of the intrinsic importance of

the compressive strength of concrete in construction.

Jostin,.. . . (IJ0SER) July- 2014

International Journal of Science and Engineering Research (IJ0SER),

Vol 2 Issue 7 july-2014

Specimen Properties Type & No. of

Tested Test Replacement specimens

Conventional

3

7 & 28 days 10%

Cube compressive

strength 20% 3

30% 3

Cylinder Conventional Fig Casted Reinforced Beams

3

28 days split 10% 3 IV. RESULT AND DISCUSSION

tensile

strength 20%

3 A. COMPRESSIVE STRENGTH TEST

30% 3 The compressive strength of a material is that value of

PCC 28 days Conventional uniaxial compressive stress reached when the material fails

Prism flexural 1 completely. The compressive strength is usually obtained

strength experimentally by means of a compressive test. The apparatus

28 days 10% 1 used for this experiment is the same as that used in a tensile

compressive test. However, rather than applying a uniaxial tensile load, a

strength 20% 1 uniaxial compressive load is applied. As can be imagined, the

30% 1 specimen (usually cylindrical) is shortened as well as

Beam 28 days Conventional spread laterally. A Stress–strain curve is plotted by the

flexural 1 instrument and would look similar to the following:

strength

28 days 10% 1

compressive

strength 20% 1

30% 1

Compressive strength of concrete is usually found by testing

Cubes and cylinders. Cube of size 150 mm X 150mm X

150mm concrete specimens were casting using M50 grade

concrete. Specimens with Nominal concrete and glass powder

concrete (glass powder is partially replaced with Natural sand)

were casted. During casting the cubes were manually

compacted using tamping rods. After 24 hours, the specimens

Fig. Casted Cubes

were removed from the mould and subjected to water curing

for 28 days. After curing, the specimens were tested for

compressive strength using a compression testing machine

.

Fig. Casted Cylinders Fig.. Crack occurred in Cube

Jostin,.. . . (IJ0SER) July- 2014

International Journal of Science and Engineering Research (IJ0SER),

Vol 2 Issue 7 july-2014

When comparing with conventional concrete the glass powder

concrete of shows an increased strength of 9.45% in 10%

replacement.

TABLE

COMPRESSIVE TEST ON CUBES

S.No Type Of COMPRESSIVE

Specimen STRENGTH

Load in KN Strength in

N/mm2 Fig. Crack occurred in the Cylinder

Mean after Mean after

TABLE

3-trials 3-trials

TENSION TEST ON CYLINDERS

1 Conventional 1176.6 52.29

2 10% glass 1288.3 57.25 S.No Type Of Compressive strength

powder Specimen

3 20% glass 1231.6 54.73 Load in kN Strength in N/mm2

powder Mean after Mean after 3-trails

4 30% glass 1250 55.55 3-trails

powder

1 Conventional 222.66 3.14

2 10% glass 274.33 3.88

powder

3 20% glass 228.33 3.31

powder

4 30% glass 248.33 3.51

powder

Fig Compressive strength

C. SPLIT TENSILE STRENGTH TEST

Fig. Split Tensile Strength

C. FLEXURAL STRENGTH OF PCC BEAMS

Split tensile strength of concrete is usually found by Flexural strength is the one of the measure of tensile strength

testing plain concrete cylinders. Cylinders of size 100mm x of concrete. It is the ability of a beam to resist failure in

200 mm were casting using M50 grade concrete. Specimens bending. It is measured by loading un-reinforced

with Nominal concrete and glass powder concrete (glass 150mmX150mm concrete beams with a span 1200mm. Beam

powder is partially replaced with Natural sand) were casted. of size 150mm x 150mm x 1200 mm were casting using M50

grade concrete. Specimens with Nominal concrete and glass

During moulding, the cylinders were manually powder concrete (glass powder is partially replaced with

compacted using tamping rods. After 24 hours, the specimens Natural sand) were casted. During moulding, the beams were

were removed from the mould and subjected to water curing manually compacted using tamping rods. After 24 hours, the

for 28 days. After curing, the specimens were tested for specimens were removed from the mould and subjected to

compressive strength using a calibrated compression testing water curing for 28days. After curing, the specimens were

machine. tested for compressive strength on a standard reinforced

Jostin,.. . . (IJ0SER) July- 2014

International Journal of Science and Engineering Research (IJ0SER),

Vol 2 Issue 7 july-2014

concrete. The bed of testing machine should be supported, and Load in kN Deflection in Stiffness in

these rollers should be mounded that the distance from center mm kN/mm

is 300mm for 1200mm specimen. The beam is simply 12 0.5 24

supported and subjected to one third points loading flexure 18 1 18

failure. The maximum tensile stress reached in the modulus of 31 1.5 20.67

rupture values for concrete using sand and glass powder. 42 2 21

52 2.5 20.8

63 3 21

75 3.5 21.43

82 4 20.5

88 4.5 19.56

92 5 18.8

95 5.5 17.27

Fig. Cracks Occurred In Beam Specimen 96 6 15.83

97 6.5 14.94

While performing bending test on the glass powder concrete

shows an increased strength of 71.4% in 10% replacement.

S.No Type Of Flexural

Specimen Load

in kN Strength in

4.34 N/mm2

1 Conventional 16.30

10% glass

7.46

2 powder 28

20% glass

5.68

3 powder 21.30

30% glass Fig. Load Vs Deflection Curve for Conventional Beam

5.33

4 powder 20

E. 10% REPLACEMENT BEAM

TABLE

LOAD VS DEFLECTION CURVE FOR 10% REPLACEMENT BEAM

LOAD IN KN DEFLECTION IN STIFFNESS IN

MM KN/MM

10 0.5 20

20 1 20

33 1.5 22

44 2 22

50 2.5 20

60 3 20

64 3.5 18.29

Fig Flexural Strength of PCC Beam 70 4 17.5

75 4.5 16.89

D. LOAD Vs DEFLECTION CURVE OF REINFORCED

CONCRETE BEAM OF 28 DAYS 78 5 15.6

CONVENTIONAL BEAM 84 5.5 14.91

TABLE 87 6 14.7

92 6.5 14.5

LOAD VS DEFLECTION CURVE FOR CONVENTIONAL BEAM

Jostin,.. . . (IJ0SER) July- 2014

International Journal of Science and Engineering Research (IJ0SER),

Vol 2 Issue 7 july-2014

G. 30% REPLACEMENT BEAM TABLE

96 7 14.15

LOAD Vs DEFLECTION CURVE FOR 30% REPLACEMENT

98 7.5 14.14

BEAM

102 8 13.6 LOAD IN DEFLECTION IN MM STIFFNESS IN KN/MM

KN

15 0.5 13.26

24 1 24

35 1.5 23.33

48 2 24

60 2.5 24

71 3 23.66

80 3.5 22.85

87 4 21.75

92 4.5 20.44

Fig Load Vs Deflection Curve for 10% Replacement Beam

96 5 19.6

F. 20% REPLACEMENT BEAM 97 5.5 18

TABLE

98 6 16.5

.LOAD VS DEFLECTION CURVE FOR 20% REPLACEMENT BEAM

LOAD IN KN DEFLECTION IN STIFFNESS IN KN/MM

MM

12 0.5 24

23 1 23

33 1.5 22

44 2 22

53 2.5 21.2

64 3 21.33 Fig. Load Vs Deflection Curve for 30% Replacement Beam

75 3.5 21.43

V. DISCUSSION

83 4 21

Based on the results of the materials properties and the

90 4.5 20

experimental investigation on concrete made with glass

93 5 18.6 powder, the reason for the variation observed is summarized

as follows.

95 5.5 17.28

A. Summary of material properties

97 6 16

99 6.5 14.92 1. Fineness modulus of sand is more than that of glass

powder. This means glass powder is finer than sand.

2. Grading curve of both sand and glass powder is

uniform and sand falls within the limits of zone II

3. Sand particles rounded and globular where as glass

powder particles are angular, flaky and irregular in

shape.

4. The reasons with the fact that glass powder is finer

than sand.

B. Summary of experimental investigation on concrete

Jostin,.. . . (IJ0SER) July- 2014

International Journal of Science and Engineering Research (IJ0SER),

Vol 2 Issue 7 july-2014

[1] Reni Mullukattil Lukose / International Journal of Research in Modern

1. The compressive strength of concrete with glass Engineering and Emerging Technology Vol. 1, Issue: 6, July: 2013

(IJRMEET) ISSN: 2320-6586

powder is more than the conventional concrete. [2] Use Of Waste Glass As Powder And Aggregate Incement-Based

The increase in compressive strength is the Materials Sbeidco – 1st International Conference On Sustainable Built

interlocking properties of particles in the glass Environment Infrastructures in Developing Countries ENSET Oran

(Algeria) - October 12-14, 2009

powder.

[3] Glass fibre reinforced concrete use in construction ©gopalax -

2. Split tensile strength of concrete increases for international journal of technology and engineering system(ijtes):jan –

glass powder. The reason for variation is the march 2011- vol.2.no.2.

shape and texture of glass powder. [4] Development of Concrete Containing Waste Glass

[5] G. D. Perkins, Civil Engineering Research Unit, Division of Civil &

3. Flexural strength (modulus of rupture) of

Mechanical Engineering, Faculty of Advanced Technology, University

concrete increases for glass powder. The reasons of Glamorgan, Pontypridd, CF37 1DL

for variation are the shape and texture of the [6] The Open Civil Engineering Journal, 2010, 4, 65-71 65 1874-1495/10

glass powder. 2010 Bentham Open.The Use of Sheet Glass Powder as Fine

Aggregate Replacement in Concrete M. Mageswari1,* and Dr.

B.Vidivelli2

[7] GLOBAL CEMENT to 2020, report on world production and

consumption of cement by International cement review.(Dec. 2007),

VI. CONCLUSIONS 201-203.

[8] Hawkins, G. J., Bhatty, J. I and O ‟ Hare, A. T., Cement kiln dust

The development of concrete with glass powder as production, management and disposal, Portland Cement Association,

PCA, R&D No. 2737, 2003.

fine aggregate has been successfully completed and the results [9] P. C. PARIS and G. C. SIH, ASTM STP 381 (American Society for

were presented and analyzed in the previous chapters. Based Testing and Materials, Philadelphia, 1965)p. 30.

on the test results of M50 concrete the following conclusions

are drawn: BIOGRAPHIES

A. General Conclusions He is now working as an assistant

professor of civil Engg. Dept., R.V.S

1) It is possible to replace glass powder by scarce sand Technical Campus. He finished his

for concrete. B.E.(CIVIL) in Periyar Maniammai

2) The glass powder concrete is less workable, strong University and doing his M.E (structural

and durable compared to sand concrete engg.) in karpagam university,

Coimbatore.

B. Specific conclusions

1) The increase of 9 % in the 28 day cube compressive

strength of glass powder concrete when compared to

Conventional concrete. She is percusing M.E construction

2) Increase cylinder tensile strength there is an increase engineering and management. in R.V.S

of about 23% in 28 days of glass powder concrete Technical Campus. She completed her

when compared to conventional concrete. B.E.(civil) in avinashilingam university

3) There is an increase of 74 % in the 28 day flexural for women,Coimbatore

strength of glass powder concrete when compared to

conventional concrete

She is percusing M.E construction

REFERENCES

engineering and management. in R.V.S

Technical Campus., Coimbatore. She

A. Books And Is-Codes completed her B.E.(civil) in PSR college

of engineering and rechnology at

[1] M. S. Shetty, Concrete Technology Theory & Practice, Published by S. sivakasi .

CHAND & Company, Ram Nagar, New Delh

[2] M. L. Gambhir, Concrete Technology (3rd Edition), Published by The

McGraw-Hill Companies, New Delhi

[3] IS 10262- 2007 Recommended Guidelines for Concrete Mix Design

[4] IS 456- 2000 Plain and Reinforced Concrete - Code of Practice

[5] IS 516- 1959 Methods of Tests for Strength of Concrete

[6] IS 5816- 1999 Splitting Tensile Strength of Concrete -Method of Test

Jostin,.. . . (IJ0SER) July- 2014

View publication stats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- STRUCTURAL PEER REVIEW GUIDEDocument3 pagesSTRUCTURAL PEER REVIEW GUIDEaltarzakov100% (2)

- CT Testing Kit Tettex t2767-FcDocument8 pagesCT Testing Kit Tettex t2767-Fcdhanasekaran19731945No ratings yet

- Mechanical Design and Stress Analysis of a Distillation ColumnDocument7 pagesMechanical Design and Stress Analysis of a Distillation ColumnSumant Pilgaonkar100% (1)

- 12 Samss 005 PDFDocument6 pages12 Samss 005 PDFfetihNo ratings yet

- Side RibbonDocument1 pageSide RibbonSaqib ShaikhNo ratings yet

- Torrent Downloaded From RARBGDocument1 pageTorrent Downloaded From RARBGSaqib ShaikhNo ratings yet

- Kingthings LicenseDocument1 pageKingthings LicenseRey CanelaNo ratings yet

- Order 2 (Saq)Document10 pagesOrder 2 (Saq)Saqib ShaikhNo ratings yet

- Shayad by Jaun Elia-Zemtime - Com DjvuDocument115 pagesShayad by Jaun Elia-Zemtime - Com DjvuSaqib ShaikhNo ratings yet

- Sneha LataDocument6 pagesSneha LataSaqib ShaikhNo ratings yet

- Order 3.0 (Saq)Document8 pagesOrder 3.0 (Saq)Saqib ShaikhNo ratings yet

- Hello EveryoneDocument2 pagesHello EveryoneSaqib ShaikhNo ratings yet

- Notice CHSL 03122019 PDFDocument56 pagesNotice CHSL 03122019 PDFRajeev KumarNo ratings yet

- PDF To WordDocument1 pagePDF To WordSaqib ShaikhNo ratings yet

- Hall Ticketib PDFDocument1 pageHall Ticketib PDFSaqib ShaikhNo ratings yet

- Hall Ticketib PDFDocument1 pageHall Ticketib PDFSaqib ShaikhNo ratings yet

- Sneha Front SynopsisDocument1 pageSneha Front SynopsisSaqib ShaikhNo ratings yet

- MarutiDocument89 pagesMarutiNagnath B Halgonde0% (2)

- A Project Report NeelamDocument56 pagesA Project Report NeelamSaqib ShaikhNo ratings yet

- Annual Report 2017 18Document160 pagesAnnual Report 2017 18Saqib ShaikhNo ratings yet

- Performance Management SystemDocument101 pagesPerformance Management Systemmona88_scribd75% (4)

- Project On Honda Two WheelersDocument46 pagesProject On Honda Two WheelersC SHIVASANKARNo ratings yet

- PDF To WordDocument121 pagesPDF To WordSaqib ShaikhNo ratings yet

- A Project Report On: A Study of Employee SatisfactionDocument65 pagesA Project Report On: A Study of Employee SatisfactionSaqib ShaikhNo ratings yet

- A Project Report On: A Study of Employee SatisfactionDocument65 pagesA Project Report On: A Study of Employee SatisfactionSaqib ShaikhNo ratings yet

- A Project Report NeelamDocument56 pagesA Project Report NeelamSaqib ShaikhNo ratings yet

- Detailed Advertisement For The Recruitment of 312 Administrative Officers (Generalists and Specialists) (Scale I) 2018Document26 pagesDetailed Advertisement For The Recruitment of 312 Administrative Officers (Generalists and Specialists) (Scale I) 2018msadithianNo ratings yet

- A Project Report On: A Study of Employee SatisfactionDocument65 pagesA Project Report On: A Study of Employee SatisfactionSaqib ShaikhNo ratings yet

- A Study of Effectiveness of Performance Management System (PMS) at Maruti Suzuki India LimitedDocument8 pagesA Study of Effectiveness of Performance Management System (PMS) at Maruti Suzuki India LimitedSaqib ShaikhNo ratings yet

- Synopsis Maruti CarsDocument12 pagesSynopsis Maruti CarsSaqib ShaikhNo ratings yet

- Mass XL Nutrition Plan by Guru MannDocument5 pagesMass XL Nutrition Plan by Guru MannSaqib Shaikh100% (1)

- Build Muscle and Gain Strength with this 10-Week Workout PlanDocument4 pagesBuild Muscle and Gain Strength with this 10-Week Workout PlanSaqib Shaikh50% (2)

- Fastrack Objective MathematicsDocument1,727 pagesFastrack Objective MathematicsDiptabrataSaha80% (10)

- 02 Samss 005Document15 pages02 Samss 005Cherukunnon JubuNo ratings yet

- Final TT-End Sem - Spring Sem2022-23 - 13.04.2023Document4 pagesFinal TT-End Sem - Spring Sem2022-23 - 13.04.2023Ritwik NandiNo ratings yet

- S.No Item No. Description of Item Unit Rate (RS.) Quantity Amount (RS.) Reference For Rate Schedule A - Excavation, Tunnel 1Document29 pagesS.No Item No. Description of Item Unit Rate (RS.) Quantity Amount (RS.) Reference For Rate Schedule A - Excavation, Tunnel 1George K GeorgeNo ratings yet

- Resume - Mark Edison D Fellone - 2014Document2 pagesResume - Mark Edison D Fellone - 2014api-262936729No ratings yet

- ESR 2539 ChemofastDocument15 pagesESR 2539 ChemofastEduardo Antonio Duran SepulvedaNo ratings yet

- TS00E v1.2 Student Noteset PDFDocument303 pagesTS00E v1.2 Student Noteset PDFpatrick morris100% (1)

- Simplify drive solutions up to 2,400 kWDocument12 pagesSimplify drive solutions up to 2,400 kWcatalinccNo ratings yet

- Railway Over Bridge Training ReportDocument50 pagesRailway Over Bridge Training ReportMitulChopra100% (1)

- Advanced Module in Mechatronics IntroDocument12 pagesAdvanced Module in Mechatronics Introbalaji3108No ratings yet

- CE 123 Construction and Management NotesDocument3 pagesCE 123 Construction and Management NotesCherie Lynne GomintongNo ratings yet

- Software 4 Model Answer Papers From 2019 To 2022Document27 pagesSoftware 4 Model Answer Papers From 2019 To 2022tapstaps902No ratings yet

- Concrete Production ProcessDocument34 pagesConcrete Production ProcessHan Kyung SoonNo ratings yet

- Uav Design - Part IiDocument1 pageUav Design - Part IiPradeep KumarNo ratings yet

- Panel LG Display Lc320eun-Sem2 0Document36 pagesPanel LG Display Lc320eun-Sem2 0Carlos ChNo ratings yet

- Seismic Performance Assessment Methodology Volume 1Document340 pagesSeismic Performance Assessment Methodology Volume 1JuanAlfaroRodríguezNo ratings yet

- LG DT Multif FDXDocument769 pagesLG DT Multif FDXmikintosNo ratings yet

- Impact TestDocument4 pagesImpact TestZoHaib JaWedNo ratings yet

- New EM Graduate ProgramDocument18 pagesNew EM Graduate ProgramabofahadNo ratings yet

- LarruDocument118 pagesLarruRafael VerdeliNo ratings yet

- Presentation For MTR VisitDocument12 pagesPresentation For MTR VisitA. K. mauryaNo ratings yet

- PT I Girder Design 20mDocument18 pagesPT I Girder Design 20msamirbendre1No ratings yet

- WideFlange All PDFDocument19 pagesWideFlange All PDFDede HerdiantoNo ratings yet

- PVC Pipes & Fittings: Sanitary Fittings CatalogDocument3 pagesPVC Pipes & Fittings: Sanitary Fittings CatalogDesiree jayne NoriegaNo ratings yet

- Computer EngineeringDocument14 pagesComputer EngineeringJeff GicharuNo ratings yet

- ProblemSheet - Unit 1Document1 pageProblemSheet - Unit 1Vishal VaziraniNo ratings yet

- Master Aubs enDocument1,045 pagesMaster Aubs enZar MaghustNo ratings yet