Professional Documents

Culture Documents

Buku Istighfar

Uploaded by

Afif MudzakkirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buku Istighfar

Uploaded by

Afif MudzakkirCopyright:

Available Formats

JOB SAFETY ANALYSIS DATE: NEW JSA

JOB TITLE Confined Space Entry JSA NO. ANALYSIS BY:

TITLE OF PERSON OVERSEEING TASK: REVIEWED BY: Gene Jones

JOB # : DEPT.: y APPROVED

g BY: Gene Jones -1/12/2016

PROTECTIVE EQUIPMENT: Respiratory protection as needed. SUPERVISOR:

STEP NO. SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE

Review and make sure only trained personal are entering/attending the entry.

Select all necessary tools, fall protection, Untrained/Unfamiliar entrants/attendants with

Rescue and retrieval equipment are at location and in good working order. All

rescue notification, equipment and materials. procedure/processes. Entrapment/affrication,

1 air monitoring equipment is calibrated and working properly for the type of

Preform tailgate pre-entry meeting with entry injury/loss of conscience, dangerous/toxic or

entry being preformed. All respirator, supplied air and escape air is operating

supervisor, entrants and attendants explosive atmosphere.

properly, and fit check made.

Access work area. Set up tripod, rescue

equipment, and communication with Use proper ladder safety (3 points of contact,), harness properly worn, SRL or

Slip, Trip and fall hazards. Dropped objects,

2 supervisor, entrants, attendants and rescue lanyard is correct for application. Hoist all tools and material by means of

improper confined space equipment set up .

team, have correct tools and material staged bucket and rope. Do not carry tools or material up ladders by hand

and ready to use/work.

Assure air monitor devices are calibrated and current, all personal monitors

Low/high oxygen content can lead to affrication.

are functioning properly. Attendant and entry supervisor take air sample

LEL can lead to explosion or fire hazard.

Complete Confined Entry Permit, and Air reading starting at the bottom, middle and top of the space and record results

Presence of toxic atmosphere. Presence of

monitor checks, LO/TO procedures (if onto CSP. Review results with entry crew. Ventilated the space as required

3 hazardous or toxic substances or materials,

applicable) Illumination is low voltage and per standard/procedure until reading are within LEL and oxy limits for entry.

product or other material introduced into the

explosion proof. Fire extinguisher on hand., and all sources of ignition are removed fro the

space from other point not the entry way. fire

space. proper lighting is supplied and all sources or material or energy sources

from welding, cutting, grinding burning.

have been LO/TO.

Slip/fall hazard to elevated work area. Dropped

Utilize 3 points of contact when ascending/ descending ladder. Use 100% fall

tools/materials. Attendant not ready or proper

protection above 4ft. Calibrated air monitor and attendant at entry point, all

4 Prepare and enter the space for work. entry set-up complete. Space not properly

readings in acceptable limits, fire extinguisher and rescue PPE at the entry

ventilated and rechecks complete. May contain

point, and rescue team on stand by.

toxic/hazardous atmosphere

Continuous atmospheric testing by the attendant,. Constant communication

Presences or build-up of toxic or hazardous with entrants. Tool inspection and proper materials. Entrants respirators and

Enter the CS and preform atmospheres, entrapment, medical/health or air supply hose and respirators are properly fit, correct size and hose

5

work/inspection/cleaning. injury. Air supply or respirator failure. Tool or entanglement hazard has been addressed. All personal monitors , and alarms

material failure. are functioning properly and worn. Rescue team has been notified of the entry

and on stand by.

Utilize 3 point of contact when ascending/descending. Use bucket and rope to

Slip/fall hazard due to material/tools/debris inside lift any tools/material from the car. Have attendant hold exit ladder or tie off to

the space, dropped tools or materials being stable object to prevent slipping. Do not lay tools or material on top of car or

Complete the work/inspection/cleaning and

6 passed out from the space to the employee on the catwalk that could be knocked into the exit opening. Keep cords/leads hoses

exit the CS

outside. Entanglement with air supply hose, centrally located as much as possible. Complete the CSP, and check that all

lighting cords. Limited visibility due to respirator. entrants have exited the space, and rescue team notified to return to stand

down mode.

7

8

9

Employees Signatures

You might also like

- Rohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkDocument3 pagesRohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkAbhaySngh100% (1)

- BW Gas Detector ManualDocument3 pagesBW Gas Detector ManualYume HendraNo ratings yet

- Fire Hydrant AccessoriesDocument8 pagesFire Hydrant AccessoriesDan Nicole Dadivas100% (1)

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- Guidelines Flagmen - Banksmen (English)Document1 pageGuidelines Flagmen - Banksmen (English)Pirlo PoloNo ratings yet

- Hot Work - Definition, Responsibility, Process and Risks On-Board ShipsDocument6 pagesHot Work - Definition, Responsibility, Process and Risks On-Board ShipsGiorgi KandelakiNo ratings yet

- Jasons Cradle Factsheet Jc103Document2 pagesJasons Cradle Factsheet Jc103veluchamymuthukumarNo ratings yet

- JSA Arc WeldingDocument2 pagesJSA Arc WeldinganeshseNo ratings yet

- Part II - 08 Abrasive BlastingDocument5 pagesPart II - 08 Abrasive Blastingsalah abddayemNo ratings yet

- Jsa Bearing Replacement-OverhaulingDocument2 pagesJsa Bearing Replacement-Overhaulingashish engineeringNo ratings yet

- Risk Assessment - Working Ship SideDocument3 pagesRisk Assessment - Working Ship SideSatya SatishNo ratings yet

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- Power Failure DrillDocument2 pagesPower Failure DrillAbu Syeed Md. Aurangzeb Al Masum100% (1)

- Man Overboard: Group #5 Bm2 Jomel O San Agustin PN Bm2 Nixon S Diloy PN Rd2 Ronelo S Gatacilo PNDocument29 pagesMan Overboard: Group #5 Bm2 Jomel O San Agustin PN Bm2 Nixon S Diloy PN Rd2 Ronelo S Gatacilo PNJomel San AgustinNo ratings yet

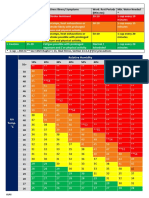

- Aramco Heat IndexDocument1 pageAramco Heat IndexDLPS HSE0% (1)

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 pageHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30No ratings yet

- ERP-20-Structure FailureDocument5 pagesERP-20-Structure FailureChRistian KingsNo ratings yet

- Jazeera C Primer-MsdsDocument5 pagesJazeera C Primer-MsdsMahmoud Flefil100% (1)

- Standard Operating Procedure For HSDDocument3 pagesStandard Operating Procedure For HSDisjglfdskNo ratings yet

- 2.0 Windsock Wind SpeedsDocument1 page2.0 Windsock Wind SpeedsSoham Mukherjee100% (2)

- Suspended From Man-Rider (Vertical Rescue Plan)Document1 pageSuspended From Man-Rider (Vertical Rescue Plan)Paul100% (1)

- EPM EHS SP F 040 Boom Truck ChecklistDocument2 pagesEPM EHS SP F 040 Boom Truck ChecklistTamoor MirzaNo ratings yet

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Working at Height Rescue Plan: WHS-FM-008Document2 pagesWorking at Height Rescue Plan: WHS-FM-008Purwo PrihartonoNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Job Safety Analysis (Jsa)Document9 pagesJob Safety Analysis (Jsa)MohdHuzairiRusliNo ratings yet

- Dellag La 3-36Document2 pagesDellag La 3-36FAIYAZ AHMEDNo ratings yet

- Breaking of Tow Line Checklist - Attachment XLIVDocument3 pagesBreaking of Tow Line Checklist - Attachment XLIVFaiqah AzmirNo ratings yet

- PDF Gi 0002721 2016 Arc Flash CompressDocument23 pagesPDF Gi 0002721 2016 Arc Flash CompressMark DingalNo ratings yet

- Personnel Transfer Procedure (PEX), RevaDocument33 pagesPersonnel Transfer Procedure (PEX), RevaHSE PULAI ANo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- 0006 - 007-Reporting of Contractor On-Job Injuries Occupational Illnesses PDFDocument10 pages0006 - 007-Reporting of Contractor On-Job Injuries Occupational Illnesses PDFIssac JohnNo ratings yet

- Conined Space Entry ChecklistDocument2 pagesConined Space Entry ChecklistJoelNo ratings yet

- JSA #28 - Use of Hand ToolsDocument1 pageJSA #28 - Use of Hand ToolsSubham SohalNo ratings yet

- Caretaker Risk Assessment - Working at HeightDocument8 pagesCaretaker Risk Assessment - Working at HeightLina MarcelaNo ratings yet

- Gi-0006 011Document2 pagesGi-0006 011malika_00No ratings yet

- Fire Extinguisher Inspection Log TemplateDocument1 pageFire Extinguisher Inspection Log Templatejonathan cambaNo ratings yet

- JSEA FOR DISMNTLING OF MACHINES (Central Work Shop)Document16 pagesJSEA FOR DISMNTLING OF MACHINES (Central Work Shop)B&R HSE BALCO SEP SiteNo ratings yet

- Jha Crane OperationsDocument2 pagesJha Crane OperationsJaycee Bareng Pagador100% (1)

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- Ako AcknowledgmentDocument1 pageAko Acknowledgmentclaude stanton0% (1)

- Hi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisDocument3 pagesHi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisPHH9834No ratings yet

- Lift Plan NRS - Toilet Block - Meram ECWDocument40 pagesLift Plan NRS - Toilet Block - Meram ECWTagubilin DailyNo ratings yet

- Cutting WorkDocument1 pageCutting WorkGudduNo ratings yet

- JSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyDocument4 pagesJSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyMuhammad TariqNo ratings yet

- Osha Wheel ChocksDocument2 pagesOsha Wheel ChocksAhmed Emad AhmedNo ratings yet

- Confined Space SlideDocument65 pagesConfined Space SlideSyahrul AnisNo ratings yet

- Ramapo College Vehicle Fueling SOPDocument1 pageRamapo College Vehicle Fueling SOPAnees EkNo ratings yet

- Housekeeping JsaDocument9 pagesHousekeeping JsaShahid BhattiNo ratings yet

- JSA - Foam RefillingDocument13 pagesJSA - Foam RefillingMuhammad Umar GondalNo ratings yet

- WSH Guidelines for Landscape and Horticulture WorksDocument69 pagesWSH Guidelines for Landscape and Horticulture Workslwin_oo2435No ratings yet

- JSA FOR Fall ProtectionDocument2 pagesJSA FOR Fall Protectionwahyu nugroho100% (3)

- Job Safety Analysis (Jsa) : Damage and Personal InjuryDocument2 pagesJob Safety Analysis (Jsa) : Damage and Personal InjuryReda Bouali100% (1)

- Eye WashDocument21 pagesEye Washapi-273019508100% (1)

- Confined Space JSADocument1 pageConfined Space JSADILAL B P100% (16)

- Risk Assesment SheetDocument1 pageRisk Assesment SheetdilanNo ratings yet

- 021 Manual Excavation JSA For FLS SiteDocument3 pages021 Manual Excavation JSA For FLS SiteViron BaxhiaNo ratings yet

- CS3001 Emanual (Electronic) JOHN DEERE ENGLISH PDFDocument235 pagesCS3001 Emanual (Electronic) JOHN DEERE ENGLISH PDFJailson Dantas100% (2)

- Asphalts Catalog Tcm14-55227Document54 pagesAsphalts Catalog Tcm14-55227Savaşer YetişNo ratings yet

- Seminar ON Fuel Cells::Anirudh Gupta: Electrometallurgy and Corrosion.: 902 2011Document15 pagesSeminar ON Fuel Cells::Anirudh Gupta: Electrometallurgy and Corrosion.: 902 2011Devashish JoshiNo ratings yet

- BSM SM CVDocument36 pagesBSM SM CValexsmn100% (1)

- Electrical Drive Advantages of Electrical DriveDocument4 pagesElectrical Drive Advantages of Electrical DriveSylesh SreehariNo ratings yet

- Continuous Energy: Product CatalogDocument40 pagesContinuous Energy: Product CatalogNegash JaferNo ratings yet

- Lumigon: Technical SheetDocument2 pagesLumigon: Technical SheetMouhamadou AdjNo ratings yet

- Risk and Asset Management of Transmission System in A Reformed Power SectorDocument6 pagesRisk and Asset Management of Transmission System in A Reformed Power SectorumairNo ratings yet

- Dual Operational Amplifier: Semiconductor Technical DataDocument9 pagesDual Operational Amplifier: Semiconductor Technical DataRafael Jaime GonçalvesNo ratings yet

- "Electrons in Atoms": Chemistry Atlantic Bilingual School Christian Campbell MDDocument75 pages"Electrons in Atoms": Chemistry Atlantic Bilingual School Christian Campbell MDusmcdoc113597No ratings yet

- Electrolysis 1 PDFDocument2 pagesElectrolysis 1 PDFAlfred JacobNo ratings yet

- ChemistryQB Topic6a MC eDocument59 pagesChemistryQB Topic6a MC eNg Swee Loong StevenNo ratings yet

- Modelling of Subcooled Flow Boiling Heat Transfer of Water Through A Vertical Heated PipeDocument4 pagesModelling of Subcooled Flow Boiling Heat Transfer of Water Through A Vertical Heated PipeDr Mohammed AzharNo ratings yet

- Energy Band Theory in SolidsDocument3 pagesEnergy Band Theory in Solidsashok pradhanNo ratings yet

- Nano Based CoatingsDocument22 pagesNano Based CoatingspincoNo ratings yet

- Mitsubishi Electric PLFY-P VBM-E Service Manual EngDocument44 pagesMitsubishi Electric PLFY-P VBM-E Service Manual Engengenharia proclimaNo ratings yet

- Kittel Solutions AKDocument79 pagesKittel Solutions AKAra Martínez-Olguín100% (5)

- TSB1380YGSDocument2 pagesTSB1380YGSlelopNo ratings yet

- (6600) - 4 CYL AG TRACTOR (9/75-12/81) (06E01) - OIL PUMP & PAN (SUMP) New Holland AgricultureDocument4 pages(6600) - 4 CYL AG TRACTOR (9/75-12/81) (06E01) - OIL PUMP & PAN (SUMP) New Holland AgriculturerodrigoNo ratings yet

- Molar Mass of ButaneDocument11 pagesMolar Mass of ButaneReena0% (1)

- Installation Instructions: MFP RangeDocument12 pagesInstallation Instructions: MFP RangeSoheil GhasemiNo ratings yet

- Sky Air Seasonal Classic Conductos Baja Silueta Serie DDocument1 pageSky Air Seasonal Classic Conductos Baja Silueta Serie DmiroNo ratings yet

- English Airplane ArticleDocument2 pagesEnglish Airplane Articleapi-462230056No ratings yet

- Boq Gabung Gi Teluk Naga Ii - Full Digital.r3-SentDocument237 pagesBoq Gabung Gi Teluk Naga Ii - Full Digital.r3-SentTika LorenzaNo ratings yet

- BMC Brochure WebDocument4 pagesBMC Brochure WebVikram Pratap SinghNo ratings yet

- Cleaning and Inspection For Oxygen Service: B. Haribabu Inox Air ProductsDocument54 pagesCleaning and Inspection For Oxygen Service: B. Haribabu Inox Air ProductskanchanabalajiNo ratings yet

- Proximity Probe Mounting OptionsDocument6 pagesProximity Probe Mounting OptionstoilalongNo ratings yet

- Modularization in Chemical Processing: Special Section: Process IntensificationDocument9 pagesModularization in Chemical Processing: Special Section: Process IntensificationJohn AnthoniNo ratings yet

- PLC-controlled Stepper Motor Drive For NC PositionDocument10 pagesPLC-controlled Stepper Motor Drive For NC PositiondeoarshiNo ratings yet

- Gas Heat Pump Technical SpecsDocument139 pagesGas Heat Pump Technical SpecsalexandreNo ratings yet