Professional Documents

Culture Documents

Manual Guides Knife Gate Valves f952 Gland Packing Instructions Larger Sizes Keystone en en 2719066

Uploaded by

marklaforestCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Guides Knife Gate Valves f952 Gland Packing Instructions Larger Sizes Keystone en en 2719066

Uploaded by

marklaforestCopyright:

Available Formats

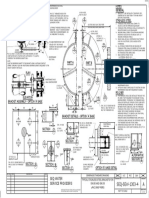

KEYSTONE KNIFE GATE VALVES

FIGURE 952

Gland packing replacement instructions for DN 250 - 600 (NPS 10 - 24)

Figure 952 knife gate valves

PACKING REPLACEMENT

16

18 23

22 For optimum performance, the packing

18 material should be replaced whenever the

17

valve has been disassembled for routine

maintenance. This is a very simple procedure

which can be done leaving the valve in the

8

pipeline.

9

Correct packing is essential for leak-free

15 operation. Use Emerson’s preformed and pre-

14 5 cut packing replacement kits for best results.

19

20 Kits are available in the following types:

K-LON - Standard packing material.

D-LON - Food grade packing.

G-LON - High cyclic packing.

2 H-LON - Abrasive service packing.

Ensure packing material selected is suitable

for the service.

DISASSEMBLY PROCEDURE

10

12 11 1. Ensure the pipeline is not pressurized and

21 any hazardous medium is drained away.

2. Close valve.

6 3

3. Remove gland box nuts (10) and washers

(11, 12). A 32 mm (1¼”) AF spanner suits all

7

valve sizes.

4. Remove clevis bolts (19) and nuts (20).

4 1 5. Remove pillar nut (23) and washer (22).

13 6. Remove upright mounting bolts (14) and

washers (15) at valve body (1).

7. Remove handwheel (16) upright (8) and

spindle (5) as an assembly.

8. Remove gland box (3) from gate (2)

leaving the gate in the valve body.

9. Remove scraper (7) (Not fitted on

Note: DN 250 - 600 (NPS 10 - 24) valve illustrated.

polyurethane trim valves) and packing

segments (6) from gland box, noting number

of layers.

10. Clean gland box (3).

NOTE

Although not essential, valve gate can also be removed

for inspection at this stage.

For optimum leak-free service, gate faces and edges

must be smooth, and free of galling or burring.

Repair or replace if excessively worn or damaged.

When re-fitting gate, ensure bevelled edge of knife

gate is upstream and away from seating face.

Emerson.com/FinalControl © 2017 Emerson. All Rights Reserved. VCIOM-02045-EN 16/02

KEYSTONE KNIFE GATE VALVES

FIGURE 952

PACKING PROCEDURE NOTE

1. At commissioning or plant start-up, open and 16

NOTE close valve to check it is operating correctly - 18 23

22

Care should be taken to stagger the mitred joints gland nuts (8) may require adjustment.

18

in each layer of packing to the opposite side of the Please ensure to tighten equally.

gland box, e.g.; 2. To minimize risk to personnel, Emerson 17

• 1st packing layer joint to the front of the valve recommend the use of purpose built guards

• 2nd packing layer joint to the rear of the valve and shrouds. Refer to the Emerson data sheet or

8

• 3rd packing layer joint to the front of the valve. consult factory for details.

9

11. Press first layer of gland packing (6) into CAUTION 15

gland box (3) cavity by hand, then repeat Do NOT over tighten gland packing as it will cause 14 5

the process with the second layer ensuring excessive resistance to gate movement. 20

the joints of the two layers are on opposing 19

sides of the cavity

12. Fit the RTFE scraper blade (7) (Not fitted on

polyurethane trim valves) in bottom of gland

box. 2

ASSEMBLY PROCEDURE

1. Using masking tape, hold packing in place

temporarily by passing tape through gland

10

box slot around packing onto edge of 12 11

gland box (one piece per side minimum

21

recommended).

2. Coat gland box studs (21) with nickel based 3

6

anti-seize compound.

3. Place the gland box (3) over gate (2), sliding

7

the gland box down to make contact with

the body and remove temporary holding

tape. 4 1

4. Tighten gland box nuts equally (10) ensuring 13

nylon washer (12) is positioned between

metal washer (11) and gland box (3).

5. Replace handwheel (16), upright (8) and

spindle (5) assembly.

6. Replace pillar bolts (14) and washers (15)

at valve body (1).

7. Replace pillar nut (23) and washer (22) Note: DN 250 - 600 (NPS 10 - 24) valve illustrated.

ensuring thread is coated with nickel based

anti-seize compound.

8. Lower the spindle clevis (5) onto the gate (2)

and replace clevis mounting bolts (19) and

nuts (20).

9. Check the alignment of spindle, upright and

pillar and tighten fasteners (14, and 23).

10. Assembly is complete, actuate to check all

is functioning as desired and gate reseats

itself into the wedges at bottom of the valve

body.

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Keystone is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson,

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl

You might also like

- MN 03007Document16 pagesMN 03007hyarub9No ratings yet

- Yarway Blow Off Valves Operation ManualDocument4 pagesYarway Blow Off Valves Operation ManualLeoNo ratings yet

- Imo 004enDocument4 pagesImo 004enHASBUL AZIZI BIN MAHMUNNo ratings yet

- Manual KGD Knife Gate Valves Iom Clarkson en en 5193462Document16 pagesManual KGD Knife Gate Valves Iom Clarkson en en 5193462Nicolas Iturrieta BerriosNo ratings yet

- Bendix - Master-Vac - Power Brake Service Manual - 9-208 Supplement No. 1 - OCR - 4 PagesDocument4 pagesBendix - Master-Vac - Power Brake Service Manual - 9-208 Supplement No. 1 - OCR - 4 Pagesgreg titanNo ratings yet

- Stainless-Steel-Ball-Valves F262 Pentair Seat Seal ReplacementDocument4 pagesStainless-Steel-Ball-Valves F262 Pentair Seat Seal Replacementred patriotNo ratings yet

- Operations Maintenance Manual Medallion Hydrant 380caae9Document9 pagesOperations Maintenance Manual Medallion Hydrant 380caae9babmech6007No ratings yet

- 2 5-In. MPV Pressure-Test Bypass Valve: SectionDocument26 pages2 5-In. MPV Pressure-Test Bypass Valve: Sectionsong LiNo ratings yet

- 79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)Document12 pages79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)COILED TUBINGNo ratings yet

- 43 88 - Mechanical - Seal - Replacement - Instructions - TCDocument4 pages43 88 - Mechanical - Seal - Replacement - Instructions - TCAlan MercesNo ratings yet

- Ni-252 GBDocument4 pagesNi-252 GByacineonlineNo ratings yet

- Posh Solus Mkii Basin Mixer 9502635 Tech WarrantyDocument3 pagesPosh Solus Mkii Basin Mixer 9502635 Tech WarrantymainpersonNo ratings yet

- A 1020Document16 pagesA 1020Pong KrubNo ratings yet

- CAT LIFT TRUCK MANUAL MODEL DP40K DP40KL DP45K DP50K DP60 DP70: Engine Main PartsDocument50 pagesCAT LIFT TRUCK MANUAL MODEL DP40K DP40KL DP45K DP50K DP60 DP70: Engine Main PartsHarlinton descalzi100% (4)

- Engine Main Parts GuideDocument53 pagesEngine Main Parts GuideAmri Anwar100% (2)

- Design 461 Anti-Coke Valve Body (Fishebj: Fisher ControlsDocument16 pagesDesign 461 Anti-Coke Valve Body (Fishebj: Fisher ControlsDatt NguyenNo ratings yet

- 43.88UK Mechanical Seal Replacement Instructions TCDocument4 pages43.88UK Mechanical Seal Replacement Instructions TCMohammed Mostafa El HaddadNo ratings yet

- VA.G Service Workshop Manual Provides Comprehensive Repair GuideDocument158 pagesVA.G Service Workshop Manual Provides Comprehensive Repair GuideAlexandru CraiovanNo ratings yet

- Torque Converter Clutch Case: Automatic TransmissionDocument4 pagesTorque Converter Clutch Case: Automatic TransmissionAnton FortovNo ratings yet

- 6.38 10M EH Single Shear Seal BOPDocument19 pages6.38 10M EH Single Shear Seal BOPpramodptvpm_65797156No ratings yet

- Series 9200 ManualDocument31 pagesSeries 9200 Manualtxlucky80No ratings yet

- Cameron Type U Blowout PreventerDocument15 pagesCameron Type U Blowout PreventerEdmo Virgens0% (1)

- Ultramat Plus Pneumo UFM PDocument6 pagesUltramat Plus Pneumo UFM PIsraelNo ratings yet

- Rci 400 Series Installation & Maintenance InstructionsDocument2 pagesRci 400 Series Installation & Maintenance InstructionsSandro MartinezNo ratings yet

- 9852 1302 01e Maintenance Instruction COP 2150-2550 - 2150EX - 2550EXDocument22 pages9852 1302 01e Maintenance Instruction COP 2150-2550 - 2150EX - 2550EXeko sunaryo100% (3)

- Kennedy Valve: Kennedy Valve Resilient Wedge Gate Valve Maintenance ManualDocument11 pagesKennedy Valve: Kennedy Valve Resilient Wedge Gate Valve Maintenance ManualttyNo ratings yet

- Install, Operate, Maintain AL320P, AL321P Globe Angle ValvesDocument2 pagesInstall, Operate, Maintain AL320P, AL321P Globe Angle ValvesyusufNo ratings yet

- General Maintenance AND Assembly Instructions Control Valves in HP Bypass SystemDocument25 pagesGeneral Maintenance AND Assembly Instructions Control Valves in HP Bypass SystemsumitNo ratings yet

- Group 4 Disassembly and Assembly: 1. Main PumpDocument23 pagesGroup 4 Disassembly and Assembly: 1. Main PumpPriscila RodriguesNo ratings yet

- MSI LT Valve Maintenance ManualDocument34 pagesMSI LT Valve Maintenance ManualAnis GharsellaouiNo ratings yet

- B2-01 Booster Gun: Instruction ManualDocument2 pagesB2-01 Booster Gun: Instruction ManualJod RichNo ratings yet

- Assembly and Disassembly: Isave 21Document16 pagesAssembly and Disassembly: Isave 21Jan Antonius DjunaediNo ratings yet

- Fisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyDocument24 pagesFisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyGieNo ratings yet

- Cat 45Document48 pagesCat 45Lada LabusNo ratings yet

- 9852 1007 01d Maintenance Instr COP 1840HE, HEXDocument19 pages9852 1007 01d Maintenance Instr COP 1840HE, HEXButnariu CristianNo ratings yet

- 3DD029-A06-IOM-Gate Globe and Check ValvesDocument6 pages3DD029-A06-IOM-Gate Globe and Check ValvesgabrielNo ratings yet

- Farris Maintenance ManualDocument12 pagesFarris Maintenance ManualAcep WahyudinNo ratings yet

- Fisher CP Duplex Packing GuideDocument2 pagesFisher CP Duplex Packing GuideSMcNo ratings yet

- Amt Owner's ManualDocument8 pagesAmt Owner's ManuallrolindoNo ratings yet

- Evk2rv 110-390 Manual enDocument13 pagesEvk2rv 110-390 Manual enKjsNo ratings yet

- Fisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyDocument20 pagesFisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyAlberto GuillenNo ratings yet

- Sherwood Valves Cylinder ValvesDocument17 pagesSherwood Valves Cylinder Valvesklr_sean100% (1)

- Maintenance M44 Series BrakesDocument27 pagesMaintenance M44 Series BrakesDonna Schwenk LinsnerNo ratings yet

- 7. اذرعت التحكم (العصيان)Document14 pages7. اذرعت التحكم (العصيان)المهندسوليدالطويلNo ratings yet

- Arcl Om1 2Document6 pagesArcl Om1 2Farhan FalahNo ratings yet

- Operation & Maintenance: AnnuallyDocument1 pageOperation & Maintenance: AnnuallyADVIKA GOWTHAMNo ratings yet

- Renewal of Valve Tappet On The 14 Litre Engine: BackgroundDocument5 pagesRenewal of Valve Tappet On The 14 Litre Engine: BackgroundjoaojitoNo ratings yet

- Control Valve Norriseal - Series2200 O&MDocument16 pagesControl Valve Norriseal - Series2200 O&MJairo AlonsoNo ratings yet

- Bucyrus: Technical ManualDocument7 pagesBucyrus: Technical ManualJohn GrayNo ratings yet

- 81463015accumulator Charging ValveDocument3 pages81463015accumulator Charging ValveЯрослав ВалькоNo ratings yet

- WheelHorse Lawn Sweeper Manual 7-2511Document4 pagesWheelHorse Lawn Sweeper Manual 7-2511Kevins Small Engine and Tractor Service100% (1)

- Hygienic Butterfly Valves F250 F251 Pentair Installation OperationDocument8 pagesHygienic Butterfly Valves F250 F251 Pentair Installation OperationronnelNo ratings yet

- Piper Seneca II Magneto Service ManualDocument9 pagesPiper Seneca II Magneto Service ManualTríade MusicNo ratings yet

- Inspeção de MagnetoDocument9 pagesInspeção de MagnetoTríade MusicNo ratings yet

- FG HSD 001Document3 pagesFG HSD 001orisNo ratings yet

- Fisher CP PTFE Packing GuideDocument2 pagesFisher CP PTFE Packing GuideSMcNo ratings yet

- 019061-InstallationGuideDocument1 page019061-InstallationGuidehadrian luciferNo ratings yet

- 40.20.31.pdf New Labrynth Input SealDocument2 pages40.20.31.pdf New Labrynth Input SealMichel FloresNo ratings yet

- Maintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterFrom EverandMaintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterNo ratings yet

- Rotork Profibus ControlDocument16 pagesRotork Profibus ControlmarklaforestNo ratings yet

- Specifications: Limitorque MX Selection DataDocument18 pagesSpecifications: Limitorque MX Selection DatamarklaforestNo ratings yet

- SEQ-SEW-1303-4 A: Seq Water Service ProvidersDocument1 pageSEQ-SEW-1303-4 A: Seq Water Service ProvidersmarklaforestNo ratings yet

- Rotork Profibus ControlDocument16 pagesRotork Profibus ControlmarklaforestNo ratings yet

- Iccons CIS Threaded Inserts TDSDocument2 pagesIccons CIS Threaded Inserts TDSmarklaforestNo ratings yet

- Bridco Load Rated 2016Document16 pagesBridco Load Rated 2016marklaforestNo ratings yet

- As Passavant Shut Off Devices en WEBDocument4 pagesAs Passavant Shut Off Devices en WEBmarklaforestNo ratings yet

- Limitorque Actuation SystemsDocument16 pagesLimitorque Actuation SystemsmarklaforestNo ratings yet

- Rtt-Ind-001 Rev 9 (No 13 Solvent) 11092017 JfoDocument11 pagesRtt-Ind-001 Rev 9 (No 13 Solvent) 11092017 JfomarklaforestNo ratings yet

- SS300 adhesive series property comparisonDocument2 pagesSS300 adhesive series property comparisonmarklaforestNo ratings yet

- LMENIM2306 Enaq - PDDocument112 pagesLMENIM2306 Enaq - PDmarklaforestNo ratings yet

- Bridco Load Rated 2016Document16 pagesBridco Load Rated 2016marklaforestNo ratings yet

- Q LD Procurement PolicyDocument20 pagesQ LD Procurement PolicymarklaforestNo ratings yet

- Weld-On Structural Adhesives: Product Reference GuideDocument1 pageWeld-On Structural Adhesives: Product Reference GuidemarklaforestNo ratings yet

- SS300 React Vs TempDocument1 pageSS300 React Vs TempmarklaforestNo ratings yet

- VCB22 Series - Data Sheet (En)Document11 pagesVCB22 Series - Data Sheet (En)marklaforest0% (1)

- Queensland Government GazetteDocument53 pagesQueensland Government GazettemarklaforestNo ratings yet

- TolerancesDocument9 pagesTolerancesAnugrah YudhaNo ratings yet

- Chemical Resistance Guide: Resin SelectionDocument4 pagesChemical Resistance Guide: Resin SelectionmarklaforestNo ratings yet

- Constitution For Sample Pty LTDDocument20 pagesConstitution For Sample Pty LTDmarklaforestNo ratings yet

- Business Plan TemplateDocument37 pagesBusiness Plan TemplatemarklaforestNo ratings yet

- Introduction to AS/NZS 2312.2 guide on HDG corrosion protectionDocument2 pagesIntroduction to AS/NZS 2312.2 guide on HDG corrosion protectionmarklaforestNo ratings yet

- Flange TableDocument0 pagesFlange TablemkstngrNo ratings yet

- ISO Hole Tolerances ChartDocument1 pageISO Hole Tolerances ChartmarklaforestNo ratings yet

- Guide to Protecting Steel from CorrosionDocument17 pagesGuide to Protecting Steel from CorrosiondilrangiNo ratings yet

- Linear Actuator LA37 Data Sheet EngpdfDocument28 pagesLinear Actuator LA37 Data Sheet EngpdfmarklaforestNo ratings yet

- CPV Process Valve ActuatorDocument12 pagesCPV Process Valve ActuatormarklaforestNo ratings yet

- TolerancesDocument9 pagesTolerancesariyarathneNo ratings yet

- CPV Process Valve ActuatorDocument12 pagesCPV Process Valve ActuatormarklaforestNo ratings yet

- Indian Standard: Mild Steel Wire For General Engineering PurposesDocument7 pagesIndian Standard: Mild Steel Wire For General Engineering PurposesDevendrasinh PadhiyarNo ratings yet

- REX Relay Board2Document1 pageREX Relay Board2Abdalhakeem AlturkyNo ratings yet

- Low Band Receiving AntennasDocument50 pagesLow Band Receiving AntennasDavid Bohorquez RamosNo ratings yet

- WWW Scribd Com Document 415705066 HMT Machine Tools LTD Internship ReportDocument20 pagesWWW Scribd Com Document 415705066 HMT Machine Tools LTD Internship Reporthigom17162No ratings yet

- Soal Bing Xi BaruDocument5 pagesSoal Bing Xi BarumujiamanNo ratings yet

- Data Packets Analyzer AND Controller LanDocument7 pagesData Packets Analyzer AND Controller LanMumbai AcademicsNo ratings yet

- The Best of PupungDocument3 pagesThe Best of PupungPeter ParkerNo ratings yet

- Vijeo Citect +PowerConnect Installation GuideDocument12 pagesVijeo Citect +PowerConnect Installation GuidePavun RajNo ratings yet

- MS - Electrical Second FixDocument9 pagesMS - Electrical Second Fixirfan vpNo ratings yet

- Voltage Source Drive Programming Manual SummaryDocument262 pagesVoltage Source Drive Programming Manual SummaryCarolina HuertaNo ratings yet

- Hydrophore Set (Mectron Engineering)Document2 pagesHydrophore Set (Mectron Engineering)KelvinNo ratings yet

- Lesson 1 - Unit Pressure PDFDocument60 pagesLesson 1 - Unit Pressure PDFJenuine LimonNo ratings yet

- International Journal of Soft Computing and Engineering (IJSCE)Document1 pageInternational Journal of Soft Computing and Engineering (IJSCE)DrShiv K SahuNo ratings yet

- CV - Hamdullah UÇAR-ıngDocument3 pagesCV - Hamdullah UÇAR-ıngHamdullah UcarNo ratings yet

- Aerodynamics II NotesDocument166 pagesAerodynamics II NotesAlexShearNo ratings yet

- Steam Tank Pressure & QualityDocument5 pagesSteam Tank Pressure & QualityAri Reza KNo ratings yet

- Soft Computing Techniques for Neural Networks, Fuzzy Logic & Genetic AlgorithmsDocument2 pagesSoft Computing Techniques for Neural Networks, Fuzzy Logic & Genetic AlgorithmsPRANAV KUMAR 17BEC0473No ratings yet

- Internal Loadings: External LoadsDocument13 pagesInternal Loadings: External LoadsMuhammad Adeel AhsenNo ratings yet

- Fundamentals of Electric Vehicles Lecture on Vehicle DynamicsDocument15 pagesFundamentals of Electric Vehicles Lecture on Vehicle DynamicsaerovinuNo ratings yet

- Shaker Screen Interchange Sell Sheet 1Document2 pagesShaker Screen Interchange Sell Sheet 1NME KaridaNo ratings yet

- New SplineDocument20 pagesNew SplineHiyeedNo ratings yet

- DOH 90 % Site Inspection Required ChecklistDocument3 pagesDOH 90 % Site Inspection Required Checklistarshad209No ratings yet

- WG FM Report Summarizes Key Discussions and DecisionsDocument41 pagesWG FM Report Summarizes Key Discussions and DecisionsJeandelaSagesseNo ratings yet

- A 85 A 0 Module 2 UpDocument39 pagesA 85 A 0 Module 2 UphimnnnNo ratings yet

- BECK USA Electrical ActuatorsDocument56 pagesBECK USA Electrical ActuatorsnprashanNo ratings yet

- Section R6 Selected Granular Material-Sub-Base CourseDocument21 pagesSection R6 Selected Granular Material-Sub-Base CourseBALEN KAKLNo ratings yet

- iNTERRUPTOR 3AF01 PDFDocument27 pagesiNTERRUPTOR 3AF01 PDFJames IzquierdoNo ratings yet

- JAR 66 Module 1 Propeller Exam PracticeDocument43 pagesJAR 66 Module 1 Propeller Exam Practicerobija1No ratings yet

- 3 Re 445 DSL SPC PDFDocument58 pages3 Re 445 DSL SPC PDFThomasBaby KavoorazhikathuNo ratings yet

- Pa80 User PDFDocument10 pagesPa80 User PDFNenad StankovNo ratings yet