Professional Documents

Culture Documents

ICF/Chennai WPQR Test Certificate

Uploaded by

aravindanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICF/Chennai WPQR Test Certificate

Uploaded by

aravindanCopyright:

Available Formats

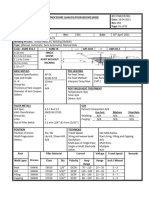

ICF/Chennai – 38. Form No.

ICF/IMS/F023

Welding Procedure Qualification Manufacturer’s WPQR No:

Record (WPQR) for ARC welding Manufacturer’s WPS No

Test certificate. Code/Testing standard: EN ISO 15614-1/EN ISO 15613.

Description /Thickness: Material specification :

Range of qualification:

Variable Actual Testing Range Qualified.

Welding process

Type of joint and weld

Parent material group and sub group

Parent material thickness

Weld metal thickness (mm)

Throat thickness (mm)

Single run/multi run

Filler material designation

Filler material size

Designation of shielding gas

Designation of backing gas

Type of welding current and polarity

Welding position

Preheat temperature

Interpass temperature

Post heating

Post weld heat treatment

Other information

Certified that test welds prepared, welded and tested satisfactorily in accordance with the requirements of

the code/testing standard indicated above.

Prepared By Examiner Scrutinized by APPROVED BY

SSE/Shop Sr. Instructor / AWTI Dy.CME/User Dy.CME/Design

IWE/IWT Ref.No:

Details of test:

Welding Process& Code as per ISO 4063

Weld Position as per ISO 6947: PA/ PB/PC/PD/PF/PG

Type of joint: Butt/ Tee/ Lap/ corner/Edge/ Flare Bevel

Weld type:

Method of preparation/cleaning

Weld preparation details &Joint Design

Type of joint:

Throat size/weld size:

Welding Details:

Run Welding Size of Filler Current Voltage Type of Wire Travel Speed Remarks.

Process Material(Dia) (A) (V) current/ feed (mm/min)

polarity speed

(m/min)

Filler material designation and make Distance contact tube/work piece

Any Special baking or drying Torch angle

Shielding Gas as per ISO 14175 Preheat/post heat details:

Gas flow rate Weaving (maximum width of run)

Tungsten electrode details: Details of back gouging/backing

Prepared By Examiner Scrutinized by APPROVED BY

SSE/Shop Sr. Instructor / AWTI Dy.CME/User Dy.CME/Design

IWE/IWT ref.no:

You might also like

- P WPSDocument3 pagesP WPSAnilkumar G NairNo ratings yet

- ISO 15614-1 - 2004 - Red Corr 2008-6Document5 pagesISO 15614-1 - 2004 - Red Corr 2008-6TasmanijskaNemaNo ratings yet

- WPQRDocument3 pagesWPQRDimitris NikouNo ratings yet

- WPS FormatDocument1 pageWPS FormatbalamuruganNo ratings yet

- WPQR PipeDocument3 pagesWPQR PipeThanasis KyrgiazoglouNo ratings yet

- WPQR TIG Fillet Welding ProcedureDocument3 pagesWPQR TIG Fillet Welding ProcedureDimitris NikouNo ratings yet

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- Welder WQTDocument85 pagesWelder WQTKy100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- WPS FormatDocument7 pagesWPS FormatPradip SalunkheNo ratings yet

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- Welding Procedure Qualification Records (WPQR) GuideDocument3 pagesWelding Procedure Qualification Records (WPQR) Guideramesh rajaNo ratings yet

- Visual Inspection EquipmentDocument7 pagesVisual Inspection EquipmentArunNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Record of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014Document2 pagesRecord of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014cisar0007No ratings yet

- WPQR Welding Procedure Qualification RecordsDocument3 pagesWPQR Welding Procedure Qualification Recordsramesh rajaNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- 01 - WPS - Welder Qualification and WPQR For MS 5.0 MM RAKESH Fillet T JointDocument5 pages01 - WPS - Welder Qualification and WPQR For MS 5.0 MM RAKESH Fillet T JointssqiindiapvtltdNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4Document1 pagePessing Libya INC: As Per P No.3,4 To As Per P No.3,4Mahmoud HaggagNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design Welding SequencesDocument1 pageWelding Procedure Specification (WPS) : Joint Design Welding SequencesFerhat KahveciNo ratings yet

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- Wps 141 PA #5Document2 pagesWps 141 PA #5cosmo5555No ratings yet

- Wps 2-8Document1 pageWps 2-8Anonymous XYt4Y9qNo ratings yet

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Document2 pagesPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- WPQR - Form As Per EN PDFDocument3 pagesWPQR - Form As Per EN PDFAnilNo ratings yet

- Weld Checklist PQRDocument2 pagesWeld Checklist PQRScott Trainor100% (1)

- Piping WPS PQR DocumentationDocument4 pagesPiping WPS PQR DocumentationAlexander Joseph100% (1)

- WPQR6Document3 pagesWPQR6Dimitris NikouNo ratings yet

- ISO 15609-1 welding procedure specificationDocument4 pagesISO 15609-1 welding procedure specificationKDTNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- Specification (WPS) Welding ProcedureDocument1 pageSpecification (WPS) Welding ProcedureBranko FerenčakNo ratings yet

- WPS for Welding Stainless Steel PipesDocument1 pageWPS for Welding Stainless Steel PipesNicu PrunaNo ratings yet

- Welding Procedure SpecificationDocument13 pagesWelding Procedure SpecificationsamNo ratings yet

- 00 WPS STR 10-12-2018Document35 pages00 WPS STR 10-12-2018alok987No ratings yet

- Welding Procedure Specification According To EN ISO 15609, 2004Document2 pagesWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Welding Procedure Specification (WPS) of The ManufacturerDocument9 pagesWelding Procedure Specification (WPS) of The ManufacturerfallalovaldesNo ratings yet

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- Welding Procedure Qualification Record (WPQR)Document8 pagesWelding Procedure Qualification Record (WPQR)Belin InversoNo ratings yet

- 0160e - Welding Procedures Data SheetDocument1 page0160e - Welding Procedures Data SheetAmanpreet SinghNo ratings yet

- 3 Con 8749 Rec 324 - Welder Approval Test ReportDocument1 page3 Con 8749 Rec 324 - Welder Approval Test ReporttinzarmoeNo ratings yet

- En Iso 15609Document2 pagesEn Iso 15609Parminder SinghNo ratings yet

- WPS 01 - Pipe - SSDocument1 pageWPS 01 - Pipe - SSAdvanced Quality Centre AQCNo ratings yet

- Technical Data - 2019EBDocument4 pagesTechnical Data - 2019EBManoj AgarwalNo ratings yet

- Pessing Libya INC: Sfa. No: A5.9Document1 pagePessing Libya INC: Sfa. No: A5.9Mahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/ADocument1 pagePessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/AMahmoud HaggagNo ratings yet

- WQRDocument3 pagesWQRMascot InternationalNo ratings yet

- Aws PQR FormDocument3 pagesAws PQR Formndi101No ratings yet

- Guidance 1GDocument5 pagesGuidance 1GWahyu HaryadiNo ratings yet

- Metal bellows expansion joint specification data sheetDocument1 pageMetal bellows expansion joint specification data sheetYavuz SolmazNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Operating Instructions For Eclipse Refractometer - 2013 - EnglishDocument16 pagesOperating Instructions For Eclipse Refractometer - 2013 - Englisharavindan100% (1)

- Operating Instructions For Eclipse Refractometer - 2013 - English PDFDocument8 pagesOperating Instructions For Eclipse Refractometer - 2013 - English PDFaravindanNo ratings yet

- Operating Instructions For Eclipse Refractometer - 2013 - English PDFDocument8 pagesOperating Instructions For Eclipse Refractometer - 2013 - English PDFaravindanNo ratings yet

- Sample of UT InstructionDocument4 pagesSample of UT Instructionmusaismail8863No ratings yet

- Disposable Field Indicator - Operating Manual - Jun18Document2 pagesDisposable Field Indicator - Operating Manual - Jun18aravindanNo ratings yet

- Disposable Field Indicator - Operating Manual - Jun18Document2 pagesDisposable Field Indicator - Operating Manual - Jun18aravindanNo ratings yet

- Yuasa NP12-6 VRLA Battery Technical Data SheetDocument1 pageYuasa NP12-6 VRLA Battery Technical Data SheetaravindanNo ratings yet

- ZP 14a Pds July17Document3 pagesZP 14a Pds July17aravindanNo ratings yet

- Rp20lt Pds July17Document2 pagesRp20lt Pds July17aravindanNo ratings yet

- D30a D30plus Pds Nov18Document3 pagesD30a D30plus Pds Nov18aravindanNo ratings yet

- Operating Instructions - Ketos Test Ring - Oct14Document2 pagesOperating Instructions - Ketos Test Ring - Oct14aravindanNo ratings yet

- Yuasa NP12-6 VRLA Battery Technical Data SheetDocument1 pageYuasa NP12-6 VRLA Battery Technical Data SheetaravindanNo ratings yet

- Stepdown Transformerl PDS Aug17Document1 pageStepdown Transformerl PDS Aug17aravindanNo ratings yet

- Activated Carbon PDS July17Document1 pageActivated Carbon PDS July17aravindanNo ratings yet

- Yuasa NP12-6 VRLA Battery Technical Data SheetDocument1 pageYuasa NP12-6 VRLA Battery Technical Data SheetaravindanNo ratings yet

- L10 Electromagnetic Coil: Use To Detect Transverse CracksDocument1 pageL10 Electromagnetic Coil: Use To Detect Transverse CracksaravindanNo ratings yet

- L10 Electromagnetic Coil: Use To Detect Transverse CracksDocument1 pageL10 Electromagnetic Coil: Use To Detect Transverse CracksaravindanNo ratings yet

- Test Pieces LPI PDS Jun18Document9 pagesTest Pieces LPI PDS Jun18aravindanNo ratings yet

- QB1 Quick Break Tester - Operating Manual - Jun18Document4 pagesQB1 Quick Break Tester - Operating Manual - Jun18aravindanNo ratings yet

- Understanding casting defects and their causesDocument94 pagesUnderstanding casting defects and their causestanydhillon100% (1)

- 1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesDocument2 pages1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesaravindanNo ratings yet

- Liquid Penetrant Testing Product Data SheetDocument1 pageLiquid Penetrant Testing Product Data SheetaravindanNo ratings yet

- Solvent-Based Developer: Product Data SheetDocument3 pagesSolvent-Based Developer: Product Data SheetaravindanNo ratings yet

- QQIs - Operating Manual - Jun18Document4 pagesQQIs - Operating Manual - Jun18aravindanNo ratings yet

- Solvent-Based Developer: Product Data SheetDocument3 pagesSolvent-Based Developer: Product Data SheetaravindanNo ratings yet

- Disposable Field Indicator - Operating Manual - Jun18Document2 pagesDisposable Field Indicator - Operating Manual - Jun18aravindanNo ratings yet

- QB1 Quick Break Tester - Operating Manual - Jun18Document3 pagesQB1 Quick Break Tester - Operating Manual - Jun18aravindanNo ratings yet

- QB1 Quick Break Tester - Operating Manual - Jun18Document4 pagesQB1 Quick Break Tester - Operating Manual - Jun18aravindanNo ratings yet

- Magnetic Yokes Brochure - Jan18Document3 pagesMagnetic Yokes Brochure - Jan18aravindanNo ratings yet

- ETT Series - Operating Manual - Jun18Document10 pagesETT Series - Operating Manual - Jun18aravindanNo ratings yet

- WIweld01 Co2 Welding Rev 01Document1 pageWIweld01 Co2 Welding Rev 01Gautam KumarNo ratings yet

- SPARE PARTS MANUAL of AM7 SHC2 RH VERSION, Edition - Dec '16 TMDocument74 pagesSPARE PARTS MANUAL of AM7 SHC2 RH VERSION, Edition - Dec '16 TMMECHANICAL KOLLAMNo ratings yet

- Pengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMDocument15 pagesPengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMMulYadi100% (1)

- Study of Mechanical Properties of Fiber Reinforced Concrete With Conventional ConcreteDocument2 pagesStudy of Mechanical Properties of Fiber Reinforced Concrete With Conventional ConcreteSandesh LamsalNo ratings yet

- NAS1834Document2 pagesNAS1834Ray DutchmanNo ratings yet

- H05V-K PVC Single Core Cable SpecsDocument2 pagesH05V-K PVC Single Core Cable SpecsAlicia AltamiranoNo ratings yet

- Avikote AV 650-5 PDFDocument2 pagesAvikote AV 650-5 PDFAmer Y KNo ratings yet

- BT Silfos 15 ENDocument1 pageBT Silfos 15 ENIonutCiobanuNo ratings yet

- Din 1.2714Document3 pagesDin 1.2714harieduidNo ratings yet

- Project schedule and activity timelineDocument4 pagesProject schedule and activity timelineGauri WaikarNo ratings yet

- ASTERITE® Ice Technical-Data-Sheet.1569415465Document2 pagesASTERITE® Ice Technical-Data-Sheet.1569415465Mamoon ShahidNo ratings yet

- Wall Sections-Built ExamplesDocument21 pagesWall Sections-Built ExamplesRoma Vadola100% (2)

- Hvac Valves and Actuators CatalogueDocument56 pagesHvac Valves and Actuators CatalogueMokhammad Sanpradipto JaluntoroNo ratings yet

- Plinth Area Rate 2011 12Document14 pagesPlinth Area Rate 2011 12sankum0100% (2)

- Stressing Record Sheet: Dynamic Apco Concessionaire I. E. Rep...Document4 pagesStressing Record Sheet: Dynamic Apco Concessionaire I. E. Rep...rohit kumar100% (1)

- DSI ALWAG Systems - Mechanical Anchors and Rebar Rock Bolts PDFDocument16 pagesDSI ALWAG Systems - Mechanical Anchors and Rebar Rock Bolts PDFxenNo ratings yet

- Pad footing design calculationsDocument39 pagesPad footing design calculationsismail adeizaNo ratings yet

- Buhl MannDocument2 pagesBuhl ManndsiucNo ratings yet

- SPLE - Plumbing Code No. 02 - Answer KeyDocument4 pagesSPLE - Plumbing Code No. 02 - Answer KeyAlexander Nuevo San AndresNo ratings yet

- Field Inspection ReportDocument14 pagesField Inspection ReportRanjit SinghNo ratings yet

- Paper IDocument75 pagesPaper IThe AnarchistNo ratings yet

- 75 Civil Engineering Questions & AnswersDocument2 pages75 Civil Engineering Questions & AnswersTimothy James M. MadridNo ratings yet

- Single bolt capacity and fillet weld strengthDocument17 pagesSingle bolt capacity and fillet weld strengthabhijitNo ratings yet

- Design of Beam B-1 for Proposed ApartmentDocument3 pagesDesign of Beam B-1 for Proposed ApartmentKhael Angelo Zheus JaclaNo ratings yet

- Fundamentals of Structural Engineering gnv64 PDFDocument6 pagesFundamentals of Structural Engineering gnv64 PDFAbhishekNo ratings yet

- IS 4682 Part 3 - 1969Document31 pagesIS 4682 Part 3 - 1969Lekshminarayanan SNo ratings yet

- Cmaa CM01 2019Document32 pagesCmaa CM01 2019Moren AlfonsoNo ratings yet

- FSB Novelties 2006Document60 pagesFSB Novelties 2006mrubio73No ratings yet

- KC Steel Fabricators Procedure Qualification Record for API 5L X52 PipeDocument3 pagesKC Steel Fabricators Procedure Qualification Record for API 5L X52 PipeKevin ParentNo ratings yet

- Cost Estimate GharDocument6 pagesCost Estimate GharJaved AlamNo ratings yet