Professional Documents

Culture Documents

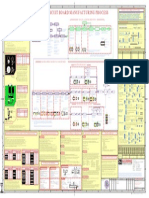

Bor PLan

Uploaded by

Budi SantonyOriginal Description:

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Bor PLan

Uploaded by

Budi SantonyCopyright:

Horizontal Directional Drilling (HDD) Bore Plan Template

Failure to provide all requested information will cause a delay or rejection of your request.

Bore Pipe Information:

Pipe Size (O.D.): _________ Pipe Material & Grade: _______________________ Weight of Pipe (lb/ft): _____________________

(Outside Diameter of pipe to be bored) HDPE must be grade SDR 11 or better (thicker wall)

Maximum size of bore hole: ______________” Number and Diameter of back reams: _______________________________________

****The maximum size of the bore hole may not exceed Outside Diameter (O.D.) x 1.5 if O.D. is 12” or less. If the O.D. is greater

than 12”, the bore hole may not exceed O.D. x 1.3 or O.D. + 12” whichever is less.

Equipment Information:

Proposed Equipment (Brand/Model): ___________________________________________________________________________________

Method of Drilling Fluid Recovery: ____________________________________________________________________________________

Maximum Drilling Machine Pullback Capabilities: ________________________________________________________________________

Minimum Drilling RPM: __________ Maximum Drilling RPM: ________________

Minimum Drilling PSI: __________ Maximum Drilling PSI: _________________

Minimum Drilling GPM: _________ Maximum Drilling GPM: _______________

Drilling Head Type: __________ Dia.: _________ in. Number/Size of Holes/Nozzles: ________________________

Back Reamer Head: Type: __________ Dia.: __________ in. Number/Size of Holes/Nozzles: ____________________

Drilling Head Fluid Pressure: Pilot Bore: _________ psi/min _________ psi/max _________ Operating psi

Back Ream: _________ psi/min _________ psi/max _________ Operating psi

Anticipated Drilling Fluid Rate: Pilot Bore: _________ gal/min Back Ream: _________ gal/min

Geotechnical: Soil Type: ______________________________________ Bearing Capacity: _______________ psi

***For bores 20” or larger; a soil boring geotechnical profile is required

Design Information: Entry Angle: __________ Exit Angle: __________ Depth: Base of rail to Top of Casing: ____________

We will adopt CSX Transportation’s Fraction Mitigation Contingency Plan for Directional Drilling: _______ (Y/N)

NOTES:

Once the bore enters CSXT property, the work must be continuous until the drilling is complete and the pipe is pulled in place.

The bore must be tracked constantly, with the location and depth marked every 10 feet.

All construction activities must comply with CSXT’s Interim Guidelines for Horizontal Directional Drilling (HDD).

The project must comply with all conditions, obligations, and additional safety precautions required by the local CSXT Division.

Owner or Contractor shall give a minimum of Thirty (30) days advance notice to CSXT Representative for anticipated need for Flagging

and Inspection service. No work shall be undertaken until the Flag Person(s) and Inspector(s) are at the job site.

Drilling fluid with Bentonite additive is required.

Dry Bores and Wet Bores (Jetting) are not allowed.

To minimize the potential of the bore hole collapsing, all back reaming must utilize trailing rods.

Last revised February 22, 2016

You might also like

- Pumping Test FormDocument4 pagesPumping Test FormdisassociatedNo ratings yet

- Production Engineering: Jig and Tool DesignFrom EverandProduction Engineering: Jig and Tool DesignRating: 4 out of 5 stars4/5 (9)

- KickOff Plug Job Procedure 1Document6 pagesKickOff Plug Job Procedure 1محمد سعيدNo ratings yet

- Katalog PeralatanDocument438 pagesKatalog PeralatanSurya Kazu MaruNo ratings yet

- Drilling Application: Name of Company: Well Name & Number: Date: July 12, 2013Document1 pageDrilling Application: Name of Company: Well Name & Number: Date: July 12, 2013scrbdgharaviNo ratings yet

- Shop& FLD Train GDocument64 pagesShop& FLD Train GaripramonoNo ratings yet

- PRO2000Document72 pagesPRO2000scrbdgharaviNo ratings yet

- 4 RFQ - DSPM000576Document6 pages4 RFQ - DSPM000576GigiNo ratings yet

- Repair Procedure - Zpi-3lpe-01Document3 pagesRepair Procedure - Zpi-3lpe-01Suresh KrishnanNo ratings yet

- Drill Collar According To DS1Document1 pageDrill Collar According To DS1Hayder Habib100% (1)

- DCS 006 29.03.10 Perforation of UPVC PipesDocument4 pagesDCS 006 29.03.10 Perforation of UPVC Pipesmirza057No ratings yet

- WD946-EZ300-00009 Procedure For Painting Rev 0Document21 pagesWD946-EZ300-00009 Procedure For Painting Rev 0Manuel BurdilesNo ratings yet

- SVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage TankDocument4 pagesSVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage Tanknguyenquoc1988100% (1)

- Repair Procedure CBR 3lpe 00Document3 pagesRepair Procedure CBR 3lpe 00Suresh KrishnanNo ratings yet

- Confidential: FGD Inquiry SheetDocument1 pageConfidential: FGD Inquiry SheetChevronelleNo ratings yet

- Owner: Project:: Hindustan Oil Exploration Company Ltd. (HOEC) PY-1 Gas Processing FacilityDocument8 pagesOwner: Project:: Hindustan Oil Exploration Company Ltd. (HOEC) PY-1 Gas Processing FacilityjackNo ratings yet

- Concrete Placement RecordDocument1 pageConcrete Placement RecordRoshin99100% (1)

- Owner Project: LSTK Contractor: A Issued For Information REV Date Purpose Prepared BY Checked by Approved BYDocument1 pageOwner Project: LSTK Contractor: A Issued For Information REV Date Purpose Prepared BY Checked by Approved BYAlvin SmithNo ratings yet

- DS-1 Volume 4 Addendum PDFDocument15 pagesDS-1 Volume 4 Addendum PDFMuhammad Bilal KhattakNo ratings yet

- Drilling Tools & Subs Inspection Report: Visual Body, Visual Connections, Blacklight Connections, Dimensional 3Document18 pagesDrilling Tools & Subs Inspection Report: Visual Body, Visual Connections, Blacklight Connections, Dimensional 3Michael OkwuwaNo ratings yet

- Tender 5126Document267 pagesTender 5126tahir_rubbani6985No ratings yet

- DHG-PVE-DD-1-IN-BOD-101 Design Basis For Instrumentation - A - 290714 PDFDocument40 pagesDHG-PVE-DD-1-IN-BOD-101 Design Basis For Instrumentation - A - 290714 PDFhai_solincvnNo ratings yet

- 90206-000-CV-SP-107 SPECIFICATION FOR Grouting IN ALL AREAS (Rev.A0) PDFDocument10 pages90206-000-CV-SP-107 SPECIFICATION FOR Grouting IN ALL AREAS (Rev.A0) PDFamini_mohiNo ratings yet

- Drilling Programme - ChecklistDocument5 pagesDrilling Programme - ChecklistFill Jose100% (1)

- General SpecificationsDocument20 pagesGeneral SpecificationsMohannad Al RayesNo ratings yet

- Feasibilty Radial Drilling RevisedDocument8 pagesFeasibilty Radial Drilling RevisedAbrar Ahmed KhanNo ratings yet

- F-PMD-001 - Rev2 - Concrete Pouring RequestDocument1 pageF-PMD-001 - Rev2 - Concrete Pouring RequestAlexander RaposasNo ratings yet

- Gas Liquid Liquid Solid Separator Application Data Sheet - Rev 7.31.15 - 2Document2 pagesGas Liquid Liquid Solid Separator Application Data Sheet - Rev 7.31.15 - 2Eryl YeongNo ratings yet

- Summary of Bitumen Spraying Rate Test Results For The Period .... / .... / . To ../ ../ .Document34 pagesSummary of Bitumen Spraying Rate Test Results For The Period .... / .... / . To ../ ../ .clementwongpyNo ratings yet

- Determing Calculation For Repair of Storage TankDocument4 pagesDeterming Calculation For Repair of Storage TankHendra Yudistira100% (2)

- Blasting Coating ProcedureDocument61 pagesBlasting Coating ProcedureZohair Aftab100% (1)

- Part 2: Statement of Requirements: Rocurement Eference O: Domestic DDF Water 02/2021Document6 pagesPart 2: Statement of Requirements: Rocurement Eference O: Domestic DDF Water 02/2021nyasha moyoNo ratings yet

- 7-Concrete Pouring RequestDocument2 pages7-Concrete Pouring Requestkoyangi jagiyaNo ratings yet

- 2014 Hilti Hit-Hy 200 With Hit-ZDocument5 pages2014 Hilti Hit-Hy 200 With Hit-ZDifa LiuNo ratings yet

- Process Design Basis Process Design BasisDocument17 pagesProcess Design Basis Process Design Basisdeion29100% (3)

- Opss - Prov 932: Ontario Provincial Standard SpecificationDocument10 pagesOpss - Prov 932: Ontario Provincial Standard SpecificationRaymondLeungNo ratings yet

- CVP32Document17 pagesCVP32boypardedeNo ratings yet

- F 321 Inspection Request For Back FillingDocument1 pageF 321 Inspection Request For Back FillingSaad Al Deen HashemNo ratings yet

- Clubhouse-ID Works-Addendum No 2 To Tender PDFDocument33 pagesClubhouse-ID Works-Addendum No 2 To Tender PDFVietHungCao100% (1)

- Rabigh RequirementDocument33 pagesRabigh RequirementKris TolentinoNo ratings yet

- INF 2887378 PCB Fab WallchartDocument1 pageINF 2887378 PCB Fab Wallchartnoman888100% (1)

- 2013 Hilti Hit-Hy 200 With His - (R) NDocument4 pages2013 Hilti Hit-Hy 200 With His - (R) NDifa LiuNo ratings yet

- Project Report: Design of Mould & Press ToolDocument67 pagesProject Report: Design of Mould & Press ToolBharat SinghNo ratings yet

- Capron PDFDocument14 pagesCapron PDFKrishna ChaturvediNo ratings yet

- HDD Applications and ProcessDocument6 pagesHDD Applications and Processcatalinboja1100% (1)

- The Determination of In-Place Stiffness by The Dynamic Cone Penetrometer (DCP)Document7 pagesThe Determination of In-Place Stiffness by The Dynamic Cone Penetrometer (DCP)bluemoon1172No ratings yet

- LS - prt.TUB.068 Sub InspectionDocument5 pagesLS - prt.TUB.068 Sub InspectionAlphonse YACKAMAMBO DIBACKANo ratings yet

- Natural Gas Piping DesignDocument104 pagesNatural Gas Piping DesignnguyenmainamNo ratings yet

- Section - Iii: 1 Compound Wall - Non SEZ Area 15,269,242.00Document10 pagesSection - Iii: 1 Compound Wall - Non SEZ Area 15,269,242.00Ravi Shankar KolluruNo ratings yet

- C Pump SP Sheet1 PDFDocument1 pageC Pump SP Sheet1 PDFladreidNo ratings yet

- Diy - CNC Router TableDocument53 pagesDiy - CNC Router Tablezaoioaz100% (4)

- Work OrderDocument16 pagesWork Orderalankar realitiesNo ratings yet

- Fire Water Make Up PumpDocument7 pagesFire Water Make Up PumpAlvin SmithNo ratings yet

- 010-MS For Grouting PDFDocument33 pages010-MS For Grouting PDFKöksal PatanNo ratings yet

- Indian Oil Corporation Limited: CIN - L23201MH1959GOI011388Document10 pagesIndian Oil Corporation Limited: CIN - L23201MH1959GOI011388Yatendra TyagiNo ratings yet

- 07 HM-20120718RPH051052 - 1Document17 pages07 HM-20120718RPH051052 - 1AmitabhaNo ratings yet

- Statement of Inquiry GombaDocument26 pagesStatement of Inquiry Gomba2021acek1407fNo ratings yet

- Shell & Tube Heat ExchangerDocument9 pagesShell & Tube Heat ExchangerSushant PaiNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Pipeline Post Trenching Pre Qualification Document Offshore Offshore ConstructionDocument33 pagesPipeline Post Trenching Pre Qualification Document Offshore Offshore ConstructionBudi Santony100% (2)

- 161 Daftar Lelang Bucket Wheel Conveyor Bottom Ash Handling BanjarsariDocument2 pages161 Daftar Lelang Bucket Wheel Conveyor Bottom Ash Handling BanjarsariBudi SantonyNo ratings yet

- Qra Version FDocument60 pagesQra Version Fbukaro85No ratings yet

- Offshore Risk Assessment - Methods and ToolsDocument80 pagesOffshore Risk Assessment - Methods and ToolsBudi SantonyNo ratings yet

- Epc3 Free Span Correction Procedure d1Document33 pagesEpc3 Free Span Correction Procedure d1Budi SantonyNo ratings yet

- Rab PdamDocument3 pagesRab PdamBudi SantonyNo ratings yet

- Air Insulated Medium VOltage Compact SwitchgearsDocument56 pagesAir Insulated Medium VOltage Compact SwitchgearsBudi SantonyNo ratings yet

- Chap 2Document1 pageChap 2Budi SantonyNo ratings yet

- Drum Plan Paket-8 (2017-03-07)Document1 pageDrum Plan Paket-8 (2017-03-07)Budi SantonyNo ratings yet

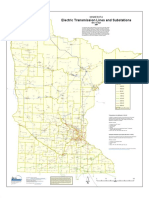

- Transmission Line Models PDFDocument17 pagesTransmission Line Models PDFDBachai84No ratings yet

- Subdesignvol1 PDFDocument50 pagesSubdesignvol1 PDFgeoghoNo ratings yet

- DPR PT Adiartha SwabuanaDocument1 pageDPR PT Adiartha SwabuanaBudi SantonyNo ratings yet

- Cable Entries Pipe Entries Sub StationsDocument24 pagesCable Entries Pipe Entries Sub StationsBudi SantonyNo ratings yet

- Preventative Maintenance For 15 KV Metal-Clad SwitchgerDocument172 pagesPreventative Maintenance For 15 KV Metal-Clad SwitchgerBudi SantonyNo ratings yet

- 06B1 e 0020Document8 pages06B1 e 0020Budi SantonyNo ratings yet

- SEC StdsDocument65 pagesSEC Stdserson1981No ratings yet

- SwicthgerDocument6 pagesSwicthgerBudi SantonyNo ratings yet

- Install Manual Outdoor Gear PDFDocument37 pagesInstall Manual Outdoor Gear PDFAndres AguirreNo ratings yet

- GAS-INSULATED SWITCHGEARELK-14 & THE MODULAR SYSTEM FOR GIS 245kV PDFDocument24 pagesGAS-INSULATED SWITCHGEARELK-14 & THE MODULAR SYSTEM FOR GIS 245kV PDFBudi SantonyNo ratings yet

- Transmission Line and Substation ComponentsDocument72 pagesTransmission Line and Substation ComponentsAbbas KeyvanNo ratings yet

- Pita Grounding Yang Sudah TerpasangDocument17 pagesPita Grounding Yang Sudah TerpasangBudi SantonyNo ratings yet

- Dead End Tubular Steel MonopoleDocument2 pagesDead End Tubular Steel MonopoleBudi SantonyNo ratings yet

- INSTALL MANUAL Indoor and Outdoor Medium Voltage Metal-Clad Switchgear Outdoor Power Control EnclosureDocument7 pagesINSTALL MANUAL Indoor and Outdoor Medium Voltage Metal-Clad Switchgear Outdoor Power Control EnclosureBudi SantonyNo ratings yet

- Gap c1 PDFDocument4 pagesGap c1 PDFBudi SantonyNo ratings yet

- Hdpe Physical PropertiesDocument10 pagesHdpe Physical PropertiesGabriel Lopez BarajasNo ratings yet

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- A. Days: HDD Calculator For AVTECH TVI Camera RecordingDocument2 pagesA. Days: HDD Calculator For AVTECH TVI Camera RecordingBudi SantonyNo ratings yet

- Current Design PracticeDocument14 pagesCurrent Design Practicejakeer7No ratings yet

- Dead End Tubular Steel Monopole PDFDocument15 pagesDead End Tubular Steel Monopole PDFBudi SantonyNo ratings yet

- Polymer ProDocument25 pagesPolymer ProJeerisuda KingklangNo ratings yet

- Jurnal RustamDocument15 pagesJurnal RustamRustamNo ratings yet

- Unipole Multipole-973098Document225 pagesUnipole Multipole-973098Medes GraciaNo ratings yet

- SM Electrical Guidelines: General Notes:: Site HereDocument1 pageSM Electrical Guidelines: General Notes:: Site HereNathaniel DreuNo ratings yet

- NOTIFIER ERCES-Bi-Directional Amplifier Systems (BDA) Webinar 6-4-2019Document50 pagesNOTIFIER ERCES-Bi-Directional Amplifier Systems (BDA) Webinar 6-4-2019culeros1No ratings yet

- B 700 FDocument25 pagesB 700 FMohammed HdyliNo ratings yet

- 2457-Article Text-14907-2-10-20120724Document6 pages2457-Article Text-14907-2-10-20120724desi meleniaNo ratings yet

- A Novel Procedure For Transient CFD Modeling of Basin Solar Stills, Coupling of Species and Energy EquationsDocument16 pagesA Novel Procedure For Transient CFD Modeling of Basin Solar Stills, Coupling of Species and Energy EquationsAverroesNo ratings yet

- Eaton BECOPAD P Range TechnicalDataSheet enDocument4 pagesEaton BECOPAD P Range TechnicalDataSheet enEsteban Fernando Meza IbacetaNo ratings yet

- WAUZZZ8K0BA159120Document10 pagesWAUZZZ8K0BA159120Vedad VedaddNo ratings yet

- Location: Map of Naga CityDocument2 pagesLocation: Map of Naga Citycatherine boragayNo ratings yet

- Osteoarthritis DissertationDocument8 pagesOsteoarthritis DissertationPaperHelpJackson100% (1)

- Pre-Feasibility Report: at Plot No. 15/B-3, Jigani Industrial Area Anekal Taluk, Bangalore South District Karnataka byDocument41 pagesPre-Feasibility Report: at Plot No. 15/B-3, Jigani Industrial Area Anekal Taluk, Bangalore South District Karnataka by12mchc07No ratings yet

- JAMB Biology Past Questions 1983 - 2004Document55 pagesJAMB Biology Past Questions 1983 - 2004Keith MooreNo ratings yet

- Colonel SandersDocument17 pagesColonel SandersAmandaNo ratings yet

- Asking and Showing Rooms in Hospital2Document17 pagesAsking and Showing Rooms in Hospital2Roland DelNo ratings yet

- Review Related LiteratureDocument3 pagesReview Related LiteratureHanz EspirituNo ratings yet

- Jan Precious Mille BDocument1 pageJan Precious Mille BJebjeb C. BrañaNo ratings yet

- Registration of Hindu Marriage: A Project On Family Law-IDocument22 pagesRegistration of Hindu Marriage: A Project On Family Law-Iamit dipankarNo ratings yet

- Carapace DigitalDocument15 pagesCarapace DigitalVillain ChatNo ratings yet

- Genomics and Crop ImprovementDocument56 pagesGenomics and Crop Improvementsenguvelan100% (6)

- AIR Modeller 78 2018Document68 pagesAIR Modeller 78 2018StefanoNo ratings yet

- Knopp2017 Article OnceACheaterAlwaysACheaterSeriDocument11 pagesKnopp2017 Article OnceACheaterAlwaysACheaterSeriAnda F. CotoarăNo ratings yet

- X FEDEX EIDocument13 pagesX FEDEX EINISREEN WAYANo ratings yet

- Plumber PDFDocument68 pagesPlumber PDFshehanNo ratings yet

- High Voltage - WikipediaDocument7 pagesHigh Voltage - WikipediaMasudRanaNo ratings yet

- Exercise 3 ASC0304 - 2019-1Document2 pagesExercise 3 ASC0304 - 2019-1Nuraina NabihahNo ratings yet

- Battle Healing PrayerDocument9 pagesBattle Healing PrayerSolavei LoanerNo ratings yet

- FALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewDocument51 pagesFALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewVAHEESNo ratings yet

- Recipe Book: Yule Logs 2020Document28 pagesRecipe Book: Yule Logs 2020Cwt Chan100% (1)