Professional Documents

Culture Documents

Astar 02

Uploaded by

HAKANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astar 02

Uploaded by

HAKANCopyright:

Available Formats

Technical Data Sheet

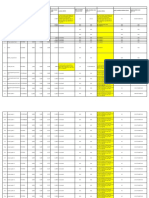

Approved 582;583;1525 1,2 582 zinc ethyl silicate ^(ValidationDate) 1

Muki Z 2001

Product description

This is a two component inorganic low zinc moisture curing zinc ethyl silicate coating. It is a shop primer

designed for very high welding and cutting speed, giving reduced weld porosity and back burning. It is fast

drying and has good abrasion resistance making it suitable for stacking shortly after application. Can be used as

temporary primer in a new construction phase or as primer in a complete coating system in atmospheric and

immersed environments. Suitable for properly prepared carbon steel substrates and recommended to be applied

in an automated shop priming line. Compatible with advanced welding technologies including MIG, MAG and G-

FCAW.

Typical use

Marine:

Suitable as shop primer for entire vessels.

Protective:

Suitable for structural steel and piping to be exposed to corrosive environments up to very high and immersed.

Recommended for offshore environments, refineries, power plants, bridges, buildings, mining equipment and

general structural steel.

Other

Approvals and certificates

Approved for PSPC for Water Ballast Tanks according to IMO Res. MSC 215(82)

Welding approved according to DVS-guideline 0501

Type approved as shop primer by DNV

Type approved shop primer according to PSPC IMO Res. MSC 82/W

Type approved shop primer for Germanischer Lloyd

Health approved for use as shop primer by FORCE institute

Additional certificates and approvals may be available on request.

Colours

green, grey, red

Product data

Property Test/Standard Description

Solids by volume OCCA Monograph No. 4 28 ± 2 %

Gloss level (GU 60 °) ISO 2813 matt (0-35)

Flash point ISO 3679 Method 1 14 °C

Density calculated 1.4 kg/l

VOC-US/Hong Kong US EPA Method (theoretical) 616 g/l

(CARB(SCM)2007, SCAQMD rule 1113, Hong Kong)

VOC-EU IED (2010/75/EU) (theoretical) 628 g/l

VOC-Korea Korea Clean Air Conservation Act (tested) 662 g/l

The provided data is typical for factory produced products, subject to slight variation depending on colour.

All data is valid for mixed paint.

Gloss description: According to Jotun Performance Coatings' definition.

Date of issue: 19 March 2018 Page: 1/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Muki Z 2001

Film thickness per coat

Typical recommended specification range

Dry film thickness 15 - 20 μm

Wet film thickness 55 - 70 μm

Theoretical spreading rate 18.7 - 14 m²/l

Surface preparation

To secure lasting adhesion to the subsequent product all surfaces shall be clean, dry and free from any

contamination.

Surface preparation summary table

Surface preparation

Substrate Minimum Recommended

Carbon steel Sa 2½ (ISO 8501-1) Sa 2½ (ISO 8501-1)

Application

Application methods

The product can be applied by

Spray: Use air spray or airless spray.

Brush: Recommended for touch-up purposes.

Product mixing ratio (by volume)

Muki Z 2001 Comp A 10 part(s)

Muki Z 2001 Comp B 6.75 part(s)

Thinner/Cleaning solvent

Thinner: Jotun Thinner No. 4 / Jotun Thinner No. 25

Jotun Thinner No. 4: for fast evaporation.

Jotun Thinner No. 25: for slow evaporation.

Guiding data for airless spray

Nozzle tip (inch/1000): 15-23

Pressure at nozzle (minimum): 50 bar/700 psi

Date of issue: 19 March 2018 Page: 2/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Muki Z 2001

Drying and Curing time

Substrate temperature 23 °C 40 °C

Surface (touch) dry 1 min 20 sec

Walk-on-dry 3 min 1 min

Dry to over coat, minimum 1d 1d

Dried/cured for service 1d 1d

Dried/cured for immersion 1d 1d

For maximum overcoating intervals, refer to the Application Guide (AG) for this product.

Drying and curing times are determined under controlled temperatures and relative humidity below 85 %, and

at average of the DFT range for the product.

Surface (touch) dry: The state of drying when slight pressure with a finger does not leave an imprint or reveal

tackiness.

Walk-on-dry: Minimum time before the coating can tolerate normal foot traffic without permanent marks,

imprints or other physical damage.

Dry to over coat, minimum: The recommended shortest time before the next coat can be applied.

Dried/cured for service: Minimum time before the coating can be permanently exposed to the intended

environment/medium.

Dried/cured for immersion: Minimum time before the coating can be permanently immersed in sea water.

Induction time and Pot life

Paint temperature 23 °C

Pot life 24 h

Heat resistance

Temperature

Continuous Peak

Dry, atmospheric 400 °C 400 °C

Immersed, sea water 50 °C 50 °C

Peak temperature duration max. 1 hour.

The temperatures listed relate to retention of protective properties. Aesthetic properties may suffer at these

temperatures.

Note that the coating will be resistant to various immersion temperatures depending on the specific chemical

and whether immersion is constant or intermittent. Heat resistance is influenced by the total coating system. If

used as part of a system, ensure all coatings in the system have similar heat resistance.

Date of issue: 19 March 2018 Page: 3/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Muki Z 2001

Product compatibility

Depending on the actual exposure of the coating system, various primers and topcoats can be used in

combination with this product. Some examples are shown below. Contact Jotun for specific system

recommendation.

Subsequent coat: epoxy, epoxy mastic, alkyd, acrylic, zinc epoxy

Packaging (typical)

Volume Size of containers

(litres) (litres)

Muki Z 2001 Comp A 10 10

Muki Z 2001 Comp B 6.75 20

The volume stated is for factory made colours. Note that local variants in pack size and filled volumes can vary

due to local regulations.

Storage

The product must be stored in accordance with national regulations. Keep the containers in a dry, cool, well

ventilated space and away from sources of heat and ignition. Containers must be kept tightly closed. Handle

with care.

Shelf life at 23 °C

Muki Z 2001 Comp A 6 month(s)

Muki Z 2001 Comp B 24 month(s)

In some markets commercial shelf life can be dictated shorter by local legislation. The above is minimum shelf

life, thereafter the paint quality is subject to re-inspection.

Caution

This product is for professional use only. The applicators and operators shall be trained, experienced and have

the capability and equipment to mix/stir and apply the coatings correctly and according to Jotun's technical

documentation. Applicators and operators shall use appropriate personal protection equipment when using this

product. This guideline is given based on the current knowledge of the product. Any suggested deviation to suit

the site conditions shall be forwarded to the responsible Jotun representative for approval before commencing

the work.

Health and safety

Please observe the precautionary notices displayed on the container. Use under well ventilated conditions. Do

not inhale spray mist. Avoid skin contact. Spillage on the skin should immediately be removed with suitable

cleanser, soap and water. Eyes should be well flushed with water and medical attention sought immediately.

Colour variation

Date of issue: 19 March 2018 Page: 4/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Muki Z 2001

When applicable, products primarily meant for use as primers or antifoulings may have slight colour variations

from batch to batch. Such products may fade and chalk when exposed to sunlight and weathering.

Disclaimer

The information in this document is given to the best of Jotun's knowledge, based on laboratory testing and

practical experience. Jotun's products are considered as semi-finished goods and as such, products are often

used under conditions beyond Jotun's control. Jotun cannot guarantee anything but the quality of the product

itself. Minor product variations may be implemented in order to comply with local requirements. Jotun reserves

the right to change the given data without further notice.

Users should always consult Jotun for specific guidance on the general suitability of this product for their needs

and specific application practices.

If there is any inconsistency between different language issues of this document, the English (United Kingdom)

version will prevail.

Date of issue: 19 March 2018 Page: 5/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

You might also like

- Muki Z 2001Document5 pagesMuki Z 2001CESAR CHAVEZNo ratings yet

- TDS 582 Muki+Z+2001 Euk GBDocument5 pagesTDS 582 Muki+Z+2001 Euk GBIsyfi QulubanaNo ratings yet

- Muki Z 2001: Technical Data SheetDocument5 pagesMuki Z 2001: Technical Data SheetIan PerdanaNo ratings yet

- Resist 65: Technical Data SheetDocument5 pagesResist 65: Technical Data Sheetchristian210789No ratings yet

- Penguard Express ZP: Technical Data SheetDocument5 pagesPenguard Express ZP: Technical Data Sheetinfospinster0% (1)

- Marathon 1000 GF Technical Data SheetDocument5 pagesMarathon 1000 GF Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Technical Data Sheet for Epoxy Mastic CoatingDocument5 pagesTechnical Data Sheet for Epoxy Mastic CoatingRamlialianNo ratings yet

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- Technical Data Sheet for Barrier 80 Zinc Epoxy PrimerDocument5 pagesTechnical Data Sheet for Barrier 80 Zinc Epoxy PrimerBalaji GuruNo ratings yet

- Technical Data Sheet for Zinc-Rich PrimerDocument5 pagesTechnical Data Sheet for Zinc-Rich PrimerJayaraman KamarajNo ratings yet

- TDS 11480 Pilot ACR Euk GBDocument5 pagesTDS 11480 Pilot ACR Euk GBeeng gilangNo ratings yet

- Technical Data Sheet for Zinc-Rich PrimerDocument5 pagesTechnical Data Sheet for Zinc-Rich PrimerRohit KambleNo ratings yet

- Barrier SmartpackDocument5 pagesBarrier SmartpackMhd EbalNo ratings yet

- TDS 15520 Jotaguard 630 Euk GBDocument5 pagesTDS 15520 Jotaguard 630 Euk GBNilu RohmanNo ratings yet

- TDS - 2080 - Penguard Midcoat - Euk - GBDocument5 pagesTDS - 2080 - Penguard Midcoat - Euk - GBRifki ArifinNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- Penguard Midcoat MIO: Technical Data SheetDocument4 pagesPenguard Midcoat MIO: Technical Data Sheetgst ajahNo ratings yet

- Tds - TDS 9804 Jotaguard 82 Euk GBDocument5 pagesTds - TDS 9804 Jotaguard 82 Euk GBRicardo CarvalhoNo ratings yet

- Technical Data Sheet - Jotun Jotatemp 540 ZincDocument5 pagesTechnical Data Sheet - Jotun Jotatemp 540 ZincPolem IskandarNo ratings yet

- Tankguard Flexline Technical Data SheetDocument5 pagesTankguard Flexline Technical Data Sheetraza.slietNo ratings yet

- Datasheet Penguard TopcoatDocument5 pagesDatasheet Penguard Topcoatabdulgafoor54No ratings yet

- TDS - Resist 65Document5 pagesTDS - Resist 65Teknik produksi wikonNo ratings yet

- Jotaprime 500: Technical Data SheetDocument5 pagesJotaprime 500: Technical Data SheetRudhi AfghaniNo ratings yet

- Tankguard Zinc Jotun PaintDocument5 pagesTankguard Zinc Jotun PaintGurdeep Sungh AroraNo ratings yet

- TDS - Tankguard Zinc - Issued 01.08.2014Document5 pagesTDS - Tankguard Zinc - Issued 01.08.2014Arya Kemal Pratama PutraNo ratings yet

- Jotun Muki EPS PDS Promain 09 09 2022Document5 pagesJotun Muki EPS PDS Promain 09 09 2022이선엽No ratings yet

- Barrier Smart Pack Jotun PaintDocument5 pagesBarrier Smart Pack Jotun PaintGurdeep Sungh AroraNo ratings yet

- TDS 765 Vinyguard Silvergrey 88 Euk GBDocument5 pagesTDS 765 Vinyguard Silvergrey 88 Euk GBlasse.hamre98No ratings yet

- Technical Data Sheet for Safeguard Universal ES Tie CoatDocument5 pagesTechnical Data Sheet for Safeguard Universal ES Tie CoatIsaacNarendraAkbarNo ratings yet

- Technical Data Sheet for Barrier 80 S Zinc Epoxy PrimerDocument5 pagesTechnical Data Sheet for Barrier 80 S Zinc Epoxy PrimerHung Mai VanNo ratings yet

- Technical Data Sheet for Epoxy Mastic CoatingDocument5 pagesTechnical Data Sheet for Epoxy Mastic CoatingJayasurya PaluriNo ratings yet

- Technical Data Sheet for Penguard TopcoatDocument5 pagesTechnical Data Sheet for Penguard TopcoatajuhaseenNo ratings yet

- Technical Data Sheet for High-Performance Epoxy CoatingDocument5 pagesTechnical Data Sheet for High-Performance Epoxy CoatingDamar WardhanaNo ratings yet

- Resist 86: Technical Data SheetDocument5 pagesResist 86: Technical Data SheetantonyfmNo ratings yet

- Marathon 1000 GFDocument5 pagesMarathon 1000 GFNabeel K SNo ratings yet

- Technical Data Sheet for Epoxy CoatingDocument5 pagesTechnical Data Sheet for Epoxy CoatingPablo Ahumada G.No ratings yet

- TDS 20920 Penguard HSP ZP Euk GBDocument5 pagesTDS 20920 Penguard HSP ZP Euk GBpavan kumarNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake Specialmajmor-1No ratings yet

- Alkyd Primer Technical Data SheetDocument5 pagesAlkyd Primer Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Technical Data Sheet for Zinc PrimerDocument4 pagesTechnical Data Sheet for Zinc PrimerBiju_PottayilNo ratings yet

- Jotatemp 540 Zinc Technical Data SheetDocument5 pagesJotatemp 540 Zinc Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Hardtop Optima PDFDocument5 pagesHardtop Optima PDFBiju_PottayilNo ratings yet

- Hardtop Optima: Technical Data SheetDocument5 pagesHardtop Optima: Technical Data SheetBiju_PottayilNo ratings yet

- Hardtop XPL: Technical Data SheetDocument5 pagesHardtop XPL: Technical Data SheetRACHED ABBOUDNo ratings yet

- TDS Penguard HSP ZP GB English ProtectiveDocument5 pagesTDS Penguard HSP ZP GB English Protective폴로 쥰 차No ratings yet

- JotundatasheetsDocument172 pagesJotundatasheetsAli MudhafarNo ratings yet

- TDS Penguard Midcoat M20 (Midcoat)Document5 pagesTDS Penguard Midcoat M20 (Midcoat)rndsb.aopNo ratings yet

- TDS 5340 Penguard HB II Euk GBDocument5 pagesTDS 5340 Penguard HB II Euk GBmybottle6996No ratings yet

- Express MIO 80Document5 pagesExpress MIO 80shnauserNo ratings yet

- P68 M13 Painting Documents PDFDocument708 pagesP68 M13 Painting Documents PDFJohn TerryNo ratings yet

- TDS Stainless Steel Paint Jotamastic 70Document5 pagesTDS Stainless Steel Paint Jotamastic 70rndsb.aopNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- MoM TemplateDocument2 pagesMoM TemplateHAKANNo ratings yet

- CV Template-01Document4 pagesCV Template-01HAKANNo ratings yet

- CV TemplateDocument4 pagesCV TemplateHAKANNo ratings yet

- Map of Roads 5-7Document1 pageMap of Roads 5-7HAKANNo ratings yet

- CPR 520 Doroport Alesd Rev 2020 En-RevDocument1 pageCPR 520 Doroport Alesd Rev 2020 En-RevHAKANNo ratings yet

- Road Construction-DME - QC - CIVIL - RMA - 0001 - Approved AC2Document30 pagesRoad Construction-DME - QC - CIVIL - RMA - 0001 - Approved AC2HAKANNo ratings yet

- rs0021 RMX OradeaDocument3 pagesrs0021 RMX OradeaHAKANNo ratings yet

- 49 Dop Doroport TB 25 Ae v3 Feb 21 En-RevDocument1 page49 Dop Doroport TB 25 Ae v3 Feb 21 En-RevHAKANNo ratings yet

- EF-2019-012-5671D005-000 Rev06 - As-Built PDFDocument1 pageEF-2019-012-5671D005-000 Rev06 - As-Built PDFHAKANNo ratings yet

- 16.11.2021 - Method Statement - Road WorksDocument17 pages16.11.2021 - Method Statement - Road WorksHAKANNo ratings yet

- Road Works - ChecklistDocument3 pagesRoad Works - ChecklistHAKAN100% (1)

- HIL0480 (EFOR) - Mesh Sertifikası PDFDocument2 pagesHIL0480 (EFOR) - Mesh Sertifikası PDFHAKANNo ratings yet

- Road Schedule Concept.v2Document1 pageRoad Schedule Concept.v2HAKANNo ratings yet

- Pde-Cvc-0970-Ec-00001 - 000 - 00 - Tehnical Descriprion - Road DesignDocument19 pagesPde-Cvc-0970-Ec-00001 - 000 - 00 - Tehnical Descriprion - Road DesignHAKANNo ratings yet

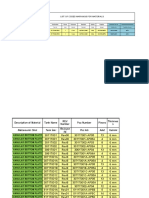

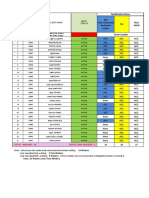

- List of Coded Markings For Materials (Eksik sertifikaANNULAR-BOTTOM-RING) - 8.09.2020Document17 pagesList of Coded Markings For Materials (Eksik sertifikaANNULAR-BOTTOM-RING) - 8.09.2020HAKANNo ratings yet

- NO Welder Id Welder Name: Team LeaderDocument1 pageNO Welder Id Welder Name: Team LeaderHAKANNo ratings yet

- Api Ast Subcommittee: Impact: Minimal 620 Appendix X-Duplex Stainless Steel Storage Tanks X.1 ScopeDocument14 pagesApi Ast Subcommittee: Impact: Minimal 620 Appendix X-Duplex Stainless Steel Storage Tanks X.1 ScopeHAKANNo ratings yet

- WPS & PQRDocument84 pagesWPS & PQRjoseph.maquez24100% (4)

- Detecting Harmful Phases in Duplex SteelDocument9 pagesDetecting Harmful Phases in Duplex SteelutreshwarmiskinNo ratings yet

- Insulation (ROOF) Insulation (SHELL) : R L) D H)Document6 pagesInsulation (ROOF) Insulation (SHELL) : R L) D H)HAKANNo ratings yet

- 8 WeldingofduplexstainlesssteelsDocument39 pages8 WeldingofduplexstainlesssteelsHAKANNo ratings yet

- İş Programı Montaj Planlaması-Rev01Document1 pageİş Programı Montaj Planlaması-Rev01HAKANNo ratings yet

- RFIDocument1 pageRFIHAKANNo ratings yet

- CU-0845 - Survey of Platforms LevelDocument4 pagesCU-0845 - Survey of Platforms LevelHAKANNo ratings yet

- Polyol ProjectDocument1 pagePolyol ProjectHAKANNo ratings yet

- Rti Brochure Process Manual - Na - en PDFDocument189 pagesRti Brochure Process Manual - Na - en PDFHAKANNo ratings yet

- POLYOLWELDGAS 01rev 02Document1 pagePOLYOLWELDGAS 01rev 02HAKANNo ratings yet

- Pre Int Sample Unit PDFDocument12 pagesPre Int Sample Unit PDFHAKANNo ratings yet

- RFIDocument1 pageRFIHAKANNo ratings yet

- Approximate RT Calculation For API 650 TankDocument2 pagesApproximate RT Calculation For API 650 Tankjayaarnav100% (6)

- SCM25 steel alloy properties and applicationsDocument1 pageSCM25 steel alloy properties and applicationsPeterWayNo ratings yet

- Mid-Term Test 2012Document9 pagesMid-Term Test 2012Muhammad FauzanNo ratings yet

- Makoto Tsubota - Quantum Turbulence: From Superfluid Helium To Atomic Bose-Einstein CondensatesDocument49 pagesMakoto Tsubota - Quantum Turbulence: From Superfluid Helium To Atomic Bose-Einstein CondensatesQMDhidnwNo ratings yet

- M.Sc. Previous, Analytical Chemistry: Paper-Iv MAX: MARKS: 100Document4 pagesM.Sc. Previous, Analytical Chemistry: Paper-Iv MAX: MARKS: 100Ƞƛǝǝm KĦáńNo ratings yet

- DSSC PresentationDocument50 pagesDSSC PresentationWisaruth MaethasithNo ratings yet

- Lewatit Monoplus TP 260: Product InformationDocument5 pagesLewatit Monoplus TP 260: Product InformationChang Chee HongNo ratings yet

- Ecosystem Poster - Introduction and RubricDocument7 pagesEcosystem Poster - Introduction and Rubricapi-271661638No ratings yet

- Freezing, Melting, and EvaporationDocument81 pagesFreezing, Melting, and EvaporationKris Paolo CamiasNo ratings yet

- Fujikura 12S CDocument2 pagesFujikura 12S CCristian BolañosNo ratings yet

- Giacoqest 0164en-General CatalogueDocument32 pagesGiacoqest 0164en-General CatalogueMartin CervasioNo ratings yet

- 1732Document30 pages1732rikechNo ratings yet

- The Report ofDocument8 pagesThe Report ofAhyana RehaniNo ratings yet

- ITT American Electric Power-Pad Horizontal Cutoff Series 213 & 214 Spec Sheet 9-81Document8 pagesITT American Electric Power-Pad Horizontal Cutoff Series 213 & 214 Spec Sheet 9-81Alan MastersNo ratings yet

- Relationship Between Polarity and PropertiesDocument12 pagesRelationship Between Polarity and PropertiesJustine KylaNo ratings yet

- Step By Step Guide to Free Energy Lesson 1Document1 pageStep By Step Guide to Free Energy Lesson 1vandor_ouNo ratings yet

- 6 Warna Water Based Inkjet InkDocument21 pages6 Warna Water Based Inkjet InksabunbeningNo ratings yet

- 2017 Sato Dentin Bonding Durability of Two-Step Self-Etch Adhesives With Improved of Degree of Conversion of Adhesive ResinsDocument7 pages2017 Sato Dentin Bonding Durability of Two-Step Self-Etch Adhesives With Improved of Degree of Conversion of Adhesive ResinsComarzzoNo ratings yet

- J. Chem. SOC.(A), 1971: Single-crystal Raman and Far-infrared Spectra of Tetrakis(thiourea)-nickel(ii) DichlorideDocument3 pagesJ. Chem. SOC.(A), 1971: Single-crystal Raman and Far-infrared Spectra of Tetrakis(thiourea)-nickel(ii) DichlorideFernandaIbarraVázquezNo ratings yet

- Furnaces and BoilersDocument23 pagesFurnaces and BoilersPraveen VaratharajanNo ratings yet

- USP-NF 857 Ultraviolet-Visible SpectrosDocument12 pagesUSP-NF 857 Ultraviolet-Visible SpectrosAbsheen ZamanNo ratings yet

- Lecture # 12Document11 pagesLecture # 12api-15026641100% (2)

- Sop Rota VaporDocument5 pagesSop Rota VaporeyobNo ratings yet

- Unraveling The Structure of Iron (III) Oxalate Tetrahydrate and Its Reversible Li Insertion CapabilityDocument9 pagesUnraveling The Structure of Iron (III) Oxalate Tetrahydrate and Its Reversible Li Insertion CapabilityOlga Viviana Cardenas LunaNo ratings yet

- RetroSled OverviewDocument1 pageRetroSled OverviewdigdreamNo ratings yet

- GUIDELINES FOR PREPARATION OF OIL SPILL RESPONSE CONTINGENCY PLAN OISD - GUIDELINES-200 Amended Edition October 2002 - OISD-GDN-200Document36 pagesGUIDELINES FOR PREPARATION OF OIL SPILL RESPONSE CONTINGENCY PLAN OISD - GUIDELINES-200 Amended Edition October 2002 - OISD-GDN-200Vaishnavi JayakumarNo ratings yet

- Physica A: H. Hassanabadi, S. Sargolzaeipor, W.S. ChungDocument8 pagesPhysica A: H. Hassanabadi, S. Sargolzaeipor, W.S. ChungMilton David SernaNo ratings yet

- A Torque, Tension and Stress Corrosion Evaluation of High Strength A286 Bolts PDFDocument28 pagesA Torque, Tension and Stress Corrosion Evaluation of High Strength A286 Bolts PDFBrad PhillipsNo ratings yet

- Buried Pipe - Neven DrobnjakDocument9 pagesBuried Pipe - Neven DrobnjakAnjani PrabhakarNo ratings yet

- R&AC Assigment-cum-Turorial Questions - Unit-V - 2017Document6 pagesR&AC Assigment-cum-Turorial Questions - Unit-V - 2017sivakrishna100% (1)

- en 10213 2007 Steel Castings For Pressure Purposes PDFDocument29 pagesen 10213 2007 Steel Castings For Pressure Purposes PDFPramod NautiyalNo ratings yet