Professional Documents

Culture Documents

Understanding The U.S. Mattress Flammability Standard

Uploaded by

irwanchem0 ratings0% found this document useful (0 votes)

32 views2 pagesUnderstanding the U.S. Mattress Flammability Standard

Original Title

Understanding the U.S. Mattress Flammability Standard

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUnderstanding the U.S. Mattress Flammability Standard

Copyright:

© All Rights Reserved

0 ratings0% found this document useful (0 votes)

32 views2 pagesUnderstanding The U.S. Mattress Flammability Standard

Uploaded by

irwanchemUnderstanding the U.S. Mattress Flammability Standard

Copyright:

© All Rights Reserved

You are on page 1of 2

Volume 13, Number 1, August 2006

This information is provided as a service from the Polyurethane

Foam Association to improve the understanding of key issues that

Summary affect flexible polyurethane foam cushioning. To learn more about

how combustion-modifying additives function within flexible

The U.S. Consumer Product Safety Commission (CPSC) polyurethane foam cushioning, contact a member of the

approved 16 CFR Part 1633, the new Federal Open- Polyurethane Foam Association.

Flame Mattress Standard, on February16, 2006. It was

developed with the active participation and support of This bulletin is intended to serve as a reference regarding the general properties and uses

many members of the U.S. mattress industry. In of polyurethane foam and has been developed as a service for the Polyurethane Foam

response to the industry's concerns, the CPSC staff Association’s (PFA) members and their customers. The information contained in this bulletin

is offered in good faith, developed from sources deemed to be reliable, and believed to

adopted several important changes to the proposed

standard, which applies to mattresses and foundations

be accurate when prepared, but is offered without warranty, express or implied, as to

merchantability, fitness for a particular purpose, or any other matter. The PFA and its

I N F O R M AT I O N O N F L E X I B L E P O LY U R E T H A N E F O A M

(boxsprings). members disclaim all responsibility for any loss or damage arising from reliance on such IN•TOUCH® is a regular publication of the Polyurethane Foam Association (PFA). It covers topics of interest to users of flexible polyurethane foam and is designed as a quick reference for background information on key issues. To get more detailed

information by any party. This bulletin is not intended to be all-inclusive on any subject information about a particular topic, consult a PFA member.

matter. The PFA makes no endorsements, assurances, warranties, or guarantees concerning

Proactive industry groups such as the International

the quality, uses, or applications of polyurethane foam or specific products produced from

Sleep Products Association (ISPA) and the Sleep polyurethane foam. PFA does not endorse the proprietary products or processes of any Understanding the U.S.

Products Safety Council (SPSC) "got in at the ground manufacturer. PFA and its members do not assume any responsibility for compliance

with applicable laws and regulations. The PFA makes no representations regarding the

Mattress Flammability

floor" to work with the CPSC on developing the new

standard. The PFA provided information on the ignition

combustibility of polyurethane foam under different applications or in different formulations. Standard

Photo courtesy National Institute of Standards and Technology

It is the responsibility of readers and purchasers or users of polyurethane foam to acquaint

and combustion performance The U.S. Consumer Product Safety Commission (CPSC)

themselves with its combustibility characteristics both as to usage and storage, and any

approved 16 CFR Part 1633, the new Federal Open-Flame

of FPF mattress materials. questions concerning applications and the combustibility of polyurethane foam must be

directed to individual foam manufacturers or suppliers.

Mattress Standard, on February 16, 2006. Few business people

are ever happy to embrace a new layer of regulation, but in the case of the

The regulation is largely modeled on TB603, a standard new open-flame mattress standard, many industry members see it as the

adopted in California in 2005. Compliance with the fed- best possible result that could potentially have emerged from the standard

© 2006 Polyurethane Foam Association, Inc. All rights reserved. development process. This outcome is due to the active participation and

eral 16 CFR Part 1633 is similar to the requirements of

This document may not be reproduced in whole or in part without support of many members of the U.S. mattress industry, barrier suppliers,

TB603, with some differences regarding testing condi-

the written permission of the Polyurethane Foam Association. and the flexible polyurethane foam (FPF) industry, who had a hand in

tions. A key advantage of the new mattress standard is helping to shape the new standard. A dual propane burner is used in the CPSC test rig to simulate how burning bedclothes

its flexibility. It requires composite performance and (heat flux and duration) may affect a mattress and box spring or a mattress alone.

A complete library of PFA IN•TOUCH® issues

leaves it up to the manufacturer to find the best way to The new standard addresses stringent manufacturing, testing

can be found on the Internet at http://www.pfa.org.

comply. and document retention requirements. It also preempts states from

component materials. Using this approach, manufacturers can continue to use

setting different mattress flammability rules. The standard becomes

better quality foam cushioning materials, which offer all the comfort,support

effective on July 1, 2007 and applies to residential mattresses and

Despite the potentially burdensome requirements of and lasting physical performance required of a good mattress product.

foundations (boxsprings) manufactured, imported or renovated on or

compliance, the new standard offers marketing and after that date.

business advantages to Industry Influenced the New Standard

industry members affected by mattress sales. Flexibility is the Key The new national standard is based on California's TB603, a mattress

A key advantage of the new mattress standard is that it requires composite flammability standard adopted in 2005, which was developed with substan-

Compliance is not optional. performance. Wisely, it was drafted not to be a test of individual components, tial input from the bedding industry and its suppliers. The standard was

but rather to leave it up to the manufacturer to find the best way to comply. based, in part, on research performed by the National Institute of Standards

In fact, fire-retardant (FR) additives are not required in the FPF or any other and Technology (NIST). Throughout the TB603 standard development

The best protection and first line of defense against component. process, stakeholders voiced the

fire is to practice responsible fire prevention in the belief that, to be effective, any

This flexibility leaves the door open for continuous innovation and product mattress flammability standard The full text of the new

home. improvements. Mattresses often include a high-performance FPF component must be based on good science Federal Open-Flame

Polyurethane Foam Association to meet consumer comfort, support and appearance retention demands of and research representing the Mattress Standard

A federal flammability standard for upholstered furni- 9724 Kingston Pike, Suite 503, Knoxville, TN 37922 eight-hour-a-night use in conditions of elevated temperatures and humidity. entire composite mattress product. is available at:

Phone (865) 690-4648 Fax (865) 690-4649 Most mattress manufacturers are expected to comply initially with the new Synergistic interaction during

ture remains in the developmental phase. flammability standard by adding an ignition-resistant barrier material combustion affects all components www.pfa.org/1633

http://www.pfa.org between the outside cover, or ticking fabric, and the interior, built-up used in mattress construction.

Proactive industry groups such as the International Sleep Products Association 5. Part 1633 Preempts Different State Mattress Mattresses and FPF cotton, wool, nylon, polyester, polyethylene, and polystyrene and other

(ISPA) and the Sleep Products Safety Council (SPSC) "got in at the ground floor" Flammability Rules: plastic materials. It is the responsibility of the foam buyer to select the

to work with the CPSC on developing the new standard. The American Textile Given that the mattress manufacturing and retailing market is national in Fillings Flammability proper FPF to meet specific end-use requirements. It is the end-user's

Manufacturers Association provided materials for some aspects of the research. scope, the industry requested the CPSC to make clear that Part 1633 is a responsibility to comply with any applicable building code, occupancy

The PFA provided information to the CPSC on the ignition and combustion national standard that should be applied uniformly throughout the country. The Role of Flexible Polyurethane Foam

performance of FPF materials when used in mattress construction. The new requirements and flammability standards and to take reasonable

Response: In issuing its new federal standard, the CPSC stated that once it issues

Flexible polyurethane foam (FPF) is often used in manufacturing precautions to protect FPF products from ignition.

standard incorporates a number of important elements that were part of the a flammability standard for a product, federal law provides that a state may not

public comments filed on behalf of the mattress industry by the ISPA and the maintain a different flammability standard for the same product. mattresses to provide lasting comfort and support. While a room

SPSC on the draft standard proposed in January 2005. In response to the fire usually involves many combustible home furnishing items, One potential danger of flammability standards is that consumers

industry's concerns, the CPSC staff adopted several important changes to the 6. Miscellaneous Definitional Issues: the foam component inside a mattress is almost never the first thing to ignite. could develop a false sense of security when they see labels on

proposed standard, including: To reduce possible confusion in application of Part 1633, the industry mattresses and foundations indicating that the components in the

requested clarifications of certain existing Part 1633 definitions and several While having a national flammability standard may add a measure of bedding are fire retardant or resistant. In fact, the best protection

1. Imported Mattresses: additional definitions. fire safety, we know that, despite having a standard in place, there will and first line of defense against fire is to practice responsible fire

ISPA and SPSC were concerned that importers might misinterpret the Response: CPCS staff clarified and added several definitions in still be fires involving mattresses. Even combustion-modified cushioning prevention in the home. Families can help prevent household fires

proposed standard's general statement that "an importer would be Part 1633, including: components, including fabric, fiberfill, down and foam, have the potential by keeping burning cigarettes away from sofas, chairs, mattresses

considered a manufacturer" for purposes of Part 1633, and were also Prototype developer: Added to recognize that parties other than

concerned about how the CPSC would be able to verify a foreign to burn if exposed to sufficient heat or source of ignition. and foundations. People should keep matches, lighters and candles

mattress manufacturers may develop prototypes.

manufacturer's compliance, including access to necessary records, Prototype pooling: Clarified to define the responsibilities of away from children. Every household should install smoke detectors

review of those records in English, and accurate identification of the For more than 25 years, PFA has provided up-to-date information about

manufacturers that rely on a prototype developed by another party to and test them often. Family emergency evacuation drills and

foreign manufacturer. conduct confirmation tests. FPF flammability to members and consumers. Flexible polyurethane foam

other educational activities help children learn how to escape a

Response: CPSC staff clarified that mattress importers have clear, significant compli- Mattress sets: Added to provide a convenient definition for an is an organic material and, like all organic materials, will burn. Organic

fire situation.

ance obligations, and are required to maintain, in the U.S., test records and other intended mattress/foundation combination. materials include a variety of common substances including wood, paper,

documentation (in English) that foreign manufacturers must prepare that show com- Subordinate and Confirmed prototypes: Added to provide clearer

pliance with the new standard. The importer, given its legal status as a "manufactur- distinctions between products for which prototype testing is

er" for purposes of Part 1633, would also be responsible for conducting "corrective required and products based on qualified prototypes developed

actions," such as product recalls, if necessary. under a pooling arrangement.

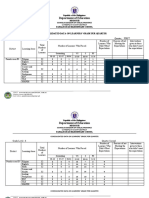

Comparison of CPSC Open Flame Standard with California TB 603

2. Renovated Mattresses:

The industry was concerned that the proposed standard's policy statement CPSC Standard California TB 603

“A Standard You Can Live With”

dealing with renovated mattresses was somewhat vague and might not have Despite the potentially burdensome requirements of compliance, the new Duration of Test 30 minutes 30 minutes

the same legal significance as an express provision of the standard. standard offers advantages to industry members affected by mattress sales.

Response: CPSC staff clarified that mattresses subject to this standard also include According to the IEEE Standards Association, “Standards make good business Peak Heat Release 200 kW 200 kW

renovated mattresses. This means that renovators must comply with the same pro- sense. Successful businesses benefit from standards both by actively partici- Total Heat Release for 15 mega joules 25 mega joules

totype testing, quality assurance and other requirements as a manufacturer of new pating in the standardization process and by using standards as strategic 1st 10 Minutes

mattresses. market instruments.” Recordkeeping Yes. Manufacturers must maintain records concerning No

Requirement prototype testing, pooling and confirmation testing,

3. Retention of Physical Samples: Get with the Program and quality assurance procedures and any associated

In the proposed standard, the CPSC stated that mattress manufacturers Compliance is not optional. All stakeholders in the mattress industry must testing for as long as mattresses/sets based on the

would be required to maintain physical samples of materials used to make prototype are in production and must be retained

work diligently to comply with the national standard. While the national for three years thereafter.

mattress prototypes for the production duration of the prototype plus three mattress flammability standard may restrict some traditional product

years. The industry was concerned that storing such samples would be constructions, it also creates opportunities for product innovation at all Test Method Same as TB 603, except: Flame Source: Two 30.48 cm wide

cumbersome; the samples might be prone to loss, damage or deterioration levels of supply and product design. T-shaped propane burners intending to simulate

Sample room conditioning standards narrower the effect of burning bed clothing.

and that objective documentation of the physical characteristics of the than TB 603.

materials would be preferable to storage of physical samples. The industry groups involved in developing the new federal mattress Burner Exposure Time: 50 seconds vertical, 70

Response: CPSC staff agreed that manufacturers would not be required to flammability standard are available to assist retailers, vendors, consumers, Test parameters narrower than TB 603. seconds horizontal.

maintain physical samples, which should substantially simplify their records environmental regulators and others with questions regarding compliance Test Duration: Monitored for 30 minutes, but if

maintenance obligations. with the standard. In 2005, the California Dept. of Consumer Affairs self extinguishment occurs any time less than 30

produced an overview of compliance requirements for California’s TB603, minutes without the peak heat release and total

4. Sample Conditioning: heat release criteria being exceeded the test is

which are not substantially different from those of 16 CFR Part 1633. completed and considered a pass.

To promote test result consistency, the industry asked that the CPSC specify Information on compliance can be found under “Flammability FAQs”

narrower sample conditioning requirements prior to conducting test burns. on the ISPA website at www.sleepproducts.org.

Response: CPSC staff agreed.

2 3

You might also like

- 10 3306 15 FAPU 88 EN C HR 20 21 PDFDocument2 pages10 3306 15 FAPU 88 EN C HR 20 21 PDFirwanchemNo ratings yet

- Novel Technology To Influence Hardness of Flexible Pu FoamsDocument16 pagesNovel Technology To Influence Hardness of Flexible Pu FoamsirwanchemNo ratings yet

- Flexible Polyurethane Foam Industri Is Proactive On SustainabilityDocument4 pagesFlexible Polyurethane Foam Industri Is Proactive On SustainabilityirwanchemNo ratings yet

- The Role of Flexible Polyrethane Foam in Relation To Fiber SpringsDocument4 pagesThe Role of Flexible Polyrethane Foam in Relation To Fiber SpringsirwanchemNo ratings yet

- Reach SVHC List Excel TableDocument7 pagesReach SVHC List Excel TableirwanchemNo ratings yet

- 56 Fapu en 56 PDFDocument44 pages56 Fapu en 56 PDFirwanchemNo ratings yet

- Flexible Polyurethane Foam in PackagingDocument6 pagesFlexible Polyurethane Foam in PackagingirwanchemNo ratings yet

- The Importance of DensityDocument4 pagesThe Importance of DensityirwanchemNo ratings yet

- How Foam Firmness AffectsDocument5 pagesHow Foam Firmness AffectsirwanchemNo ratings yet

- Laboratory Tests of Foam PerformanceDocument4 pagesLaboratory Tests of Foam PerformanceirwanchemNo ratings yet

- Proper Handling and Storage of Flexible Polyurethane FoamDocument4 pagesProper Handling and Storage of Flexible Polyurethane FoamirwanchemNo ratings yet

- Flexible Polyurethane Foam in Matress ConstructionDocument6 pagesFlexible Polyurethane Foam in Matress ConstructionirwanchemNo ratings yet

- Polyurethane Foam and The Environtment A Progress ReportDocument6 pagesPolyurethane Foam and The Environtment A Progress ReportirwanchemNo ratings yet

- Flexible Polyurethane Foam in The Transportation IndustriDocument8 pagesFlexible Polyurethane Foam in The Transportation IndustriirwanchemNo ratings yet

- California Technical Bulletin 133 (TB 133) and Furniture Fire SafetyDocument4 pagesCalifornia Technical Bulletin 133 (TB 133) and Furniture Fire SafetyirwanchemNo ratings yet

- Flexible Polyurethane Foam Fabrication Equipment and Capabilies UpdateDocument4 pagesFlexible Polyurethane Foam Fabrication Equipment and Capabilies UpdateirwanchemNo ratings yet

- Compression Modulus (Support Factor)Document4 pagesCompression Modulus (Support Factor)irwanchemNo ratings yet

- California Technical Bulletin 117-2013 and Residential Furniture Fire SafetyDocument4 pagesCalifornia Technical Bulletin 117-2013 and Residential Furniture Fire SafetyirwanchemNo ratings yet

- ANZ 4680 2006 Hot Dip GalvanizeDocument7 pagesANZ 4680 2006 Hot Dip GalvanizeirwanchemNo ratings yet

- Foam FabricationDocument4 pagesFoam FabricationirwanchemNo ratings yet

- Flexible Polyurethane Foam A PrimerDocument7 pagesFlexible Polyurethane Foam A PrimerirwanchemNo ratings yet

- JWC EWMA Supplement NPWT Jan 2018 AppendixDocument155 pagesJWC EWMA Supplement NPWT Jan 2018 AppendixirwanchemNo ratings yet

- Flexible Polyurethane Foam Fabrication Adhesive UpdateDocument4 pagesFlexible Polyurethane Foam Fabrication Adhesive UpdateirwanchemNo ratings yet

- How Importance of Cell Structure For Viscoelastic Foams PolyuretgabDocument13 pagesHow Importance of Cell Structure For Viscoelastic Foams PolyuretgabajoilhamNo ratings yet

- Intumescent Paint BrochureDocument6 pagesIntumescent Paint Brochureirwanchem100% (2)

- Polymer FoamsDocument17 pagesPolymer FoamsSachin PatilNo ratings yet

- Rohs2 Directive 2011/65/eu: Rohs2 Directive Officially in Effect The Most Important ChangeDocument5 pagesRohs2 Directive 2011/65/eu: Rohs2 Directive Officially in Effect The Most Important ChangeirwanchemNo ratings yet

- Ad 1041960Document14 pagesAd 1041960ajoilhamNo ratings yet

- ISOPA-FACTSHEET Recycling and RecoveryPolyurethanes V02Document2 pagesISOPA-FACTSHEET Recycling and RecoveryPolyurethanes V02irwanchemNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Blake Mouton Managerial GridDocument3 pagesBlake Mouton Managerial GridRashwanth Tc100% (1)

- Probation Period ReportDocument17 pagesProbation Period ReportMiranti Puspitasari0% (1)

- Scrum Exam SampleDocument8 pagesScrum Exam SampleUdhayaNo ratings yet

- Prediction of Compressive Strength of Research PaperDocument9 pagesPrediction of Compressive Strength of Research PaperTaufik SheikhNo ratings yet

- Acoustic Glass - ENDocument2 pagesAcoustic Glass - ENpeterandreaNo ratings yet

- L GSR ChartsDocument16 pagesL GSR ChartsEmerald GrNo ratings yet

- SM EFATEX Rev D2 3 1 2018 PDFDocument20 pagesSM EFATEX Rev D2 3 1 2018 PDFGuilhermePlacidoNo ratings yet

- Entrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanDocument3 pagesEntrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanMamoonaMeralAysunNo ratings yet

- Technical Sheet Racloflex NTDocument2 pagesTechnical Sheet Racloflex NTAnthony AngNo ratings yet

- DLP English 10 AIRADocument8 pagesDLP English 10 AIRAMae Mallapre100% (1)

- TTDM - JithinDocument24 pagesTTDM - JithinAditya jainNo ratings yet

- Third Party Risk Management Solution - WebDocument16 pagesThird Party Risk Management Solution - Webpreenk8No ratings yet

- Modern Construction HandbookDocument498 pagesModern Construction HandbookRui Sousa100% (3)

- Aristotle - OCR - AS Revision NotesDocument3 pagesAristotle - OCR - AS Revision NotesAmelia Dovelle0% (1)

- I. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)Document5 pagesI. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)thmeiz.17sNo ratings yet

- BIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Document32 pagesBIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Md TayfuzzamanNo ratings yet

- Cap1 - Engineering in TimeDocument12 pagesCap1 - Engineering in TimeHair Lopez100% (1)

- FT2020Document7 pagesFT2020Sam SparksNo ratings yet

- AP8 Q4 Ip9 V.02Document7 pagesAP8 Q4 Ip9 V.02nikka suitadoNo ratings yet

- Trucks Part NumbersDocument51 pagesTrucks Part NumbersBadia MudhishNo ratings yet

- Strategic Management SlidesDocument150 pagesStrategic Management SlidesIqra BilalNo ratings yet

- Stress Management HandoutsDocument3 pagesStress Management HandoutsUsha SharmaNo ratings yet

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDocument4 pagesDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaNo ratings yet

- BDocument28 pagesBLubaNo ratings yet

- Chakir Sara 2019Document25 pagesChakir Sara 2019hiba toubaliNo ratings yet

- Categorical SyllogismDocument3 pagesCategorical SyllogismYan Lean DollisonNo ratings yet

- Section 1 Company Overview StandardsDocument34 pagesSection 1 Company Overview StandardsChris MedeirosNo ratings yet

- 5620 SAM Rel 14 License Point Configuration ToolDocument416 pages5620 SAM Rel 14 License Point Configuration Toolluis100% (1)

- Superlab Manual PDFDocument76 pagesSuperlab Manual PDFGabriela Soares100% (1)

- Job Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeDocument16 pagesJob Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeNaveen KumarNo ratings yet