Professional Documents

Culture Documents

DVS 2203-5-1999

Uploaded by

Jorge67%(3)67% found this document useful (3 votes)

258 views3 pagesTest cupon PP-R

Original Title

DVS 2203-5-1999 Takabplast.com

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTest cupon PP-R

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

67%(3)67% found this document useful (3 votes)

258 views3 pagesDVS 2203-5-1999

Uploaded by

JorgeTest cupon PP-R

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

pening and oping, evenin Be orm of exert, nly whe conse ha publener

Testing of welded joints

of thermoplastics plates and tubes:

Technological bend test

DVS - DEUTSCHER VERBAND

FOR SCHWEISSEN UND

\VERWANDTE VERFAHREN EV.

Direction

DVS 2203-5 vi

nf

Contents:

1 Scope

2 Method and desion

2.4 Requiremants on ost equipment

Measurement of bend angle

2.1.2 Measurement of ram aispiacement

3” Performance

31 Evaluation

Determination ofthe band angle

Determinaton of tie ram asplacement

Geodibad evaluation

Study of paramolers;Comparison of methods

Cciteta of faite

Test report

Normative references

312

313

1 scope

‘The bend test may be used in conjunction with other tests 0

assess the performance of butt welded assemblies made from

thermoplastics matorals,

‘Welded parts wth comparable soam geometries, 2.9, on profes,

can also be tested wit referenee to tis guideline

‘The bend angle, he ram cisplacement while bending and the

fracture appearance when the tests terminated provide @ guide

to the duchy of a welded joint and hence tho wo'd qualty

The ductity properties ofthe material, the applied weld mothods

and the gacmety ofthe fest specimens influence the achievable

bend angle resp. ram eisplacement and they have to be taken in

onsideraion while evaluating

The results derived from the bend tests can only partly be used

to-assoss the long tm behaviour of welded joints.

‘The bend tests cen also te used to optimize welding parameters,

In this caso tis helpful touso nono standard test conditons (0-4

to decrease the test lomperature or to increase the speed of

bensing)

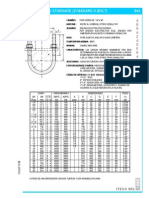

Table 1 Dimensions of he teat arvengement and the tes! apecimens.

(august 1990) (SY

2. Method and design

‘The technological bend testis performed with reference to DIN,

50121

The tests shall be carried out atleast eight hours afer welding

No heat treatment oporatons aro allowed to 80 cartiod outon the

test specimen

Fig. 1 shows the test arrangement

‘heknese otal gpaciman

wath oftestspeamen| A

{oiling of apecarion diame of am

since Setweon ace of ole © Demeter ofthe roles nam

‘Sketen ofthe est arangement

‘am daslecoment

end annie.

Table 1 gives the dimensions of the test arangement and the

lest specimans. The dimensions of he spacimens mentioned are

Felated fo te nominal dimensions ofthe semi-finished products

For a thickness > 30 mm itis recommended to reduce the

thicknesses of tho ast spocimens to loss than 30 mm by

matching from the sides in contact wih the ram end (pipes fram

the outside}. In cage of apes the maximum thicknesses al the

Test specimen

width b

ten

thickness =

[mm

Pominal value

Be

otal

mins 6

max:30

plate

aee2 5

Bess 10

5215

sees. 20

2028530

distance between

x05 of roles Ly

iin)

‘diameter of ram a

‘minimum length Ly ds)

[rm

750

200

200

250

300

Se ee a le

“21 and those inveivec in prepsring this publication are exempt om any Babity

DVS, Technical Committee, Working Group "Joining of Plastics

(Ondars to: OVS eriag Gmbh. PO. Box "07965, 400'0 aldo, Garmny, Phane:+@0(0)211I90%-0, Tl: + 49(0}211/9991-150

Page 2 to DVS 2203-5,

edges of the specimens have to be taken into accaunt before

‘oping the chamlers. The dislance between the rolers for test

Specimens with thickness > 30 mm which wil be tested without

reduction of thickness is calculated withthe formula

Lg=D+arae

(B= 50 mm; a= 25 mm: $= thickness of test specimen).

The wit of ram and the width of supports have to be larger than

the width of specimen, The ram has to be posttoned in the

middie ofthe woic. The tendency of he specimens to sip during

testing can be reduced by using a corugated ram or grinding

paper a the tip ofthe ram.

In case of welded pipes the test specimens have to be cut

uniformly distributed around the ercumference of te pipe. The

test specimens shal be cut either radially or with paral sides

The width of the specimens cut radialy is gven by the mean

value ofthe largest and the smaiest width,

Figure 2, Cross sections of specinens ot frm noes

The beads have to be removed where the ram isin contact with

the specmen during testing. A maximum of 1 mm of the

longitisinal edges of the toast specimen to be subjected 10

texlension shall be removed at an angle of epproximately 45°

‘These chamfers shall be continous tough tre bead

Figure 3. Geometry ofthe chants

24 Requirements on test equioment

‘The momen! when the tip of the rom isin contact with the

specimen has fo be recorded reproducibly. The test procedure

has to be stopped automaticaly or manually when the specimen

breaks ora crack occurs, The result has to be recorded

2.4.4 Measurement of band angle

The accuracy ofthe measuring device and the dsplay shall be at

least 1". For this reason the equipment shall have an

Slocironical or mechanical measuring dovice with sufficient

precision.

Due to the fact thatthe point of contact between the specimen

and the rollers is moving continuously during tre test the result

Shall o bo corrected By an non-inoar Scale, a correction factor o¢

{an appropriaie measuring equipment whichis able to guide the

cenie

2.4.2. Mensurement of ram displacement

‘The accuracy of the measuring devlee and the display shal be

0.1 mm atleast

3 Performance

Unless otherwise specified or fxed by technical specifications the

test shal be carried out according to DIN 50014-23'50-2

[At least 6 test specimens shell be tested for each welded test

piece. In the case of welded olaies, 3 tesl specimens shall be

tested for each face of tho weld. In case of welded pipes the

Inside shall be subjected to extension.

‘The ram speod is gan in table 2.

Tablo2. Ram speed for some thermoplastics.

‘material test speed

mimi

PERO 0

PPR 50

PPH, 6 20

POF 2

PYCU o

24. Evaluntion

‘The technological bending test daes not provide values for the

sign of thermoplastic constructions. Novertholess a spocialist,

is able to assess generally the welded joints by the resuls ofthe

formation beraviour

‘Tho rosuits of technological bending tosts can be evaluated in

two ways, a8 bend angle or 2s ram displacement. Bend arle

‘and ram displacement cannot be transferred into each oer

‘mathematically

aaa

Determination ofthe bend angle

‘The bend angi is determined as the dference betwoen the fal

angle viten either ractire occurs or a crack S visible and the

inital angle. The angles at both ends of the specimen culside of

the roles are measured. The bend angle is calculated by

Addition of Both values. Possibly axistng anglo-doviations from

the hodzonlal are tbe determined and considered (Fg, 4)

‘The full bonding ofthe specimen in the doscrbed tot equipment

Is considared a8 “na falure” ard tre bond angle is defined wih @

valua oF 160" for th caleulaton of tho mean value,

3:42 Determination ofthe ram displacement

‘The ram displacement is determined as the dfferonce between

to nal ram dsplacement when eltnr fracture occurs ora rack

is vise andthe inal positon ofthe ram, The ful bending ofthe

Specimen in the described test equipment is considered 2s “no

falure’ and the ram displacement taken fom table 3 for the

calculation of the maan value,

Table 3. Rar dsplacements corresponding to the bend angle of

460" im enan of no fair forthe ale

Thickness of test specimen [bend angle [ram displacement

[eam] a Fn)

3e8< 5 ©

Beers 70

188520 180 85

errr 110

26<3=30 150

342 Good! bad evaluation

For 8 goodibad evaluation the singe values shall be taken into

consideration. Each value shall be equal of larger to the

minimum bene angles or the minimurn ram displacements given

in guideline OVS 2203-1. If up to two test specimens do not

‘chiave the minimum bend angla or ram clsplacament as

spocifod in tho roquiromonts, two furhor test specimens from the

‘seme welded test place cut in the same cretion can be tested

No more than two adltional test specimens shal be tested. The:

‘additional test specimens shall meet the requirements,

bean ona #8) +10,°8)

Figure 4

‘Scnematis eaph ofthe determination af bend argo and mm

Page 3 to DVS 2208-5

24.4 Study of paramaters!Comparizon of methods

‘The calculstion of arithmetic mean velues without addtional

specimens i recommended in. the case of comparative

inyestgatione sko optimizing welding parameters or optmizing

welding procedures.

32 Criteria of fare

‘The test specimen can fall by @ spontaneous break or by starting

2 crack and continuous crack grown

When either a crack occurs or 8 starting ereck becomes visible

with the naked eva, the messured vale fe deleeyned. A starting

crack has @ depth of ca. 0.5 mm. Condition for the sure

recognition is @ suffer iluminaton of the critoal aroas of the

lest specimen and a sufficient observation 8.9, by @ mor,

4 Test report

‘The test report shall refer to this guideline and it shall include et

least the following information:

~ material, kind of delivery and designation ofthe product,

~ date and mothod ofthe wolded joint

~ positon ofthe test specimen inthe product

~ shape ofthe test specimen (ether rad or parallel sidos)

~ thickness of tho test specimens in mm (pominal value)

~ width ofthe test specimens in mm

~ number of the test specimens

= conditioning while testing

test speed in mmimin

= bend ange or ram displacement

kind of alure, crack progress if necessery

test date

5 Normative references

DIN 50014 Atmospheres and the technical application, standard

atmosphere

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- GOULDS 3175iomDocument36 pagesGOULDS 3175iomJorgeNo ratings yet

- Valvulas MariposaDocument6 pagesValvulas MariposaJesus Fernando Sotelo ChavezNo ratings yet

- Abre Bridas Enerpac PDFDocument1 pageAbre Bridas Enerpac PDFJorgeNo ratings yet

- Manguera GemelaDocument2 pagesManguera GemelaJorge100% (1)

- Ermeto Original Din FittingsDocument130 pagesErmeto Original Din FittingsgkhnbcrNo ratings yet

- Manual Desing Pressure VesselDocument246 pagesManual Desing Pressure VesselJorgeNo ratings yet

- Apunte Teorico de CombustionDocument111 pagesApunte Teorico de CombustionJorgeNo ratings yet

- Accesorios OutletsDocument7 pagesAccesorios OutletsOscar David Benavides CastilloNo ratings yet

- Tripolifosfato de Sodio PDFDocument3 pagesTripolifosfato de Sodio PDFJorgeNo ratings yet

- Guia de Trampas para VaporDocument33 pagesGuia de Trampas para VaporJorgeNo ratings yet

- Trazado de Plantilla para TubosDocument112 pagesTrazado de Plantilla para TubosFernando Francisco96% (49)

- Weldy Katalog 2017-18 Es LowDocument8 pagesWeldy Katalog 2017-18 Es LowJorgeNo ratings yet

- Accesorios OutletsDocument7 pagesAccesorios OutletsOscar David Benavides CastilloNo ratings yet

- Weldy Katalog 2017-18 Es LowDocument52 pagesWeldy Katalog 2017-18 Es LowJorgeNo ratings yet

- Weldy Katalog 2017-18 Es LowDocument52 pagesWeldy Katalog 2017-18 Es LowJorgeNo ratings yet

- AntorchaDocument128 pagesAntorchaFavio Jhonny Fernandez MartinezNo ratings yet

- PTS Termofusión PP750 Spanish 9-2008Document32 pagesPTS Termofusión PP750 Spanish 9-2008torresdeepNo ratings yet

- Chapter D UKDocument20 pagesChapter D UKxuantienhtNo ratings yet

- PTS Termofusión PP750 Spanish 9-2008Document32 pagesPTS Termofusión PP750 Spanish 9-2008torresdeepNo ratings yet

- Hormigón Armado - 8 EdiciónDocument744 pagesHormigón Armado - 8 EdiciónJorgeNo ratings yet

- PTS Termofusión PP750 Spanish 9-2008Document32 pagesPTS Termofusión PP750 Spanish 9-2008torresdeepNo ratings yet

- Catalogo U BoltDocument1 pageCatalogo U BoltAlfonso AraqueNo ratings yet

- DGA452Document76 pagesDGA452JorgeNo ratings yet

- Method Janssen PDFDocument308 pagesMethod Janssen PDFJorgeNo ratings yet

- Trav L Cutter - CATALOGO PDFDocument2 pagesTrav L Cutter - CATALOGO PDFJorgeNo ratings yet

- Llaves Combinadas Antichispa PDFDocument1 pageLlaves Combinadas Antichispa PDFJorgeNo ratings yet

- Te 30-A36 Es Pub 5130081 000Document17 pagesTe 30-A36 Es Pub 5130081 000JorgeNo ratings yet

- Strainer Y TypeDocument2 pagesStrainer Y TypeJorgeNo ratings yet

- Te 30-A36 Es Pub 5130081 000Document17 pagesTe 30-A36 Es Pub 5130081 000JorgeNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)