Professional Documents

Culture Documents

Ascensor

Uploaded by

Blass Hernández CastroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ascensor

Uploaded by

Blass Hernández CastroCopyright:

Available Formats

fa=råáèìÉ=PM.3.002352.

EN

Blatt/sheet D389MGB.000

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version C-23.07.2015

Geprüft/approved WAT/FLE

*D389MGB$111*

Operating instructions

Car Frame WCS60 Suspension 2:1 / 4:1

D389MGB 07.2015

WITTUR Austria GmbH

Sowitschstrasse 1 • A-3270 Scheibbs, Austria

Tel. +43 (0) 7482/42542-0 • Fax +43 (0) 7482/42542-232

http://www.wittur.com • E-Mail: info.at@wittur.com

No part of this publication may be reproduced or We reserve the right to make alterations with respect

translated, even in part, without prior written to the specifications and figures in this manual.

permission from WITTUR Austria GmbH.

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.001

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

Contents Page

1 General information prior to installation

1.1 Description and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.002

1.2 Liability and guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.002

1.3 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.003

1.4 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.003

1.5 Safety gear name plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.004

1.6 Content of supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.005

2 Installation

2.1 Placing the bottom cross beam between the rails . . . . . . . . . . . . . . . . . . . . . . .D389MGB.007

2.2 Securing the uprights to lower cross beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.008

2.3 Installing Crosshead beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.009

2.4 Installing isolated platform supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.010

2.5 Installing “non-isolated” platform supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.010

2.6 Installing the diagonal rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.011

2.7 Travelling cable hanger and compensation chain fixings . . . . . . . . . . . . . . . . . .D389MGB.012

2.8 Car installation (isolated platform support) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.013

2.9 Car installation (non-isolated platform support) . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.014

2.10Finalizing Car installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.015

2.11Tightening of diagonal rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.015

2.12Car fixing bolts (isolated platform support) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.015

2.13Roping of the car frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.016

2.14Overspeed governor rope fixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.017

2.15Adjustment of safety gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.018

2.16Load weighing device WLWD-M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.019

3 Function testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.020

4 Maintenance, inspection and repair

4.1 Maintenance and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.021

4.2 Carrying out repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.022

4.3 Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D389MGB.023

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.002

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

1 General information prior to installation

1.1 Description and functions

The car frame WCS60 is a car frame used for pas- The built-in safety devices are set, synchronized

senger-goods and freight elevators with nominal and lead sealed ex-works, according to the order.

load up to 6000kg. For reasons of safety, it is forbidden to readjust

these settings once they have been made.

The car frame operating range is defined as fol-

lows:

WCS60:

• All up load ≤ 17000 kg (Q ≤ 6000 kg) 1.2 Liability and guarantee

• Car depth ≤ 6500 mm

• Car width ≤ 6290 mm This instruction handbook is written for people

• Rated speed ≤ 2.0 m/s who are familiar with lift servicing and installa-

tion. Sufficient knowledge of lifts is essential.

General:

• Safety gear: Roller type SG WITTUR accept no responsibility for damage

Progressive type SG caused by improper handling, or for damage

• Sliding guide shoe (SLG4, SLG4A) caused as a result of actions other than those stat-

• Suspension: 2:1 and 4:1 with 2 pulleys ed in these operating instructions.

above car

Further options: The WITTUR guarantee may be voided if parts

• Load weighing system other than those described in these instructions

• Platform support beams are installed.

• Compensation chain hanger

• Travelling cable hanger Unless stated otherwise, the following are not per-

missible due to technical safety reasons:

• The use of safety gear devices or brake com-

ponents other than those installed

• Carrying out modifications, of any kind, on

brake components

• Destroying of seals

• Frame modification

• Modification of the actuating mechanism

• Readjustment of settings have been made ex-

works

• Carrying out faulty or improper maintenance,

maintenance or inspection checks

• using unsuitable accessories, spare parts or

operating material which has neither been re-

leased by the WITTUR Company nor consists of

original WITTUR spare parts

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.003

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

1.3 Safety precautions Before starting installation work:

WITTUR machine installation or repair engineers Only properly trained personnel may carry

are chiefly responsible for the safe operation of out work, or be allowed access to the

machinery. installation site.

It is essential to comply with and keep abreast of - Attach safety devices to guard against falling

all safety rules and legal obligations in order to (platform or harnesses)

avoid personal / product damage during installa- - Cover any floor openings

tion, maintenance and repair work. - Secure installation tools or objects against

accidental falling

Important safety advice and danger warnings are - Lift shaft openings should be cordoned off

emphasized with the following symbols: and suitable warning signs should be erected

when working in shaft openings

General danger warning - Work involving electrical equipment should

only be carried out by an electrical engineer or

qualified personnel.

High danger risk warning (i.e. crushing 1.4 Preparation

edge, cutting edge etc.).

Before beginning installation work it is in your

own interest to ascertain the constructional and

spatial conditions. Where (workshop or on site)

Risk of damage to machinery parts (i.e. due and when which installation operations can or

to incorrect installation, or such like). must be carried out. It is recommended therefore,

taking into account all the given circumstances, to

plan the various operational sequences in advance,

rather than carrying them out prematurely and in

Important information sign an unconsidered manner.

On receipt of the delivery, the goods or compo-

nents should be checked for correctness and com-

pleteness with the order sheet

These operating instructions belong with the The details on the name plates should be com-

whole installation and must be kept in a safe place pared with the order sheet and also check:

at all times (i.e. machine room). - that the factory and order number correspond

- the rail head width and model

The proper assembly and installation of WITTUR - the total load (G)

car frames requires correspondingly well trained - the tripping speed

fitting engineers. The responsibility of training lies - the rope pulley diameter, the number of rope

with the company appointed to carry out the grooves and rope groove diameter are suited

work. to the ropes

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.004

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

1.5 Safety gear name plate

The safety gear device identification indicators are

located near the safety block. These consist of a Type test designation

name plate and a identification sticker. and CE-label

Date of manufacture

Type term

Order number

(refer to delivery

or order sheet)

Serial number

Mass to be gripped

Fmax = (kg,lb)

Tripping speed

vmax = (m/s,fpm)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.005

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

1.6 Content of supply Car Frame WCS60

Suspension 2:1 / 4:1

Operating instructions

Car Frame WCS60 Suspension 2:1 / 4:1

Blatt/sheet D389MGB.000

Datum/date

Stand/version

11.02.2002

11.02.2002

Geprüft/approved WAT/FLE

Progr. type safety gear SGB01, SGB02,

Operating instructions

SGB03, SGB05

Progr. type safety gear

Blatt/sheet D7A4MGB.000

Datum/date

Stand/version

24.08.2001

24.08.2001

Geprüft/approved WAT/FLE

Sliding guide shoes

Operating instructions

Sliding guide shoes

Blatt/sheet D622MGB.000

Datum/date

Stand/version

24.01.2002

24.01.2002

Geprüft/approved WAT/FLE

Electronic Load Weighing Device

WLWD-M

Operating instructions

Electronic Load Weighing Device

Blatt/sheet D961MGB.000

Datum/date

Stand/version

31.01.2002

31.01.2002

Geprüft/approved WAT/FLE

SGB01, SGB02, SGB03, SGB05 for car frame and counterweight

Guide rail lubricator

After delivery, check the lift car frame for damage

Sliding guide shoe

D389MGB 02.2002

D7A4MGB 02.2002

01.2002

01.2002

D622MGB

D961MGB

and for full delivery of parts. The content of sup-

ply covers: WITTUR GmbH

Sowitschstrasse 1 • A-3270 Scheibbs, Austria

Tel. +43 (0) 7482/42542-0 • Fax +43 (0) 7482/42542-32

WITTUR GmbH

Sowitschstrasse 1 • A-3270 Scheibbs, Austria

Tel. +43 (0) 7482/42542-0 • Fax +43 (0) 7482/42542-32

http://www.wittur.at • E-Mail: info@wittur.at

WITTUR GmbH

Sowitschstrasse 1 • A-3270 Scheibbs, Austria

Tel. +43 (0) 7482/42542-0 • Fax +43 (0) 7482/42542-32

WITTUR GmbH

Sowitschstraße1, • A-3270 Scheibbs, Austria

Tel. +43 (0) 7482/42542-0 • Fax +43 (0) 7483/42542-32

http://www.wittur.at • E-Mail: info@wittur.at http://www.wittur.at • E-Mail: info@wittur.at http://www.wittur.at • E-Mail: info@wittur.at

No part of this publication may be reproduced or We reserve the right to make alterations with respect Nachdruck, Übersetzung und Vervielfältigung in Änderungen gegenüber den in dieser Betriebsanlei- No part of this publication may be reproduced or We reserve the right to make alterations with respect No part of this publication may be reproduced or We reserve the right to make alterations with respect

translated, even in part, without prior written permis- to the specifications and figures in this manual. jeglicher Form - auch auszugsweise - bedürfen der tung aufgeführten Angaben und Abbildungen behal- translated, even in part, without prior written permis- to the specifications and figures in this manual. translated, even in part, without prior written permis- to the specifications and figures in this manual.

sion from WITTUR GmbH. schriftlichen Genehmigung der WITTUR AG. ten wir uns vor. sion from WITTUR GmbH. sion from WITTUR GmbH.

Änderungen vorbehalten! Subject to change without notice! Änderungen vorbehalten! Subject to change without notice! Änderungen vorbehalten! Subject to change without notice! Änderungen vorbehalten! Subject to change without notice!

THE LMC LIFTCOMPONENTS MANUFACTURING AND COMMERCE COMPANY THE LMC LIFTCOMPONENTS MANUFACTURING AND COMMERCE COMPANY THE LMC LIFTCOMPONENTS MANUFACTURING AND COMMERCE COMPANY THE LMC LIFTCOMPONENTS MANUFACTURING AND COMMERCE COMPANY

- Car frame operating instructions manual

- Safety gear operating instructions manual

- Guide shoe operating instructions manual

- Load weighing dev. operating instr. manual

- Crosshead beam incl. rope pulleys

(pre-assembled)

- Bottom Cross beam incl. safety gear and syn-

chronization

(pre-assembled and pre-adjusted)

Instantaneous or Progressive type

type safety gear safety gear

- Ringbeams

- Diagonals and fixing brackets

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.006

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

- Uprights

- Platform supports incl. lower car fixing

material (optional)

Accessories:

- Upper car fixing (incl. isolation buffer)

- Guide shoes

- Screw packages

Optional parts:

- Load weighing sensors

(incl. amplifier box)

- Compensation chain fixing

- Travelling cable hanger

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.007

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2 Installation

Car frame installation can either be carried Note the correct position of the bottom

out at the bottom of the lift shaft or on a cross beam in relationship to the governor

stable installation platform in the lift rope position (check layout drawing).

shaft. Also guide clamps could be used

which can take the total load of frame and During installation the frame must be sup-

car! ported so that it does not rest on the

guides.

The guide rails should have been already

properly set. The distance between the (1)

guide rails should be checked before

installing the car frame.

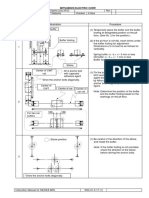

2.1 Placing the bottom cross beam

between the rails (1,4)

(2)

The bottom cross beam is delivered pre-assembled.

It contains the safety gear, the synchronization

and the buffer plates. The safety gear is bolted and

synchronized.

(1) If WCS60 is delivered with duplex (double) (1a)

safety gear, remove one guide rail. Mark the

location of the guide before removing.

(1a)If WCS60 is delivered with progressive type

safety gear, set the cross beam at an angle (see

Fig.).

(2) Clip one safety gear head onto the rail (2) (3)

(3) Turn Cross beam back into the horizontal posi-

tion, pushing the second safety gear device

onto the rail.

(4) Re-install the guide rail

(5) Adjust the cross beam in the middle of the

guide rails (safety gear gripping wedge must

overlap guide rail blade)

Check that the beam is horizontal in the

lateral direction.

(6)

(6) Fix the guide shoe to the safety gear housing

(for setting refer to operating instruction (5)

manuals of guide shoes)

Take care of tightening torque

Screw M20: 385Nm

Screw ... M20x40 (12x)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.008

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

(7) Lift OSG-lever by hand and

(8) ... secure it with a rope or wire around nearest

(7-8)

guide fixing

2.2 Securing the uprights to lower

cross beam

(1) Install the uprights to the bottom cross beam

Tighten the screw joints loosely only!

(2) Adjust the uprights in plumb and in centre to

the guide rails.

(3) Before tightening the screw joints, pack out

the spaces between upright and cross beam

with the shims if necessary.

Take care of tightening torque (1-2)

Screw M16: 195Nm

Shim

(3)

Screw ... M16x50 (32x)

Nut ........ M16

Safety nut ... M16

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.009

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 09.09.2003

Geprüft/approved WAT/FLE

Operating instructions

2.3 Installing Crosshead beam

The crosshead beam is delivered pre-assembled. It (3) Fit the guide shoe to the adapter plate (for

contains the beams, the rope suspension pulleys setting refer to operating instruction manuals

and adapter plates for the guide shoes. of guide shoe)

(1) Lift in the crosshead beam into the uprights

(2) Fit the beam to the uprights. If necessary add Remove lock-pin!

shims between beam and upright.

(3)

Take care of tightening torque

Screw M16: 195Nm

Screw M20: 385Nm

Screw ... M20x80 (12x)

(2)

Shim

Screw ... M16x40 (32x)

Nut ........ M16

Safety nut ... M16 (1)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.010

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2.4 Installing isolated platform sup-

ports

If the WCS60 is delivered with isolated platform (1-3)

support beams ...

(1) Fit the platform support to the lower cross

beam

Tighten the screw joints loosely only!

(2) Check that the support beams are

in horizontal position.

(3) Tighten then all screw joints

Take care of tightening torque

Screw M16: 195Nm

Screw ... M16x70 (12x)

2.5 Installing “non-isolated” platform

supports

If the WCS60 is delivered without isolated plat- (1-2)

form support beams ...

(1) Fit the platform support to the lower cross

beam (adjust according car platform needs)

Tighten the screw joints loosely only!

(2) Check that the support beams are in horizon-

tal position.

Tighten screw joints after car platform is

adjusted!

Screw ... M12x50

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.011

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2.6 Installing the diagonal rods

(1) Bolt the fixing brackets to the uprights

Use upper fixing holes in the upright

(lower group is used for upper car isola-

tion).

If car frame is delivered without isolated

platform support beams go on with car

platform installation section 2.9.

Screw ... M12x80 (12x)

(2) Install the ring beams below the platform

support beams

(3) Install the diagonal rods (1)

Take care of tightening torque

Screw M12: 80Nm

Do not tighten the 4 nuts at

(3)

the lower ends of the support

now (refer to section 2.11)!

Nut ... M36

(2)

Screw ... M30

Screw ... M12x35 (16x)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.012

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2.7 Travelling cable hanger and com-

pensation chain fixings

Before installing the car, fix the cable

hanger and chain fixings to lower cross

beam (for position refer to layout draw-

ing).

Take care of tightening torque

Screw M12: 80Nm

Travelling cable hanger types:

Screw package

611604G..

Compensation chain

fixing types:

Screw package

611604G..

Take care of different fixing

methods for different compen-

sation chain types.

Chain type: Other Chain

WF10, QL10 or types

similar

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.013

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2.8 Car installation (isolated platform

support)

(1) Lift the car floor (A) onto the fixing plates (B) (4) Adjust the car floor horizontally

of the platform support beams. Adjust the Secure the car by means of wooden sup-

floor to its place. ports at the front and rear edges.

The car floor must not touch the uprights. (5) Tighten the nut (G) by hand

(6) Install the car walls and the roof.

(2) Fit the T-bolt (D) to the car floor channel (E)

and move them to the opening at the fixing

plates. A

(3) Fasten the car floor against the fixing plates E

so that the disk washer (F) becomes fully com-

pressed. F B

Make sure that the T-bolts are hanging D

freely from the openings of the platform

supports!

G

(1-6)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.014

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2.9 Car installation (non-isolated

platform support)

(1) Lift the car floor (A) onto the support plates (4) Install the ring beams below the car floor.

(C). Adjust the floor and the plates to its place. Needed holes (D=18mm) must be drilled into

the ring beam!

The car floor must not touch the uprights.

(5) Install the diagonal rods

(2) Adjust the car floor horizontally Take care of tightening torque

Screw M12: 80Nm

(3) Fasten the car floor against the support plates

(fasten all the screw joints)

(6) Install the car walls and the roof.

A C

(1-3)

Nut ... M36

(5) (4)

Do not tighten the 4 nuts at the lower

ends of the support now (refer to section

2.11)!

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.015

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2.10 Finalizing Car installation

(1) Fix the upper car isolation to the car roof

channel (handtighten T-bolts)

(2) Fix the upper car isolation to the upright

Take care of tightening torque

Screw M12: 80Nm (2)

(3) Tighten the T-bolts

Take care of tightening torque

Screw M10: 46Nm

M12x35 (12x)

Remove the wooden supports under the

car floor!

(1,3)

(5-6) T-bolt M10

2.11 Tightening of diagonal rods

(5) Tighten the nuts (A) of all diagonals by hand

against the bottom fixing

(6) Tighten then the nuts (A) half a turn more, and

A

lock the fixing with the nut (B)

2.12 Car fixing bolts (isolated platform (7-9)

support)

(7) Adjust the nut (C) so that the square washer

(D) has a distance of approx. 3mm to the sup-

port beam profile edge E

(8) Push the square washer (D) against the nut by

means of the rubber ring (E) D

(9) Lock the fixing with the nut (F)

C

F

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.016

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2.13 Roping of the car frame 4:1 Suspension

C

(1) Check that the diverter pulley is exactly in the

middle between the cross head beam profiles.

If necessary, loosen the lower nuts (A) of the

isolations a little and adjust the diverter pulley

in lateral direction.

(2) Remove the rope guards (B)

(3) Pass the rope round the diverter pulleys

When used number of ropes is

less than the number of grooves

on the diverter pulley, the ropes are placed

according to the figure below. B

(2)

(4) Re-fit and adjust the rope guards (B) and the

rope pulley cover plates (C)

Ensure 3mm gap between rope guard and

ropes.

The car must be in the topmost floor (5) If WCS60 is delivered with pulley safety cover

when adjusting the cover plates. (D), mount it together with fixing nuts of the

rope guards (B).

(4)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.017

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2.14 Overspeed governor rope fixing

(1) Install the rope housing to the safety gear lift-

ing lever.

AK= Progressive type

Tighten the screw only so much, that the 350 Safety gear

rope housing can move a little.

(2) Fit and install the overspeed governor rope to

its place in the housing

(3) Install the rope grips

(2-3)

The rope grip clamp link must be on the

side of the rope end!

Rope grip

Rubber square

washer

OSG rope

Rope housing Roller type

Safety gear

(1) AK=

250

Package 392772G..

Safety gear

lever

(2-3)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.018

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2.15 Adjustment of safety gear syn-

chronization

(6) Adjust the safety gear in accordance with the

The safety gear device (safety gear, synchroniza- operating instruction manual

tion, safety gear contact) is delivered pre-adjusted. Take care of required safety gear running

Therefore no additional assembling of the safety clearance (referring also to the type of

gear device is needed. guide shoe used)

(1) Operate the safety gear lever by hand and

check that both safety gears begin gripping at

the same time

... If not (with progressive type safety gear):

(2) Loosen the screw joint (A) a little

(3) Pull the safety gear wedges on both sides

down so that the fixing links (B) are against (5)

the spring block (C). Switch

(4) Tighten the screw joints again without

changing the location of the safety gear A

wedges.

(5) Check the safety gear contact

function - adjust if necessary

The contact must break just

before safety gear gripping!

(1-4)

Safety switch (manual- or self reset type)

- use category: AC 15, A300, Ue/Ie 240V (3A)

- thermal current: Ithe = 10A Safety gear

- insulation voltage: Ui = 250V AC lever

- protection type: IP 43

- approved in accordance: VDE 0470

IEC/EN 60947-5-1

self reset manual reset (6)

Safety gear

B (duplex)

23 24 13 14

11 12 21 22

C

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.019

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

2.16 Load weighing device WLWD-M

For setup of the load weighing device WLWD-M

refer to the operating instruction manual.

(1) Fit the load weighing device to the upper cross (1)

beams

Screw M8

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.020

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

3 Function testing

Operational reliability of the installation is assured, Static & dynamic function testing

assuming that all guide lines were adhered to dur-

ing proper installation. The quality and function of Refer to the operating instructions of the relevant

individual components are subject to thorough safety device.

inspection and is checked before dispatch from

our works. Once installation fitting is complete, Examine the lift car frame for changes

the lift car frame system should undergo an oper- after carrying out the safety gear test:

ational test before commissioning or before possi- - deformation of components

ble inspection from a technical institute. - that the screws are firmly in place

- signs of damage or wear on the rope

First test run after installation pulleys, guides and suspension points

Before the first test run: There must not be anybody in the lift car

Clean the guide rails! when carrying out test runs or functions

tests!

Clear all people and objects from the lift

shaft before commencing the test run

Risk of crushing injuries!

The entire lift travel path should be slowly trav-

elled (in inspection mode) before the functions

tests. Attention should be paid to the clearance of

all fastened parts, especially with regards to the

guide brackets/safety gear devices. Find and

remove any protruding bolts or other dangerous

restrictions well in advance.

Safety clearance inspections at the bottom of the

shaft and shaft head (observe the applicable regu-

lations/guidelines):

- Check the following distances between the

shaft floor, after descending the shaft pas-

sage:

- Distance between guide - floor

- Distance between cross beam - floor

- Check the following distances to the shaft

ceiling, on completion of ascension of the lift

shaft:

- Distance between guide - ceiling

- Distance between rope pulleys - ceiling

- Distance between cross beam - ceiling

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.021

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

4 Maintenance, inspection and repair

4.1 Maintenance and inspection

The WITTUR lift car frame requires little servicing. The lift installation must be immediately

taken out of use should any damage or

Inspection checks must be carried out at regular irregularities to the lift car frame arise

intervals (minimum twice a year with each service) which could possibly impair operational

to guarantee safe operation. Alterations, damage safety.

or other irregularities should be reported, and

repaired if possible. Frequent servicing and control Please contact us at WITTUR if you have

checks not only make operation of the installation any problems or queries.

safer, but also ensure long and reliable lifetime.

Maintenance work should be expertly car-

It is recommended that control checks and servic- ried out with utmost care in order to guar-

ing be carried out before legally prescribed func- antee safe installation operation.

tional tests (e.g. before TÜV tests).

WITTUR car frame maintenance and inspection check list

General: Safety gears:

- Visual inspection for general irregularities (i.e. - Check the operation of the safety gear at

dirt build up, corrosion, deformation, fractur- every service call. Refer to the operating

ing etc.) instructions of the installed safety device.

- Check the screw connections - The surface of the wedge area has to be clean.

Wedge and roller must not be cracked.

- Check the overspeed governor rope fixing

Lubricator:

- Replenish Rope pulley:

- Check the felt inserts for damage, replace if

necessary - Signs of wear on the rope pulley; replace if

necessary

- Check the condition of the rope pulley bear-

Guide shoes: ings by listening to the running noise (refer to

the Chapter “Carrying out repairs”)

- Check sliding inlays at every service call.

Replace the sliding inlays by new one if the

running clearance is more then 2mm (refer to Platform support (isolation beams):

the Chapter “Carrying out repairs”)

- Check visually that the platform support is not

twisted (release diagonal rods to untwist)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.022

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

4.2 Carrying out repairs

The following repairs should be carried out on site

As a rule, damage or deformation of a car by qualified fitters/service personnel:

frame (i.e. as result of bending or heating)

cannot be repaired or straightened. The • The sanding down of rust (i.e. caused as result

damaged parts should be replaced. Only of damage to the undercoat) and application

use WITTUR spare parts. of a suitable paint sealant.

• Changing the guides / guide shoe inserts

Repairs should be expertly carried out with • Changing the rope pulleys

utmost care in order to guarantee safe

installation operation. Please contact WITTUR if for any reason

something is unclear, or you encounter

Follow all the local safety instructions dur- damage that cannot be repaired with the

ing the maintenance work. help of these instructions.

4.2.1 Changing the guides/inserts 4.2.2 Changing the rope pulley

The components for the guides which are subject- The rope pulleys can be delivered individually as

to-wear (sliding inlays) can be delivered individu- spare parts (refer to “Spare parts” chapter).

ally as spare parts: (see Chapter “Spare parts”).

Procedures for changing a rope pulley:

The distance (play) to the rails (distance

between guides) must be readjusted after • Lower the lift car onto its contact buffer

replacement of the inlays and remounting. • Safeguard the counterweight against falling

• Release the ropes

• Unscrew the complete rope pulley / axle / axle

bracket unit

• Dismantle rope pulley / axle / axle bracket unit

• Replace the rope pulley, and remount the parts

following the instructions above in reverse

order

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D389MGB.023

Car Frame WCS60 Datum/date 11.02.2002

Suspension 2:1 / 4:1 Stand/version 11.02.2002

Geprüft/approved WAT/FLE

Operating instructions

4.3 Spare parts list

Component Type Spare part Number... Art. No.

Sliding guide shoe SLG4 Guide shoe rail width 29 mm 1 473004G29

32 mm 1 473004G32

SLG4A Guide shoe rail width 29 mm 1 473004G29A

32 mm 1 473004G32A

Guide rail lubricator rail width 29 mm 1 89870G29

32 mm 1 89870G32

Sliding inlay “white” colored (SLG4) 29 mm 1 433371H29

Note: Fixing material to be ordered separately 32 mm 1 433372H32

Sliding inlay “green” colored (SLG4A) 29 mm 1 433373H29

Note: Fixing material to be ordered separately 32 mm 1 433374H32

Rope pulley DR=656mm Rope DL=13mm NRmax=9 1 471341G02

(incl. bearings) Rope DL=16mm NRmax=8 1 471341G03

DR=780mm Rope DL=13mm NRmax=9 1 471343G02

Rope DL=16mm NRmax=8 1 471343G01

DR=895mm Rope DL=13mm NRmax=9 1 471342G04

Rope DL=16mm NRmax=9 1 471342G03

Änderungen vorbehalten! Subject to change without notice!

You might also like

- Allison 1000 y 2000Document672 pagesAllison 1000 y 2000Mauricio Gomez Gomez100% (10)

- MAYR Elevator BrakesDocument8 pagesMAYR Elevator Brakesgeorge_zouridisNo ratings yet

- Solutions HW5Document4 pagesSolutions HW5Far Away Archipelago50% (4)

- 1 Homework 1Document7 pages1 Homework 1Alexis DelgadoNo ratings yet

- Hydraulic Car Frame WLF03 / WLF06 / WLF10 / WLF16 / WLF20Document57 pagesHydraulic Car Frame WLF03 / WLF06 / WLF10 / WLF16 / WLF20mario escottoNo ratings yet

- Hydraulic Car Frame WHF35 Direct and IndirectDocument38 pagesHydraulic Car Frame WHF35 Direct and Indirectmario escottoNo ratings yet

- PM 7 000338 en 01Document30 pagesPM 7 000338 en 01Anonymous N57sCcpiNo ratings yet

- Isolated Roller Guides Shoes WRG150, WRG150HDDocument16 pagesIsolated Roller Guides Shoes WRG150, WRG150HDhabibullaNo ratings yet

- Electronic Load Weighing Device WLWD-MDocument28 pagesElectronic Load Weighing Device WLWD-MCoil98No ratings yet

- PM 5 000279 en 01Document23 pagesPM 5 000279 en 01SavoyNo ratings yet

- WCF-SERIES-Top Suspension Manual PDFDocument36 pagesWCF-SERIES-Top Suspension Manual PDFYiannis ToufexisNo ratings yet

- PM 3 002348 en 01Document28 pagesPM 3 002348 en 01wilderness_666No ratings yet

- Isolated Roller Guide Shoes WRG200, WRG300Document15 pagesIsolated Roller Guide Shoes WRG200, WRG300Johan GuíaNo ratings yet

- 5elevator Installation Manual For Elevator With Machine Room V1.4 - 1Document113 pages5elevator Installation Manual For Elevator With Machine Room V1.4 - 1aneesh tNo ratings yet

- 006 - 5install CWT Roping and Remove Top Floor Working Platform - MRDocument5 pages006 - 5install CWT Roping and Remove Top Floor Working Platform - MRAli DiabNo ratings yet

- CDD983 01Document20 pagesCDD983 01Patrick KeeneNo ratings yet

- 630 KG (Car 1400 X 1100)Document2 pages630 KG (Car 1400 X 1100)Myo AungNo ratings yet

- Escalator Otis: 506NCE - EN - FM1Document55 pagesEscalator Otis: 506NCE - EN - FM1Rafael BrunoNo ratings yet

- Goods Lifts: 300 - 2000kg CapacityDocument14 pagesGoods Lifts: 300 - 2000kg CapacityAnton LyakhovNo ratings yet

- S3300ap-Brochure Ascensor PDFDocument20 pagesS3300ap-Brochure Ascensor PDFStephanie García100% (1)

- TT TN Connection MainsDocument9 pagesTT TN Connection MainsYasmin QuintelaNo ratings yet

- EOS UCM Package EBRA20-UCM Insert For Operation Manual PM.7.002883.ENDocument16 pagesEOS UCM Package EBRA20-UCM Insert For Operation Manual PM.7.002883.ENВиктор АлимовNo ratings yet

- DokumenDocument14 pagesDokumenTroubleshootingNo ratings yet

- 1117 32 0013 Assembly Manual EngDocument31 pages1117 32 0013 Assembly Manual Engjavier ariasNo ratings yet

- MUSE ED Elevator: Installation ManualDocument6 pagesMUSE ED Elevator: Installation ManualMoises PerelloNo ratings yet

- MagnubroucherDocument12 pagesMagnubroucherrmdarisaNo ratings yet

- Otis Offer PDFDocument12 pagesOtis Offer PDFgoodsum01No ratings yet

- Dokumen Dari Jon@Th@n Verrell-2-1Document101 pagesDokumen Dari Jon@Th@n Verrell-2-1omotu79No ratings yet

- Weltweit ! Worldwide!: RollenführungDocument3 pagesWeltweit ! Worldwide!: RollenführungsmsobhanNo ratings yet

- LiftDocument8 pagesLiftpooja modia100% (1)

- Tool Velino FT853Document12 pagesTool Velino FT853Polinho DonacimentoNo ratings yet

- ARES Escalator 5Document3 pagesARES Escalator 5GutmonarchNo ratings yet

- MUSE ED Elevator: Installation ManualDocument16 pagesMUSE ED Elevator: Installation ManualMoises PerelloNo ratings yet

- 01 Iris1Document35 pages01 Iris1AndiosoNo ratings yet

- Thyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetDocument15 pagesThyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetTek tek hapNo ratings yet

- Otis ADV 211HD LCB II Diagramas PDFDocument10 pagesOtis ADV 211HD LCB II Diagramas PDFelectroliticoNo ratings yet

- Sigma MRL E1000 PDFDocument8 pagesSigma MRL E1000 PDFMitroNo ratings yet

- Opman Ap230924capDocument171 pagesOpman Ap230924capMohamadNo ratings yet

- EC100 Elevator Intelligent Integrated Machine Operation Maual V2.3Document252 pagesEC100 Elevator Intelligent Integrated Machine Operation Maual V2.3Бахтияр ЮмачиковNo ratings yet

- Door Operation Controller Drive BLDCDocument20 pagesDoor Operation Controller Drive BLDCБахтияр ЮмачиковNo ratings yet

- ARES Escalator 6Document7 pagesARES Escalator 6GutmonarchNo ratings yet

- Elevator Programming CodeDocument178 pagesElevator Programming Code100mphNo ratings yet

- NICE7000 DebuggingDocument4 pagesNICE7000 DebuggingTroubleshootingNo ratings yet

- MUSE ED Elevator: Installation ManualDocument25 pagesMUSE ED Elevator: Installation ManualMoises PerelloNo ratings yet

- Vol88 PDFDocument32 pagesVol88 PDFArnold Thamrin van LutteranNo ratings yet

- Prepared Oyama (July 2012) Rev. WIG-21 Checked T.Natsume Checked K.HaraDocument18 pagesPrepared Oyama (July 2012) Rev. WIG-21 Checked T.Natsume Checked K.HaraEtienneNo ratings yet

- ATLAS 2 - 1-PL - DATA-v2.5-2009-EN PDFDocument11 pagesATLAS 2 - 1-PL - DATA-v2.5-2009-EN PDFzajednosexNo ratings yet

- Gearless Machines March 2018 2 PDFDocument39 pagesGearless Machines March 2018 2 PDFMauro Enrique Ortiz Castelán100% (1)

- Diagram Fx3u Yaskawa Fuji 01 2017Document10 pagesDiagram Fx3u Yaskawa Fuji 01 2017Dhany ElectronicNo ratings yet

- Division 14 - Elevator Design Standards 1 GeneralDocument28 pagesDivision 14 - Elevator Design Standards 1 GeneralAnsara Pasir TumbohNo ratings yet

- PresentationDocument19 pagesPresentationChang Chang100% (1)

- Solon PremiumDocument30 pagesSolon PremiumWildan HeroNo ratings yet

- 06 - High Speed AdjustmentDocument3 pages06 - High Speed AdjustmentMoises PerelloNo ratings yet

- NICE3000 电梯一体化控制器用户手册 (英文详版) - V1.0 PDFDocument232 pagesNICE3000 电梯一体化控制器用户手册 (英文详版) - V1.0 PDFAsdrubal Fredy GutierrezNo ratings yet

- Steel W Orks Products (Thailand) : Elevator Controller SystemDocument4 pagesSteel W Orks Products (Thailand) : Elevator Controller Systemtran xobonNo ratings yet

- Quick Reference Installation Guide: The Peelle CompanyDocument62 pagesQuick Reference Installation Guide: The Peelle CompanyRodrigo Antonio100% (1)

- Installation: SA OLE BufferDocument20 pagesInstallation: SA OLE BufferAli DiabNo ratings yet

- Thyssenkrupp Elevator: Stage 1 BDocument3 pagesThyssenkrupp Elevator: Stage 1 Bgajendrabanshiwal8905No ratings yet

- Mel 03 - 08C2 - ElenessaDocument1 pageMel 03 - 08C2 - ElenessaUmer FarooqNo ratings yet

- KONE - Machine Room Type - 1600 KG, Speed 2.5 PDFDocument1 pageKONE - Machine Room Type - 1600 KG, Speed 2.5 PDFNghia100% (1)

- XJ Schindler Passazhirskiy LiftDocument32 pagesXJ Schindler Passazhirskiy Liftkonsuba teknik perkasaNo ratings yet

- Ornek Sorular Cilt1Document52 pagesOrnek Sorular Cilt1ThorisNo ratings yet

- Natrayan 2018Document7 pagesNatrayan 2018Agastin RubanNo ratings yet

- Camisas Refrigeracion Flowsleeves Pi-058 GB 2013-06-12Document38 pagesCamisas Refrigeracion Flowsleeves Pi-058 GB 2013-06-12daniel2rialNo ratings yet

- Compressor Design PDFDocument7 pagesCompressor Design PDFwaheedNo ratings yet

- Rigid Pavement at IPTMDocument33 pagesRigid Pavement at IPTMPadma ShahiNo ratings yet

- Supracell Circular Daf: Dissolved Air Flotation ClarifierDocument2 pagesSupracell Circular Daf: Dissolved Air Flotation ClarifierKevin KeaneNo ratings yet

- Kerax 380 P6X4Document6 pagesKerax 380 P6X4sulimanNo ratings yet

- Experimental Investigation On Chromium-Diamond Like Carbon (CR-DLC)Document7 pagesExperimental Investigation On Chromium-Diamond Like Carbon (CR-DLC)Yến Nhi Nguyễn HồNo ratings yet

- P & ID Review Check List: Chemical Engineering SiteDocument7 pagesP & ID Review Check List: Chemical Engineering SiteMayur ParmarNo ratings yet

- Brosur MCV, BCV & Sprinkler Head DUYARDocument12 pagesBrosur MCV, BCV & Sprinkler Head DUYARArya WisnuNo ratings yet

- Double Duplex BaggingDocument3 pagesDouble Duplex BaggingariefNo ratings yet

- Bard UP03Document12 pagesBard UP03Alan VazquezNo ratings yet

- Mock Final ExamDocument15 pagesMock Final ExamMing SuNo ratings yet

- PSAD 4 May 5 2023Document19 pagesPSAD 4 May 5 2023Renne Jude Rollorata100% (1)

- InnoPlus LD2420D - InnoPlusDocument3 pagesInnoPlus LD2420D - InnoPlusEko SabtianNo ratings yet

- Technical Data of The Fan: RZR 13-1250: To Motor: Siemens-IE3 1LE1003-1DB43-4AB4/IE3Document3 pagesTechnical Data of The Fan: RZR 13-1250: To Motor: Siemens-IE3 1LE1003-1DB43-4AB4/IE3mahmadwasiNo ratings yet

- OsmaDrain Jointing Quick GuideDocument2 pagesOsmaDrain Jointing Quick GuideHatem AbdelnabiNo ratings yet

- Micro To MACRO Mathematical Modelling in Soil Mechanics (Trends in Mathematics)Document407 pagesMicro To MACRO Mathematical Modelling in Soil Mechanics (Trends in Mathematics)Renova HnNo ratings yet

- Scorpio Crde Wiring Manual Rev3 Reduced PDFDocument51 pagesScorpio Crde Wiring Manual Rev3 Reduced PDFhelorcaNo ratings yet

- Servo Gun v2.8 (Eng) ObaraDocument63 pagesServo Gun v2.8 (Eng) Obaralogaing13No ratings yet

- Fundamentlsof Rotor and Power Train Maintenance Techniques and ProceduresDocument68 pagesFundamentlsof Rotor and Power Train Maintenance Techniques and ProceduresrfriosEPNo ratings yet

- Vigo Elec Wiring DiagramDocument18 pagesVigo Elec Wiring DiagramVinh PhạmNo ratings yet

- Astm A 490Document6 pagesAstm A 490Pedro Diaz UzcateguiNo ratings yet

- Cylinder 80-300 W INERGEN PDFDocument1 pageCylinder 80-300 W INERGEN PDFIskandar HasibuanNo ratings yet

- Ae 4425Document1 pageAe 4425أبو زينب المهندسNo ratings yet

- Units and Measurements. NEET 01docxDocument2 pagesUnits and Measurements. NEET 01docxWesNo ratings yet

- Steel To Concrete Joints Design-Manual II enDocument292 pagesSteel To Concrete Joints Design-Manual II enSujeevan Tharmakulasingam100% (2)