Professional Documents

Culture Documents

km8112356 Section 13

Uploaded by

luis eduardo corzo enriquezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

km8112356 Section 13

Uploaded by

luis eduardo corzo enriquezCopyright:

Available Formats

13T2000 A PA D S Tr o u b l e s h o o t i n g

KM811236 12/00

KENWORTH HVAC SYSTEMS

Section

T2000 APADS Troubleshooting

13A C2TX Cab Unit Troubleshooting

13B Cab Heater – A/C Circuit Description

13C Sleeper Temperature Control – Trouble-

shooting Guide

13D Cab Unit C2TX

13E C2TX Communications via SAE J1587/J1798

13F C2TX HVAC Controller

13G Wiring Diagram – P94-1125 (Cab & Sleeper

with APADS)

(12/00) KM811236 13-1

13

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Section 13A C2TX Cab Unit Troubleshooting

APADS and Automatic For troubleshooting the Cab Unit C2TX, see the following tables:

Temperature Control 1. Table 13-1, “Cab Unit C2TX Troubleshooting – Compressor Clutch

Does Not Engage.”

2. Table 13-2, “Cab Unit C2TX Troubleshooting – Unit Not Broadcasting

Ambient Temperature.”

3. Table 13-3, “Cab Unit C2TX Troubleshooting – HVAC Not Maintaining

Constant Discharge Temperatures.”

4. Table 13-4, “Cab Unit C2TX Troubleshooting – Blower Won’t Turn On.”

5. Table 13-5, “Cab Unit C2TX Troubleshooting – Ambient Temperatures

being Broadcast are Incorrect.”

13-2 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Table 13-1 Cab Unit C2TX Troubleshooting – Compressor Clutch Does Not Engage

CONDITION DIAGNOSTIC CODE POSSIBLE CAUSE ACTION

Compressor clutch Low pressure fault.1 Loss of refrigerant. Check system for leaks.

does not engage.

Defective low pressure If the low side pressure is

switch. adequate (more than 30

psi), the pressure switch

should be closed. Replace

switch if it is not.

Open circuit between Check wiring and repair as

C2TX module and the low necessary.

pressure switch.

High pressure fault. Overcharge of refrigerant Reclaim refrigerant and

in system. charge to the correct

amount.

Blocked air flow through Remove restriction from

condenser (e.g. bugs, condenser.

leaves.)

No fan engagement. 1. Check air lines for

restriction.

2. Inspect operation of

solenoid valve.

3. Check operation of fan

hub.

High side pressure switch Make sure the AC

failure. compressor is off. Open

connection to the switch

At start up, after 15 and measure the

seconds, compressor resistance value of the

clutch does not engage but pressure switch. If the

engine fan engages. resistance shows greater

than 5 ohms, remove

switch and repeat

measurement. If resistance

is still greater than 5 ohms,

replace switch.

Open clutch Open wire or contact or Check wiring and clutch

defective (open) clutch. and repair/replace as

necessary

Shorted clutch Short circuit in wiring (pin Check wiring and clutch.

19 to + battery) or in Clutch impedance could be

clutch. greater than 2.9 ohms.

(12/00) KM811236 13-3

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Table 13-1 Cab Unit C2TX Troubleshooting – Compressor Clutch Does Not Engage (Continued)

CONDITION DIAGNOSTIC CODE POSSIBLE CAUSE ACTION

Evaporator temperature Wiring or contact problem Check wiring. If wiring

sensor fault (AC not between C2TX and appears to be OK, open

allowed if evaporator evaporator sensor. the connector and

temperature can not be Defective sensor measure the impedance of

measured.) the evaporator thermistor

(20K ohms @ 77° F, 66K

ohms @32° F. (Less than

2.2K ohm or more than 1

megaohm is “BAD.”)

Low voltage or high voltage Truck electrical system. Check truck wiring for

(voltage at C2TX: module drops. Check other

must be between 11 and components for sources of

16 volts for AC clutch excess voltage.

operation).

High pressure switch open. Open circuit to the high Check wiring and contacts

pressure switch. between C2TX module

and high pressure switch.

None/AC clutch not Unit is functioning properly.

engaging during first 15 Regardless of AC system

seconds after ignition is state at start up, the AC

turned on. clutch is disengaged for

the first 15 seconds.

None/Cold weather Unit is more than likely To confirm that cold

functioning correctly. Low weather and the low

ambient temperatures pressure switch are

reduce refrigerant blocking AC operation,

pressures to the point slightly heat the ambient

where the low pressure sensor. After the ambient

switch may open and block sensor is above 48° F for

AC operation. “Low more than 3 minutes, the

pressure faults” are not C2TX will generate a “Low

generated when the pressure fault.” Ambient

ambient temperature is sensor is at the bottom of

below 48° F. the passenger side mirror.)

1

1. The low pressure fault does not “clear” (from ACTIVE to INACTIVE) on the next ignition cycle. All other

faults do. This fault will continue in the active state and will continue to block AC operation until it is

cleared. Clear by cycling the ignition switch 4 times (one second on/one second off). If the fault condition

still exists, it will again become active.

13-4 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Table 13-2 Cab Unit C2TX Troubleshooting – Unit Not Broadcasting Ambient Temperature

CONDITION DIAGNOSTIC CODE POSSIBLE CAUSE ACTION

Unit not broadcasting None Power not getting to C2TX Check fuse, wiring and

ambient temperature (pins 10 and 20 on contacts.

(once /10 seconds). module).

Data Bus: Are other Yes: Data bus is not a

devices broadcasting problem.

normal information on the

data bus? No: Check to determine

if one device is corrupting

the data bus.

C2TX has power and data Replace C2TX.

bus is OK.

Table 13-3 Cab Unit C2TX Troubleshooting – HVAC Not Maintaining Constant Discharge Temperatures

CONDITION DIAGNOSTIC CODE POSSIBLE CAUSE ACTION

Not maintaining None Bad blend temperature Check blend thermistor

constant discharge sensor (the C2TX drives wiring and impedance

temperatures as the blend door output (2.8K at 77° F. Less than

ambient and directly as a function of the 220 ohms or more than

fresh/recirc conditions cab potentiometer input.) 100K ohms is “BAD.”)

change.

Blend door actuator bad. Check input voltage to

door. If voltage changes as

NOTE: To quickly determine if temperature control

the blend air door is function-

changes and actuator does

ing properly, perform the fol-

not move, actuator is bad.

lowing test.

Replace.

1.Remove heater coil

from HVAC unit.

2.With ignition key ON,

have an assistant

slowly rotate cab tem-

perature control dial

from full cold to full hot.

3.At same time, observe

door movement

(through heater coil

opening) as control dial

is rotated.

4.Blend air door should

open and close fully as

control dial is rotated.

5.If blend air door does

not move during this

test, follow trouble-

shooting procedures

above.

(12/00) KM811236 13-5

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Table 13-4 Cab Unit C2TX Troubleshooting – Blower Won’t Turn On

CONDITION DIAGNOSTIC CODE POSSIBLE CAUSE ACTION

Blower won’t turn on. None C2TX monitors the blower Check blower motor and

for “on/off” status, but circuit integrity (fuse,

cannot inhibit normal switch, and wiring).

manual operation.

Table 13-5 Cab Unit C2TX Troubleshooting – Ambient Temperatures being Broadcast are Incorrect

CONDITION DIAGNOSTIC CODE POSSIBLE CAUSE ACTION

Ambient temperatures Ambient erratic Wiring or contact problem Check connections (3)

being broadcast are between C2TX and between C2TX and sensor.

incorrect ambient sensor (inside Check sensor for physical

passenger mirror). damage. (If mirror is

damaged, the sensor may

also be damaged.) Check

impedance of sensor

(between 500K ohms and

800 ohms).

13-6 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

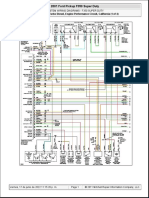

Section 13B Cab Heater – A/C Circuit Description

1. FROM CAB HARNESS See diagram P94-1125.

C102AC – Lt. Ground for Engine Fan Solenoid (Switched by control module)

Green/White

C102ACN – Lt. Ground for A/C clutch relay (switched by control module).

Green/White

C102ACP – Lt. Power for A/C Clutch

Green/White

L13LI – Gray Power to panel lights.

P30CHA – Lt. Sleeper Temperature Setpoint

Blue/Black

P30CHC – Lt. Switched battery power to blower motor (through 40 amp fuse).

Blue/Black

P30CHD – Lt. Switched battery power to electronic controls.

Blue/Black

GND68 – White Ground for Blower Motor

P124HT – Lt. Switched battery power for sleeper switch (through 20 amp fuse).

Green/White

P124SHA – Lt. Power to sleeper heater (switched on cab control)

Green/White

GND78 – White Ground for Electronics.

C108DB – Lt. Data Bus ( + )

Blue/Black

(Twisted)

C109DB – Data Bus ( - )

Blue/Black

(Twisted)

P30CHA – Lt. Sleeper temperature setpoint voltage from sleeper control.

Blue/Black

2. TO UNIT

C102ACN – Lt. Ground for A/C clutch relay (switched by Control Module).

Green/White

(12/00) KM811236 13-7

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

ACTDEF – Red Control voltage for defrost door actuator.

Mode Voltage

Vent 12V

Vent/Floor 12V

Heat 2V

Heat/Defrost <1V

Defrost <1V

ACTVH – Red Control voltage for vent/heat door actuator.

Mode Voltage

Vent <1V

Vent/Floor 6V

Heat 12V

Heat/Defrost 6V

Defrost <1V

C102AC – Lt. Ground for engine fan solenoid (Switched by control module)

Green/White

C102ACP – Lt. Power for A/C Clutch

Green/White

HI – Green Blower high speed (switches to ground)

MED – Green Blower medium speed (switches to ground)

MEDLO – Green Blower medium-low speed (switches to ground).

LO – Green Blower low speed (switches to ground)

P30CHA – Lt. Sleeper temperature setpoint voltage from sleeper control

Blue/Black

P30CHC – Lt. Power for blower.

Blue/Black

P30CHD – Lt. Power for electronic actuators.

Blue/Black

ACTBLD – Blue Control voltage for blend air door (12V for cold, 1V for hot).

ACTFA – Purple Control voltage for fresh air door (1V for fresh air, 12V for recirculation.

GND68 – White Ground for Blower Motor.

TEMP SEL Set temperature for cab ATC (12V for cold, <1V for hot).

GND78 – White Ground for electronics and actuators.

C108DB – Lt. Data Bus (+)

Blue/Black

(Twisted)

13-8 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

C109DB – Data Bus (-)

Blue/Black

(Twisted)

AMBIENT SENSOR

OAT1 – Black Outside Air Temperature

OAT2 – Black Return Line Sensor

(12/00) KM811236 13-9

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

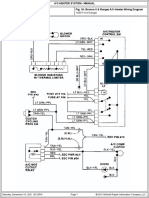

Section 13C Sleeper Temperature Control – Troubleshooting Guide

Theory of Operation The temperature control system consists of three major components. See

diagram P94-1125.

1. Control Module with built-in temperature sensor and potentiometer.

2. Blower switch.

3. Blend air door actuator.

These components are tied together by three wires:

1. SACT1 – 12V supply for the system.

2. GND – ground for the system.

3. SACT2 – control output voltage

You can change the potentiometer position in order to change the setpoint

temperature, (between 50° F and 130° F). If the temperature is above the

setpoint, the control module puts out approximately 1 volt. This moves the

blend air door to close off the hot air passage. If the temperature goes

below the setpoint, the control module starts to increase its output volt-

age, opening the door.

The control also provides the sleeper requested temperature on circuit

P30CHA. The cab automatic temperature control uses this to help deter-

mine when air conditioning is required.

Component Troubleshooting

Blend Air Door The blend air door actuator has three circuits:

1. SACT1 – 12V supply for actuator – pin 10 on actuator and pin A on

unit connector.

2. GND – Ground connection – pin 7 on actuator and pin C on unit con-

nector.

3. SACT2 – Control voltage – pin 8 on actuator and pin B on unit con-

nector.

If SACT2 is not connected, the actuator will go to the center of its travel

and stay there. If SACT2 is connected to the 12 volt supply, the blend air

door will open the hot air passage all the way. If SACT2 is connected to

ground, the blend air door will close the hot air passage all the way.

Control Module The control module has three circuits:

1. SACT1 – 12V supply for module – pin 3 on module.

2. GND – Ground connection – pin 1 on module.

3. SACT2 – Control voltage – pin 2 on module.

4. P30CHA – Sleeper setpoint – pin 4 on module.

13-10 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

If the sleeper is at room temperature, (65° F to 80° F), turning the temper-

ature control knob to full cold (counter-clockwise) will make the control

voltage go to 0 volts. Turning the knob full hot (clockwise) will make the

control voltage go to within 1 volt of the supply voltage.

In order to check the function of the temperature sensor, have the ignition

on, but don't run the engine. Turn the blower on low to provide power.

Attach the voltmeter to measure the voltage of wire SACT2. Adjust the

control knob so the voltage is about 6 to 7 volts. Blow gently on the sensor

grill in order to warm the sensor. Watch that the control voltage goes

down, then returns to roughly the original voltage as the sensor cools

back down.

(12/00) KM811236 13-11

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Troubleshooting Tree

Complaint: 1. After checking the engine block valve and blower operation, check for

Sleeper Won't power to SACT1 from blower switch.

Heat

1.1. If no power, check connections and blower switch and repair or

replace as necessary, retest system.

1.2. If power is OK, go to step 2.

2. Check ground connection from sleeper harness.

2.1. If no ground, repair connection, retest system.

2.2. If ground is OK, go to step 3.

3. Make sure sleeper temperature is below 80° F. Turn control knob to

full hot (clockwise) position. Check SACT2 voltage at actuator (pin 8).

It should be above 11 volts.

3.1. If not, check for SACT2 voltage at temperature control module

(pin 2). If there is no control voltage at pin 2, replace control

module. Retest system.

3.2. If pin 2 voltage at control module is OK , check for open or short

in wiring from control module to actuator. Repair wiring as nec-

essary.

3.3. If wiring from control module to actuator is OK, check SACT1

for system voltage at actuator (pin 8), and ground (pin 7). If

power and ground are OK, replace actuator. If not, repair wiring

as necessary. Retest system.

Complaint: Won't 4. After checking the air conditioner compressor and blower operation,

Cool check for power to SACT1 from the blower switch.

4.1. If no power, check connections and blower switch and repair or

replace as necessary, retest system.

4.2. If power is OK, go to step 5.

5. Check ground connection from sleeper harness.

5.1. If no ground, repair connection, retest system.

5.2. If ground is OK, go to step 7.

6. Make sure sleeper temperature is above 65° F. Turn the control knob

full cold (counter-clockwise). Check that SACT2 voltage is below 1.5

volts.

6.1. If not, unplug the control module and check the actuator (see

component check above).

6.1.1. If actuator checks OK, replace control module, retest sys-

tem.

6.1.2. If actuator does not work, remove it from the blend air door

and retest. Replace the defective component and retest

system.

6.2. If voltage is OK, check wiring continuity to actuator.

13-12 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

6.2.1. If no continuity or high resistance connection, repair wiring

and retest the system.

6.2.2. If wiring is OK, check actuator and replace if defective.

Retest system.

Complaint: Poor 7. Check to make sure nothing is obstructing air flow to the sensor, (i.e.,

Control hanging clothes, etc.).

7.1. If air flow is OK, check temperature sensor function (see com-

ponent check above).

7.1.1. If sensor is bad, replace module and retest system.

7.1.2. If sensor is OK, check blend air door actuator and replace if

bad. Retest system.

Complaint: Erratic 8. Check wiring for intermittent, loose, or corroded connections.

Operation

8.1. If any are found, correct and retest system.

8.2. If not, disconnect and check blend air door actuator.

8.2.1. If actuator or blend air door is bad, replace and retest sys-

tem.

8.2.2. If actuator is OK, check control module and replace if bad.

(12/00) KM811236 13-13

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Section 13D Cab Unit C2TX

Product Overview The C2TX is an electronic, micro-processor based device that imple-

ments the functions of a blend vent ATC (Automatic Temperature Control)

and APADS (Air Conditioning Protection and Diagnostics System) control

and diagnostic functions. It is specifically designed to reduce air condi-

tioning maintenance costs in vehicular Txv HVAC systems by increasing

the life of system components and aiding in the diagnosis of system

faults. The unit receives inputs from pressure switches, temperature sen-

sors, Control Panel switches/potentiometers, and data available on the

SAE J1587 compatible data bus. The input signals are processed to drive

outputs to the AC clutch coil, fan actuator circuit, blend door actuator and

a Blower Relay. C2TX diagnostic codes are available on the Databus.

With this control system the C2TX controller becomes the only device

through which power is switched to the AC clutch coil. It is the primary

control of the AC and blend temperature system. The module is housed in

an aluminum capsule and installed in the cab unit.

Functional Description The C2TX operates as the primary AC system and cab temperature con-

trol. The module provides outputs to the AC compressor clutch coil, the

fan actuator, the blend air door actuator and a blower relay. All outputs are

a function of the ATC and APADS control algorithms as detailed later in

this section. The controller incorporates its own high current driver elimi-

nating external relays to engage the AC clutch. Fault diagnostic communi-

cation is accomplished through the SAE J1587 databus interface.

The pointed features of the C2TX are that it acts to control the vent outlet

temperature to a fixed value, independent of various system variables

such as initial ambient temperature, blower speed, engine RPM and circu-

lation mode.

The ATC function of the C2TX controls the blend air door actuator to

maintain a target temperature in the blend chamber. This target tempera-

ture is a function of control panel and temperature sensor inputs, primarily

setpoint input and blend temperature.

The ATC function also determines when Air Conditioning is needed. This

control logic requests AC when the desired blend chamber temperature

cannot be achieved without Air Conditioning. AC will always be requested

when the Temperature Set potentiometer is in the full CCW position and

when MODE select is in the defrost position above freezing conditions. It

will also be requested when ambient temperature is within several

degrees of the temperature requested by the Bunk Set temperature knob.

13-14 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

C2TX Input The module interfaces and receives inputs from the following sensors and

Descriptions devices:

1. AC Input – Input that indicates whether AC is requested. Temperature

select to full cold commands continuous AC within operation

temperature limits. Other Temperature selections default to ATC

command.

2. AMBIENT Temperature – Outside ambient temperature sensing NTC

thermistor, 1.0 Kohm nominal resistance at 25° C.

3. BLEND Temperature – Blend chamber temperature sensing ther-

mistor, 2.795 Kohm nominal resistance at 25° C, used for primary

control of the blend door actuator.

4. BLOWER Sense – A voltage input signal from the switched side of

the blower motor.

5. BUNK Set Temperature – Temperature set control potentiometer, 3

terminal, 10 Kohm, 189 degree rotation, linear taper. Center tap input

signal increases with setpoint increase. If this signal indicates that

Bunk control is active the Blower relay output is turned "on", when the

bunk unit demands A/C.

6. CAB Set Temperature – Dash mounted temperature set control

potentiometer. This is a 3 terminal 10 Kohm potentiometer with a lin-

ear taper, approximately 180 degree rotation and 21 position detents

distributed over the 180 degrees. The center tap of this potentiometer

is input to the controller. This signal level decreases as the setpoint

input increases. CW terminal is connected to ground, CCW terminal

is connected to battery voltage.

7. DATABUS+ and DATABUS- hardware interface to J1587/J1708 vehic-

ular databus. DATA+ is the positive connection to the differential bus

DATA- is the negative connection to the differential bus. These signals

provide for bidirectional data communications.

8. EVAP Temperature – This NTC thermistor senses the temperature of

the evaporator core. It has a nominal resistance of 20 Kohms at 25C

and is the primary AC compressor on/off control input.

9. LOW Px – Low Pressure Switch located in the suction side of the

refrigerant compressor on the thermal expansion valve. Contacts

open when the pressure falls below approximately 14 psi and re-close

after the pressure climbs back above 54psi (nominal). Low pressure

switch activity is the primary indicator of a loss of charge and is also

used to preclude compressor operation in extremely cold tempera-

tures. *Since this switch does not have an internal resistor, an open

wire to this switch will be diagnosed as a low pressure condition.

10. HIGH Px – High Pressure Switch. Located in the discharge side of

the refrigerant compressor on the thermal expansion valve, this

device has a 2.49 Kohm resistor installed in parallel with the electrical

contacts to allow diagnosing of sensor wiring and connector faults.

The switch contacts are closed when the pressure is below 245 psi

(nominal). Contacts open when the pressure climbs above approxi-

mately 285 psi and reclose after the pressure falls back below 245 psi

(12/00) KM811236 13-15

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

(nominal). This switch is the primary control for the fan and is used to

preclude compressor operation when excessive discharge pressures

are present.

11. MODE Sense 1 – This input monitors the defrost actuator drive signal

that is generated by the MODE Select Control on the Control Head.

12. MODE Sense 2 – This input monitors the vent/heat actuator drive sig-

nal that is generated by the MODE Select Control on the Control

Head.

C2TX Output The module produces the following output signals to control the following

Descriptions devices:

1. BLEND Drive – The module provides an output that is ratiometric to

the supply voltage. The output ranges between .15 VIGN (Voltage

Ignition) and .85 VIGN. Nominally the Blend Door is fully closed (max.

cold) when the output signal reaches .80 VIGN. It is fully open at .20

VIGN.

2. AC Clutch (Compressor Clutch Drive) – A low side MOSFET power

driver, with flybac clamping engages the AC compressor clutch coil

when activated.

3. DATABUS+ and DATABUS- (see #7 in Input section).

4. FAN Trigger (Fan actuator) – A normally closed (low level = fan off)

low side, open drain FET is used to signal the fan actuator circuit to

activate the fan drive. A fan “on” state is requested when the FET is in

the non-conducting (off) state.

5. BLOWER Relay – This low side open drain FET is turned on to acti-

vate the blower relay. This signal is output when a minimum signal

level on the Bunk set potentiometer indicates that the Bunk Tempera-

ture Control system is requesting AC. The blower relay forces the

blower to be "on" at low speed. If the Control Panel has requested a

higher speed the Control Panel will prevail.

6. DIAGNOSTICS – Upon detection of system faults, the unit broad-

casts or responds to request for diagnostic information over the data-

bus. The diagnostic information is used to indicate system faults and

status.

Software Description The C2TX software, for purposes of description, can be partitioned into

several distinct modules of functional operation: first, the implementation

and functionality of the ATC: second, the APADS functionality; and third,

communication definition that defines the nature in which the C2TX com-

municates over the J1587/J1708 databus.

The C2TX has non volatile memory for storing statistics and configuration

parameters. Brackets around a variable denote that it is a programmable

value. The nominal value, unless otherwise specified, is contained within

the square brackets [x].

13-16 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Section 13E C2TX Communications via SAE J1587/J1798

C2TX Transmits

Table 13-6 PID 194 – Transmitter System Diagnostic Code and Occurrence Count

APADS MID # OF

FAULT TYPE PID 194 P/SID DIAG CODE

190 CHARS

Decimal 190 194 2 xxx 0xlxxx

Representation

In HEX C2h 2 XX XX

Low Pressure – 190 194 2 Sl 49

ACTIVE

Beh C2h 2 1 31h

Low Pressure – 190 194 2 Sl 113

INACTIVE

Beh C2h 2 1 71h

Suggested Text HVAC Cntlr RefrgChg LO

High Pressure – Active 190 194 2 Sl 48

BEh C2h 2 1 30h

High Pressure – 190 194 2 Sl 112

Inactive

BEh C2h 2 1 70H

Suggested Text HVAC Cntlr RefrgChg HI

Open Clutch – ACTIVE 190 194 2 S6 53

BEh C2h 2 6 35h

Open Clutch – 190 194 2 S6 117

INACTIVE

BEh C2h 2 6 75h

Suggested Text HVAC Cntlr AC CItch OPN CIRC

Shorted Clutch – 190 194 2 S6 54

ACTIVE

BEh C2h 2 6 36h

Shorted Clutch – 190 194 2 S6 118

INACTIVE

BEh C2h 2 6 76h

Suggested Text HVAC Cntlr AC CItch OVR CURR

High Pres Switch Open 190 194 2 S228 53

– ACTIVE

BEh C2h 2 E4 35h

(12/00) KM811236 13-17

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Table 13-6 PID 194 – Transmitter System Diagnostic Code and Occurrence Count (Continued)

APADS MID # OF

FAULT TYPE PID 194 P/SID DIAG CODE

190 CHARS

High Pres Switch Open 190 194 2 S228 117

– INACTIVE

BEh C2h 2 E4 75h

Suggested Text HVAC Cntlr HI SW OPN CIRC

Low Voltage – ACTIVE 190 194 2 P158 36

BEh C2h 2 9Eh 24h

Low Voltage – 190 194 2 P158 100

INACTIVE

BEh C2h 2 9Eh 64h

Suggested Text HVAC Cntir Battery LO

High Voltage – ACTIVE 190 194 2 P158 35

BEh C2h 2 9Eh 23h

High Voltage – 190 194 2 P158 99

INACTIVE

BEh C2h 2 9Eh 63h

Suggested Text HVAC Cntlr Battery HI

Evap Temp Sensor – 190 194 2 S7 50

ACTIVE

BEh C2h 2 7 32h

Evap Temp Sensor – 190 194 2 S7 114

INACTIVE

BEh C2h 2 7 72h

Suggested Text HVAC Cntlr Evap ERRATIC

Ambient Temp Sensor 190 194 2 P171 34

– ACTIVE

BEh C2h 2 ABh 22h

Ambient Temp Sensor 190 194 2 P171 98

– INACTIVE

BEh C2h 2 ABh 62h

Suggested Text HVAC Cntlr Ambient ERRATIC

13-18 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Table 13-7 PID 196 – Diagnostic Data Count Clear Response Message, Request a Fault Count be Cleared

# OF

FAULT TYPE PID 196 P/SID DIAG CODE

CHARS

Decimal 196 2 xxx 011x xxxx

Representation

In HEX C4h 2 XX XX

Low Pressure 196 2 S1 113

C4h 2 1 71h

High Pressure 196 2 S1 112

C4h 2 1 70h

Open Clutch 196 2 S6 117

C4h 2 6 75h

Shorted Clutch 196 2 S6 118

C4h 2 6 76h

High Pressure Switch 196 2 S228 117

Open

C4h 2 E4 75h

Low Voltage 196 2 P168 100

C4h 2 A8h 64h

High Voltage 196 2 P168 99

C4h 2 A8h 63h

Evap. Temp. Sensor 196 2 S7 114

C4h 2 7 72h

Ambient Temp. Sensor 196 2 P171 98

C4h 2 ABh 62h

(12/00) KM811236 13-19

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Table 13-8 PID 196 – Diagnostic Data Count Clear Response Message, Request All Faults Count be Cleared

# OF

FAULT TYPE PID 196 P/SID DIAG CODE

CHARS

Decimal 196 2 xxx 128-191

Representation

In HEX C4h 2 XX 80h thru BFh

Table 13-9 PID 234 – Software Revision Request, Reply

# OF MAJOR SW MINOR SW

FAULT TYPE PID 234

CHARS REV REV

Software Revision PID 234 007 049 046 048

Eah 03h 31h 2Eh 30h

1 . 0

1.0 is the first release, 0.x are prerelease versions.

Table 13-10PID 243 – Component Identification Request, Reply

# OF

FAULT TYPE PID 234 MID TEXT STRING

CHARS

Component ID 243 16 190 073 078 068 069 088 042 072

086 065 067 032 067 084 082

076

F3h 10h BEh 49h 4Eh 44h 45h 58h 2Ah 48h

56h 41h 43h 20h 43h 54h 52h

4Ch

INDEX * HVAC^CTRL

Table 13-11PID 158 – Battery and Battery, Switched Request, Reply

FAULT TYPE PID 158 LSB MSB

Battery 0 to 3276.75V, 0.05V/bit

158 xxx xxx

9Eh XXh XXh

13-20 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Table 13-12PID 171 – Ambient Temperature, Reply

FAULT TYPE PID 171 LSB MSB

Ambient Temperature -8192 to +8191.75F, 0.25/bit

171 xxx xxx190

ABh XXh XXh

Table 13-13PID 194 – Fault Request, Reply

# OF

FAULT TYPE PID 194

CHARS

All Faults Nonexistent 194 0

C2h 00h

Fault(s) ACTIVE / INACTTVE – Transmit appropriate mes-

sages listed in previous section.

Table 13-14J1587 Bus Data – Provided by the C2TX Module

FAULT TYPE PID LSB MSB

Ambient Temperature -8192 to +8191.75, 0.25/bit

Transmit once every 10

seconds or upon 171 xxx xxx

request. ABh XXh XXh

(12/00) KM811236 13-21

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

C2TX Receives

Table 13-15PID 195 – Diagnostic Data Request/Request a Fault Count be Cleared

# OF

FAULT TYPE PID 195 MID 190 P/SID DIAG CODE

CHARS

Decimal 195 3 190 xxx 011xxxx

Representation

In HEX C3h 3 BEh XX XX

Low Pressure 195 3 190 S1 113

C3h 3 Beh 1 71h

High Pressure 195 3 190 S1 112

C3h 3 Beh I 70h

Open Clutch 195 3 190 S6 117

C3h 3 Beh 6 75h

Shorted Clutch 195 3 190 S6 118

C3h 3 Beh 6 76h

High Pressure Switch 195 3 190 S228 117

Open

C3h 3 Beh E4 75h

Low Voltage 195 3 190 P168 100

C3b 3 Beh A8h 64h

High Voltage 195 3 190 P168 99

C3h 3 Beh A8h 63h

Evap. Temp. Sensor 195 3 190 S7 114

C3h 3 Beh 7 72h

Ambient Temp Sensor 195 3 190 P171 98

C3h 3 Beh ABh 62h

Table 13-16PID 195 – Diagnostic Data Request/Request All Faults be Cleared

# OF

FAULT TYPE PID 195 MID 190 P/SID DIAG CODE

CHARS

Decimal 195 3 190 xxx 128-191

Representation

In HEX C3h 3 BEh XX 80h-BFh

13-22 KM811236 (12/00)

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Table 13-17PID 0, PID 128 – Request Parameter and Component Specific Request

REQUEST PARAMETER COMPONENT SPECIFIC REQUEST

FAULT TYPE REQUESTED REQUESTED

PID 00 PID 128 COMPONENT

PID PID

Decimal 00 xxx 128 xxx 190

Representation

In HEX 00h XX 80h XX Beh

Software Revision PED 00 234 128 234 190

00h EAh 80h EAh BEh

Component DD 00 243 128 243 190

00h F3h 80h F3h BEh

Battery, Switched 00 158 128 158 190

00h 9Eh 80h 9Eh BEh

Ambient Temperature 00 171 128 171 190

00h ABh 80h ABh BEh

Faults Present 00 194 128 194 190

00h C2h 80h C2h BEh

Table 13-18J1587 Bus Data – Used by the C2TX Module

DATA 1 DATA 2

FAULT TYPE PID

LSB MSB

Rotational Velocity 0 to 16383.75 RPM, 0.25 RPM/bit

(RPM)

190 xxx xxx

BEh XXh XXh

Only uses MSB, 64RPM/Bit

(12/00) KM811236 13-23

KENWORTH HVAC SYSTEMS

T2000 APADS Troubleshooting 13

Section 13F C2TX HVAC Controller

Product Description and See “C2TX HVAC Controller, Description/Troubleshooting Manual

Troubleshooting Manual (T2000)”, 4046049.

Section 13G Wiring Diagram – P94-1125 (Cab & Sleeper with APADS)

See diagram P94-1125 in the Diagram section of ServiceNet.

13-24 KM811236 (12/00)

You might also like

- Programming The PowertrainDocument10 pagesProgramming The PowertrainMiller Andres ArocaNo ratings yet

- 2014 Truck Products Catalogue (Usa)Document28 pages2014 Truck Products Catalogue (Usa)Adolfo CisnerosNo ratings yet

- L00146 Fan Clutch Catalog 3-11Document84 pagesL00146 Fan Clutch Catalog 3-11Jose MellaNo ratings yet

- Check and Test J1939 and Truck CAN NetworksDocument9 pagesCheck and Test J1939 and Truck CAN NetworksJOHN Wright100% (1)

- Instructions Egr DeleteDocument8 pagesInstructions Egr Deletegeorge100% (1)

- Hvac 2016Document44 pagesHvac 2016api-359742263No ratings yet

- Fan Ring Separacion MackDocument2 pagesFan Ring Separacion MackHamilton MirandaNo ratings yet

- Color-coded wires CascadiaDocument1 pageColor-coded wires CascadialuisNo ratings yet

- Service Manual: Airglide 400 / 460 / 690 Air Spring SuspensionDocument21 pagesService Manual: Airglide 400 / 460 / 690 Air Spring Suspensionj100% (2)

- Argosy Driver's ManualDocument222 pagesArgosy Driver's ManualRodolfo Alberto Muñoz CarcamoNo ratings yet

- 3000 and 4000 Product Families Troubleshooting Manual-Allison 4 Generation ControlsDocument6 pages3000 and 4000 Product Families Troubleshooting Manual-Allison 4 Generation ControlsElectroventica ElectroventicaNo ratings yet

- 2011 Mad PogDocument81 pages2011 Mad PogBruno Pilieci100% (1)

- US Peterbilt Insurance Catalog-1 PDFDocument17 pagesUS Peterbilt Insurance Catalog-1 PDFAnonymous YeLHIzFkMNo ratings yet

- Diesel Decoder: User ManualDocument44 pagesDiesel Decoder: User ManualRamonNo ratings yet

- Chrome 052017Document12 pagesChrome 052017api-359742263No ratings yet

- Automotive TransmissionDocument146 pagesAutomotive TransmissionTony Neal100% (1)

- Esig - HX - ClusterDocument41 pagesEsig - HX - Clusterjose sierraNo ratings yet

- Pv776 K Ved7 EngineDocument11 pagesPv776 K Ved7 EngineHamilton Miranda100% (3)

- Brake ValveDocument72 pagesBrake ValveEduardo TorresNo ratings yet

- Mack - All Engines (2003 & Older VMAC III) .VMAC III (E-Tech)Document6 pagesMack - All Engines (2003 & Older VMAC III) .VMAC III (E-Tech)fernandoNo ratings yet

- Service Manual Trucks Group 87 Air Heater Espar D1LC CompactDocument58 pagesService Manual Trucks Group 87 Air Heater Espar D1LC CompactNeojai jaiyuNo ratings yet

- Cylinder Head Install D13A 211 78 1-8-06Document13 pagesCylinder Head Install D13A 211 78 1-8-06Minn Thet NaingNo ratings yet

- Cummins M-11 Sleeve Removal & Installation ManualDocument4 pagesCummins M-11 Sleeve Removal & Installation ManualJoseDavidSanchezYepes100% (1)

- Diagrama Cableado IsxDocument1 pageDiagrama Cableado IsxMoctezuma ChinoNo ratings yet

- Transmission and Transfer Case: Manual Transmission - G56 - Service InformationDocument68 pagesTransmission and Transfer Case: Manual Transmission - G56 - Service InformationRyanNo ratings yet

- Service Bulletin Trucks: Instrumentation TroubleshootingDocument4 pagesService Bulletin Trucks: Instrumentation Troubleshootingsetiup holjiNo ratings yet

- Freightliner Business Class M2 Cab Configurations Reference GuideDocument58 pagesFreightliner Business Class M2 Cab Configurations Reference GuideThong ChanNo ratings yet

- Cylinder Head Removal D13A 211 76 1-8-06Document12 pagesCylinder Head Removal D13A 211 76 1-8-06Minn Thet NaingNo ratings yet

- tp99124 PDFDocument20 pagestp99124 PDFDieselkNo ratings yet

- QuickServe Online - (4021271) ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 PDFDocument6 pagesQuickServe Online - (4021271) ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 PDFmds9185No ratings yet

- Alliance - Filter CatalogDocument82 pagesAlliance - Filter CatalogSamNo ratings yet

- Especificaciones Eaton Junio 2000Document12 pagesEspecificaciones Eaton Junio 2000jesus perez100% (1)

- Coil Viscous Fan Drive TestDocument12 pagesCoil Viscous Fan Drive TestWilson BuenoNo ratings yet

- Body Builder Transmission InterfacesDocument5 pagesBody Builder Transmission InterfacesHamilton MirandaNo ratings yet

- Vecu5 pc28 23970505011wDocument145 pagesVecu5 pc28 23970505011wramon hidalgoNo ratings yet

- MM 0112Document112 pagesMM 0112Rob PenndotNo ratings yet

- Air Conditioning Type & Capacity SpecsDocument2 pagesAir Conditioning Type & Capacity SpecsMeadows TruckNo ratings yet

- Mack-Gen2-23086355 03 1Document144 pagesMack-Gen2-23086355 03 1Fredy CoyagoNo ratings yet

- 451-3540-03 Isx Dohc Casting Cut InstructionsDocument12 pages451-3540-03 Isx Dohc Casting Cut InstructionsJoseDavidSanchezYepesNo ratings yet

- DDDL706 ReadmeDocument3 pagesDDDL706 ReadmeTuấn NeoNo ratings yet

- 2013 Cummins ISX New Valve Camshaft Roller and Rocker LeversTSB - 100551Document1 page2013 Cummins ISX New Valve Camshaft Roller and Rocker LeversTSB - 100551juanNo ratings yet

- Engine Replacement ProceduresDocument29 pagesEngine Replacement Proceduresvicente456No ratings yet

- Installation Instructions For DC and AC Electric Rewind ReelsDocument4 pagesInstallation Instructions For DC and AC Electric Rewind ReelsGinoGuanNo ratings yet

- Cummins Gearing Recommendations for On-Highway VehiclesDocument40 pagesCummins Gearing Recommendations for On-Highway Vehicleskamikazeee100% (1)

- Heavy-Duty Diagnostic: Product CatalogDocument12 pagesHeavy-Duty Diagnostic: Product CatalogMartin CasillasNo ratings yet

- Tuning The TBIDocument21 pagesTuning The TBINacer MezghicheNo ratings yet

- Maintenance Manual Lubrication Chart - K100 SeriesDocument5 pagesMaintenance Manual Lubrication Chart - K100 SeriesJuan Jose PerdomoNo ratings yet

- VECU and Transmission ECU Wire Harness Rub-Through - CX, CH and CV Models Equipped WithDocument2 pagesVECU and Transmission ECU Wire Harness Rub-Through - CX, CH and CV Models Equipped WithHamilton MirandaNo ratings yet

- Mack Titan AutraliaDocument8 pagesMack Titan AutraliaDIONYBLINKNo ratings yet

- TRTS0062 - 0811tms800e Gav-524Document316 pagesTRTS0062 - 0811tms800e Gav-524Angel DlsgNo ratings yet

- EATON RR Trts 0062Document316 pagesEATON RR Trts 0062Joaquim SantosNo ratings yet

- Trsm0940en Us PDFDocument255 pagesTrsm0940en Us PDFSelvin Escobar RojasNo ratings yet

- Mack VisionCXN603Document4 pagesMack VisionCXN603Foromaquinas50% (4)

- Help W - Insite 8.5 InstallDocument2 pagesHelp W - Insite 8.5 InstallDenisEcheverriNo ratings yet

- Wiring ComunicacionDocument4 pagesWiring ComunicacionHamilton MirandaNo ratings yet

- L30030W Trailer Service Manual PLC, PLC-Plus, PLC-Select 6-03 Web-OnlyDocument99 pagesL30030W Trailer Service Manual PLC, PLC-Plus, PLC-Select 6-03 Web-Onlyenzo7259No ratings yet

- Axsm 0042Document144 pagesAxsm 0042aliNo ratings yet

- Audio System Troubleshooting GuideDocument12 pagesAudio System Troubleshooting GuideCuong DinhNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Engine ElectricalDocument99 pagesEngine Electricalluis eduardo corzo enriquezNo ratings yet

- Motor Grader Hyd SchemDocument2 pagesMotor Grader Hyd Schemssinokrot100% (2)

- SM PC200, PC200LC-7Document810 pagesSM PC200, PC200LC-7caing92% (13)

- Group 6 RCV Pedal: 1. StructureDocument6 pagesGroup 6 RCV Pedal: 1. StructureАлексейNo ratings yet

- Testing and Adjusting Hydraulic System: Shutdown SIS Previous ScreenDocument55 pagesTesting and Adjusting Hydraulic System: Shutdown SIS Previous Screenluis eduardo corzo enriquezNo ratings yet

- Configuration DiagramsDocument25 pagesConfiguration Diagramsluis eduardo corzo enriquezNo ratings yet

- 12G, 130G & 140G Hydraulic System Motor Graders: 61M6940-UP 74V1525-UP 72V3722-UPDocument2 pages12G, 130G & 140G Hydraulic System Motor Graders: 61M6940-UP 74V1525-UP 72V3722-UPErnesto Rodriguez Gonzalez100% (1)

- GROUP 4 TRAVEL DEVICE CONSTRUCTION AND FUNCTIONDocument13 pagesGROUP 4 TRAVEL DEVICE CONSTRUCTION AND FUNCTIONluis eduardo corzo enriquezNo ratings yet

- F350 Fuse BoxDocument1 pageF350 Fuse Boxluis eduardo corzo enriquezNo ratings yet

- Group 2 Specifications: 1. Major ComponentDocument21 pagesGroup 2 Specifications: 1. Major Componentluis eduardo corzo enriquezNo ratings yet

- GROUP 5 RCV LEVER TITLEDocument8 pagesGROUP 5 RCV LEVER TITLEJuan Pablo Leon RualesNo ratings yet

- Uptime Maintenance Planner: Service IntervalsDocument2 pagesUptime Maintenance Planner: Service Intervalsluis eduardo corzo enriquezNo ratings yet

- PC300 electrical diagramsDocument33 pagesPC300 electrical diagramsluis eduardo corzo enriquezNo ratings yet

- Section 2 Structure and Function: Group 1 Pump DeviceDocument19 pagesSection 2 Structure and Function: Group 1 Pump Deviceluis eduardo corzo enriquezNo ratings yet

- 962g Trans Clutch CalibrateDocument8 pages962g Trans Clutch Calibrateluis eduardo corzo enriquez100% (1)

- Ignition System: General InformationDocument38 pagesIgnition System: General Informationluis eduardo corzo enriquezNo ratings yet

- 962g Trans TestDocument14 pages962g Trans Testluis eduardo corzo enriquezNo ratings yet

- F350 Elec Diag 4Document1 pageF350 Elec Diag 4luis eduardo corzo enriquezNo ratings yet

- Ranger 89 Fuse PanelDocument1 pageRanger 89 Fuse Panelluis eduardo corzo enriquezNo ratings yet

- F350 Elec Diag 3Document1 pageF350 Elec Diag 3luis eduardo corzo enriquezNo ratings yet

- F350 Elec Diag 2Document1 pageF350 Elec Diag 2luis eduardo corzo enriquezNo ratings yet

- Instrument PanelDocument1 pageInstrument Panelluis eduardo corzo enriquezNo ratings yet

- Voyager97 Wiring DiagrDocument490 pagesVoyager97 Wiring Diagrluis eduardo corzo enriquezNo ratings yet

- F350 Elec Diag 1Document1 pageF350 Elec Diag 1luis eduardo corzo enriquezNo ratings yet

- TCC Clutch Solenoid DiagDocument1 pageTCC Clutch Solenoid Diagluis eduardo corzo enriquezNo ratings yet

- Transaxle and Power Transfer Unit - Voyager GS 1996 - PDFs Free OnlineDocument182 pagesTransaxle and Power Transfer Unit - Voyager GS 1996 - PDFs Free Onlineluis eduardo corzo enriquezNo ratings yet

- Ranger Rear Anti-Lockbrake SystemDocument1 pageRanger Rear Anti-Lockbrake Systemluis eduardo corzo enriquezNo ratings yet

- HEGO Sensor DiagDocument1 pageHEGO Sensor Diagluis eduardo corzo enriquezNo ratings yet

- Ranger 89 Ac ControlDocument1 pageRanger 89 Ac Controlluis eduardo corzo enriquezNo ratings yet

- Ecu y Conector Test PinsDocument1 pageEcu y Conector Test Pinsluis eduardo corzo enriquezNo ratings yet

- Manaoag Spiritual CenterDocument8 pagesManaoag Spiritual CenterMaria Hazelle Ann AlentonNo ratings yet

- Arabian Sun # 43 - 11-12-2014Document12 pagesArabian Sun # 43 - 11-12-2014Saeed M. Al MubarakNo ratings yet

- HVAC TrainingDocument55 pagesHVAC TrainingKkrkollam KrishnaKumarNo ratings yet

- HVAC Design Standards for Saudi FacilitiesDocument87 pagesHVAC Design Standards for Saudi FacilitiesMohammed Abdul Moied100% (2)

- Rr410305 Refrigeration Air ConditioningDocument8 pagesRr410305 Refrigeration Air ConditioningSrinivasa Rao G100% (5)

- Chapter 2 Rolling Stock Functional RequirementsDocument56 pagesChapter 2 Rolling Stock Functional Requirementsdyka89No ratings yet

- Design Guidelines for Mechanical SystemsDocument117 pagesDesign Guidelines for Mechanical SystemsJoe QuekNo ratings yet

- VeloAir ImpDocument8 pagesVeloAir ImpRehan YousafNo ratings yet

- Basic Civil and Mechanical Engineering - Question BankDocument4 pagesBasic Civil and Mechanical Engineering - Question BankA.R. Pradeep Kumar100% (1)

- Psvcalculationsflare 130225000902 Phpapp02 UnprotectedDocument116 pagesPsvcalculationsflare 130225000902 Phpapp02 UnprotectedMike DukasNo ratings yet

- Air Conditioning Refrigerant Line Installation ProcedureDocument16 pagesAir Conditioning Refrigerant Line Installation ProcedureLyndon Lim LominoqueNo ratings yet

- High Static Pressure - DUCTEDDocument32 pagesHigh Static Pressure - DUCTEDsyed mustafa aliNo ratings yet

- AGL 001184 VIC Summer Catalogue WEB SmallDocument4 pagesAGL 001184 VIC Summer Catalogue WEB SmallVMRONo ratings yet

- Axial FanspecDocument7 pagesAxial FanspecDebraj PaulNo ratings yet

- Implementation Rules For Compulsory Certification of Electrical and Electronic ProductsDocument24 pagesImplementation Rules For Compulsory Certification of Electrical and Electronic ProductsIzzah AmalinaNo ratings yet

- Calculating Server Room Heat Loads - Portable Air ConditioningDocument4 pagesCalculating Server Room Heat Loads - Portable Air ConditioningAdnan AttishNo ratings yet

- 15-1-1 - Air Conditioning SystemDocument12 pages15-1-1 - Air Conditioning Systemfarshan296015No ratings yet

- Catalogo de Sporlan de Válvula de EspansionDocument40 pagesCatalogo de Sporlan de Válvula de EspansionLuciano FloresNo ratings yet

- Case Study on Sustainability in the Telecom IndustryDocument4 pagesCase Study on Sustainability in the Telecom IndustryRajeshwari HegdeNo ratings yet

- HVAC Questions 100+ PDFDocument12 pagesHVAC Questions 100+ PDFabdullahNo ratings yet

- Change for life: Service Manual Models GWH09-18AKC-K6DNA1ADocument92 pagesChange for life: Service Manual Models GWH09-18AKC-K6DNA1AdanNo ratings yet

- Standards for Living Conditions on ShipsDocument17 pagesStandards for Living Conditions on ShipsWilanNo ratings yet

- 101 Reading Blueprints Course DescriptionDocument2 pages101 Reading Blueprints Course DescriptionAnonymous q9eCZHMuSNo ratings yet

- SWOT analysis of 4 major air conditioning unit typesDocument5 pagesSWOT analysis of 4 major air conditioning unit typesSecret TalagaNo ratings yet

- Curriculum For Bachelor of Science in Mechanical EngineeringDocument13 pagesCurriculum For Bachelor of Science in Mechanical EngineeringCharo GironellaNo ratings yet

- Vertiv VRC Self-Contained IT Rack Cooling SystemDocument8 pagesVertiv VRC Self-Contained IT Rack Cooling SystemnoneNo ratings yet

- Fan Dry Coil Unit System For Acc 5th Rev.cDocument19 pagesFan Dry Coil Unit System For Acc 5th Rev.candy5310No ratings yet

- FYP Presentation TemplateDocument20 pagesFYP Presentation TemplateAliNo ratings yet

- Technical Paper On District CoolingDocument9 pagesTechnical Paper On District CoolinggaryckfanNo ratings yet

- Central Control Unit User Manual Pr2 - UTS + ECSDocument34 pagesCentral Control Unit User Manual Pr2 - UTS + ECSkaasim_1100% (1)