Professional Documents

Culture Documents

Intls of NLG

Uploaded by

je_carD23Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intls of NLG

Uploaded by

je_carD23Copyright:

Available Formats

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

** ON A/C ALL

TASK 32-41-12-400-001-A

Installation of the NLG Wheel

WARNING: BE CAREFUL WHEN YOU USE CONSUMABLE MATERIALS. OBEY THE MATERIAL

MANUFACTURER'S INSTRUCTIONS AND YOUR LOCAL REGULATIONS.

WARNING: MAKE SURE THAT THE GROUND SAFETY-LOCKS ARE IN POSITION ON THE LANDING

GEAR. MOVEMENT OF THE LANDING GEAR CAN CAUSE INJURY TO PERSONS AND DAM-

AGE TO THE AIRCRAFT AND/OR EQUIPMENT.

FIN : 2659GM , 2660GM

1. Reason for the Job

If you replace the NLG wheel when you do the TSM TASK 32-20-00-810-802-A "Vibration Felt on the NLG

during Takeoff and Lift Off Phases", we recommend that you replace the two NLG wheels.

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific 1 AIR SOURCE FILTERED, DRY

No specific AR WARNING NOTICE(S)

No specific Torque wrench: range to between 0.4 and 0.45 m.daN

(35.40 and 39.82 lbf.in)

No specific Torque wrench: range to between 0.4 and 0.51 m.daN

(35.40 and 45.13 lbf.in)

** ON A/C 001-014, 016-250

No specific Torque wrench: range to between 0.56 and 0.9 m.daN

(49.56 and 79.65 lbf.in)

** ON A/C ALL

No specific Torque wrench: range to between 10.26 and 11.34 m.daN

(75.66 and 83.63 lbf.ft)

No specific Torque wrench: range to between 20.71 and 22.89 m.daN

(152.73 and 168.81 lbf.ft)

(1324A) 1 HANDLING TOOL

(J47549) 1 ADAPTOR NLG

B. Consumable Materials

REFERENCE DESIGNATION

(Material No. 03GBB1) Synthetic Oil base Grease-General Purpose Clay Thickened -

(Material No. 03GCB1) Synthetic Oil base Grease-Landing Gear Wheel Bearing Lithium

Thickened -

(Material No. 06LCG9) Non Hardening Jointing Putty-Medium Temp. Area - -

(Material No. 08BBB1) Non Aqueous Cleaner-- Petroleum Based -

C. Work Zones and Access Panels

Print Date: February 02, 2018 Page 1 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

ZONE/ACCESS ZONE DESCRIPTION

711 NOSE GEAR

D. Expendable Parts

FIG.ITEM DESIGNATION IPC-CSN

** ON A/C 251-300

4 cotter pins 32-21-13-12-060

** ON A/C 001-014, 016-250

9 cotter pins 32-21-13-12-060

** ON A/C 251-300

3 nuts 32-21-13-12-070

** ON A/C 001-014, 016-250

8 nuts 32-21-13-12-070

** ON A/C 251-300

4 cotter pins 32-21-13-22-060

** ON A/C 001-014, 016-250

9 cotter pins 32-21-13-22-060

** ON A/C 251-300

3 nuts 32-21-13-22-070

** ON A/C 001-014, 016-250

8 nuts 32-21-13-22-070

5 cotter pin 32-49-15-01-010

3 preformed packings 32-49-15-01-050

** ON A/C ALL

E. Referenced Information

REFERENCE DESIGNATION

(Ref. 07-12-00-582-001-A). Jacking of the Nose Landing Gear

(Ref. 12-14-32-614-001-A). Nitrogen Filling of the Tires

(Ref. 32-00-00-081-001-A). Removal of the Safety Devices from the Landing Gears

(Ref. 32-00-00-481-001-A). Installation of the Safety Devices on the Landing Gears

(Ref. 32-41-00-210-003-A). Inspection/Check of the Tire Pressure

(Ref. 32-41-00-910-001-A). Tire Mixability Precautions

** ON A/C 001-014, 016-250

(Ref. 32-49-00-720-001-A). Crosscheck of TPIS Reading and Tire Pressure Gauge

** ON A/C ALL

(Ref. 12-22-00-00). LUBRICATION - DESCRIPTION AND OPERATION

Print Date: February 02, 2018 Page 2 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

REFERENCE DESIGNATION

** ON A/C 251-300

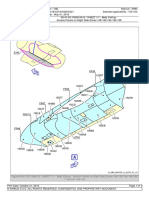

Nose Gear Wheel SHEET 1

** ON A/C 001-014, 016-250

Nose Gear Wheel SHEET 1

Print Date: February 02, 2018 Page 3 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

A

1

2

3

4 A

2660GM

5 2659GM

A

6

11

10

5

4

3

2

9

8

7

N_MM_324112_4_AAM0_01_00

Figure 32-41-12-991-00100-00-A / SHEET 1/1 - Nose Gear Wheel

** ON A/C 251-300

Print Date: February 02, 2018 Page 4 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

A

1

2

9

3 A

4 8

6 2660GM

7

2659GM

5 10

11 A

12

13

19

18

17

10

9

8

7

16

15

14

N_MM_324112_4_ACM0_01_00

Figure 32-41-12-991-00100-00-B / SHEET 1/1 - Nose Gear Wheel

** ON A/C 001-014, 016-250 | EMB SB 32-1392 for A/C 001-002

Print Date: February 02, 2018 Page 5 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

3. Job Set-up

Subtask 32-41-12-865-051-A

A. Make sure that this(these) circuit breaker(s) is(are) open, safetied and tagged:

PANEL DESIGNATION FIN LOCATION

** ON A/C 001-014, 016-200

121VU HYDRAULIC/TIRE/PRESS 1GV M31

** ON A/C ALL

121VU HYDRAULIC/BRAKING AND STEER- 4GG M36

ING/SYS2/SPLY

121VU HYDRAULIC/BRAKING AND STEER- 3GG M35

ING/SYS2/CTL

121VU HYDRAULIC/BRAKING AND STEER- 1GG M34

ING/SYS1/CTL

121VU HYDRAULIC/BRAKING AND STEER- 2GG M33

ING/SYS1/IND AND/SPLY

** ON A/C 201-250

121VU TIRE/PRESS 1GV M31

** ON A/C ALL

Subtask 32-41-12-860-052-A

B. Aircraft Maintenance Configuration

(1) Make sure that the wheel chocks are in position at the main landing gear.

(2) Make sure that the NLG is in the correct configuration for the wheel change (Ref. AMM TASK 07-12-

00-582-001) .

(3) Make sure that the WARNING NOTICE(S) is on the panel 400VU to tell persons not to operate the

landing gear.

(4) Make sure that the safety devices are installed on the landing gear (Ref. AMM TASK 32-00-00-481-

001) .

(5) Make sure that the PROTECTOR NLG (J47548) is installed.

4. Procedure

** ON A/C 251-300

(Ref. Fig. Nose Gear Wheel SHEET 1)

** ON A/C 001-014, 016-250

EMB SB 32-1392 for A/C 001-002

(Ref. Fig. Nose Gear Wheel SHEET 1)

** ON A/C ALL

NOTE: If the wheel has a pressure-sensor seal cap, make sure that the seal cap is correctly installed and

safetied with a nut and a cotter pin.

Print Date: February 02, 2018 Page 6 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

NOTE: If the wheel has a Tire Pressure Indicating System (TPIS), the tie-bolt balance weight must be installed

180 degrees from the TPIS sensor holder.

NOTE: If the aircraft has the TPIS, install the TPIS balance weight, refer to the NLG wheel Component Main-

tenance Manual (CMM). If the aircraft has no TPIS, no TPIS balance weight is necessary.

Subtask 32-41-12-210-054-A

A. Tires of different type

(1) Obey the tire mixability precautions (Ref. AMM TASK 32-41-00-910-001) .

** ON A/C 251-300

Subtask 32-41-12-420-053-A

B. Installation of the NLG Wheel

CAUTION: MAKE SURE THAT THE GREASE USED FOR THE AXLE SLEEVE IS THE SAME AS

THE GREASE USED FOR THE BEARINGS (CONE AND CAGE). IF YOU USE A DIFFER-

ENT GREASE, YOU CAN CAUSE DAMAGE TO THE BEARINGS.

(1) Prepare for installation

(a) Make sure (if it is not permitted to use tires of different types) that the wheel you install has the

same type of tire (radial or cross-ply) as the other wheel on the NLG.

(b) Make sure that the retaining ring (11) is in its housing.

(c) Clean the axle sleeve (1) with Non Aqueous Cleaner-- Petroleum Based - (Material No. 08BBB1)

and dry it with AIR SOURCE FILTERED, DRY.

(d) Make sure that the axle sleeve (1) is in the correct condition.

(e) Apply a thin layer of Synthetic Oil base Grease-General Purpose Clay Thickened

- (Material No. 03GBB1) or as alternative Synthetic Oil base Grease-Landing Gear Wheel

Bearing Lithium Thickened - (Material No. 03GCB1) on the axle sleeve (1) and the threads of the

axle.

NOTE: For lubricant grease specification and lubrication requirements, refer to (Ref. AMM D/

O 12-22-00-00) .

(f) Do a visual inspection of the hubcap to make sure that it is in the correct condition and

serviceable. If damage is found, refer to the applicable CMMs for damage limits and repair

procedures.

(2) Installation of the wheel

(a) Clean the inner surface of the wheel bearings (surface that touches the axle). Do not apply

grease on these surfaces.

(b) Install the wheel with a HANDLING TOOL (1324A) . Make sure that the valve is outboard.

(c) Remove the PROTECTOR NLG (J47548) .

(d) Install the axle nut (10).

(e) TORQUE the axle nut (10) to between 20.71 and 22.89 m.daN (152.73 and 168.81 lbf.ft) with

the ADAPTOR NLG (J47549) and, at the same time, turn the wheel in the same direction.

(f) Loosen the axle nut (10).

Print Date: February 02, 2018 Page 7 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

NOTE: You must make sure that the wheel does not turn when you loosen the axle nut.

(g) TORQUE the axle nut (10) to between 10.26 and 11.34 m.daN (75.66 and 83.63 lbf.ft) with the

ADAPTOR NLG (J47549) and, at the same time, turn the wheel in the same direction.

(h) Tighten the axle nut (10).

CAUTION: MAKE SURE THAT YOU ALIGN THE NUT HOLE WITH THE SUBSEQUENT

AXLE HOLE (WITH THE SMALLEST POSSIBLE ROTATION ANGLE). IF YOU

DO NOT OBEY THIS INSTRUCTION, THERE IS A RISK THAT YOU TIGHTEN

THE AXLE NUT TOO MUCH AND CAUSE DAMAGE TO THE EQUIPMENT.

1 Tighten the axle nut (10) until one hole is aligned with the first subsequent hole in the axle.

(i) Turn the wheel and make sure that the wheel is installed correctly.

(j) Install the casing (9).

(k) Installation of the bolts

CAUTION: MAKE SURE THAT YOU INSTALL THE BOLT AGAINST THE INNER SIDE OF

THE AXLE NUT, AND THE WASHERS AND NUTS AGAINST THE OUTER SIDE

OF THE AXLE NUT. IF YOU DO NOT, YOU CAN CAUSE DAMAGE TO THE

NOSE WHEEL.

1 Install the bolts (5), the washers (2) and the new IPC -CSN (32-21-13-12-070) nuts (3) or

IPC -CSN (32-21-13-22-070) nuts (3).

(l) TORQUE the nuts (3) to between 0.4 and 0.45 m.daN (35.40 and 39.82 lbf.in).

(m) Safety the nuts (3) with the new IPC -CSN (32-21-13-12-060) cotter pins (4) or IPC -CSN (32-

21-13-22-060) cotter pins (4).

** ON A/C 001-014, 016-250

EMB SB 32-1392 for A/C 001-002

Subtask 32-41-12-420-053-B

B. Installation of the NLG Wheel

CAUTION: MAKE SURE THAT THE GREASE USED FOR THE AXLE SLEEVE IS THE SAME AS

THE GREASE USED FOR THE BEARINGS (CONE AND CAGE). IF YOU USE A DIFFER-

ENT GREASE, YOU CAN CAUSE DAMAGE TO THE BEARINGS.

(1) Prepare for installation

(a) Make sure (if it is not permitted to use tires of different types) that the wheel you install has the

same type of tire (radial or cross-ply) as the other wheel on the NLG.

(b) Make sure that the retaining ring (19) is in its housing.

(c) Clean the axle sleeve (1) and the drive dog (13) with Non Aqueous Cleaner-- Petroleum Based

- (Material No. 08BBB1). Dry them with AIR SOURCE FILTERED, DRY.

(d) Make sure that the axle sleeve (1) is in the correct condition.

(e) Apply a thin layer of Synthetic Oil base Grease-General Purpose Clay Thickened

- (Material No. 03GBB1) or as alternative Synthetic Oil base Grease-Landing Gear Wheel

Print Date: February 02, 2018 Page 8 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

Bearing Lithium Thickened - (Material No. 03GCB1) on the axle sleeve (1), drive dog (13) and

the threads of the axle.

NOTE: For lubricant grease specification and lubrication requirements, refer to (Ref. AMM D/

O 12-22-00-00) .

(f) Do a visual inspection of the hubcap to make sure that it is in the correct condition and

serviceable. If damage is found, refer to the applicable CMMs for damage limits and repair

procedures.

(2) Installation of the wheel

(a) Install the wheel with a HANDLING TOOL (1324A) . Make sure that the valve is outboard.

(b) Remove the PROTECTOR NLG (J47548) .

(c) Install the axle nut (17).

(d) TORQUE the axle nut (17) to between 20.71 and 22.89 m.daN (152.73 and 168.81 lbf.ft) with

the ADAPTOR NLG (J47549) and, at the same time, turn the wheel in the same direction.

(e) Loosen the axle nut (17).

NOTE: You must make sure that the wheel does not turn when you loosen the axle nut.

(f) TORQUE the axle nut (17) to between 10.26 and 11.34 m.daN (75.66 and 83.63 lbf.ft) with the

ADAPTOR NLG (J47549) and, at the same time, turn the wheel in the same direction.

(g) Tighten the axle nut (17).

CAUTION: MAKE SURE THAT YOU ALIGN THE NUT HOLE WITH THE SUBSEQUENT

AXLE HOLE (WITH THE SMALLEST POSSIBLE ROTATION ANGLE). IF YOU

DO NOT OBEY THIS INSTRUCTION, THERE IS A RISK THAT YOU TIGHTEN

THE AXLE NUT TOO MUCH AND CAUSE DAMAGE TO THE EQUIPMENT.

1 Tighten the axle nut (17) until one hole is aligned with the first subsequent hole in the axle.

2 Install the bolts (10), the washers (7) and the new IPC -CSN (32-21-13-12-070) nuts (8) or

IPC -CSN (32-21-13-22-070) nuts (8).

(h) TORQUE the nuts (8) to between 0.4 and 0.45 m.daN (35.40 and 39.82 lbf.in) and safety them

with the new IPC -CSN (32-21-13-12-060) cotter pins (9) or IPC -CSN (32-21-13-22-060) cotter

pins (9).

** ON A/C 251-300

Subtask 32-41-12-410-051-A

C. Close access

(1) Put the hubcap (6) in position.

(2) Apply a thin layer of Non Hardening Jointing Putty-Medium Temp. Area - - (Material No. 06LCG9) to

the screws (7).

(3) Install the screws (7) and the washers (8).

(4) TORQUE the screws (7) to between 0.4 and 0.51 m.daN (35.40 and 45.13 lbf.in).

NOTE: The hubcap attachment holes have screw-lock inserts. It is not necessary to install lockwire

on the screws (7).

Print Date: February 02, 2018 Page 9 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

** ON A/C 001-014, 016-250

Subtask 32-41-12-410-051-B

C. Close access

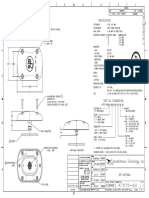

(1) Remove the blanking cap and connect the electrical connector (11) to the connector (18).

(2) Install the grommet (16) on the cable of the pressure transducer (4).

(3) Install the grommet (16) on the hubcap (12) and put the hubcap (12) in position.

(4) Engage the drive dog (13) in the fork of the rotating mechanism.

(5) Apply a thin layer of Non Hardening Jointing Putty-Medium Temp. Area - - (Material No. 06LCG9) to

the screws (14).

(6) Install the screws (14) and washers (15).

NOTE: Do not torque the screws (14) at this step.

(7) Apply a thin layer of Synthetic Oil base Grease-General Purpose Clay Thickened

- (Material No. 03GBB1) or as alternative Synthetic Oil base Grease-Landing Gear Wheel Bearing

Lithium Thickened - (Material No. 03GCB1) to the shaft (2).

NOTE: For lubricant grease specification and lubrication requirements, refer to (Ref. AMM D/O 12-

22-00-00) .

(8) Install the new IPC -CSN (32-49-15-01-050) preformed packings (3) on the shaft (2).

(9) Make sure that the IPC -CSN (32-49-15-01-050) preformed packings (3) are in the correct position

on the shaft (2).

(10) Install the pressure transducer (4) on the shaft (2).

NOTE: Make sure that the pressure transducer (4) is in the correct position.

(11) Install the nut (6) on the shaft (2).

(12) TORQUE the nut (6) to between 0.56 and 0.9 m.daN (49.56 and 79.65 lbf.in).

(13) Safety the nut (6) with the IPC -CSN (32-49-15-01-010) cotter pin (5).

(14) Clean the inner surface of the wheel bearings (surface that touches the axle). Do not apply grease on

these surfaces.

(15) TORQUE the screws (14) to between 0.4 and 0.51 m.daN (35.40 and 45.13 lbf.in).

NOTE: The hubcap attachment holes have screw-lock inserts. It is not necessary to install lockwire

on the screws (14).

** ON A/C ALL

Subtask 32-41-12-860-051-A

D. Aircraft Maintenance Configuration

(1) Inflate the tire to the unloaded pressure (Ref. AMM TASK 12-14-32-614-001) .

(2) Lower the aircraft on its wheels (Ref. AMM TASK 07-12-00-582-001) .

(3) Make sure that the pressure of the tire is correct (Ref. AMM TASK 32-41-00-210-003) .

Subtask 32-41-12-865-052-A

E. Remove the safety clip(s) and the tag(s) and close this(these) circuit breaker(s):

Print Date: February 02, 2018 Page 10 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : SVA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2018

32-41-12-400-001-A - Installation of the NLG Wheel

PANEL DESIGNATION FIN LOCATION

** ON A/C 001-014, 016-200

121VU HYDRAULIC/TIRE/PRESS 1GV M31

** ON A/C ALL

121VU HYDRAULIC/BRAKING AND STEER- 4GG M36

ING/SYS2/SPLY

121VU HYDRAULIC/BRAKING AND STEER- 3GG M35

ING/SYS2/CTL

121VU HYDRAULIC/BRAKING AND STEER- 1GG M34

ING/SYS1/CTL

121VU HYDRAULIC/BRAKING AND STEER- 2GG M33

ING/SYS1/IND AND/SPLY

** ON A/C 201-250

121VU TIRE/PRESS 1GV M31

** ON A/C 001-014, 016-250

Subtask 32-41-12-720-050-A

F. Do the functional test of the tire pressure indicating system (Ref. AMM TASK 32-49-00-720-001) .

** ON A/C ALL

5. Close-up

Subtask 32-41-12-942-051-A

A. Removal of the Equipment

(1) Remove the safety devices from the landing gears (Ref. AMM TASK 32-00-00-081-001) .

(2) Make sure that the work area is clean and clear of tools and other items.

(3) Remove the warning notice(s).

End of document

Print Date: February 02, 2018 Page 11 of 11

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

You might also like

- NLG - Removal InstallationDocument9 pagesNLG - Removal InstallationKeilaeFrancisco Arce100% (1)

- MLG - Removal InstallationDocument14 pagesMLG - Removal InstallationKeilaeFrancisco ArceNo ratings yet

- Rmoval of NLGDocument6 pagesRmoval of NLGje_carD23100% (1)

- JCP TitleDocument14 pagesJCP Titlebilly100% (1)

- AMM - A318, A319, A320, A321 - PGT - Rev. Num 34 - 01-Aug-2021 - 71-11-00-000-041-A - Removal of The Air Intake Cowl. MSN 05879Document1 pageAMM - A318, A319, A320, A321 - PGT - Rev. Num 34 - 01-Aug-2021 - 71-11-00-000-041-A - Removal of The Air Intake Cowl. MSN 05879hamdNo ratings yet

- 24-00 - Electrical Power - GeneralDocument55 pages24-00 - Electrical Power - GeneralMohammad NorouzzadehNo ratings yet

- 32-41-11-000-006-A Removal of The MLG Wheel 32-41-11-400-006-A Installation of The MLG WheelDocument40 pages32-41-11-000-006-A Removal of The MLG Wheel 32-41-11-400-006-A Installation of The MLG WheelalfonsofelipesaraviaNo ratings yet

- Amm - 12 14 32 614 001 ADocument3 pagesAmm - 12 14 32 614 001 Araiday84No ratings yet

- Washing of The Engine Gas Path With Pure WaterDocument14 pagesWashing of The Engine Gas Path With Pure WaterridwansadelyNo ratings yet

- Stretching The A320Document7 pagesStretching The A320Nagaraja BhagavNo ratings yet

- Qucik Dispatch Guide A320 AMM Reference OnlyDocument10 pagesQucik Dispatch Guide A320 AMM Reference OnlyAbdul Qadeer KhanNo ratings yet

- A330 Stayover Check ECAM Maintenance TasksDocument12 pagesA330 Stayover Check ECAM Maintenance Tasksjeeva225100% (1)

- ON A/C 051-100: Zone/Access Zone DescriptionDocument7 pagesON A/C 051-100: Zone/Access Zone DescriptionEder LucianoNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument129 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- On A/C All: Reference Qty DesignationDocument7 pagesOn A/C All: Reference Qty DesignationRicardoBillEdwinNo ratings yet

- Technical Data Support and Services: Aircraft Schematic Manual (ASM) Aircraft Wiring Manual (AWM)Document1 pageTechnical Data Support and Services: Aircraft Schematic Manual (ASM) Aircraft Wiring Manual (AWM)JAYACHANDRANNo ratings yet

- TR - A320 MLG - ServicingDocument23 pagesTR - A320 MLG - ServicingJohn Detrick100% (2)

- Training Manual A 319/320/321: ATA 30 Ice and Rain ProtectionDocument46 pagesTraining Manual A 319/320/321: ATA 30 Ice and Rain ProtectionHansraj Kayda100% (1)

- Chapter 10 PDFDocument131 pagesChapter 10 PDFAmjad SalamNo ratings yet

- Cfm56-5B - HP Duct Crack: Engineering SupportDocument3 pagesCfm56-5B - HP Duct Crack: Engineering SupportJivendra Kumar -100% (2)

- CB by Fin: Component Location ManualDocument13 pagesCB by Fin: Component Location ManualvinayNo ratings yet

- A320 Landing Gear Technical TrainingDocument34 pagesA320 Landing Gear Technical TrainingDuvan Cardona SanchezNo ratings yet

- 7 SRMDocument22 pages7 SRMChristian Oliveira100% (3)

- A319/A320/A321 ECS - System Schematic: Air Conditioning PneumaticDocument1 pageA319/A320/A321 ECS - System Schematic: Air Conditioning PneumaticvictormaviNo ratings yet

- Figure 06-41-53-15600-G / SHEET 1/1 - Belly Fairing - Access Panels On Right Side Zones 148-192-194-196-198 ON A/C 105-150Document1 pageFigure 06-41-53-15600-G / SHEET 1/1 - Belly Fairing - Access Panels On Right Side Zones 148-192-194-196-198 ON A/C 105-150Ivan KryskoNo ratings yet

- Training Manual A319 / A320 / A321: ATA 21 Air ConditioningDocument44 pagesTraining Manual A319 / A320 / A321: ATA 21 Air ConditioningSomendra Brijesh PandeyNo ratings yet

- ATA 29 Level 1Document28 pagesATA 29 Level 1Saman Mahdi AbadiNo ratings yet

- A320 Modification ListDocument1,336 pagesA320 Modification ListAhsanNo ratings yet

- Zone and ATA Chapter PDFDocument25 pagesZone and ATA Chapter PDFdnes9999No ratings yet

- A320 NE0 Fuel or Hydraulic or Oil Leakage LimitsDocument19 pagesA320 NE0 Fuel or Hydraulic or Oil Leakage LimitsArjuna SamaranayakeNo ratings yet

- Brake Alternate Servovalve Fault - WISEDocument2 pagesBrake Alternate Servovalve Fault - WISERizwan100% (1)

- AMM Insp Checks of Wheel and Tires PDFDocument12 pagesAMM Insp Checks of Wheel and Tires PDFVincent RadityaNo ratings yet

- Airbus LeafletDocument32 pagesAirbus LeafletReggie Joshua100% (1)

- A320 06-41-57 PDFDocument34 pagesA320 06-41-57 PDFFahmi AlghifariNo ratings yet

- Engine Variant: V2527-A5Document12 pagesEngine Variant: V2527-A5Kartika Ningtyas100% (1)

- Air Tanker Spec PDFDocument41 pagesAir Tanker Spec PDFollieknightNo ratings yet

- A330 Tire and Brake InspectionDocument21 pagesA330 Tire and Brake InspectionRithesh Ram NambiarNo ratings yet

- Training Manual A319 / 320 / 321: ATA 22 AutoflightDocument158 pagesTraining Manual A319 / 320 / 321: ATA 22 AutoflightŞevval YalınNo ratings yet

- EfcsDocument4 pagesEfcsJai DeepNo ratings yet

- A320 38 Water and WasteDocument7 pagesA320 38 Water and WasteSudip AcharyyaNo ratings yet

- A320 Braking DiagramDocument12 pagesA320 Braking DiagramDome DomeyNo ratings yet

- 12 Servicing PDFDocument1,005 pages12 Servicing PDFK Apichai KasamutNo ratings yet

- Boeing 787 MMEL Revision 15 HighlightsDocument238 pagesBoeing 787 MMEL Revision 15 HighlightsCatevario Negro50% (2)

- Isi 23.28.00028Document3 pagesIsi 23.28.00028Anonymous SIS1ieNo ratings yet

- Chapter 25 PDFDocument4,749 pagesChapter 25 PDFaaaadem100% (1)

- Task 53-00-14-300-002Document5 pagesTask 53-00-14-300-002mashobih hussururNo ratings yet

- Brake InspectionDocument5 pagesBrake InspectionbillyNo ratings yet

- Airbus 320 APUDocument136 pagesAirbus 320 APUSelcuk GuncanNo ratings yet

- A320 PPG TB - A320Document2 pagesA320 PPG TB - A320Jivendra Kumar100% (1)

- A318/A319/A320/A321 Landing Gear: Lufthansa Technical TrainingDocument32 pagesA318/A319/A320/A321 Landing Gear: Lufthansa Technical TrainingBELISARIONo ratings yet

- 28 Fuel AmmDocument177 pages28 Fuel AmmAmal Vinod100% (2)

- Mmel 767Document237 pagesMmel 767jjaavvmm100% (1)

- Title: Engine Fuel and Control - Fadec System - Introduce Ecu Software Standard 5.B.T.F1 On Fadec1+ Hardware On Cfm56-5B EnginesDocument72 pagesTitle: Engine Fuel and Control - Fadec System - Introduce Ecu Software Standard 5.B.T.F1 On Fadec1+ Hardware On Cfm56-5B EnginesVolNo ratings yet

- At575 234W TNCF 000 RG 29.5 NMDocument3 pagesAt575 234W TNCF 000 RG 29.5 NMMarlene SalazarNo ratings yet

- 94-00-00 P 0003 Sheet 1 - Main Wire Routing - List of Fictitious Circuits - Zoning On A/C AllDocument1 page94-00-00 P 0003 Sheet 1 - Main Wire Routing - List of Fictitious Circuits - Zoning On A/C AllMuhammad Nasir Habib0% (1)

- NwaDocument20 pagesNwaNandlal PrasadNo ratings yet

- Intl of SleeveDocument3 pagesIntl of Sleeveje_carD23No ratings yet

- Wheel InspectionDocument36 pagesWheel InspectionRemoNo ratings yet

- Job Card: 32-41-12-400-001-A - Installation of The NLG WheelDocument7 pagesJob Card: 32-41-12-400-001-A - Installation of The NLG WheelbillyNo ratings yet

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document38 pagesAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNo ratings yet

- Gen Av+ 2017 PDFDocument2 pagesGen Av+ 2017 PDFje_carD23No ratings yet

- EASA TCDS E.067 - Issue 02 - 20180417Document12 pagesEASA TCDS E.067 - Issue 02 - 20180417je_carD23No ratings yet

- AERO Q406 Article4Document9 pagesAERO Q406 Article4Late ArtistNo ratings yet

- GE90 Engine Data With 3D CutawayDocument19 pagesGE90 Engine Data With 3D CutawayjauuulNo ratings yet

- Michelin Aircraft Tyre Maintenance PDFDocument101 pagesMichelin Aircraft Tyre Maintenance PDFIonut Marian PenciuNo ratings yet

- NW-1 flight path dataDocument1 pageNW-1 flight path dataje_carD23No ratings yet

- Ukv PRD b737 Checklist v2Document2 pagesUkv PRD b737 Checklist v2fabiozimba100% (2)

- Arinc Industry Activities Cabin Systems Overview: Version 2018-01Document42 pagesArinc Industry Activities Cabin Systems Overview: Version 2018-01je_carD23No ratings yet

- A LimitationsDocument7 pagesA LimitationstugayyoungNo ratings yet

- Boeing 777 BA27-01 Component Maintenance Manual PDFDocument52 pagesBoeing 777 BA27-01 Component Maintenance Manual PDFje_carD23100% (1)

- LIST OF REQUIREMENTS - ZERO TIME STUDENTS (V.2018jan) - 1 PDFDocument1 pageLIST OF REQUIREMENTS - ZERO TIME STUDENTS (V.2018jan) - 1 PDFje_carD23No ratings yet

- RPVM PDFDocument37 pagesRPVM PDFje_carD230% (1)

- Intl of SleeveDocument3 pagesIntl of Sleeveje_carD23No ratings yet

- B777 Eaton Comp PDFDocument8 pagesB777 Eaton Comp PDFje_carD23No ratings yet

- 44-30-00 PB 001 Conf 00 - External Communication System - Description and OperationDocument1 page44-30-00 PB 001 Conf 00 - External Communication System - Description and Operationje_carD23No ratings yet

- Airbus A320 CFM56Document322 pagesAirbus A320 CFM56Claudio FerreiraNo ratings yet

- The Future of The Engine PDFDocument31 pagesThe Future of The Engine PDFje_carD23No ratings yet

- EASA TCDS E.067 - Issue 02 - 20180417Document12 pagesEASA TCDS E.067 - Issue 02 - 20180417je_carD23No ratings yet

- GSR 750Document2 pagesGSR 750je_carD23No ratings yet

- Navlog PDFDocument3 pagesNavlog PDFje_carD23No ratings yet

- Seat CMMDocument2 pagesSeat CMMje_carD23No ratings yet

- TMP Tech Application FormDocument2 pagesTMP Tech Application Formje_carD23No ratings yet

- 50 Years of Engine Improvements Sept 2009Document34 pages50 Years of Engine Improvements Sept 2009je_carD23No ratings yet

- TMP Tech Application FormDocument2 pagesTMP Tech Application Formje_carD23No ratings yet

- Gas Engine FundamentalsDocument13 pagesGas Engine Fundamentalsherdin56No ratings yet

- Resume Example 2014 BED PrimDocument1 pageResume Example 2014 BED Primje_carD23No ratings yet

- Arm A330 20091101 PDFDocument551 pagesArm A330 20091101 PDFje_carD230% (1)

- VeeruDocument4 pagesVeeruMohanraj VenuNo ratings yet

- Apple's History and ProductsDocument19 pagesApple's History and ProductsMurtaza Hussain TuriNo ratings yet

- Designing an Advanced Battery Charger with the BatMod ModuleDocument2 pagesDesigning an Advanced Battery Charger with the BatMod ModuleSugun Kumar PedapudiNo ratings yet

- Big BazaarDocument3 pagesBig BazaarShreya BatraNo ratings yet

- RSA306B USB Real Time Spectrum Analyzer Datasheet 37W603759Document26 pagesRSA306B USB Real Time Spectrum Analyzer Datasheet 37W603759HafiziAhmadNo ratings yet

- Vuly 134 Monkey BarDocument24 pagesVuly 134 Monkey BarsimonNo ratings yet

- Lab 2: Introduction To Assembly Language ProgrammingDocument9 pagesLab 2: Introduction To Assembly Language Programmingdarwinvargas2011100% (1)

- 1SCA121459R1001 Otdc32f3 DC Switch DisconnectorDocument2 pages1SCA121459R1001 Otdc32f3 DC Switch DisconnectorRicardo MosqueiraNo ratings yet

- Intel® Select Solutions Implementation Guide For Simulation and ModelingDocument36 pagesIntel® Select Solutions Implementation Guide For Simulation and ModelingAshmisNo ratings yet

- Protecciones Secundario SelectivoDocument9 pagesProtecciones Secundario Selectivoelectric104No ratings yet

- User's Manual of Haiwell PLC Programmable Power ModuleDocument13 pagesUser's Manual of Haiwell PLC Programmable Power ModuleEmmy-HaiwellNo ratings yet

- Safe Solutions for Your IndustryDocument36 pagesSafe Solutions for Your IndustrycarlosmandopintoNo ratings yet

- Ict Trial 2013 Kerian Perak Answer 1Document7 pagesIct Trial 2013 Kerian Perak Answer 1lielynsmkkmNo ratings yet

- FT-GL & FT-GLF Parts ManualDocument24 pagesFT-GL & FT-GLF Parts ManualPitter M Montilla NNo ratings yet

- ResumeDocument2 pagesResumeapi-397601484No ratings yet

- Instalacion Channel Master Type 120Document14 pagesInstalacion Channel Master Type 120Fredy Turpo TiconaNo ratings yet

- Inventory Voucher Kya He, Stock Journal Voucher - Tally Seekhe Tally Learn in HindiDocument9 pagesInventory Voucher Kya He, Stock Journal Voucher - Tally Seekhe Tally Learn in Hindipreeti gahlotNo ratings yet

- zNID-GPON-2511: Quick Installation InstructionsDocument1 pagezNID-GPON-2511: Quick Installation InstructionsayalamexNo ratings yet

- Eng DS Epp-2314 1410Document2 pagesEng DS Epp-2314 1410MarkusAldoMaquNo ratings yet

- Engineering Note. Connectivity To Allen-Bradley Controllers: by Eduardo BallinaDocument16 pagesEngineering Note. Connectivity To Allen-Bradley Controllers: by Eduardo BallinaJavier MiramontesNo ratings yet

- Data Representation: Digital Number SystemsDocument8 pagesData Representation: Digital Number Systemsspecific guy2019No ratings yet

- Software TestingDocument61 pagesSoftware Testingmalik143iNo ratings yet

- 10 Technologies That Have Changed The Way We Live - Technology & Science - NBC NewsDocument2 pages10 Technologies That Have Changed The Way We Live - Technology & Science - NBC Newstheartanto :3No ratings yet

- DOP11B - Operating InstructionsDocument0 pagesDOP11B - Operating InstructionsCaner AybulusNo ratings yet

- Pcs Command ReferenceDocument4 pagesPcs Command Referencegyan1No ratings yet

- FH e - FL eDocument2 pagesFH e - FL eKiet Pham TanNo ratings yet

- 1 800 SpaldingDocument20 pages1 800 Spaldingjoeyb12120% (1)

- Wireless Extension For Acms: Electronics & DefenseDocument2 pagesWireless Extension For Acms: Electronics & DefenseKitKat ShArryNo ratings yet

- Micom P12X/Y: Three Phase and Earth Fault Overcurrent RelaysDocument8 pagesMicom P12X/Y: Three Phase and Earth Fault Overcurrent RelaysAndri WahyudiNo ratings yet

- Timers of ATmega16 MicrocontrollerDocument21 pagesTimers of ATmega16 MicrocontrolleralfibariaNo ratings yet