Professional Documents

Culture Documents

Automatic escalator control using PLC

Uploaded by

Carl Justin de JesusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic escalator control using PLC

Uploaded by

Carl Justin de JesusCopyright:

Available Formats

Vol-2 Issue-2 2016 IJARIIE-ISSN(O)-2395-4396

AUTOMATIC ESCALATOR CONTROL

SYSTEM USING PLC

Vitwale Sudhir M.1 , Patil Nikhil P.2 , Rakte Yogesh U.3 , Jadhav Snehal H.4

Prof. Bhanegaonkar Tejas R.5

1

(BE Electrical, AVCOE, SPPU)

2

(BE Electrical, AVCOE, SPPU)

3

(BE Electrical, AVCOE, SPPU)

4

(BE Electrical, AVCOE, SPPU)

5

(Assistant professor, AVCOE, SPPU)

ABSTRACT

Today is the world of automation and automation mostly use in industries. When we are talking about

automation, we must think about PLC. This project is to design and build an automatic es calator system by

using PLC software and also using hardware. This project is about an escalator that will function when there is

an object on it. This escalator is a standard design of escalator except it has a sensor. This sensor will detect an

object and will start moving when it detected an object. There is a sensor which will switch on and off the

escalator. PLC programming has timer tool which will set how long it takes to turn off and turn on the

escalator. Moreover, it will count the object that move pass by the sensor by using counter in PLC .

Keyword: - PLC with software, Escalator design, IR sensor, DC motor.

1. INTRODUCTION

The basic motto of our project is to conserve energy in escalators so as to reduce energy consumption as well as

reduce energy bills. Escalators are use since the beginning of 21st century. However the escalators were made to

run even when they are unoccupied. This resulted in wastage of electricity; moreover, it also resulted in

increased energy bills.

How electricity is wasted in Escalators?

As the malls theatres and airports run day and night, escalators used in them are also used for the whole day.

Now if there is no person using the escalator, still its motor runs idle wasting the precious energy?

Why should we conserve energy in escalators?

Scarcity of electrical energy is increasing day by day. Hence the main objective of the 21 st century is to

Conserve Energy. Cities are the major energy consumers, as lot of energy is consumed in big cities for luxurious

purposes, load shedding is done in small towns and villages on a large scale. Hence to bridge this gap between

demand & supply we need to use energy conservation techniques. [4]

Hence we have made a circuit that keeps the escalator operational only when the person inte nds to use it,

however if there is no person using it, then our circuit automatically switches off the motor driving the escalator

thus conserves energy.

2. BLOCK DIAGRAM

Fig -1: Block Diagram

1975 www.ijariie.com 1791

Vol-2 Issue-2 2016 IJARIIE-ISSN(O)-2395-4396

3. PLC

Day by day new facilities and inventions are introducing in development of the nation which tremendously rises

the standard of living of people lives in metro cities. Due to this the construction of buildings are also highly

increases for the malls, housing purposes etc. Thus the elevators becomes very important p art of such luxurious

infrastructure for carrying people and goods. So, control system is essential in the smooth and safe operation of

the elevators.

That’s why we are using PLC for operation. Programmable logic controller is a digital computer used for

automation of industrial processes such as control of machinery on factory assembly lines. Unlike general

purpose computers the PLC is also designed for multiple input & output arrangements, extended temperature

ranges, immunity to electrical noise, resistance to vibrations and impact. PLC can handle severe conditions like

dust, humidity. These are highly reliable fast and flexible. Programs to control machine operation are typically

stored in non-volatile memory. A PLC is an example of a real time system since output results must be produced

in response to input condition within a given period of time. [2]

In short, this project is to design and construct an automatic escalator using programmable logic controller and

IR sensor is used to know the position.

The first Programmable Logic Controller, PLC was developed by a group of engineers at General Motors in

1968. The three main parts of PLC are namely the central processing unit (CPU), the input output selection and

the programming device. The block diagram of PLC can be seen as follows . [1]

Fig -2: Block diagram representing the different parts of PLC. [1]

Fig -3: Structure of PLC [5]

1975 www.ijariie.com 1792

Vol-2 Issue-2 2016 IJARIIE-ISSN(O)-2395-4396

3.1 PLC Specifications

Program 33K steps

capacity

Total program 2.88KB(application+ladder)

memory

Execution 60.0ns/contact

Speed 240.01ns/coil

373.35ns/16 bit transfer

Temperature 0 to 60ºc (operating), -20 to

85ºc(storage)

Humidity 10 to 90 % non-condensing

Dimentions 100mm(H)x26mm(W )x70mm(D)

(mm)

Weight 150 gms.

(approx.)

Table -1: PLC Specifications

4. WORKING

In this project we want to control escalator using PLC. The PLC works on 24V DC power supply. By using step

down transformer (230V/24V) we convert 230V AC supply to 24V AC, then full wave Bridge rectifier converts

24V AC into Equivalent DC supply. The filter capacitor of 1000µf converts pulsating DC into pure DC power

supply. Voltage regulator IC’s 7805 and 7812 gives 5V DC and 12V DC respectively for IR (Infra -red) sensors

and Dc motor operations.

When an object is detected by IR sensor it gives necessary signals to PLC. Output of IR sensor is connected to

PLC. If person or object is detected by IR sensor, output 1 given to PLC. Similarly if person or object is not

present in front of IR sensor the output of PLC is 0. Output of PLC is connected to relay inp ut isolation board.

In this PCB opto-coupler circuit is present, this circuit senses input and output is given to the relay board. This

isolation board separate input and output ground and provides protection to PLC. Relay circuit controls motor of

escalator as per the signals given by PLC.

When an object is detected in front of IR sensor motor starts and escalator moves for specific period of time

given in down counter. If one object moving upward and at the same time another object detected by sensor then

down counter gets reset and starts counting from initial value.

5. LADDER LOGIC

In this chapter we discuss about the ladder logic network development. Based on our requirements and

depending on the need the logic has to be developed and the relevant PLC has been chosen. Here we choose

flexisoft for developing and to download ladder logic into the PLC. We developed various logics for different

operations of working model of an escalator. [4]

Image -1: Flexisoft Software

1975 www.ijariie.com 1793

Vol-2 Issue-2 2016 IJARIIE-ISSN(O)-2395-4396

6. ADVANTAGES, DISADVANTAGES & APPLICATION

6.1 Advantages

Due to the use of PLC manual error does not occur in system.

PLC with monitor continues input supply and taking automatic decision.

The Escalator can work in automated mode as we programmed as well as in continuous mode.

Escalator can be made “ON” only when required, thereby saving electrical energy by av oiding

unnecessary running of escalator as a conventional one.

Escalator can be worked on scheduled mode.

Reduces losses in equipment. If the losses are less then the system efficiency increases.

The reliability of the system is more.

6.2 Disadvantages

It is compatible for special purposes application and costly for the general purposes

6.3 Applications

Department stores/shopping: - As noted above, a few escalator types were installed in stores. Escalators

proved instrumental in the layout and design of shopping venues. In Stores and Malls they are actually

used to carry Shoppers & Customers from one floor to the next floor.

Public Transportation: - It help passenger to reach platform on a given time. It also help passengers on

airport to undergo fast check-inn and check-outs.

Industrial Production Environments : - Escalators help to carry its workers between floors four times a

day. By using the escalator the efficiency of operator increases because escalator reduces stair climbing

efforts.

Military use: - Escalator also plays an important role in military for the transportation of aircraft and

pilots.

7. CONCLUSION

For fulfilling the increasing energy demand it is very essential to use energy efficiently. From this paper the

author can conclude that by using PLC and IR sensor more energy can be conserve as compare to traditional

technique. This system can easily implemented on modern as well as traditional escalators.

Image -2: Hardware Model

8. ACKNOWLEDGMENT

We would like to take this opportunity to express our profound gratitude and deep regard to our guide Prof.

Bhanegaonkar T. R. for his exemplary guidance, valuable feedback and constant encouragement throughout the

duration of the paper. His valuable suggestions where of immense help throughout our project work. His

perceptive criticism kept us working to make this paper in a much better way.

1975 www.ijariie.com 1794

Vol-2 Issue-2 2016 IJARIIE-ISSN(O)-2395-4396

9. REFERENCES

[1] A. P. Tiwary, Saurabh Sharma and T. Y. Ladakhi, -Application of PLC for Elevator Control System:

International Symposium on Devices MEMS, Intelligent Systems & Communication,|| ISDMISC, 2011.

[2] S.B. Ron Carter, A. Selvaraj, -Design and Implementation of PLC based Elevator,|| International Journal of

Computer Applications (0975 –8887)Volume 68–No.7, April 2013.

[3] Darshil, Sagar, Rajiv, Pangaokar and S.A. Sharma,- Development of a PLC Based Elevator System with

Colour Sensing Capabilities for Material Handling in Industrial Plant,|| Joint International Conference on

Power System Technology and IEEE Power India Conference , pp. 1-7, 2008.

[4] Xiaoling Yang, Qunxiong Zhu and Hong Xu,- Design and Practice of an Elevator Control System Based

on PLC,|| IEEE Conference Publications, pp. 94-99, 2008.

[5] Sandar Htay , Su Su Yi Mon,- Implementation of PLC Based Elevator Control System,|| International

Journal of Electronics and Computer Science Engineering, Volume 3-No.2, pp. 91-100.

1975 www.ijariie.com 1795

You might also like

- Earthing Design TestingDocument2 pagesEarthing Design Testingblp26No ratings yet

- 400kva 500kva Mhe Riello Ups Data SheetDocument7 pages400kva 500kva Mhe Riello Ups Data SheetAra AkramNo ratings yet

- 1320083C - Plano Electrico 2018Document88 pages1320083C - Plano Electrico 2018Adhemar Vasquez AlburquequeNo ratings yet

- SoMove 2.x Installation NotesDocument8 pagesSoMove 2.x Installation NotesPaulJohnPosadasGimenaNo ratings yet

- Tta - Atc 300 Eaton PDFDocument40 pagesTta - Atc 300 Eaton PDFJaime MendozaNo ratings yet

- ABB - 4 Biggest MistakesDocument7 pagesABB - 4 Biggest MistakesAnargha BhattacharyaNo ratings yet

- Power Sector Overview in India - EARTHING DESIGN CALCULATIONDocument3 pagesPower Sector Overview in India - EARTHING DESIGN CALCULATIONnavneetNo ratings yet

- Industrial Automation Using I2c Protocol DocumentationDocument56 pagesIndustrial Automation Using I2c Protocol Documentationsrinithi99No ratings yet

- 1151 RBDocument54 pages1151 RBManuel A. Silva PainénNo ratings yet

- ViZn Energy Systems Datasheet GS200Document2 pagesViZn Energy Systems Datasheet GS200kanggg_ku3014No ratings yet

- Tamil Nadu Coke-24 V DCDocument14 pagesTamil Nadu Coke-24 V DCsyamprasadNo ratings yet

- PLCDocument37 pagesPLCArav AminNo ratings yet

- Practical File of PLC and SCADADocument17 pagesPractical File of PLC and SCADAvara prasadNo ratings yet

- Eaton 9155 Ups User Guide Manual 164201553 PDFDocument98 pagesEaton 9155 Ups User Guide Manual 164201553 PDFEdwin RTNo ratings yet

- Owner Owner Manual Manual: Operator/Installation/Service/Parts Transfer Switch 800-3000 AmpsDocument172 pagesOwner Owner Manual Manual: Operator/Installation/Service/Parts Transfer Switch 800-3000 AmpshalexNo ratings yet

- SAWO Steam-GeneratorDocument24 pagesSAWO Steam-GeneratorPena Park HotelNo ratings yet

- Installation and troubleshooting guide for Emerson Liebert PSP UPSDocument5 pagesInstallation and troubleshooting guide for Emerson Liebert PSP UPSMark Louis MagraciaNo ratings yet

- VD4 enDocument13 pagesVD4 enmaruf048No ratings yet

- Earthing PitDocument4 pagesEarthing PitChaitanya ShakyaNo ratings yet

- KBMM SMT Manual PDFDocument32 pagesKBMM SMT Manual PDFRicardo Garcia FuentesNo ratings yet

- 1151 RevaDocument55 pages1151 RevaOrwah malkawiNo ratings yet

- Logix Hot Backup SolutionsDocument2 pagesLogix Hot Backup SolutionsiedmondNo ratings yet

- WebInterface Configuration Manual BasicsDocument32 pagesWebInterface Configuration Manual BasicsprenticNo ratings yet

- Dfe-B00-Ele-Dwg-Sld-003 - Single Line Diagram For Process PCC Panel - 1 (Dry End)Document1 pageDfe-B00-Ele-Dwg-Sld-003 - Single Line Diagram For Process PCC Panel - 1 (Dry End)Electrical PCBL Team100% (1)

- L&T's Air Circuit BreakersDocument31 pagesL&T's Air Circuit BreakersNikhil SinghNo ratings yet

- Control Gear Price ListDocument15 pagesControl Gear Price ListShubham GuptaNo ratings yet

- Ahg MCC A 001Document22 pagesAhg MCC A 001Yawar QureshiNo ratings yet

- AHF Manual R5 1-27-2012 PDFDocument54 pagesAHF Manual R5 1-27-2012 PDFkaushikray06No ratings yet

- Type 2 Co-Ordination Selection ChartsDocument20 pagesType 2 Co-Ordination Selection ChartsDheeraj YadavNo ratings yet

- Rexeoth Control Panel BF-1Document4 pagesRexeoth Control Panel BF-1Hrvoje ŠkaricaNo ratings yet

- Numerical Relays Protection Relays CatalogueDocument36 pagesNumerical Relays Protection Relays CatalogueRajeev ValunjkarNo ratings yet

- Electricneutron-Star Delta Motor ConnectionDocument7 pagesElectricneutron-Star Delta Motor ConnectionJoe ElectricneutronNo ratings yet

- 12kV VCB-ABB India PVT LTDDocument18 pages12kV VCB-ABB India PVT LTDSuMit MisHraNo ratings yet

- Introduction to Automation and PLC ProgrammingDocument37 pagesIntroduction to Automation and PLC ProgrammingHappy ShubhamNo ratings yet

- SSP Booster Pump MCC Panel As Built Drawing - 24 - 01 - 2023Document12 pagesSSP Booster Pump MCC Panel As Built Drawing - 24 - 01 - 2023AkashManusmareNo ratings yet

- Star DeltaDocument6 pagesStar Deltaa durgadeviNo ratings yet

- Precon Training BrochureDocument12 pagesPrecon Training BrochurechintanNo ratings yet

- TEchnical Specification For DDUGJY and IPDS Scheme by REC, SBD DOCumentsDocument547 pagesTEchnical Specification For DDUGJY and IPDS Scheme by REC, SBD DOCumentsashutosh2291No ratings yet

- JinkoSolar N-Type Mono-facial 450-470W Solar PanelDocument2 pagesJinkoSolar N-Type Mono-facial 450-470W Solar PaneldetailsNo ratings yet

- Production (Utilities) Heavy Water Plant (Manuguru) Gautaminagar - 507 116 Khammam Dist. Telangana StateDocument52 pagesProduction (Utilities) Heavy Water Plant (Manuguru) Gautaminagar - 507 116 Khammam Dist. Telangana StatePvk Itsa BrandnameNo ratings yet

- Unit Iv Starting and Speed Control of Three Phase Induction MotorDocument19 pagesUnit Iv Starting and Speed Control of Three Phase Induction MotorVamshiNo ratings yet

- Cad Report Vikash FinalDocument23 pagesCad Report Vikash FinalVikash kumarNo ratings yet

- IAI EtherCAT Pcon Acon SpecsheetDocument2 pagesIAI EtherCAT Pcon Acon SpecsheetElectromateNo ratings yet

- Control Cable Schedule (A) - Armoured Cable, (F) - Flexible Cable, (S) - Cable With Screen. KWPCL/DRG/CS/018 Rev. 1 Sheet 1 of 3Document3 pagesControl Cable Schedule (A) - Armoured Cable, (F) - Flexible Cable, (S) - Cable With Screen. KWPCL/DRG/CS/018 Rev. 1 Sheet 1 of 3ARIJIT KUNDUNo ratings yet

- Engineering Systems LTD.: PROJECT: 90KLPD Distillery Plant Section: Fermentation ClientDocument7 pagesEngineering Systems LTD.: PROJECT: 90KLPD Distillery Plant Section: Fermentation ClientS B DubalNo ratings yet

- Samkoon HMI User Manual (HmiVietNam - Com)Document422 pagesSamkoon HMI User Manual (HmiVietNam - Com)Minh Nguyễn100% (1)

- Super Cool Technical Specification UniversalDocument5 pagesSuper Cool Technical Specification UniversalSunil SinghNo ratings yet

- Drawing - CB L2Document4 pagesDrawing - CB L2Prasetiyo HanantoNo ratings yet

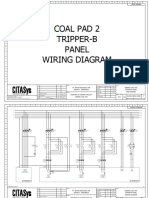

- Coal Pad 2 Tripper-B Panel Wiring Diagram: Citasys Citasys Citasys CitasysDocument7 pagesCoal Pad 2 Tripper-B Panel Wiring Diagram: Citasys Citasys Citasys CitasystomywidiansyahNo ratings yet

- PCB Design & Manufacturing CURRICULUMDocument19 pagesPCB Design & Manufacturing CURRICULUMSunita kumariNo ratings yet

- Click PLC CommunicationDocument30 pagesClick PLC CommunicationHemesh Jain SuranaNo ratings yet

- ICAM Sub StationDocument66 pagesICAM Sub StationAslam NayyerNo ratings yet

- Drive Field KCL 20181004ESAGIntegrated Motion Update October 2018Document54 pagesDrive Field KCL 20181004ESAGIntegrated Motion Update October 2018vuNo ratings yet

- New Microsoft Word DocumentDocument10 pagesNew Microsoft Word DocumentTejas KadamNo ratings yet

- PLC PDFDocument9 pagesPLC PDFloganathan sNo ratings yet

- Stepper Motor ReportDocument13 pagesStepper Motor ReportVolda0% (2)

- hệ thống kích từ trong nhà máy thủy điệnDocument344 pageshệ thống kích từ trong nhà máy thủy điệnTung NguyenNo ratings yet

- New9000English Mannual PDFDocument344 pagesNew9000English Mannual PDFLe Chi Pham100% (1)

- PLC Based Pick and Place Robot With 4 DOF: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument5 pagesPLC Based Pick and Place Robot With 4 DOF: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyGS AshishNo ratings yet

- International Journal of Computational Engineering Research (IJCER)Document4 pagesInternational Journal of Computational Engineering Research (IJCER)International Journal of computational Engineering research (IJCER)No ratings yet

- QUITTING SALE - PRICELIST - Ken DimarananDocument22 pagesQUITTING SALE - PRICELIST - Ken DimarananCarl Justin de JesusNo ratings yet

- Pneumatic SystemDocument28 pagesPneumatic SystemMohd FazillNo ratings yet

- Item Exclusive Series 1Document2 pagesItem Exclusive Series 1Carl Justin de JesusNo ratings yet

- D2 - Commonwealth - 070421 - 030915 - 2Document162 pagesD2 - Commonwealth - 070421 - 030915 - 2Carl Justin de JesusNo ratings yet

- Pneumatic SystemDocument28 pagesPneumatic SystemMohd FazillNo ratings yet

- How To Play SudokuDocument34 pagesHow To Play SudokujitnikhilNo ratings yet

- List of Last Names from A-DDocument162 pagesList of Last Names from A-DCarl Justin de JesusNo ratings yet

- D2 - Commonwealth - 070421 - 030915 - 2Document162 pagesD2 - Commonwealth - 070421 - 030915 - 2Carl Justin de JesusNo ratings yet

- Pneumatic SystemDocument28 pagesPneumatic SystemMohd FazillNo ratings yet

- History Natural GasDocument10 pagesHistory Natural GasCarl Justin de JesusNo ratings yet

- Storage and Maintenance of Quality RecordsDocument17 pagesStorage and Maintenance of Quality RecordsCarl Justin de JesusNo ratings yet

- Labor Law For LeadersDocument7 pagesLabor Law For LeadersCarl Justin de Jesus50% (2)

- Operations and Service 69UG15: Diesel Generator SetDocument64 pagesOperations and Service 69UG15: Diesel Generator SetAnonymous NYymdHgyNo ratings yet

- Unethical Business Pratices in Corporates: March 2016Document13 pagesUnethical Business Pratices in Corporates: March 2016Manju Nadh ChakravadhanulaNo ratings yet

- Acha Teff ThresherDocument62 pagesAcha Teff ThresherTANKO BAKO100% (2)

- Master Plumber Exam Coverage (Philippines)Document4 pagesMaster Plumber Exam Coverage (Philippines)Eugene Micarandayo100% (3)

- VTT R 01177 17Document27 pagesVTT R 01177 17Joseph BookerNo ratings yet

- Why I Play Bass March 14 2013Document293 pagesWhy I Play Bass March 14 2013Paul van Niekerk80% (5)

- JVC TH-M606 - 603 - SMDocument101 pagesJVC TH-M606 - 603 - SMCaillouxNo ratings yet

- Brake System: PrecautionDocument75 pagesBrake System: PrecautionRoger SwensonNo ratings yet

- Post TensioningDocument13 pagesPost TensioningAbdullah AhamedNo ratings yet

- Net HSMDocument4 pagesNet HSMJosé Tudela de la RosaNo ratings yet

- User's Manual Installation Guide for Wind DisplayDocument21 pagesUser's Manual Installation Guide for Wind DisplayVM ServicesNo ratings yet

- Types of Camera AnglesDocument2 pagesTypes of Camera AnglesMaJudith JavilloNo ratings yet

- TM4320 PDFDocument85 pagesTM4320 PDFandres cortezNo ratings yet

- ACEEE - Best Practices For Data Centres - Lessons LearnedDocument12 pagesACEEE - Best Practices For Data Centres - Lessons LearnedtonybudgeNo ratings yet

- QUICK GUIDE To Installing Oracle Database 11gR2 - PART1Document7 pagesQUICK GUIDE To Installing Oracle Database 11gR2 - PART1Peter AsanNo ratings yet

- On Tap Water Filter System InstructionsDocument48 pagesOn Tap Water Filter System InstructionsFilipa FigueiredoNo ratings yet

- 194 Sample ChapterDocument27 pages194 Sample ChapterVikas TiwariNo ratings yet

- OTC13998Document15 pagesOTC13998Raifel MoralesNo ratings yet

- Monocrystalline - 50Wp - 200Wp: 50W - 200W 17.20V - 30.10V 27.5A - 7.85A 21.10V - 36.10V 2.95A - 8.34ADocument2 pagesMonocrystalline - 50Wp - 200Wp: 50W - 200W 17.20V - 30.10V 27.5A - 7.85A 21.10V - 36.10V 2.95A - 8.34ARia IndahNo ratings yet

- 4-way switch wiring diagram for a 2 pickup guitarDocument1 page4-way switch wiring diagram for a 2 pickup guitarNebojša JoksimovićNo ratings yet

- 06b AppendixB2 (1000HPRig) 1582535891879Document103 pages06b AppendixB2 (1000HPRig) 1582535891879Harsh TiwariNo ratings yet

- Energy Equity Epic (Sengkang) Pty., Ltd. Central Gas Processing Plant Kampung Baru FieldDocument2 pagesEnergy Equity Epic (Sengkang) Pty., Ltd. Central Gas Processing Plant Kampung Baru FieldAsbar AmriNo ratings yet

- Chiller Selection Made Easier With myPLV™Document12 pagesChiller Selection Made Easier With myPLV™Omair FarooqNo ratings yet

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDDocument6 pagesMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaNo ratings yet

- Block Out TimeDocument3 pagesBlock Out TimeschumangelNo ratings yet

- Parts List CMX1402Document36 pagesParts List CMX1402Jayden BarnesNo ratings yet

- Complete Checklist for Manual Upgrades to Oracle Database 12c R1Document27 pagesComplete Checklist for Manual Upgrades to Oracle Database 12c R1Augustine OderoNo ratings yet

- Text Programming Guide For iOSDocument106 pagesText Programming Guide For iOSPetr MánekNo ratings yet

- How To Use AZUpDocument1 pageHow To Use AZUpjovicasNo ratings yet

- History Gelatin DryingDocument3 pagesHistory Gelatin DryingLe Thi Kim KhanhNo ratings yet