Professional Documents

Culture Documents

ABB ACS550 01 Quick Start PDF

Uploaded by

Zul KarnaenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABB ACS550 01 Quick Start PDF

Uploaded by

Zul KarnaenCopyright:

Available Formats

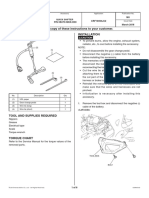

ACS550 Prepare for installation Collect motor data Install the wiring

Collect the following data from the motor

Quick Start Guide WARNING! The ACS550 should ONLY be nameplate for later use in the ACS550 startup: Wiring power

installed by a qualified electrician. 1. Open the appropriate

ACS550-01 Drives (0.75…160 kW), • Voltage __________________________

knockouts in the gland box. 2

IP21 / UL Type 1 Enclosure • Nominal motor current ______________

Unpack the drive 2. Install the cable clamps for

• Nominal frequency _________________ the power/motor cables.

1

Note: Lift the ACS550 by its chassis and not by its • Nominal speed ____________________ 3. On the input power cable, X0004

cover. • Nominal power ____________________ strip the sheathing back far

enough to route individual wires.

1. Unpack the drive. Tools required 4. On the motor cable, 7

2. Check for any damage. strip the sheathing

Screwdrivers, wire stripper, tape measure, 6

back far enough to

3. Check the contents against the order / shipping mounting screws or bolts and drill.

expose the copper wire 7

label. 4

shield so that the 3

Prepare the mounting location shield can be twisted

Check into a bundle. Keep the 8

The drive requires a IP2001

• Motor compatibility – Motor type, nominal smooth, vertical, solid bundle not longer than

current, frequency and voltage range must five times its width to minimize noise radiation.

surface, free from heat and

match drive specifications. – 360° grounding under the clamp is

moisture, with free space for

air flow – 200 mm (8 in) recommended for the motor cable to minimize

• Suitable environment – Drive requires heated, noise radiation. In this case, remove the

indoor controlled environment that is suitable above and below.

1 sheathing at the cable clamp.

Overview for the selected enclosure. 1. Mark the mounting points

5. Route both cables through the clamps.

using the template.

The installation of the ACS550 adjustable • Wiring – Follow local codes for wiring, circuit 6. Connect the bundle created from the motor

speed AC drive follows the outline below. protection and EMC requirements. 2. Drill the mounting holes.

X0002 cable shield to the GND terminal.

PREPARE for installation Refer to User’s Manual and confirm that all 7. Strip and connect the power/motor wires and

preparations are complete. Remove the front cover the power ground wire to the drive terminals

PREPARE mounting location 1. Remove the using the torques given in the table below. See

3

Drive identification control panel, if

Power connections below or, for more detail,

ACS550-01-08A8-4 see User’s Manual.

REMOVE the front cover attached. 2

U1 3~ 380...480 V Frame Tightening torque

I2N/ I2hd 8.8/6.9 A 2. Loosen the size N·m

Serno *2030700001* lb·ft 8

MOUNT the drive PN/Phd 4.0/3.0 kW captive screw

R1, R2 1.4 1

Use the following chart to interpret the type at the top.

R3 2.5 1.8

INSTALL wiring code found on the drive label. 3. Pull near the 1 R4 5.6; PE: 2 4; PE 1.5

ACS550-01-08A8-4+J404+… top to remove R5 15 11

CHECK installation the cover. R6 40; PE: 8 30; PE: 6 X0005

AC, Standard Drive – 550 series IP2000

8. Install conduit/gland box and tighten the cable

Construction (region specific) clamps.

REINSTALL the cover

01 = Setup/parts for IEC install./compliance

U1 = Setup/parts for US install./compliance Mount the drive WARNING! To disconnect the internal EMC

APPLY power Output current rating 1. Position the ACS550 and 1 filter, remove the screws marked with “-”, or

See Ratings in User’s Manual for details replace the screws marked with “ ” with the

use screws or bolts to

START-UP provided polyamide screws, depending on

Voltage rating securely tighten all four

2 = 208…240 V AC corners. the frame size.

Application 4 = 380…480 V AC System type R1...R3 R4 R5...R6

6 = 500…600 V AC Note: Lift the ACS550 by its EM1 EM3 EM1 EM3 F1 F2

This guide provides a quick reference for metal chassis. 2 IT system - - - -

installing ACS550-01 drives having a standard Options Corner grounded TN

enclosure. Examples of options: system -

No specification = IP21 / UL type 1 2. Non-English speaking IP2002

Note: This guide does not provide detailed B055 = IP54 / UL type 12 locations: Attach a 9. Install the cable clamp(s) for

installation, safety or operational UL type 12 is not available for type warning sticker in the appropriate language the control cable(s). (Power/

ACS550-01-290A-4. over the existing warning on the top of the motor cables and clamps

instructions. See ACS550 User’s Manual for

0J400 = No control panel module. not shown in the figure.)

complete information. J404 = ACS-CP-C Basic Control Panel

9

X0006

Power connections Wiring the controls Apply power

WARNING! The maximum voltage for digital

Frame size R1…R4 1. Strip control cable sheathing inputs is 30 V. Always reinstall the front cover before turning

and twist the copper shield 3 power on.

into a bundle. 4

EM3 WARNING! The ACS550 will start up

2. Route control cable(s) Check installation automatically at power up, if the external run

EM1

through clamp(s) and tighten Before applying power, perform the following command is on.

PE clamp(s). checks.

GND 3. Connect the ground shield 1. Apply input power.

Check

X0033 bundle for digital and analog When power is applied to the ACS550, the

Power input Power output to motor I/O cables at X1-1. (Ground Environment conforms to specifications. green LED comes on.

(U1, V1, W1) 2

(U2, V2, W2) only at the drive end.) The drive is mounted securely.

Note: Before increasing motor speed, check that

See table Optional Proper cooling space around the drive. the motor is running in the desired direction.

braking below. 4. Strip and connect the individual IP2003

control wires to the drive The motor and driven equipment are ready for start.

Frame size R5 terminals. Use a tightening torque of 0.4 N·m (0.3

For IT systems and corner grounded TN systems:

lb·ft). See Control connections below or, for more The internal EMC filter is disconnected (see the table Start-up

F1 information, see User’s Manual. in Wiring power).

See table Optional In start-up, enter motor data (collected earlier)

F2 braking below. 5. Install the conduit/gland box cover (1 screw). The drive is properly grounded. and, if needed, edit parameters that define how

Input power (mains) voltage matches the drive the drive operates and communicates.

Control connections nominal input voltage.

ABB Standard macro Assistant Control Panel

The input power (mains) terminals, U1, V1, W1, are

X1 1 SCR Signal cable shield (screen) connected and tightened as specified.

PE GND The Start-up Assistant steps through typical

2 AI1 Ext. freq. ref. 1: 0…10 V The input power (mains) fuses are installed. start-up selections, and runs automatically

3 AGND Analog input com.

Ref. voltage 10 V DC The motor terminals, U2, V2, W2, are connected and upon the initial power up. At other times, use

X0035 4 10V

tightened as specified. the steps below to run the Start-up Assistant.

5 AI2 Not used

Power input Power output to motor Motor cable is routed away from other cables.

(U1, V1, W1) (U2, V2, W2) 6 AGND Analog input com. 1. Use the MENU key to

7 AO1 Output freq.: 0…20 mA NO power factor compensation capacitors are in the access the Main menu.

Frame size R6 8 AO2 Output current: 0…20 mA motor cable. LOC

LOC

49.RPM

1 Hz

49.1Hz

400RPM

2. Select ASSISTANTS. 1200

12.40.

A5 A

9 AGND Analog output com. Control terminals are wired and tightened as 10.dm3/s

405 7 %

specified. 3. Select Start-up Assistant. DIR

DIR 00:00

12:45 MENU

MENU

10 24V Aux. volt. output +24 V DC

F2 NO tools or foreign objects (such as drill shavings) 4. Follow the screen

11 GND Aux. volt. common are inside the drive. instructions to configure the

12 DCOM Digital input com. for all

NO alternate power source for the motor is system.

13 DI1 Start/Stop: Active = start

connected – no input voltage is applied to the output

14 DI2 Fwd/Rev: Active = rev. dir. of the drive.

15 DI3 Constant speed sel.2

16 DI4 Constant speed sel.2 Note: For common parameters and menu items,

17 DI5 Ramp pair: Active = 2nd ramp pair. Reinstall the cover use the Help key ? to display

18 DI6 Not used 1. Align the cover descriptions.

1

and slide it on. If you encounter alarms or faults, use the

19 RO1C Relay output 1

20 RO1A Default operation: 2. Tighten the 2 Help key or refer to chapter Diagnostics in

21 RO1B Ready = 19/21 connected captive screw. User’s Manual.

See table

F1 Optional braking 22 RO2C Relay output 2 3. Install the control

below. 23 RO2A Default operation: panel.

24 RO2B Running = 22/24 connected Basic Control Panel

25 RO3C Relay output 3 3 The Basic Control Panel does not

26 RO3A Default operation: include the Start-up Assistant. Refer to

27 RO3B Fault(-1) =25/27 connected section How to start up the drive in

X0013

(Fault => 25/26 connected)

Code: 3AFE68243513 REV E / EN

User’s Manual and manually enter any

Note 1. Jumper setting (two switch types possible):

IP2009

parameter changes desired.

PE GND AI1: 0…10 V

ON

Power input Power output to motor

1 2

J1 or J1

ON

AI2: 0(4)…20 mA

Supersedes: 2007-04-16

ON

(U1, V1, W1) (U2, V2, W2)

Effective: 2009-07-07

Note 2. Code: 0 = open, 1 = connected

Optional braking DI3 DI4 Output

Frame Terminal 0 0 Reference through AI1

size labels Brake options

1 0 CONSTANT SPEED 1 (1202)

R1, R2 BRK+, BRK- Brake resistor 0 1 CONSTANT SPEED 2 (1203)

R3…R6 UDC+, UDC- • Braking unit 1 1 CONSTANT SPEED 3 (1204)

• Chopper and resistor

You might also like

- Schneider Atv LiftDocument345 pagesSchneider Atv LiftjayNo ratings yet

- SINAMICS G130 FP 1008 EngDocument30 pagesSINAMICS G130 FP 1008 Engsivakscribd100% (1)

- SiemensDocument254 pagesSiemensRogelio ValdezNo ratings yet

- MasterDrive Paramterisation PDFDocument69 pagesMasterDrive Paramterisation PDFSam eagle goodNo ratings yet

- V20 LaunchedDocument147 pagesV20 LaunchedNguyễn Viết HùngNo ratings yet

- Altivar 71Document208 pagesAltivar 71Elvins AguilarNo ratings yet

- ABB ACS880-01-065A-5 PARTS AND QUANTITIESDocument2 pagesABB ACS880-01-065A-5 PARTS AND QUANTITIESThọ NguyễnNo ratings yet

- ATV930 950 Installation Manual en NHA80932 03Document143 pagesATV930 950 Installation Manual en NHA80932 03Anonymous Th1OVYPQYTNo ratings yet

- DCM Converter 0212 en PDFDocument554 pagesDCM Converter 0212 en PDFHa le QuangNo ratings yet

- S2E2 Sinamics G120XADocument47 pagesS2E2 Sinamics G120XAVaibhav Purnale100% (1)

- S120 Startdrive Commiss Man 1218 en-USDocument314 pagesS120 Startdrive Commiss Man 1218 en-USAdam SkrebyNo ratings yet

- WinCC V7.5 Orderdata EuDocument2 pagesWinCC V7.5 Orderdata EufaisalrahmadNo ratings yet

- Motion Control DrivesDocument44 pagesMotion Control DrivesKnjigescribdNo ratings yet

- Sinamics G130 / G150 / S150: OptionsDocument30 pagesSinamics G130 / G150 / S150: OptionsANDRES CISTERNASNo ratings yet

- Ac Induction Motor BrakingDocument9 pagesAc Induction Motor BrakingWrya SaeedNo ratings yet

- Ps-481 Sq-300i Hybrid AvcDocument2 pagesPs-481 Sq-300i Hybrid AvcjayakrishnaNo ratings yet

- Operating Instructions SIMOCRANEDocument186 pagesOperating Instructions SIMOCRANEWhite Tiger100% (2)

- Simovert MasterdrivesDocument8 pagesSimovert Masterdriveseng_mhassan1No ratings yet

- VACON NX All in One Application Guide DPD00903H enDocument354 pagesVACON NX All in One Application Guide DPD00903H enSaasiNo ratings yet

- Installation and Start-Up Guide 11/2002 Edition: Ccu3 Software Version 6 Sinumerik 810DDocument350 pagesInstallation and Start-Up Guide 11/2002 Edition: Ccu3 Software Version 6 Sinumerik 810DS.Dharanipathy100% (5)

- Guideline - en Simotion PDFDocument73 pagesGuideline - en Simotion PDFqaisarharisNo ratings yet

- Ivica Bašić: 6RA70 Series Microprocessor-Based Converters From 6kW To 1900kW For Variable-Speed DC DrivesDocument47 pagesIvica Bašić: 6RA70 Series Microprocessor-Based Converters From 6kW To 1900kW For Variable-Speed DC DrivesdrabniNo ratings yet

- Ansaldo Electric Drives 15/30 kW Technical SpecsDocument4 pagesAnsaldo Electric Drives 15/30 kW Technical SpecsMr.K ch50% (2)

- Drive InverterDocument8 pagesDrive InverterSam eagle goodNo ratings yet

- SIMATIC PCS 7 Cabinet Design: 6/2 6/2 6/3 Basic Cabinet 6/4 ET 200M I/O Unit 6/5 System UnitDocument6 pagesSIMATIC PCS 7 Cabinet Design: 6/2 6/2 6/3 Basic Cabinet 6/4 ET 200M I/O Unit 6/5 System UnitadelswedenNo ratings yet

- Tia Pro1 12 FC FB EngDocument23 pagesTia Pro1 12 FC FB EngJoaquín RpNo ratings yet

- Basics of PLCsDocument88 pagesBasics of PLCshussam aldragmaNo ratings yet

- Abb Acs800 02 ManualDocument156 pagesAbb Acs800 02 Manualjosega123No ratings yet

- Sinamics g120Document472 pagesSinamics g120d-fbuser-56114163No ratings yet

- TIA Pro1 PDFDocument29 pagesTIA Pro1 PDFKerwin GrapaNo ratings yet

- Hardware Configuration: Simatic S7Document25 pagesHardware Configuration: Simatic S7Neagoe CristianNo ratings yet

- Modicon PremiumDocument459 pagesModicon Premiumsalmo83:18No ratings yet

- 6ra70 PDFDocument232 pages6ra70 PDFChowdary MnchowdaryNo ratings yet

- Dps7 eDocument38 pagesDps7 echochoroy0% (1)

- Service On Sinamics ConvertersDocument16 pagesService On Sinamics Converterssiva kumarNo ratings yet

- G120 Fieldbus FCT Man 0418 en-US PDFDocument244 pagesG120 Fieldbus FCT Man 0418 en-US PDFWilson Barco MNo ratings yet

- Encoder Parameterization V43 PDFDocument19 pagesEncoder Parameterization V43 PDFMancamiaicuruNo ratings yet

- SERV1 05E SymbolicDocument14 pagesSERV1 05E SymbolicAhmed KhairiNo ratings yet

- Vincotech Power Modules CatalogDocument134 pagesVincotech Power Modules CataloglizxcanoNo ratings yet

- Master Drive 6RA70 Parameter ListDocument186 pagesMaster Drive 6RA70 Parameter Listsanjaya srivastava100% (3)

- m340 Canopen Altivar Lexium Tesysu Preventa en PDFDocument154 pagesm340 Canopen Altivar Lexium Tesysu Preventa en PDFpham anhNo ratings yet

- Positioning of The Modular S7 Controllers ........................................................... 1-2Document16 pagesPositioning of The Modular S7 Controllers ........................................................... 1-2MiguelGonzalezNo ratings yet

- Abb Acs310-1Document50 pagesAbb Acs310-1osrinivas1234No ratings yet

- MasterDrives Compact A D InvertersDocument385 pagesMasterDrives Compact A D InvertersTuyen TruongNo ratings yet

- ABB Standard Drives: ACS550, 0.75 To 355 KW / 1 To 500 HP Technical CatalogueDocument16 pagesABB Standard Drives: ACS550, 0.75 To 355 KW / 1 To 500 HP Technical CatalogueselvnNo ratings yet

- Siemens Master Drive MaintenanceDocument43 pagesSiemens Master Drive MaintenanceElnur MamedovNo ratings yet

- d05 Cpu315 Et200s PDFDocument34 pagesd05 Cpu315 Et200s PDFMazarel AurelNo ratings yet

- HMI - WinCC FlexibleDocument1 pageHMI - WinCC FlexiblepfalencarNo ratings yet

- PRO2 01eDocument14 pagesPRO2 01eghita_gabrielNo ratings yet

- MDM23 Plus PDFDocument13 pagesMDM23 Plus PDFJesse JoabeNo ratings yet

- PowerFlex 70Document48 pagesPowerFlex 70Daniel PuenteNo ratings yet

- SIRIUS Datasheet P-1Document100 pagesSIRIUS Datasheet P-1madhan_22No ratings yet

- Prepare ACS550 Drive for InstallationDocument2 pagesPrepare ACS550 Drive for InstallationDBIBI ADBINo ratings yet

- Acs 550Document2 pagesAcs 550potoculNo ratings yet

- (3AUA0000001558)_ACS550-U1_QS_REVF FG kndDocument2 pages(3AUA0000001558)_ACS550-U1_QS_REVF FG kndPrdptiwariNo ratings yet

- Quick Guide - IP Cameras - NEW2 - ENG - v4Document2 pagesQuick Guide - IP Cameras - NEW2 - ENG - v4Juan Alberto González TriviñoNo ratings yet

- Quick Shifter 08U70-MKK-D00Document6 pagesQuick Shifter 08U70-MKK-D00Anonymous 8w6kFviL100% (1)

- AWU NUEVADocument19 pagesAWU NUEVAvaldequijoteNo ratings yet

- En Acs355 Qisg C A3Document2 pagesEn Acs355 Qisg C A3Ousséma DridiNo ratings yet

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- Betagard 6520 High PH Membrane CleanerDocument1 pageBetagard 6520 High PH Membrane CleanerZul KarnaenNo ratings yet

- DANFOSS CascadeControllerOptionInstructionManual PDFDocument68 pagesDANFOSS CascadeControllerOptionInstructionManual PDFRandy LangleyNo ratings yet

- Brosur PumpDocument7 pagesBrosur PumpZul KarnaenNo ratings yet

- 18.10-W.111-Ebd Bauer Ro Raw Water AnalysisDocument1 page18.10-W.111-Ebd Bauer Ro Raw Water AnalysisZul KarnaenNo ratings yet

- 19 43 1 PBDocument6 pages19 43 1 PBsahriNo ratings yet

- 18.10-W.111-Ebd Bauer Ro Raw Water AnalysisDocument1 page18.10-W.111-Ebd Bauer Ro Raw Water AnalysisZul KarnaenNo ratings yet

- Brosur PumpDocument7 pagesBrosur PumpZul KarnaenNo ratings yet

- 19 43 1 PBDocument6 pages19 43 1 PBsahriNo ratings yet

- 19 43 1 PBDocument6 pages19 43 1 PBsahriNo ratings yet

- Brosur PumpDocument7 pagesBrosur PumpZul KarnaenNo ratings yet

- Acs550 Acs550 02 289a 4 PN 160kw I2n 289 A Ip21Document2 pagesAcs550 Acs550 02 289a 4 PN 160kw I2n 289 A Ip21Zul KarnaenNo ratings yet

- Energizer Batteries, Chargers and Electrical Equipment Price ListDocument28 pagesEnergizer Batteries, Chargers and Electrical Equipment Price ListZainal Arifin67% (3)

- ABB ACS355 CatalogDocument15 pagesABB ACS355 CatalogZul KarnaenNo ratings yet

- PLC Nano Versi 4Document1 pagePLC Nano Versi 4Deri Yana Mabrur100% (2)

- Acs550 Acs550 02 289a 4 PN 160kw I2n 289 A Ip21Document2 pagesAcs550 Acs550 02 289a 4 PN 160kw I2n 289 A Ip21Zul KarnaenNo ratings yet

- 2017 Product CatalogDocument32 pages2017 Product CatalogZul KarnaenNo ratings yet

- 8900.090-1 Rev K English Manual-1Document52 pages8900.090-1 Rev K English Manual-1Zul KarnaenNo ratings yet

- 18.10-W.111-Ebd Bauer Ro Raw Water AnalysisDocument1 page18.10-W.111-Ebd Bauer Ro Raw Water AnalysisZul KarnaenNo ratings yet

- Motor Starter Components Finder - LC1D40AM7 PDFDocument7 pagesMotor Starter Components Finder - LC1D40AM7 PDFZul KarnaenNo ratings yet

- Prepare ACS550 Drive in Less Than 40 StepsDocument2 pagesPrepare ACS550 Drive in Less Than 40 StepsZul KarnaenNo ratings yet

- Prepare ACS550 Drive in Less Than 40 StepsDocument2 pagesPrepare ACS550 Drive in Less Than 40 StepsZul KarnaenNo ratings yet

- 150A contactor for motor control up to 100kWDocument7 pages150A contactor for motor control up to 100kWZul KarnaenNo ratings yet

- Prepare ACS550 Drive in Less Than 40 StepsDocument2 pagesPrepare ACS550 Drive in Less Than 40 StepsZul KarnaenNo ratings yet

- Acsr SPLN 41-7Document2 pagesAcsr SPLN 41-7Zul KarnaenNo ratings yet

- Chapter 1 Digital Communication - CompressedDocument46 pagesChapter 1 Digital Communication - CompressedToluwani AyubaNo ratings yet

- Korg D-Series RecordersDocument17 pagesKorg D-Series RecordersapkoumnasNo ratings yet

- YCMOU-AST Syllabus T24 Diploma in Mechanical EngineeringDocument101 pagesYCMOU-AST Syllabus T24 Diploma in Mechanical Engineeringsanchu1981No ratings yet

- VBN Vib 13 062 e C Ac3mo 038Document28 pagesVBN Vib 13 062 e C Ac3mo 038roberto_monguzziNo ratings yet

- CELDA LCD-100K DatasheetDocument2 pagesCELDA LCD-100K DatasheetJOSENo ratings yet

- JCCI - Evaluation of FSK Backscatter Tag Signal Response Using FMCW Radar System at Mmwave Frequency in Rich Clutter Noise EnvironmentDocument1 pageJCCI - Evaluation of FSK Backscatter Tag Signal Response Using FMCW Radar System at Mmwave Frequency in Rich Clutter Noise Environmentfathul muinNo ratings yet

- APCN Series Screw Chillers: Range 45 TR To 470 TR (158 KW To 1600 KW)Document43 pagesAPCN Series Screw Chillers: Range 45 TR To 470 TR (158 KW To 1600 KW)Ahmad Salah100% (1)

- 20m Elevated Vertical Antenna DesignDocument5 pages20m Elevated Vertical Antenna Designleonardo_manzanoNo ratings yet

- Solenoid Valve Mini Catalog PDFDocument255 pagesSolenoid Valve Mini Catalog PDFCh Jameel SidhuNo ratings yet

- SKYAIRDocument23 pagesSKYAIRTatiana DiazNo ratings yet

- High Resolution Spectral Analysis Using Channelizers: Ricardo LosadaDocument41 pagesHigh Resolution Spectral Analysis Using Channelizers: Ricardo Losadarajsha333No ratings yet

- PM FormatDocument51 pagesPM FormatKevin LexterNo ratings yet

- SDB CVDocument3 pagesSDB CVashwini32No ratings yet

- Ma Abb VSC (En)Document28 pagesMa Abb VSC (En)Wiliam CopacatiNo ratings yet

- MR 96aDocument53 pagesMR 96aAnonymous GhWU5YK8No ratings yet

- lm80 nt441 15 - CDocument103 pageslm80 nt441 15 - CAdhiezzz GamingNo ratings yet

- RTU Research on Electricity's Role in Daily LifeDocument6 pagesRTU Research on Electricity's Role in Daily LifeCALLOS, JOMEL C.No ratings yet

- CM Surgical Lamp PPDocument13 pagesCM Surgical Lamp PPHyacinthe KOSSINo ratings yet

- CNG Reducers Model At12 SuperDocument2 pagesCNG Reducers Model At12 SuperjovicatrpcevicNo ratings yet

- Users Manual: Power Quality LoggerDocument70 pagesUsers Manual: Power Quality LoggerAndrew SetiawanNo ratings yet

- Ilevil 3 AW Installation Instructions 1Document10 pagesIlevil 3 AW Installation Instructions 1George Cunha LimaNo ratings yet

- 00257650-0000-48EG-0001 - Rev PB - Instrumentation Requirements For Packaged EquipmentDocument17 pages00257650-0000-48EG-0001 - Rev PB - Instrumentation Requirements For Packaged EquipmentSubrata DasNo ratings yet

- High Frequency Transformer Linked Converters For Photovoltaic Applications Q Li (Thesis) (2006)Document414 pagesHigh Frequency Transformer Linked Converters For Photovoltaic Applications Q Li (Thesis) (2006)Anonymous fqHGrbwxeFNo ratings yet

- 2017-10-01 Siltech Retail Pricelist Met BTW - 0 PDFDocument13 pages2017-10-01 Siltech Retail Pricelist Met BTW - 0 PDFانس الكردي0% (1)

- Learning Module in Science 10 Q2 Week 1Document7 pagesLearning Module in Science 10 Q2 Week 1jaspher100% (1)

- On Solar Updraft TowerDocument18 pagesOn Solar Updraft TowerSunil Kumar Singh100% (1)

- Digital Oscilloscope Mso5202dDocument78 pagesDigital Oscilloscope Mso5202dNoorlida KamarudinNo ratings yet

- High Performance Stepper System ControllerDocument107 pagesHigh Performance Stepper System Controllerxor_45No ratings yet

- Independent testing lab reportDocument26 pagesIndependent testing lab reportlatifNo ratings yet

- Air Cooled Screw Chiiler - APSaDocument190 pagesAir Cooled Screw Chiiler - APSaKhaleel Butt100% (1)