Professional Documents

Culture Documents

Acceptance Level TWI Sample

Uploaded by

Fadhlan D LuffyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acceptance Level TWI Sample

Uploaded by

Fadhlan D LuffyCopyright:

Available Formats

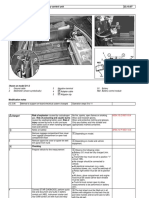

TWI Acceptance Levels for Plate and Fillet

D = depth L = length H = height t = thickness

Acceptance

Defect type

Acceptance levels plate levels

fillet

number

Table

Remarks Maximum allowance Remarks

Throat thickness

At no point shall the excess

Min t x 0.7mm

weld metal fall below the Excess weld metal will not exceed H =

Excess weld Max t + 0.5mm

1 outside surface of the 2mm in any area on the parent material,

metal Leg length

parent material. All weld showing smooth transition at weld toes.

Min = t

runs shall blend smoothly.

Max t = + 3mm

Non-metallic inclusions

The length of the slag inclusion shall not

Slag/silica trapped in the weld metal or L = 12 mm Max

2 exceed 50mm continuous or intermittent.

inclusions between the weld metal and Accumulative

Accumulative totals shall not exceed 50mm

the parent material.

No sharp indications Smooth blend

Undercut is defined as a

required. The length of any undercut shall Depth 10% of t

groove melted into the

not exceed 50mm continuous or Length 50mm

3 Undercut parent metal, at the toes of

intermittent. Accumulative totals shall not continuous or

the weld excess metal, root

exceed 50mm. Max D = 1mm for the cap intermittent

or adjacent weld metal.

weld metal. Root undercut not permitted.

Trapped gas, in weld metal, Individual pores 1.5 max. Cluster porosity

Porosity or elongated, individual pores, maximum 50mm2 total area. Elongated,

4 As for plate

Gas Cavities cluster porosity, piping or piping or wormholes 15mm max. L

wormhole porosity. continuous or intermittent.

Cracks or Transverse, longitudinal,

5 Not permitted Not permitted

Laminations star or crater cracks.

Incomplete fusion between Surface breaking lack of side wall fusion,

Lack of fusion the weld metal and base lack of inter-run fusion continuous or

6 Laps material, incomplete fusion intermittent not to exceed 15mm. As for plate

Cold lap between weld metal. (lack Accumulative totals not to exceed 15mm

of inter-run fusion) over a 300mm length of weld.

Damage to the parent

material or weld metal, from

an unintentional touch down

7 Arc strikes Not permitted Not permitted

of the electrode or arcing

from poor connections in the

welding circuit.

Damage to the parent No stray tack welds permitted

Mechanical material or weld metal, Parent material must be smoothly blended

8 As for plate

damage internal or external resulting General corrosion permitted. Max. D =

from any activities. 1.5mm. Only 1 location allowed

Mismatch between the

9 Misalignment Max H = 1.5mm N/A

welded or unwelded joint.

Excess weld metal, above

10 Penetration the base material in the root Max H 3mm N/A

of the joint.

The absence of weld metal

Lack of root

11 in the root both faces Not permitted N/A

penetration

showing.

Lack of root Inadequate cross Lack of root fusion, not to exceed 50mm

12 N/A

fusion penetration of one root face. total continuous or accumulative.

Excessive penetration,

13 Burn through Not permitted N/A

collapse of the weld root

Angular Distortion due to weld

14 5mm max. Plate only N/A

distortion contraction

Weld metal below the

Root 50mm maximum length

15 surface of both parent N/A

concavity 3mm maximum depth

materials

WIS1-60116

Appendix 2 A2-1 Copyright © TWI Ltd

You might also like

- Prophetic Dance - Mary JonesDocument7 pagesProphetic Dance - Mary Jonesm28181920No ratings yet

- Gel Electrophoresis Lab ReportDocument10 pagesGel Electrophoresis Lab Reportapi-31150900783% (6)

- CSWIP Practical Plate Exe 2007Document6 pagesCSWIP Practical Plate Exe 2007Walid SaadaniNo ratings yet

- CSWIP 3.0 Practical Fillet Welded T Joint Instruction SheetDocument4 pagesCSWIP 3.0 Practical Fillet Welded T Joint Instruction SheetOnur Altuntaş100% (2)

- 9 Practical Cswip 3.0 Practical Visual Inspection PDFDocument13 pages9 Practical Cswip 3.0 Practical Visual Inspection PDFAzim Samiin77% (13)

- CSWIP 3.0 - Appendices PDFDocument59 pagesCSWIP 3.0 - Appendices PDFsebgohgk100% (1)

- AWS D1.1 structural steel code radiographic inspection standardsDocument2 pagesAWS D1.1 structural steel code radiographic inspection standardsrohim100% (1)

- Acceptance Criteria For CSWIP 3.1Document19 pagesAcceptance Criteria For CSWIP 3.1Muhammed Abo-Fandood100% (5)

- Practical Plate AnswersDocument31 pagesPractical Plate Answersdaimahesh93% (15)

- Acceptance CriteriaDocument1 pageAcceptance CriteriaRamzi Dol Abdul Wahid50% (2)

- CSWIP 3.1 Welding Inspection NotesDocument102 pagesCSWIP 3.1 Welding Inspection NotesMohamad Junid Bin Omar91% (32)

- CSWIP 3 New Update QuestionDocument81 pagesCSWIP 3 New Update QuestionrezaNo ratings yet

- Gulliver's Travels Misogyny or MisanthropyDocument3 pagesGulliver's Travels Misogyny or MisanthropyKingshuk MondalNo ratings yet

- WIS5 - Appendix 2Document86 pagesWIS5 - Appendix 2Reza Fakhrizal100% (1)

- TWI CSWIP 3 1 WIS 5 Welding InspectionDocument11 pagesTWI CSWIP 3 1 WIS 5 Welding Inspectionsenthilkumar100% (1)

- Question Number 1: Sign-Off Product (Typical Mandatory Question)Document1 pageQuestion Number 1: Sign-Off Product (Typical Mandatory Question)DkPrince100% (1)

- Welcome To Preheat Calculation Program: C.brak@it - Fnt.hvu - NLDocument16 pagesWelcome To Preheat Calculation Program: C.brak@it - Fnt.hvu - NLKelvin Labarez100% (1)

- Cswip Exams 1 PDFDocument65 pagesCswip Exams 1 PDFFethi BELOUISNo ratings yet

- Acceptance CriteriaDocument19 pagesAcceptance CriteriaAnonymous 5iv0i3cZNo ratings yet

- CSWIP Visual Welding Inspector With Practical ModuleDocument2 pagesCSWIP Visual Welding Inspector With Practical Moduleincineratorium100% (1)

- Model Question PaperDocument48 pagesModel Question Paperselva100% (2)

- Practical Plate InspectionDocument8 pagesPractical Plate InspectionMohd Effiezool Yaser100% (1)

- Limits For Imperfections ISO 5817Document2 pagesLimits For Imperfections ISO 5817tudorteuNo ratings yet

- Technical Data Speedmaster SM 102: Printing Stock Blanket CylinderDocument1 pageTechnical Data Speedmaster SM 102: Printing Stock Blanket CylinderAHMED MALALNo ratings yet

- Welding Inspection Multi-Choice QuestionsDocument15 pagesWelding Inspection Multi-Choice Questionsniminkp123100% (1)

- Models of Collaboration Between Education and ServicesDocument17 pagesModels of Collaboration Between Education and ServicesSimran Josan100% (3)

- Summary Note For CSWIP 3.1Document9 pagesSummary Note For CSWIP 3.1Muhamad ShakyreenNo ratings yet

- Welding Exam QuestionsDocument6 pagesWelding Exam QuestionsBudimanNo ratings yet

- 'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Document36 pages'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Vinoth KannanNo ratings yet

- Heat Treatments, Welding Processes, and Carbon Steel PropertiesDocument10 pagesHeat Treatments, Welding Processes, and Carbon Steel PropertiesAhmed Ben Nouma100% (1)

- Cswip 3 1 Welding Inspector Multiple Choice Question Dec 7 2007Document43 pagesCswip 3 1 Welding Inspector Multiple Choice Question Dec 7 2007sri.majji8937100% (1)

- Top 15 Mechanical Testing - Cswip 3.1 Course Questions and AnswersDocument5 pagesTop 15 Mechanical Testing - Cswip 3.1 Course Questions and AnswersJlkKumar67% (3)

- CSWIP Practical Plate AnswersDocument31 pagesCSWIP Practical Plate AnswersSha Zha100% (1)

- Macro Inspection Part IIDocument16 pagesMacro Inspection Part IImohammed dallyNo ratings yet

- Cswip 3.1 QU MSR WI 4 05Document8 pagesCswip 3.1 QU MSR WI 4 05Luan Nguyen100% (3)

- Specification requirements for CRA/CRA clad pipelines before and during weldingDocument2 pagesSpecification requirements for CRA/CRA clad pipelines before and during weldingSơn Nguyễn TháiNo ratings yet

- Radiography Acceptance Criteria As Per B 31.3Document2 pagesRadiography Acceptance Criteria As Per B 31.3mohamedNo ratings yet

- Course Note CSWIP 3.0Document168 pagesCourse Note CSWIP 3.0JohanSitorusNo ratings yet

- Visual Plate Inspection Report SummaryDocument4 pagesVisual Plate Inspection Report SummaryLaith Salman100% (1)

- CSWIP 3.2 ExamDocument1 pageCSWIP 3.2 Examasif712No ratings yet

- CSWIP 3.1 Multiple Choice Exam QuestionsDocument7 pagesCSWIP 3.1 Multiple Choice Exam QuestionsĐặng Sơn100% (1)

- IIW World OverrviewDocument4 pagesIIW World OverrviewAnonymous hBBam1nNo ratings yet

- Cswip Appendix 02 Plate Report and QuestionsDocument48 pagesCswip Appendix 02 Plate Report and QuestionsNsidibe Michael Etim100% (1)

- The Indian Institute of WeldingDocument11 pagesThe Indian Institute of WeldingNnamdi Celestine NnamdiNo ratings yet

- CSWIP 3.1 Welding Inspector exam detailsDocument2 pagesCSWIP 3.1 Welding Inspector exam detailsSalahuddin Farooqui100% (1)

- Duties of Welding InspectorDocument11 pagesDuties of Welding Inspectormuhammadazhar50% (2)

- CSWIP 3.1 Question With Answer and Explanation - Part 12Document9 pagesCSWIP 3.1 Question With Answer and Explanation - Part 12adel100% (3)

- CSWIP Set QuestionDocument13 pagesCSWIP Set QuestionMuhammad Hannan100% (2)

- Model Question PaperDocument4 pagesModel Question Papervinaipv89% (9)

- TWI Training CSWIP 3.1 Pipe 01 (Complete)Document8 pagesTWI Training CSWIP 3.1 Pipe 01 (Complete)Suli HartoNo ratings yet

- Sample CSWIP Questions 1571543456Document42 pagesSample CSWIP Questions 1571543456Evandro Silva50% (2)

- Iwe Iwt IwsDocument2 pagesIwe Iwt IwsINSTECH ConsultingNo ratings yet

- اسئلة واجوبة CSWIPDocument64 pagesاسئلة واجوبة CSWIPLaith SalmanNo ratings yet

- Hydrogen Cracking Causes and PreventionDocument6 pagesHydrogen Cracking Causes and Preventionshahid khanNo ratings yet

- ACCEPTENCE CRITERIADocument1 pageACCEPTENCE CRITERIAPraviBeetlesNo ratings yet

- Aceptance Criteria For Visual-2Document2 pagesAceptance Criteria For Visual-2ayuNo ratings yet

- Twi CodeDocument1 pageTwi CodeHadi Azfar Bikers PitNo ratings yet

- Visual Inspection Acceptance CriteriaDocument2 pagesVisual Inspection Acceptance CriteriaJohn TerryNo ratings yet

- Acceptance Criteria in Welding TableBDocument1 pageAcceptance Criteria in Welding TableBanishk6336No ratings yet

- Welded Connections GuideDocument11 pagesWelded Connections Guideangelica abanesNo ratings yet

- Acceptance Criteria Welding API 1104 (Printed)Document1 pageAcceptance Criteria Welding API 1104 (Printed)mohammedNo ratings yet

- CONTROL OF 10mm FERRULE DIMENSIONS DURING PENSTOCK FABRICATIONDocument1 pageCONTROL OF 10mm FERRULE DIMENSIONS DURING PENSTOCK FABRICATIONSuryaveer 6th ANo ratings yet

- Welded Connections GuideDocument13 pagesWelded Connections Guideangelica abanesNo ratings yet

- PCB SpecificationsDocument3 pagesPCB SpecificationsVlad VrabieNo ratings yet

- 8-Tool Steels & Their Heat TreatmentsDocument36 pages8-Tool Steels & Their Heat TreatmentsFadhlan D LuffyNo ratings yet

- KOROSI - Corrosion in Liquid Metal 1Document13 pagesKOROSI - Corrosion in Liquid Metal 1Fadhlan D LuffyNo ratings yet

- PB SN PhaseDiagramDocument6 pagesPB SN PhaseDiagramMonachikós DrákosNo ratings yet

- PES Best FormationDocument3 pagesPES Best FormationFadhlan D LuffyNo ratings yet

- Mount BromoDocument1 pageMount BromoFadhlan D LuffyNo ratings yet

- Ozone Layer EssayDocument7 pagesOzone Layer Essayb71bpjha100% (2)

- Jurnal Aceh MedikaDocument10 pagesJurnal Aceh MedikaJessica SiraitNo ratings yet

- History of PTCLDocument4 pagesHistory of PTCLswealumair86No ratings yet

- PHY3 BJune 2004Document1 pagePHY3 BJune 2004api-3726022No ratings yet

- Optimize Your Portfolio With Modern TheoriesDocument65 pagesOptimize Your Portfolio With Modern Theoriesastro9jyotish9asim9mNo ratings yet

- Checking battery control unitDocument3 pagesChecking battery control unitjuanNo ratings yet

- 100 Seniman Yang Membentuk Sejarah DuniaDocument134 pages100 Seniman Yang Membentuk Sejarah DuniaIBRAHIM S.Sos,INo ratings yet

- Socsci 032 Midterm Compilation NotesDocument12 pagesSocsci 032 Midterm Compilation NotesCarla AbalaNo ratings yet

- Villanueva - Taxation and Regulatory ComplianceDocument8 pagesVillanueva - Taxation and Regulatory ComplianceEDRICK ESPARRAGUERRANo ratings yet

- On The Optimum Inter-Stage Parameters For Co Transcritical Systems Dr. Dan ManoleDocument8 pagesOn The Optimum Inter-Stage Parameters For Co Transcritical Systems Dr. Dan Manolemohammed gwailNo ratings yet

- Performance of Filler Material in GabionsDocument4 pagesPerformance of Filler Material in GabionsPreetham N KumarNo ratings yet

- Expository TextsDocument2 pagesExpository TextsJodi PeitaNo ratings yet

- HavellsDocument4 pagesHavellsanurag_iiitmNo ratings yet

- ADEC Al Maali International Private School 2015 2016Document18 pagesADEC Al Maali International Private School 2015 2016Edarabia.com100% (1)

- Burning Arduino Bootloader With AVR USBASP PDFDocument6 pagesBurning Arduino Bootloader With AVR USBASP PDFxem3No ratings yet

- AI vs ML: A Brief ExplanationDocument3 pagesAI vs ML: A Brief Explanationkhaoula BelghitiNo ratings yet

- Technical Data Sheet 01DT-1L..: Type OverviewDocument4 pagesTechnical Data Sheet 01DT-1L..: Type OverviewJNo ratings yet

- AirLocker PresentationDocument11 pagesAirLocker PresentationjzuckertNo ratings yet

- Bill Porter Updated PDFDocument3 pagesBill Porter Updated PDFapi-362500677No ratings yet

- Justification: Justification: Doctrine of Council of TrentDocument4 pagesJustification: Justification: Doctrine of Council of TrentMihai SarbuNo ratings yet

- Neural Networks in Data Mining: Ripundeep Singh Gill, AshimaDocument6 pagesNeural Networks in Data Mining: Ripundeep Singh Gill, AshimaIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Galway Music Officer RoleDocument20 pagesGalway Music Officer RoleJohanna KennyNo ratings yet

- Production of Carotenoids From Rhodotorula Mucilaginosa and Their Applications As Colorant Agent in Sweet CandyDocument7 pagesProduction of Carotenoids From Rhodotorula Mucilaginosa and Their Applications As Colorant Agent in Sweet CandyEspinosa Balderas GenaroNo ratings yet

- Wag Acquisition v. Vubeology Et. Al.Document29 pagesWag Acquisition v. Vubeology Et. Al.Patent LitigationNo ratings yet

- Total Cost of Ownership in PV Manufacturing - GuideDocument12 pagesTotal Cost of Ownership in PV Manufacturing - GuidebirlainNo ratings yet