Professional Documents

Culture Documents

Efficient 15-100 HP Boilers for Buildings

Uploaded by

sebaversaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Efficient 15-100 HP Boilers for Buildings

Uploaded by

sebaversaCopyright:

Available Formats

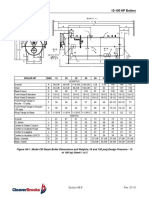

Model CB 15-100 HP Boilers

sequence shall include start, pre-purge, pilot and main fuel ignition run and

post-purge cycles.

Controller shall be the non-recycle type for maximum safety that shall

shutdown the burner and indicate as a minimum the following trip functions:

pilot and main flame failure, high and low fire proving switch faults, locking

interlocks open, false flame signal and fuel valve open (when proof of closure

switch is furnished).

The controller shall have a run/test switch. It shall allow interruptions to

sequence just after pre-purge, during pilot ignition trial and run cycles for

adjustments to firing rate motor, damper linkages and pilot flame for

minimum turndown tests.

b. Control Panel - The control panel shall be mounted on the front door of the

boiler in a location convenient to the operator. The hinged metal cabinet will

have NEMA 1A rating that includes a neoprene dust seal and a Yale cabinet

key type lock.

The panel shall contain the boiler flame safeguard controller, blower motor

starter, indicating lights and selector switches.

The panel shall have a removable sub-base for mounting the flame

safeguard controller, blower motor starter, and terminal blocks. For

combination gas-oil and heavy oil fired boilers the panel will contain the fuel

selector and/or oil heater selector switch.

The panel shall contain the following lights and switches:

Lights

• White - load demanded.

• White - fuel valve open.

• Red - low water.

• Red - flame failure.

Control Switches

• Burner On-Off.

• Manual-Automatic.

• Manual Firing Rate Control.

2. Oil, heat and moisture resistant wire shall be used and identified with circuit

numbers corresponding to the electrical wiring diagram.

3. All electrical equipment and wiring shall be in conformance with Underwriters

Laboratories requirements.

4. Boiler to be supplied with a control circuit transformer and fuse protection for the

control circuit.

5. Control Panel: The control panel shall be mounted on the front door of the boiler

in a location convenient to the operator. The hinged metal cabinet will have

NEMA 1A rating that includes a neoprene dust seal and a Yale cabinet key type

lock.

The panel shall contain the boiler flame safeguard controller, indicating lights and

selector switches.

Section A6-43 Rev. 07-10

Model CB 15-100 HP Boilers

Panel shall have a removable sub-base for mounting the flame safeguard

controller, and terminal blocks. For combination gas-oil and heavy oil fired boilers

the panel will contain the fuel selector and/or oil heater selector switch.

6. Oil, heat, and moisture resistant wire shall be used and identified with circuit

numbers corresponding to the electrical wiring diagram.

7. All electrical equipment and wiring shall be in conformance with Underwriters

Laboratories requirements.

8. Boiler to be supplied with a control circuit transformer and fuse protection for the

control circuit.

1.05 Efficiency Guarantee

The boiler manufacturer shall guarantee that, at the time of startup, the boiler will achieve

_____ fuel-to-steam efficiency at 100% firing rate when burning natural gas and _____

fuel-to-steam efficiency at 100% firing rate when burning oil (add efficiency guarantees at

25%, 50%, and 75% of rating, if required). If the boiler(s) fail to achieve the

corresponding guaranteed efficiency as published, the boiler manufacturer will rebate, to

the ultimate boiler owner, five thousand dollars ($5,000) for every full efficiency point

(1.0%) that the actual efficiency is below the guaranteed level.

The specified boiler efficiency is based on the following conditions.

A. Fuel specification used to determine boiler efficiency:

1. Natural Gas

Carbon, % (wt) = 69.98

Hydrogen, % (wt) = 22.31

Sulfur, % (wt) = 0.0

Heating value, Btu/lb = 21,830

2. No. 2 Oil

Carbon, % (wt) = 85.8

Hydrogen, % (wt) = 12.7

Sulfur, % (wt) = 0.2

Heating value, Btu/lb = 19,420

3. No. 6 Oil

Carbon, % (wt) = 86.6

Hydrogen, % (wt) = 10.9

Sulfur, % (wt) = 2.09

Heating value, Btu/lb = 18,830

B. Efficiencies are based on ambient air temperature of 80 °F, relative humidity of 30%,

and 15% excess air in the exhaust flue gas.

C. Efficiencies are based on manufacturer’s published radiation and convection losses.

(For Cleaver-Brooks radiation and convection losses, see Boiler Efficiency Facts

Guide, publication number CB-7767).

D. Any efficiency verification testing will be based on the stack loss method.

Section A6-44 Rev. 07-10

Model CB 15-100 HP Boilers

EXECUTION

1.06 Warranty

A. All equipment is to be guaranteed against defects in materials and/or workmanship

for a period of 12 months from date of start-up or 18 months from date of shipment,

whichever comes first.

1.07 Shop Tests

A. The packaged boiler must receive factory tests to check the construction, controls,

and operation of the unit. All tests may be witnessed by the purchaser, if desired.

1.08 Start-up Service

After boiler installation is completed, the manufacturer shall provide the services of a field

representative for starting the unit and training the operator at no additional costs.

A. A factory approved and authorized start-up report shall be submitted to the

customer/user at the time of start-up.

Section A6-45 Rev. 07-10

Model CB 15-100 HP Boilers

Notes

Section A6-46 Rev. 07-10

Model CB 15-100 HP Boilers

SECTION A6

MODEL CB 15-100 HP

SAMPLE SPECIFICATIONS - HOT WATER

1.01 Boiler Characteristics (Hot Water) .......................................................................................................... A6-48

1.02 General Boiler Design............................................................................................................................. A6-48

1.03 Hot Water Boiler Trim ............................................................................................................................. A6-49

1.04 Burner and Controls................................................................................................................................ A6-49

1.05 Blower ..................................................................................................................................................... A6-49

1.06 Combustion Air Control........................................................................................................................... A6-50

1.07 Fuel Specification and Piping ................................................................................................................. A6-50

1.08 Efficiency Guarantee .............................................................................................................................. A6-56

1.09 Warranty ................................................................................................................................................. A6-56

2.01 Shop Tests .............................................................................................................................................. A6-57

Section A6-47 Rev. 07-10

You might also like

- Section 16620 - Natural Gas Engine Generator Set: Division 16 Electrical Project NoDocument17 pagesSection 16620 - Natural Gas Engine Generator Set: Division 16 Electrical Project NovcharlesNo ratings yet

- INSTRUCTIONS FOR INSTALL, OPERATION, AND SERVICING - NEW YORKER CL SERIES Cast Iron Oil Fired Boiler CLDocument52 pagesINSTRUCTIONS FOR INSTALL, OPERATION, AND SERVICING - NEW YORKER CL SERIES Cast Iron Oil Fired Boiler CLEdwin GeeqNo ratings yet

- Fi 6-Fi 81F2Omf22: Burner Instruction ManualDocument36 pagesFi 6-Fi 81F2Omf22: Burner Instruction ManualMaurice Lachaud100% (1)

- SpecificationDocument3 pagesSpecificationArun SNo ratings yet

- Tech Spec of Nitrogen InjectionDocument5 pagesTech Spec of Nitrogen InjectionJustin MyersNo ratings yet

- Checkl List For Boiler Specification by K.K.parthibanDocument8 pagesCheckl List For Boiler Specification by K.K.parthibanparthi20065768No ratings yet

- Burner Logic System PDFDocument5 pagesBurner Logic System PDFshiviitd02No ratings yet

- 10 Boiler Operating Mistakes On Ships That Can Cost Big TimeDocument18 pages10 Boiler Operating Mistakes On Ships That Can Cost Big TimeThusitha DalpathaduNo ratings yet

- Linen and Laundry DepartmentDocument37 pagesLinen and Laundry DepartmentHannah Aven Malata71% (7)

- Caterpillar Naimuls PartDocument9 pagesCaterpillar Naimuls PartNishat ChowdhuryNo ratings yet

- Ge-15006 8fg-d 35 50n The Wiring Diagram For Dx-CabinDocument173 pagesGe-15006 8fg-d 35 50n The Wiring Diagram For Dx-CabinDuong Van HoanNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- SPEC Model CB Steam Jan11Document12 pagesSPEC Model CB Steam Jan11Stanford BrownNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- 900-1800 HP Boiler SpecsDocument5 pages900-1800 HP Boiler SpecssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model 4WI Boiler Warranty, Tests and StartupDocument4 pagesModel 4WI Boiler Warranty, Tests and StartupsebaversaNo ratings yet

- CB-7768 Gen - Boiler Efficiency TablesDocument4 pagesCB-7768 Gen - Boiler Efficiency TablestthennisNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- SPEC ModelCBR Steam Mar4Document10 pagesSPEC ModelCBR Steam Mar4Jason PoloNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Series 500 Water SpecDocument5 pagesSeries 500 Water SpecChristhofer Arroyo ChacónNo ratings yet

- Section A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Document4 pagesSection A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)sebaversaNo ratings yet

- Agilent 6890n DatasheetDocument5 pagesAgilent 6890n DatasheetMayar SayedNo ratings yet

- Spec Modelcble Steam Mar4Document12 pagesSpec Modelcble Steam Mar4Jason PoloNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- 9 IriDocument2 pages9 IriEnrique PauliniNo ratings yet

- Bentone ST 120 KADocument40 pagesBentone ST 120 KAAsron Ferdian FalaahNo ratings yet

- Hurst Boiler & Welding Co., IncDocument4 pagesHurst Boiler & Welding Co., IncChristian Veliz CamargoNo ratings yet

- Manual Powerflame C PDFDocument56 pagesManual Powerflame C PDFRoberto MnedezNo ratings yet

- Boiler SpecificationsDocument25 pagesBoiler Specificationspaul kioiNo ratings yet

- Model CBLE Steam Boilers from 100-800 HPDocument12 pagesModel CBLE Steam Boilers from 100-800 HPDiogenes Rafael TorresNo ratings yet

- Series 4vt Steam SpecificationsDocument5 pagesSeries 4vt Steam Specificationsagusti24No ratings yet

- Model CBLE 100-800 HP Boilers: 2.4 Efficiency GuaranteeDocument4 pagesModel CBLE 100-800 HP Boilers: 2.4 Efficiency GuaranteesebaversaNo ratings yet

- Gs 18ms 1pdDocument11 pagesGs 18ms 1pdRitesh JhaNo ratings yet

- Espeficiaciones de CalentadorDocument3 pagesEspeficiaciones de CalentadorLeonida del SolNo ratings yet

- Bentone ST133 ManualDocument14 pagesBentone ST133 ManualAsron Ferdian FalaahNo ratings yet

- 100-800 HP Model CB-LE Boilers SpecificationsDocument11 pages100-800 HP Model CB-LE Boilers SpecificationsDiogenes Rafael TorresNo ratings yet

- Model CBLE 100-800 HP BoilersDocument4 pagesModel CBLE 100-800 HP BoilerssebaversaNo ratings yet

- Turn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsDocument18 pagesTurn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsKarim Galal IsmailNo ratings yet

- Model 4WI 100 - 800 HP BoilersDocument4 pagesModel 4WI 100 - 800 HP BoilerssebaversaNo ratings yet

- Section A1 Model Cb-Le Hot Water Specifications (125-800 HP, 30 PSIG, 125 PSIG)Document4 pagesSection A1 Model Cb-Le Hot Water Specifications (125-800 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- FL 310 LG RTC enDocument35 pagesFL 310 LG RTC enandis_aNo ratings yet

- Countryman Manual (Eng) (13204)Document30 pagesCountryman Manual (Eng) (13204)Moz NazNo ratings yet

- 6890 GC Site Preparation ChecklistDocument4 pages6890 GC Site Preparation Checklistigor_239934024No ratings yet

- CGa Series 3 Boiler Manual 0520Document68 pagesCGa Series 3 Boiler Manual 0520Sonaina KhanNo ratings yet

- 2MW Turbine EnquiryDocument7 pages2MW Turbine EnquiryRamu MaddiNo ratings yet

- Gorionik GirsDocument24 pagesGorionik Girsmirce1985No ratings yet

- McQuay McEnergy HPI Technical Manual EngDocument48 pagesMcQuay McEnergy HPI Technical Manual EngZhenqian HNo ratings yet

- Weishaupt WL30 - WL40Document12 pagesWeishaupt WL30 - WL40Yacine A. Meziane100% (1)

- High-Efficiency Rooftop HVAC UnitDocument26 pagesHigh-Efficiency Rooftop HVAC UnitHikmah AdiNo ratings yet

- Hot Water Boilers ControlDocument13 pagesHot Water Boilers ControlMunir RasheedNo ratings yet

- INSTRUCTIONS FOR ASSEMBLY AND USE OF ARIZONA EVOLUTION STEEL BOILERSDocument20 pagesINSTRUCTIONS FOR ASSEMBLY AND USE OF ARIZONA EVOLUTION STEEL BOILERSAnonymous vFZME7bCWNo ratings yet

- Manual Arizona PDFDocument20 pagesManual Arizona PDFabuyeheaNo ratings yet

- Providing sustainable energy solutions worldwideDocument44 pagesProviding sustainable energy solutions worldwideMMuzammalNo ratings yet

- Caterpillar 250 kW Diesel Generator SpecificationDocument24 pagesCaterpillar 250 kW Diesel Generator SpecificationRaed Al-HajNo ratings yet

- Series 1: Forced Draft Dual Fuel BurnersDocument4 pagesSeries 1: Forced Draft Dual Fuel Burnersdiogenes torresNo ratings yet

- Installation and maintenance guide for B70-2FH oil burnerDocument15 pagesInstallation and maintenance guide for B70-2FH oil burneranweshaccNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- 60 PPM Nox Operation Natural Gas: CBEX Elite 100-800 HPDocument4 pages60 PPM Nox Operation Natural Gas: CBEX Elite 100-800 HPsebaversaNo ratings yet

- OIL HANDBOOKDocument32 pagesOIL HANDBOOKolhevlaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- 15-100 HP Boilers Dimensions SpecsDocument5 pages15-100 HP Boilers Dimensions SpecssebaversaNo ratings yet

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDocument5 pages900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- 75Document5 pages75sebaversaNo ratings yet

- 81Document5 pages81sebaversaNo ratings yet

- High-efficiency boiler specifications for 100-800 HP modelsDocument4 pagesHigh-efficiency boiler specifications for 100-800 HP modelssebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- 78Document5 pages78sebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- General Information - Diagnostic Trouble Code (DTC) Indexdtc: Auxiliary Heater Control Module (Ahcm)Document6 pagesGeneral Information - Diagnostic Trouble Code (DTC) Indexdtc: Auxiliary Heater Control Module (Ahcm)Jim LiebNo ratings yet

- How To Save 630,000 USD Per Year and Produce The Best PolyesterDocument1 pageHow To Save 630,000 USD Per Year and Produce The Best Polyesteranil kapadiaNo ratings yet

- Sunsai Pharma Equipments Pvt. ltd-1Document2 pagesSunsai Pharma Equipments Pvt. ltd-1Sunsai VasaiNo ratings yet

- Reduction of Mouldboard Plough Share Wear by A Combination Technique of HardfacingDocument5 pagesReduction of Mouldboard Plough Share Wear by A Combination Technique of HardfacingJuan Ambrosio MartinezNo ratings yet

- W4-SCIENCE Grade 5Document56 pagesW4-SCIENCE Grade 5Gladish AnsubanNo ratings yet

- Oil Grabber Model MB, Multi-Belt Oil Skimmer - Abanaki CorporationDocument4 pagesOil Grabber Model MB, Multi-Belt Oil Skimmer - Abanaki CorporationKyle ChandlerNo ratings yet

- Choosing The Inductor For A Buck ConverterDocument8 pagesChoosing The Inductor For A Buck ConverterjboronatsNo ratings yet

- 7 Behavior of Rectangular Reinforced Concrete BeamsDocument16 pages7 Behavior of Rectangular Reinforced Concrete Beamsjack21abNo ratings yet

- Manual Yamaha YST-SW105 (Service)Document17 pagesManual Yamaha YST-SW105 (Service)Alex NikitinNo ratings yet

- Labs-CIM Lab ManualDocument48 pagesLabs-CIM Lab ManualRicardoVillanuevaCabreraNo ratings yet

- Premium Water Treatment Solutions ManufacturerDocument6 pagesPremium Water Treatment Solutions ManufacturerUttaraHomesNo ratings yet

- MMCDocument39 pagesMMCgopal rao sirNo ratings yet

- CAT6 Modular Plug Installation GuideDocument2 pagesCAT6 Modular Plug Installation GuideAndrés CisnerosNo ratings yet

- Durability of HDPE Geomembranes: R.Kerry Rowe, Henri P.SangamDocument19 pagesDurability of HDPE Geomembranes: R.Kerry Rowe, Henri P.SangamAnonymous ImoZI0363No ratings yet

- Bresco CatalogueDocument60 pagesBresco Cataloguetr_freundeNo ratings yet

- Utilization of Regrind Materials in PVC Extrusion ProcessingDocument1 pageUtilization of Regrind Materials in PVC Extrusion ProcessingAntonius PrakosaNo ratings yet

- Curriculum For Hvac: Toll Free-1800-8333-999 (From Any Network)Document1 pageCurriculum For Hvac: Toll Free-1800-8333-999 (From Any Network)iplusNo ratings yet

- Shell Morlina s2 B 320Document4 pagesShell Morlina s2 B 320Aep HidayatNo ratings yet

- Fabrication of Counter-Jib Ballast Blocks GuideDocument14 pagesFabrication of Counter-Jib Ballast Blocks GuideNirmalya SenNo ratings yet

- Henry Cat ENG 2013Document100 pagesHenry Cat ENG 2013strelbNo ratings yet

- Lift Truck Gear From DTAUTO - CADocument32 pagesLift Truck Gear From DTAUTO - CAGregGGHNo ratings yet

- DUPLEX 1500 - 6500 MultiEco-V EN - 2018 - 03Document8 pagesDUPLEX 1500 - 6500 MultiEco-V EN - 2018 - 03Constantin CilibiuNo ratings yet

- Lean management principles for eliminating wasteDocument2 pagesLean management principles for eliminating wastesimranNo ratings yet

- Catalog Water Purifier 2016 YOUTHFULDocument5 pagesCatalog Water Purifier 2016 YOUTHFULhamadalami2007No ratings yet

- AccumulatorsDocument9 pagesAccumulatorsBaldo CastilloNo ratings yet

- Zintek® 300 HP + Techseal® Glossy Black SLDocument9 pagesZintek® 300 HP + Techseal® Glossy Black SLSyedMazharAliShahNo ratings yet