Professional Documents

Culture Documents

VRV Inspection and Pre-Commissioning Form

Uploaded by

dokundotCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VRV Inspection and Pre-Commissioning Form

Uploaded by

dokundotCopyright:

Available Formats

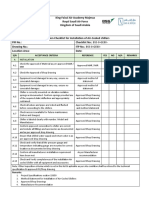

VRV INSPECTION AND PRE-COMMISSIONING FORM

VRV SERIES VRV III VRV IV

Please fill in the form for each system that is to be commissioned and send back the document atleast one week prior to the commissioning date.

The signed form shall be sent back to the following email address: techresponse@daikinmcquayme.com (cc: service@daikinmcquayme.com)

Date: Project: Installer:

Installation Data

Address: Contact Person:

Country: Mobile Phone No.:

Proposed Commissioning Date:

System Model (Check applicable model) Checklist (Check the column for items inspected on-site)

VRV-III VRV-IV (NC) VRV-IV (Cont. M) VRV-IV (Cont. S) General Check

RXYQ5P RXYQ8T RYMQ8T RYYQ8T Is the outdoor unit adequately supported according to its weight?

RXYQ8P RXYQ10T RYMQ10T RYYQ10T Is the outdoor unit mounted on good foundation?

RXYQ10P RYMQ12T

RXYQ12T RYYQ12T Is there no risk of air short cycling around the outdoor unit?

RXYQ12P

RXYQ14T RYMQ14T RYYQ14T Outdoor unit service space is provided and sufficient for maintenance?

RXYQ14P

RXYQ16T RYMQ16T RYYQ16T Piping Check

RXYQ16P RXYQ18T RYMQ18T RYYQ18T Uses proper copper pipes able to handle 40 Bar (4 MPa) pressure?

RXYQ18P RXYQ20T RYMQ20T RYYQ20T Are all refrigeration field pipes insulated properly?

RXYQ20P RXYQ22T RYMQ22T Was the pipe brazing done with proper Nitrogen ventilation?

RXYQ22P RXYQ24T RYMQ24T Are the refnet joints and headers correctly installed? (angles and position?)

RXYQ24P RXYQ26T RYMQ26T Was nitrogen pressure test done at 40 Bar for 24 Hrs?

RXYQ26P RXYQ28T

RYMQ28T Was the field piping vacuumed, and kept under vacuum for atleast 1 Hr?

RXYQ28P RXYQ30T RYMQ30T Was vacuum break done w/ R410a to create positive pressure on the piping?

RXYQ30P RXYQ32T RYMQ32T Length of liquid field piping (in meters) 7/8": 1/2":

RXYQ32P RXYQ34T RYMQ34T 3/4": 3/8":

RXYQ34P RXYQ36T RYMQ36T 5/8": 1/4":

RXYQ36P RXYQ38T RYMQ38T Electrical and Field Wiring

RXYQ38P RXYQ40T RYMQ40T

The size power of wires is according to electrical regulation?

RXYQ40P RXYQ42T RYMQ42T

Electrical Breakers are properly rated?

RXYQ42P RXYQ44T RYMQ44T

Properly rated ELCB/RCCB (Earth Leakage Circuit Breakers) are installed?

RXYQ44P RXYQ46T RYMQ46T

RXYQ48T RYMQ48T

Power was witched ON for atleast 6 hours before the commissioning?

RXYQ46P

RXYQ48P RXYQ50T RYMQ50T

F1/F2 and Q1/Q2 cable is sheathed vinyl 0.75-1.25 mm2 cable with 2 cores?

RXYQ50P RXYQ52T RYMQ52T

All indoor units and outdoor units are completely and properly wired?

RXYQ52P RXYQ54T RYMQ54T

Remote controls are properly installed and wired on the system?

RXYQ54P Power supply from mains are available on-site? (Recommended)

Generator is used to start-up the system?(Proper regulated power is required)

The indoor unit power supply is secured from the user (only for service use)?

Please write the complete O.U. model name and serial

Drain Pipe Check

no. in case it does not appear above

Outdoor Unit Model Name Serial No. Are drain pipes completely insulated?

O.U.1 (Master) Slope of drain pipes are correct?

O.U. 2 (Slave1) Leak check on drain pipe has been tested?

O.U. 3 (Slave2) Is there smooth flow of water in the Drain?

Indoor Units Model Name Serial No. Indoor Unit Check

Indoor Unit 1 Indoor unit brackets are strong enough to support the unit?

Indoor Unit 2 Indoor unit mounting and horizontal level is correct?

Indoor Unit 3 Indoor unit spaces are sufficient to create air flow (suction and discharge)?

Indoor Unit 4 Indoor service space provides access to the field piping/Air filter/Indoor PCB?

Indoor Unit 5 Centralized Controller check Central Remote I-Touch I-TManager Not Applicable

Indoor Unit 6 Centralized Controller is properly installed?

Indoor Unit 7 Centralized Wiring has been connected properly?

Indoor Unit 8 No. of Outdoor Units did not exceed limitations?

Indoor Unit 9 No. of Indoor Units did not exceed limitations?

Indoor Unit 10 Communication wires (D-III Net wiring) does not exceed 2000 m?

Indoor Unit 11 Drawing plan and wiring for central control were checked by Daikin?

Indoor Unit 12 Building Management System (BMS) BACNet LonWorks EIB/KNX Not Applicable

Indoor Unit 13 Wiring for BMS have already been completed by the contractor as planned?

Indoor Unit 14 Drawing plan and wiring for Daikin BMS equipment were approved by Daikin?

Indoor Unit 15 Point List (Control and Monitoring) were submitted and checked by Daikin?

Indoor Unit 16 System Integrator is available for integration?

Authorized Signature

Authorized Installer Name and Signature Authorized Inspector Name and Signature

* By signing this Pre-commissioning sheet, the contractor/installer certifies that the installation is based on Daikin Standard installation and practice. Daikin reserves the right to void

warranty in case there is any discrepancy on the information

*Field Electrical Safety components such as ELCB/RCCB are responsibility of the installer and should be installed to avoid risk of fire or human injury.

You might also like

- Installation Report SummaryDocument4 pagesInstallation Report SummaryMohammed IqbalNo ratings yet

- FCU ChecklistDocument11 pagesFCU Checklistsiva ramakrishnanNo ratings yet

- System Installation ChecklistDocument14 pagesSystem Installation ChecklistblahblahNo ratings yet

- Air Balancing Method StatementDocument1 pageAir Balancing Method StatementmpwasaNo ratings yet

- Air Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationDocument6 pagesAir Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationGopinath GopiNo ratings yet

- VRF Execution Check ListDocument2 pagesVRF Execution Check ListSkill IndiaNo ratings yet

- Preventive Maintenance Schedule of VRF UnitDocument2 pagesPreventive Maintenance Schedule of VRF UnitSudeep81% (16)

- Log data for water cooled chillerDocument1 pageLog data for water cooled chillerMadan Tiwari100% (1)

- Commissioning VRF overviewDocument4 pagesCommissioning VRF overviewtonylyf100% (1)

- 04 Inspection Checklist - Installation of Exhaust FansDocument2 pages04 Inspection Checklist - Installation of Exhaust Fansehtesham83% (6)

- AHU ManualDocument17 pagesAHU ManualwolfzemunNo ratings yet

- Copper Piping Checklist VRVDocument1 pageCopper Piping Checklist VRVSkill IndiaNo ratings yet

- VRV Technical SpecificationDocument7 pagesVRV Technical Specificationdheerajdorlikar100% (2)

- Inspection Checklist For Hvac (DUCT)Document2 pagesInspection Checklist For Hvac (DUCT)ResearcherNo ratings yet

- Air-Cooled Chiller Maintenance ChecklistDocument2 pagesAir-Cooled Chiller Maintenance ChecklistMd Rizwan Khan100% (3)

- Chiller Maintenance ListDocument1 pageChiller Maintenance Listadnan100% (7)

- ACU PM Checklist ADocument1 pageACU PM Checklist Aamdesilva125100% (1)

- Air Balancing Check ListsDocument11 pagesAir Balancing Check Listskumar123rajuNo ratings yet

- Air handling unit startup log templateDocument4 pagesAir handling unit startup log templateAhmed SofaNo ratings yet

- Chiller Maintenance Procedure PDFDocument4 pagesChiller Maintenance Procedure PDFMd. Yusuf100% (1)

- Log sheet chiller performance monitoringDocument1 pageLog sheet chiller performance monitoringWahyudi Pratomo67% (3)

- AHU - Pre-Commissioning Checklist FormDocument5 pagesAHU - Pre-Commissioning Checklist FormMarvin ArinueloNo ratings yet

- ASHRAE Duct Noise Vs VelocityDocument1 pageASHRAE Duct Noise Vs Velocityasdthu75% (4)

- Check HVAC duct leakage inspectionDocument1 pageCheck HVAC duct leakage inspectionyoonchankim0911100% (2)

- Duct Inspection ChecklistDocument3 pagesDuct Inspection ChecklistHaymanot Baynesagn100% (1)

- Edfmt391738 Fxmq-Pa PDFDocument64 pagesEdfmt391738 Fxmq-Pa PDFscribdquy71% (7)

- Maintenance & Troubleshoot AHUDocument11 pagesMaintenance & Troubleshoot AHUEva Sulistiany100% (1)

- Chiller ChecklistDocument3 pagesChiller ChecklistMohammed SayeeduddinNo ratings yet

- Leak Detection - DC PipeDocument75 pagesLeak Detection - DC Pipeراموندولدولاو50% (2)

- 04 Inspection Checklist - Installation of Air-Cooled ChillersDocument2 pages04 Inspection Checklist - Installation of Air-Cooled ChillersBabar Shehzad100% (3)

- Method Statement For Installation of Chillers Rev 1 - AFUDocument12 pagesMethod Statement For Installation of Chillers Rev 1 - AFUAzwan SunlineNo ratings yet

- MS - G. I. Duct FabricationDocument3 pagesMS - G. I. Duct FabricationAnonymous 3eHGEDbx100% (2)

- Air Cooled Chiller: Field Functional Test ReportDocument17 pagesAir Cooled Chiller: Field Functional Test ReportKen Wong Wm100% (4)

- Method Statement For Vav Units InstallationDocument1 pageMethod Statement For Vav Units InstallationimteyazhmdNo ratings yet

- M - Sanitary & Plumbing INSPECTION CHECKLISTDocument1 pageM - Sanitary & Plumbing INSPECTION CHECKLISTmandelaria0150% (6)

- Testing & Commissioning of Fan Coil Units FCU'sDocument3 pagesTesting & Commissioning of Fan Coil Units FCU'svin ssNo ratings yet

- Coldroom Installation ChecklistDocument3 pagesColdroom Installation ChecklistBedan KivuvaNo ratings yet

- Inspection Checklist For Hvac (DUCT Installation) F01 & F02Document4 pagesInspection Checklist For Hvac (DUCT Installation) F01 & F02Researcher100% (5)

- Air Balancing TestDocument2 pagesAir Balancing Testmanikantan100% (1)

- Inspection Checklist For Hvac (DUCT Installation) F01 & F02Document4 pagesInspection Checklist For Hvac (DUCT Installation) F01 & F02Researcher100% (1)

- 38lha 40lha h15 1pd Rev2Document28 pages38lha 40lha h15 1pd Rev2nhatNo ratings yet

- Yaep York CatalogueDocument36 pagesYaep York Cataloguecysauts58% (12)

- Method Statement For Installatioin of Grills, Diffusers, Registers & LouversDocument2 pagesMethod Statement For Installatioin of Grills, Diffusers, Registers & LouversDong VanraNo ratings yet

- VRV Pre Commissioning Checklist - DXSDocument3 pagesVRV Pre Commissioning Checklist - DXSTarun Kathpalia50% (2)

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong Vanra100% (1)

- Method Statement For Installation of Grills Diffusers Disc Valves and LouversDocument9 pagesMethod Statement For Installation of Grills Diffusers Disc Valves and LouversHelder FigueiredoNo ratings yet

- AHU ChecklistDocument11 pagesAHU Checklistaneesh50% (2)

- Chiller Operating SequenceDocument3 pagesChiller Operating Sequencejomy_pj8106No ratings yet

- HRH Prince Khaled Bin Sultan Project HVAC System Package Unit AC RooftopDocument11 pagesHRH Prince Khaled Bin Sultan Project HVAC System Package Unit AC Rooftopemanuel92No ratings yet

- Raft TT FT FT FT FT AFT AF RAFDocument31 pagesRaft TT FT FT FT FT AFT AF RAFHugo Silva100% (1)

- Fire Alarm Pretest Report Rev1 PDFDocument2 pagesFire Alarm Pretest Report Rev1 PDFWinokan DeviedNo ratings yet

- Installation of Sprinkler Piping System Checklist: Item No. Activity Yes No N/A RemarksDocument2 pagesInstallation of Sprinkler Piping System Checklist: Item No. Activity Yes No N/A Remarksshanawaz Shanu78% (9)

- Method of Statement - Testing and CommissioningDocument1 pageMethod of Statement - Testing and CommissioningTiam Yee YongNo ratings yet

- MEP Sanitary Fixtures Installation ChecklistDocument36 pagesMEP Sanitary Fixtures Installation ChecklistankurNo ratings yet

- VRV III Daikin CatalogueDocument82 pagesVRV III Daikin CatalogueJohan A. Psaila0% (1)

- Samsung DVM-S (VRF) Catalog Full 2015Document116 pagesSamsung DVM-S (VRF) Catalog Full 2015Hung Tran82% (11)

- VRF Electrical DiagramsDocument3 pagesVRF Electrical Diagramscalvin.bloodaxe447867% (3)

- Pre Commissioning Report - VRVDocument1 pagePre Commissioning Report - VRVshoaib badar100% (1)

- Manual Serviço Hitachi Rak Tem EsquemaDocument72 pagesManual Serviço Hitachi Rak Tem EsquemaFlabio OliveiraNo ratings yet

- TV JVC Av-27950 Av27980 Av27985Document92 pagesTV JVC Av-27950 Av27980 Av27985paco37No ratings yet

- Yciv 201.23-RP1 - 2Document68 pagesYciv 201.23-RP1 - 2dokundotNo ratings yet

- HVAC - R Refrigeration Circuit Cycle BasicsDocument9 pagesHVAC - R Refrigeration Circuit Cycle BasicsdokundotNo ratings yet

- RefrigPipingHandbook SuvaDocument161 pagesRefrigPipingHandbook SuvaDaveB11WhitNo ratings yet

- MAJAX-2 axial fans specification guideDocument7 pagesMAJAX-2 axial fans specification guidedokundotNo ratings yet

- 201.21 M1ycav Trobleshooting1Document40 pages201.21 M1ycav Trobleshooting1Daniel Diaz100% (1)

- Service Manual For High Efficiency High Ambient Amazon 20160805 NXPDocument401 pagesService Manual For High Efficiency High Ambient Amazon 20160805 NXPdokundot83% (6)

- Standards Spec Brochure ME WEBDocument44 pagesStandards Spec Brochure ME WEBReza TambaNo ratings yet

- Siguran Rad Na LestvamaDocument7 pagesSiguran Rad Na LestvamaJessica CaldwellNo ratings yet

- TECNAIR Serie P PDFDocument28 pagesTECNAIR Serie P PDFdokundotNo ratings yet

- Service Manual For High Efficiency Amazon 20161108 PDFDocument355 pagesService Manual For High Efficiency Amazon 20161108 PDFdokundot67% (3)

- Maksal Copper Pipes CatalogDocument4 pagesMaksal Copper Pipes Catalogdokundot50% (2)

- Koko Refrigerant Piping Sizing GuideDocument9 pagesKoko Refrigerant Piping Sizing Guidedokundot0% (1)

- Dutypoint Dirt & Air SeparatorsDocument12 pagesDutypoint Dirt & Air SeparatorsdokundotNo ratings yet

- Caleffi Decoupler PipingDocument1 pageCaleffi Decoupler PipingdokundotNo ratings yet

- Calibration ValidationDocument12 pagesCalibration Validationelmira100% (2)

- Profit en Catalogue PE 2017Document54 pagesProfit en Catalogue PE 2017dokundotNo ratings yet

- Dutypoint Dirt & Air SeparatorsDocument12 pagesDutypoint Dirt & Air SeparatorsdokundotNo ratings yet

- Calibration ValidationDocument12 pagesCalibration Validationelmira100% (2)

- Pipe Sizing Chart Advantage FYI167Document1 pagePipe Sizing Chart Advantage FYI167dokundotNo ratings yet

- German Language CourseDocument210 pagesGerman Language Course42099% (71)

- Carbon Steel Pipe Catalogue HebeiDocument8 pagesCarbon Steel Pipe Catalogue HebeidokundotNo ratings yet

- Foods To Fight Cancer - What To Eat PDFDocument242 pagesFoods To Fight Cancer - What To Eat PDFdokundot83% (6)

- York Cond Unit Piping GuidelinesDocument128 pagesYork Cond Unit Piping Guidelinesdokundot100% (1)

- BS en 1982 2008 1Document50 pagesBS en 1982 2008 1Anonymous SkU7PyNo ratings yet

- Welding Personal Protection and Safety Equipment: Expert GuideDocument15 pagesWelding Personal Protection and Safety Equipment: Expert GuidedokundotNo ratings yet

- York Split LargeDocument28 pagesYork Split LargedokundotNo ratings yet

- Handbook of Essential Pharmacokinetics, Pharmacodynamics, and Drug Metabolism For Industrial ScientistDocument302 pagesHandbook of Essential Pharmacokinetics, Pharmacodynamics, and Drug Metabolism For Industrial Scientistdavid_dung100% (2)

- Iso9001 Implementation Guide Final April2016Document12 pagesIso9001 Implementation Guide Final April2016mehra_rahul88No ratings yet

- PhysicsDocument580 pagesPhysicsSangam VaniNo ratings yet

- INFOR-TYCO - ACS-24 - Sounder Cum Strobe - Rev 1Document4 pagesINFOR-TYCO - ACS-24 - Sounder Cum Strobe - Rev 1Anonymous MDkp0hnb3lNo ratings yet

- 2080 Um002 - en e PDFDocument270 pages2080 Um002 - en e PDFΔημητρηςΣαρακυρουNo ratings yet

- GTG Control Description E1A2026115Document36 pagesGTG Control Description E1A2026115Sudhir Joshi100% (2)

- Electronic Devices Final Exam Practice Problem WorkthroughsDocument11 pagesElectronic Devices Final Exam Practice Problem WorkthroughsmrdantownsendNo ratings yet

- 1GT105DC PDFDocument4 pages1GT105DC PDFIsos CellNo ratings yet

- NCP1251 DatasheetDocument24 pagesNCP1251 DatasheetJose BenavidesNo ratings yet

- Jameco Part Number 1390194: Distributed byDocument31 pagesJameco Part Number 1390194: Distributed byfox7878No ratings yet

- Institute of Engineering & Science Ips Academy Indore: Major Project ReportDocument33 pagesInstitute of Engineering & Science Ips Academy Indore: Major Project Reportshruti20_mittalNo ratings yet

- Primary Assignment 1 Science 1Document15 pagesPrimary Assignment 1 Science 1IslamBachaMkdNo ratings yet

- 89543-REV - NEW: Current To Pressure ConvertorDocument44 pages89543-REV - NEW: Current To Pressure ConvertorErick FalconiNo ratings yet

- Automatic Water Level Indicator With AlarmDocument31 pagesAutomatic Water Level Indicator With Alarmchuck254No ratings yet

- Class 7 - Chapter 14 - Electric Current and Its EffectsDocument4 pagesClass 7 - Chapter 14 - Electric Current and Its EffectshamzaNo ratings yet

- Infinity ID2 PanelsDocument2 pagesInfinity ID2 PanelssalesNo ratings yet

- Harmonic Modelling For Simulation of HVDC Converter StationsDocument21 pagesHarmonic Modelling For Simulation of HVDC Converter Stationsabbd1990No ratings yet

- Data Sheet 1500kw 6.6kv Pa Fan MotorDocument4 pagesData Sheet 1500kw 6.6kv Pa Fan MotorRamesh CuppuNo ratings yet

- Pulse-Width Modulation Inverters: Pulse-Width Modulation Is The Process of Modifying The Width of The Pulses in A PulseDocument7 pagesPulse-Width Modulation Inverters: Pulse-Width Modulation Is The Process of Modifying The Width of The Pulses in A PulseEngrAneelKumarAkhani100% (1)

- Riyadh Telephone CablesDocument37 pagesRiyadh Telephone CablesMuhammad YousufNo ratings yet

- A Study of Power System Security and Contingency AnalysisDocument4 pagesA Study of Power System Security and Contingency AnalysisPurnima BiruaNo ratings yet

- сервис мануал LG 43UJ634V шасси UD74P PDFDocument101 pagesсервис мануал LG 43UJ634V шасси UD74P PDFsebas ruiz100% (1)

- 555 TimerDocument4 pages555 TimermanjunathreddychinnaNo ratings yet

- 1MRK505265-BEN - en Product Guide Busbar Protection REB650 IECDocument61 pages1MRK505265-BEN - en Product Guide Busbar Protection REB650 IECRobert RocafuerteNo ratings yet

- Sample Adam Entrance QuestionsDocument5 pagesSample Adam Entrance QuestionsMóhãmmèd Rífâz 21No ratings yet

- GT500 dual overdrive pedalDocument2 pagesGT500 dual overdrive pedalyukatan610100% (1)

- Datasheet RAM 6116Document11 pagesDatasheet RAM 6116manokotzNo ratings yet

- Physics2 Lab Report 2 DoneDocument8 pagesPhysics2 Lab Report 2 DonecffpjvmtzkNo ratings yet

- Eim 2nd Grading TopicDocument21 pagesEim 2nd Grading Topickevin john quilino100% (1)

- Conector Tipo C PanduitDocument1 pageConector Tipo C PanduitBrandon SarriaNo ratings yet

- Opt 428 BDocument120 pagesOpt 428 BNikita ToropovNo ratings yet

- Cmsq200a7w1b PDFDocument280 pagesCmsq200a7w1b PDFLeonardusNo ratings yet