Professional Documents

Culture Documents

Filler Roads For Gas Welding of Steel Chapter Ill Construction and Workmanship General

Uploaded by

Vishal Soni0 ratings0% found this document useful (0 votes)

10 views1 pagepage 12

Original Title

page-12

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpage 12

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageFiller Roads For Gas Welding of Steel Chapter Ill Construction and Workmanship General

Uploaded by

Vishal Sonipage 12

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

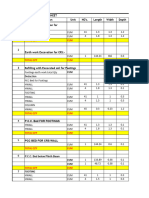

(x) Indian Boiler Regulations

FILLER ROADS FOR GAS WELDING OF STEEL

98A. Filler rods for gas welding of steel 83

CHAPTER Ill

CONSTRUCTION AND WORKMANSHIP

GENERAL

99. Preparation of plates 85'

100. Normalising of certain Steel Plates 85

101. Minimum Thickness of Plates 85'

SHELLS, ANGLE RINGS, BUIT STRAPS, ETC.

102. Cylindrical Shells

103. Position of Longitudinal Seams :�

104. Circumferential and End Seams 85

105. Angle Rings 86

106. Thickness of Shell Angle Rings 86

107. Welded Shell Plates 86

108. Longitudinal Seams 86

109. Butt Straps 86

110. Thinning of Butt Straps 86

111. Alternative Construction 87

112. Local Welding of Butt Seams 87 Q.

END PLATES

113. Flat End Plates 87

114. Strengthening of Flat End Plate at Manhole 87 Cl

115. End Plates in Steam Spaces 88

116. Hemispherical Crowns 88

117. Dished End and Crown Plates 88

118. Tube Plates 89 (1

119. Parts of Flat Tube Plates within the Tube Nests 89

120. Flanging ofEnd Plates 89

FURNACES

121. Furnaces in General 89

122. Furnaces of Horizontal Boilers 89 '

123. Furnaces of Vertical Boilers 90

124. Longitudinal Seams 91

125. Fusion Welded Longitudinal Seams 91

126. Furnace Crown 92

127. Cross Tubes 92

128. Uptakes 92

129. Loco Type Fire.boxes 93

129A. Welded Joints to Copper Fire Boxes 93

STAYS

130. Bar Stays 96

131. Longitudinal Stays 96

132. Nuts and Washers for Stays 96

133. Jointed Stays 96

134. Diagonal Bar or Rod Stays 96

SCREWED STAYS

135. Screwed Stays 97

136. Axial Drilling 97

137. Stay Nuts 97

138. Spacing of End Stays-Allowance for Curves, etc. 97

You might also like

- Indian Boiler RegulationsDocument1 pageIndian Boiler RegulationsVishal SoniNo ratings yet

- Rubber Extrusions CatalogueDocument111 pagesRubber Extrusions CatalogueS.KAMBANNo ratings yet

- Building Construction Plates A. Buchanan and W. H PDFDocument111 pagesBuilding Construction Plates A. Buchanan and W. H PDFkiri132No ratings yet

- Regulations For Determining The Working Pressure To Be Allowed On Various Parts of Boilers Other Than Fusion Welded and Seamless Forged Drums ShellsDocument1 pageRegulations For Determining The Working Pressure To Be Allowed On Various Parts of Boilers Other Than Fusion Welded and Seamless Forged Drums ShellsVishal SoniNo ratings yet

- Watchmakers and Jewelers Practical Handbook 1892Document146 pagesWatchmakers and Jewelers Practical Handbook 1892jimmy_wood100% (3)

- Wa SuspensionDocument416 pagesWa SuspensionGustavo MosqueraNo ratings yet

- Weco Unions Chicksan Swive11Document6 pagesWeco Unions Chicksan Swive11Sandro AraújoNo ratings yet

- Temperature Equivalent Chart For Orton Pyrometric Cones (°C)Document1 pageTemperature Equivalent Chart For Orton Pyrometric Cones (°C)LorenOlguínNo ratings yet

- Steel Tables by R Agor, Birla Publications PDFDocument97 pagesSteel Tables by R Agor, Birla Publications PDFankitNo ratings yet

- Build Cutty Sark Anchor DavitsDocument1 pageBuild Cutty Sark Anchor DavitsIvan KostadinovicNo ratings yet

- Hammer Theory and Practice Third EditionDocument192 pagesHammer Theory and Practice Third EditionBoopathiNo ratings yet

- IndexDocument23 pagesIndexfaizankhan23No ratings yet

- NZ Rail Maps - Napier-Gisborne LineDocument118 pagesNZ Rail Maps - Napier-Gisborne LineNZ Rail MapsNo ratings yet

- Novo-PB-03 02 2023Document153 pagesNovo-PB-03 02 2023Mariana G. AparicioNo ratings yet

- Trelleborg AVS IND Product Catalogue V032020Document120 pagesTrelleborg AVS IND Product Catalogue V032020AdvityaSapraNo ratings yet

- A Guide To Repairing Woodwinds PDFDocument5 pagesA Guide To Repairing Woodwinds PDFFr Bayern0% (1)

- Compound wall-SOUTHDocument8 pagesCompound wall-SOUTHSitaram PREDCRNo ratings yet

- v2 Indx PDFDocument36 pagesv2 Indx PDFBhupender SharmaNo ratings yet

- Handbook of Spring Design Part 1Document51 pagesHandbook of Spring Design Part 1senthilkumar D0% (1)

- Frank L. Evans Equipment Design Handbook For Refineries and Chemical Plants. Volume 2 1980Document380 pagesFrank L. Evans Equipment Design Handbook For Refineries and Chemical Plants. Volume 2 1980aderaniNo ratings yet

- CE 212 Mechanics of Solids Sessional: Department of Civil EngineeringDocument54 pagesCE 212 Mechanics of Solids Sessional: Department of Civil EngineeringjulesNo ratings yet

- Consolidated GradesDocument7 pagesConsolidated GradesjenniferNo ratings yet

- SolucionesDocument20 pagesSolucionesEsteban Fabian Sanchez TerrerosNo ratings yet

- Axial Cylindrical Roller Bearings - Cages and Washers PDFDocument14 pagesAxial Cylindrical Roller Bearings - Cages and Washers PDFkdalavadi3905No ratings yet

- Welder CTS2.0 NSQF-3Document2 pagesWelder CTS2.0 NSQF-3Abu AnoopNo ratings yet

- Mill Housings Mangal SinghDocument5 pagesMill Housings Mangal SinghGun SmithNo ratings yet

- HATCH Furnace Technology CutDocument24 pagesHATCH Furnace Technology CutBernie_Garcia__9886No ratings yet

- PARTLY OPEN TOP CONRO VESSEL SPECIFICATIONSDocument2 pagesPARTLY OPEN TOP CONRO VESSEL SPECIFICATIONSЕгор ЛядовNo ratings yet

- Jack Lewin-Hydraulic Gates and Valves in Free Surface Flow and Submerged Outlets-T. Telford (1995) PDFDocument301 pagesJack Lewin-Hydraulic Gates and Valves in Free Surface Flow and Submerged Outlets-T. Telford (1995) PDFJoão Paulo FerreiraNo ratings yet

- General Instruction Manual: Drilling Equipment - Service Lives and DepreciationDocument5 pagesGeneral Instruction Manual: Drilling Equipment - Service Lives and DepreciationAldrien CabinteNo ratings yet

- Sullivan 1927Document4 pagesSullivan 1927ayiep1202No ratings yet

- b31870818 PDFDocument352 pagesb31870818 PDFHarshal VaidyaNo ratings yet

- HK Commercial Page 1Document1 pageHK Commercial Page 1rand0No ratings yet

- Indian Boiler RegulationsDocument1 pageIndian Boiler RegulationsVishal SoniNo ratings yet

- Abbey SealDocument20 pagesAbbey SealDamonNo ratings yet

- Consteel Catalogue FULLspreadsDocument61 pagesConsteel Catalogue FULLspreadsazharigunawan.gam10092023No ratings yet

- Day to day monitoring of remaining works and cumulative completion percentageDocument1 pageDay to day monitoring of remaining works and cumulative completion percentageadil enhadeNo ratings yet

- Enviropipes CatalogueDocument164 pagesEnviropipes CatalogueguslohNo ratings yet

- Ship Construction Sketches and NotesDocument72 pagesShip Construction Sketches and NotesZainal Arifin100% (3)

- Osswald 2014Document5 pagesOsswald 2014نرگس باویNo ratings yet

- Wo General Products CatalogDocument233 pagesWo General Products CatalogRama WijayaNo ratings yet

- Cambering Steel Beams: DefinitionsDocument7 pagesCambering Steel Beams: DefinitionsOswaldo SuárezNo ratings yet

- Handbook of Spring DesignDocument119 pagesHandbook of Spring DesignAnil S Chaudhary50% (2)

- Reinforcing bar location and naming conventionDocument1 pageReinforcing bar location and naming conventionMưa Vô HìnhNo ratings yet

- Single Conductor Underground Ducts: Ampacity TablesDocument3 pagesSingle Conductor Underground Ducts: Ampacity TablesalbertoNo ratings yet

- WhatsApp Image 2021-09-14 at 03.23.21Document2 pagesWhatsApp Image 2021-09-14 at 03.23.21dzaky fawwazNo ratings yet

- The Shear Strength of Reinforced Concrete T-BeamDocument153 pagesThe Shear Strength of Reinforced Concrete T-BeamChee Soon LeeNo ratings yet

- KORADO KonvektoriDocument100 pagesKORADO KonvektoriRaske89No ratings yet

- Ostrom 1969Document172 pagesOstrom 1969Mr. LonewolfNo ratings yet

- Cat SKF 10000 EN-SRBDocument78 pagesCat SKF 10000 EN-SRBbdibujante89No ratings yet

- Who Am I SEDocument6 pagesWho Am I SEgoogleNo ratings yet

- Vibration Control (Simrit)Document117 pagesVibration Control (Simrit)ismailNo ratings yet

- Gr4 5 Bridges Student JournalDocument118 pagesGr4 5 Bridges Student JournalHeroNo ratings yet

- NDT - Cladding TechnologyDocument59 pagesNDT - Cladding TechnologySurajit Singha100% (4)

- SW BrochureDocument16 pagesSW BrochurePhong Hoang LeNo ratings yet

- The Design of Piled Foundations: Structures and Solid Body MechanicsFrom EverandThe Design of Piled Foundations: Structures and Solid Body MechanicsRating: 4 out of 5 stars4/5 (8)

- Valve Pressure-Temperature Ratings SWAGELOKDocument32 pagesValve Pressure-Temperature Ratings SWAGELOKBsSrinivas SriniNo ratings yet

- Asme B 31.3 System ClassificationDocument1 pageAsme B 31.3 System ClassificationVishal SoniNo ratings yet

- Restrain LoadsDocument1 pageRestrain LoadsVishal SoniNo ratings yet

- Schematic Diagram of Flaker Dum Assembly: Make, Made & Type ? Name Plate Details / PhotoDocument1 pageSchematic Diagram of Flaker Dum Assembly: Make, Made & Type ? Name Plate Details / PhotoVishal SoniNo ratings yet

- Fusible Plugs: Indian Boiler RegulationsDocument1 pageFusible Plugs: Indian Boiler RegulationsVishal SoniNo ratings yet

- Flanges With Nut StopsDocument1 pageFlanges With Nut StopsVishal SoniNo ratings yet

- Random Expansion AsmeDocument1 pageRandom Expansion AsmeVishal SoniNo ratings yet

- Indian boiler regulations safety valvesDocument1 pageIndian boiler regulations safety valvesVishal SoniNo ratings yet

- Types of SupportDocument1 pageTypes of SupportVishal SoniNo ratings yet

- Indian Boiler RegulationsDocument1 pageIndian Boiler RegulationsVishal SoniNo ratings yet

- Indian Boiler Regulations: (Xiii)Document1 pageIndian Boiler Regulations: (Xiii)Vishal SoniNo ratings yet

- Indian Boiler Regulations: Appendix AppendixDocument1 pageIndian Boiler Regulations: Appendix AppendixVishal SoniNo ratings yet

- Bridge Abutment Pier Design As Per IRCDocument41 pagesBridge Abutment Pier Design As Per IRCjibendra mishra88% (43)

- By L.srikanth 17b81a03k4 A.vinay Kumar 17b81a03p3 16b81a03d6Document15 pagesBy L.srikanth 17b81a03k4 A.vinay Kumar 17b81a03p3 16b81a03d6Sunil Kumar VemulaNo ratings yet

- Vectron+1-6 300713 en 1.6Document24 pagesVectron+1-6 300713 en 1.6kikokadolaNo ratings yet

- MeasurementDocument4 pagesMeasurementmuh_akbar2451No ratings yet

- Tangerine Visual Identity Guide Initial DraftDocument4 pagesTangerine Visual Identity Guide Initial DraftFrederick FullonNo ratings yet

- Drilling Cost and Hole ProblemsDocument39 pagesDrilling Cost and Hole ProblemsArun Sharma100% (1)

- Heater TreaterDocument5 pagesHeater TreaterImmanuel100% (1)

- Introduction To Electrical and Computer Engineering Lab ManualDocument124 pagesIntroduction To Electrical and Computer Engineering Lab Manualkstu1112No ratings yet

- VAYHAN AIR CONTROLS PRIVATE LIMITED Air Washer Unit SpecificationsDocument2 pagesVAYHAN AIR CONTROLS PRIVATE LIMITED Air Washer Unit SpecificationsSaleem BashaNo ratings yet

- GM-MS45 hydraulic valve technical specificationsDocument21 pagesGM-MS45 hydraulic valve technical specificationsDUVAN GARNICANo ratings yet

- ESS - Topic 1 NotesDocument6 pagesESS - Topic 1 NotesNicoleNo ratings yet

- Bearing Life CycleDocument2 pagesBearing Life CyclemoerkerkNo ratings yet

- Cat - Engine Components PDFDocument227 pagesCat - Engine Components PDFxxxxxxxxxxxxxxxxxxx100% (1)

- Wimax For DummiesDocument35 pagesWimax For DummiesMichael John MjattaNo ratings yet

- Router Table Fence Building PlansDocument11 pagesRouter Table Fence Building Plansleo100% (2)

- D. Marriot - The Development of High-Performance Post-Tensioned Rocking Systems For The Seismic Design of StructuresDocument556 pagesD. Marriot - The Development of High-Performance Post-Tensioned Rocking Systems For The Seismic Design of Structuresedicson1aNo ratings yet

- The Garrison Border Town of Elvas and Its FortificationsDocument850 pagesThe Garrison Border Town of Elvas and Its FortificationsAndré SerraNo ratings yet

- Airbase 13671Document6 pagesAirbase 13671ssarangNo ratings yet

- ROR coding standards guide for clean codeDocument2 pagesROR coding standards guide for clean codeHarish KashyapNo ratings yet

- Manual de Servicio Ichem Velocity Rev DDocument271 pagesManual de Servicio Ichem Velocity Rev DJohny Ronald Gutierrez DelgadoNo ratings yet

- CATIA V5R17 Chain & Sprocket Simulation ExplainedDocument35 pagesCATIA V5R17 Chain & Sprocket Simulation ExplainedBill Harbin50% (2)

- Gta - Sa - Weapons - Gifts - ItemsDocument24 pagesGta - Sa - Weapons - Gifts - ItemsSaikat DattaNo ratings yet

- List Inventaris PPPDocument7 pagesList Inventaris PPPasep nathanNo ratings yet

- Shear Forces and Bending Moments: Understanding Structural AnalysisDocument2 pagesShear Forces and Bending Moments: Understanding Structural AnalysisKang Lee76% (25)

- ADX 260 Test One ContentDocument20 pagesADX 260 Test One ContentrainewithaneNo ratings yet

- CE8395 QB - by WWW - Easyengineering.net 1Document18 pagesCE8395 QB - by WWW - Easyengineering.net 1sureshkumarNo ratings yet

- Elma Combitest 419 Multifunctional Meter SpecificationsDocument4 pagesElma Combitest 419 Multifunctional Meter SpecificationscipriancordeaNo ratings yet

- Survey ToolDocument74 pagesSurvey Toolk saikiranNo ratings yet

- SMK BUKIT SENTOSA TINGKATAN 4 PEPERIKSAAN AKHIR TAHUN 2014 MARKING SCHEMEDocument7 pagesSMK BUKIT SENTOSA TINGKATAN 4 PEPERIKSAAN AKHIR TAHUN 2014 MARKING SCHEMEMohd Hairul Akmal Ab. AzizNo ratings yet

- Manual Operación Balanza Génesis PDFDocument24 pagesManual Operación Balanza Génesis PDFCarolinaOrdóñezBalcázarNo ratings yet