Professional Documents

Culture Documents

Manual de Instrucciones SAB 128 & 163 MK 2 PDF

Uploaded by

yoye196850%(2)50% found this document useful (2 votes)

969 views126 pagesOriginal Title

Manual de instrucciones SAB 128 & 163 MK 2.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

50%(2)50% found this document useful (2 votes)

969 views126 pagesManual de Instrucciones SAB 128 & 163 MK 2 PDF

Uploaded by

yoye1968Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 126

201

0178.027-EN

92.01

0178-027-EN

Instruction Manual

for

SAB 163 Mk 2

‘The screw compressor and unit can be fitted

with different equipment, depending on

their function and requirements.

‘Some of these variants are described in this

instruction manual, even though they are

not fitted on your particular unit.

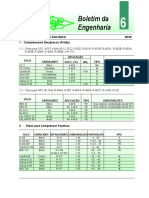

‘A cross (x) in the following table indicates

what variants are fitted on your unit — the

shop no. is stated below.

Type of dive (J wale drive [_] Female arive

Refrigerant R717 R22 Other

Shop no.

Instrument panel and manual regulation of Vi slide

Instrumentation | PROSAB I/UNISAB-S and manual regulation of Vi slide [|

PROSAB II/UNISAB-S and automatic regulation of V; slide

Water-cooled oll cooler. © OWSG/OWCG/OWRG.

Water-cooled oil cooler Type B

oe Refrigerant-cooled oil cooler coos!

Refrigerant injection in the compressor HLL

Refrigerant injection in the discharge pipe BL!

Economizer Vessel ype =

Reoravstem) Closed system and vessel type EOSE

Open system and vessel type SVER

0178-027-EN

Foreword

‘The aim of this instruction manual is to pro-

vide the operators with a thorough know-

ledge of the compressor and the unit, at the

same time furnishing information about

© the function and maintenance of the indi-

vidual components;

© service schedules;

© procedure for dismantling and reassem-

bling the compressor.

The instruction manual also draws attention

to typical sources of error which may occur

during operations, stating their cause and

explaining what should be done to rectify

them,

tis imperative that the operators familiar-

ize themselves thoroughly with the contents

of this instruction manual, both to ensure

reliable, efficient operation and because

SABROE is unable to provide a guarantee

against damage occurring during the war-

ranty period where this is attributable to in-

correct operation.

The contents of this instruction manual may

not be copied or passed on to any unauthor-

ized person without the permission of

SABROE.

Warning

If combustion motors are installed in rooms containing refrigeration machinery or rooms

where there are pipes and components containing refrigerant, you must make sure that

the combustion air for the motor is derived from an area where there is no refrigerant

gas, in case of leakage.

Failure to do so will involve a risk of the lubricating oil from the combustion motor mixing

with the refrigerant; at worst, this may give rise to corrosion and damage to the motor.

‘SABROE REFRIGERATION A/S

145627 12.66

P.O, Box 1810, DK-8270 Hajbjerg

Chr. X’s Vej 201, Arhus, Denmark

Phone:

“Telefax: +45 6274474

‘Teletex: 3622 88

di

Telex: 68740

sot

0171-500-EN

0178-027-EN

Contents

First Aid for accidents with Ammoni

First aid for accidents with CFC/HCFC .

Protecting the environment

Description of Compressor Type SAB 163 Mk2

Data for compresssor & unit SAB 128/163 Mk 2

Compressor data SAB 128/163 Mk 2.

Operating limits R22...

Operating limits R717

Compressor and Unit Operation SAB128/163 Mk 2 .

‘Preparations for start-up

Initial start-up .

Normal start-up

Regular supervision under normal operations

Normal stoppage .

Emergency stop or incorrect settings .

Preparations for a lengthy period of standstill.

Pressure testing the reftigeration plant .

‘Bvacuating the refrigeration plant .

Operating log ....

Service Schedules for Screw Compressors

Preparation for compressor inspection

Checking the oil

Activities to be carried out ateach Periodic service

Assessing the oil.

‘Major service intervals SAB 128/163

Oil charges, weights and shipping volumes SAB 163 Mk 2...

‘Temperature and Pressure Settings SAB 128/163 Mk 2 .

Servicing the Refrigeration Plant .

‘Maintenance of Compressor SAB163 Mk 2 Dismantling and nd Assembly

‘Systems for regulation of compressor capacity and Vi ratios SAB 163 Mk 2

1. Regulation of compressor capacity

2. Automatic regulation of the Vislide .

3. Manual regulation of the Vi slide:

WAURONE

aun

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- AM4 Bock 11115r-3Document1 pageAM4 Bock 11115r-3yoye1968No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- F14 BockDocument1 pageF14 Bockyoye1968No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Dibujo de Los Componentes Desglosados/visualización de La PosiciónDocument4 pagesDibujo de Los Componentes Desglosados/visualización de La Posiciónyoye1968No ratings yet

- Table of Saturated Values For R717, NH3, AmmoniaDocument3 pagesTable of Saturated Values For R717, NH3, Ammoniayoye1968No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- E00032 enDocument6 pagesE00032 enyoye1968No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- E00034 enDocument6 pagesE00034 enyoye1968No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Table of Saturated Values For R717, NH3, AmmoniaDocument3 pagesTable of Saturated Values For R717, NH3, Ammoniayoye1968No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Check Valve Type NRVA: Data Sheet - Spare Parts and AccessoriesDocument1 pageCheck Valve Type NRVA: Data Sheet - Spare Parts and Accessoriesyoye1968No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 9 Seminario IIAR Chile 2014 - Buenas Practicas en Refrigeracion Con Amoniaco - Pys - Rev 0Document64 pages9 Seminario IIAR Chile 2014 - Buenas Practicas en Refrigeracion Con Amoniaco - Pys - Rev 0yoye1968No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Dkrci - Py.fn0.b2.02 Fia InsertsDocument1 pageDkrci - Py.fn0.b2.02 Fia Insertsyoye1968No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Dkrci - Py.bm0.c7.02 Evra Evrat Evrs Evrst EvmDocument32 pagesDkrci - Py.bm0.c7.02 Evra Evrat Evrs Evrst Evmyoye1968No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Visor Liquido LLGDocument8 pagesVisor Liquido LLGyoye1968No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Dkrci - Py.aj0.a3.02 Tea Teat Teva Teaq Spare Parts SheetDocument8 pagesDkrci - Py.aj0.a3.02 Tea Teat Teva Teaq Spare Parts Sheetyoye1968No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Ebmpapst Axial - Fans - 2007 - EN PDFDocument436 pagesEbmpapst Axial - Fans - 2007 - EN PDFyoye1968No ratings yet

- Tabla AceiteTornillo BitzerDocument2 pagesTabla AceiteTornillo Bitzeryoye1968No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bock Lubricantes HFC 2014Document2 pagesBock Lubricantes HFC 2014yoye1968No ratings yet

- Geneglace F250 SB NH3Document1 pageGeneglace F250 SB NH3yoye1968No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)