Professional Documents

Culture Documents

Us 6407301

Uploaded by

Hazeq Azahar0 ratings0% found this document useful (0 votes)

20 views8 pageskolokolo

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentkolokolo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views8 pagesUs 6407301

Uploaded by

Hazeq Azaharkolokolo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

USOO64O7301B1

(12) United States Patent (10) Patent No.: US 6,407.301 B1

Foley et al. (45) Date of Patent: Jun. 18, 2002

(54) ETHYLENE PRODUCTION BY STEAM 5,132,486 A * 7/1992 Wylie......................... 585/826

CRACKING OF NORMAL PARAFFINS FOREIGN PATENT DOCUMENTS

(75) Inventors: Timothy D. Foley, Forest Park; GB 2 119398 A 3/1983

Stephen W. Sohn, Arlington Heights,

both of IL (US) OTHER PUBLICATIONS

(73) Assignee: UOP LLC, Des Plaines, IL (US) Reddoch et al., “Separation of Normal Paraffins from Iso

paraffins" presented at The 11” Australian Conference on

(*) Notice: Subject to any disclaimer, the term of this Chemical Engineering, Brisbane, Sep. 3–7, 1983.

patent is extended or adjusted under 35 sk -

U.S.C. 154(b) by 0 days. cited by examiner

Primary Examiner Walter D. Griffin

(21) Appl. No.: 09/698,948 Assistant Examiner Tam M. Nguyen

(22) Filed: Oct. 30, 2000 E.attorney Agent, or Firm John G. Tolomei, James C.

(51) Int. Cl. .......................... C10G 35/04; C10G 9/36;

C07C 4/02; C07C 7/12 (57) ABSTRACT

(52) U.S. Cl. ....................... 585/650; 585/802; 585/820; An adsorptive Separation process for preparing the Separate

585/825, 208/310 Z; 208/310 R; 208/134; feed Streams charged to naphtha reforming unit and a Steam

208/130 cracking unit is presented. The feed Stream to the Overall unit

(58) Field of Search ................................. 585/650, 820, is fractionated to yield a Cs stream and a second stream

585/825, 802; 208/310 Z, 310 R, 134, 130 containing the rest of the feed, which is passed into the

adsorptive Separation unit. The Cs Stream is utilized as the

(56) References Cited deSorbent in the adsorptive Separation. The adsorptive Sepa

U.S. PATENT DOCUMENTS ration Separates the C-plus components of the feed Stream

into a normal paraffin Stream, which is charged to the Steam

3.291,726. A 12/1966 Broughton .............. 208/310 cracking process, and non-normal hydrocarbons which are

4,006,197 A 2/1977 Bieser .......... ... 260/676 MS passed into a reforming Zone. The invention improves the

4,184,943 A 1/1980 Anderson ............... 208/310 R ields from both downstream units.

4,455,444 A 6/1984 Kulprathipanja et al. ... 585/826 y

5,026,951 A * 6/1991 Schmidt et al. ............. 585/738

5,107,052 A * 4/1992 McCulloch et al. ........ 585/738 10 Claims, 1 Drawing Sheet

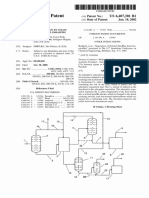

U.S. Patent Jun. 18, 2002 US 6,407.301 B1

US 6,407.301 B1

1 2

ETHYLENE PRODUCTION BY STEAM U.S. Pat. No. 3,291,726 issued to D. B. Broughton also

CRACKING OF NORMAL PARAFFINS describes the use of Simulated moving bed technology to

Separate normal paraffins from a petroleum derived fraction.

FIELD OF THE INVENTION This reference further describes that a suitable desorbent for

The invention relates to an adsorptive Separation proceSS use in the process may be provided by fractional distillation

used to prepare a feed Stream for a Steam cracking proceSS of the unit feedstock and the raffinate and extract removed

unit. The invention more specifically relates to an adsorptive from the adsorption Zone.

proceSS used to produce a high purity normal paraffin Stream SUMMARY OF THE INVENTION

used as a feed Stream to a Steam cracking process.

The invention is an adsorptive Separation process which

BACKGROUND OF THE INVENTION reduces the cost of Separating normal paraffins from a broad

Steam cracking, which is the thermal cracking of hydro boiling point range naphtha hydrocarbon fraction. The

carbons in the presence of Steam, is used commercially in invention thereby provides an improved method for recov

large Scale industrial units to produce ethylene and to a ering a broad boiling mixture of normal paraffins which is

15

lesser extent propylene. These pyrolysis units are often highly Suitable as a feed to a Steam cracking unit intended to

charged a naphtha boiling range feed Stream. The typical produce ethylene. It Simultaneously produces a very desir

petroleum derived naphtha contains a wide variety of dif able catalytic reforming feed Stock. Overall cost reduction

ferent hydrocarbon types including normal paraffins, and proceSS Simplification are obtained in part by using

branched paraffins, olefins, naphthenes, benzene, and alkyl Selective adsorption to recover normal paraffins, with the

aromatics. It is known in the art that paraffins are the most deSorbent used in the adsorption Zone being derived from

easily cracked and provide the highest yield of ethylene and the naphtha feed Stream of the overall process. This reduces

that Some compounds Such as benzene are relatively refrac the need to recover the desorbent for recycling.

tory to the typical cracking conditions. It is also known that A broad embodiment of the invention may be character

cracking normal paraffins results in a higher product yield 25

ized as a process for preparing a feedstream to be charged to

than cracking iso-paraffins. A paper entitled Separation of a Steam cracking unit, which process comprises passing a

Normal Parafins from Isoparafins presented by I. A. process feed Stream comprising Cs through Cohydrocarbons

Reddock, et al, at the Eleventh Australian Conference on including Cs through Co. normal paraffins into a first frac

Chemical Engineering, Brisbane, Sep. 4–7, 1983 discloses tionation Zone, and Separating the hydrocarbons entering the

that the ethylene yield of a cracking unit can be increased if first fractionation Zone into a first proceSS Stream rich in Cs

it is charged a C-C stream of normal paraffins rather than paraffins and a second process stream comprising C

a typical Cs-Co natural gasoline. through Cohydrocarbons, passing the Second proceSS Stream

The Separation of the myriad components of a petroleum into an adsorption Zone of an adsorptive Separation Zone and

naphtha into Specific structural types by fractional Selectively retaining normal paraffins on an adsorbent

distillation, a form of fractionation, is prohibitively expen 35

located in the adsorption Zone to yield a raffinate Stream

Sive and complicated and any attempt to improve the char comprising non-normal C through Co. hydrocarbons, pass

acter of the naphtha as a Steam cracking feed must therefore ing the first process Stream into a desorption Zone in the

employ other means which act on a class of Structural types, adsorptive Separation Zone as at least part of a desorbent

Such as extraction. Stream and removing normal paraffins from adsorbent

The benefits of Separating the various classes of hydro 40

present in the desorption Zone to yield an extract Stream

carbons in petroleum fractions have led to the development comprising C through Co. normal paraffins and Cs paraffins,

of a number of different techniques which Separate the Separating at least a portion of the extract Stream in a Second

hydrocarbons by type rather than individual molecular fractionation Zone into a third process Stream comprising Cs

weight or volatility. For instance, various forms of liquid paraffins and a fourth proceSS Stream comprising C through

extraction can be used to remove aromatic hydrocarbons 45

Co normal paraffins; and passing the fourth process Stream

from a mixture of aromatic and paraffinic hydrocarbons. into a cracking Zone producing ethylene.

Adsorptive Separation techniques have been developed to BRIEF DESCRIPTION OF THE DRAWING

Separate olefins from paraffins and to Separate normal

(straight chain) paraffins from non-normal, e.g. branch chain The drawing is a simplified proceSS flow diagram showing

paraffins and aromatics. An example of Such a proceSS is 50 a naphtha feed of line 1 being divided into a feed stream to

described in U.K. patent Application 2,119,398 which the adsorption Zone 4 and a desorbent of line 16.

employs a 5A Zeolite having crystals larger than 5 Ang PREFERRED EMBODIMENTS AND DETAILED

Stroms to Selectively adsorb Straight chain hydrocarbons to DESCRIPTION

the exclusion of non-Straight chain hydrocarbons and Sulfur

compounds. 55 The great bulk of the ethylene consumed in the production

There are great economic benefits to a large Scale unit if of various plastics and petrochemicals Such as polyethylene

an adsorptive Separation is performed in a continuous is produced by the thermal cracking of higher molecular

manner, and methods to do this have been developed. U.S. weight hydrocarbons. Steam is usually admixed with the

Pat. No. 4,006,197 to H. J. Bieser and U.S. Pat. No. feed Stream to the cracking reactor to reduce the hydrocar

4,455,444 to S. Kulprathipanja et al describe techniques for 60 bon partial preSSure and enhance olefin yield and to reduce

performing a continuous simulated moving bed (SMB) the formation and deposition of carbonaceous material in the

adsorptive Separation process for the recovery of normal cracking reactors. The process is therefore often referred to

paraffins, which is the preferred mode of operating the a Steam cracking or pyrolysis.

adsorptive Separation Zone of the Subject invention. The It is known that the composition of the feed to the steam

Bieser reference describes the fractionation of the raffinate 65 cracking reactor effects the results. A fundamental basis of

and extract Streams to recover desorbent which is reused in this is the propensity of Some hydrocarbons to crack more

the process. easily than others. The normal ranking of hydrocarbons

US 6,407.301 B1

3 4

tendency to crack to light olefins is normally given as normal materials in the first fractionation Zone. The total net over

paraffins, isoparaffins, olefins, naphthenes and aromatics. head Stream of line 16 may be passed into the adsorptive

Benzene and other aromatics are particularly refractory and Separation Zone 4 as desorbent, but the continuous recovery

undesirable as cracking feedstocks, with only the alkyl and recycling of desorbent from the adsorptive Separation

Sidechains being cracked to produce the desired product. Zone effluent Streams means that Some Cs hydrocarbons

The feed to a steam cracking unit is normally a mixture of must be rejected from the process to counteract the net Cs

hydrocarbons varying both by type of hydrocarbon and addition from the feed Stream. One optional way of doing

carbon number. This variety results in it being very difficult this is by discharging a portion of the Cs rich overhead

to separate less desirable feed components, Such as stream of line 16 from the process via line 17. The remaining

aromatics, from the feedstream by fractional distillation. The portion is then passed through line 19 and employed as

aromatics can be removed by Solvent extraction or adsorp desorbent. Alternatively Cs hydrocarbons recovered from

tion. It is an objective of the Subject invention to provide a either the extract or raffinate Stream of the adsorptive Sepa

process for upgrading (preparing) the feed to a steam ration Zone 4 can be discharged from the process, although

cracking process unit. It is a Specific objective of the Subject this material may have been Supplemented with other

process to reduce the cost of removing non-normal hydro 15 materials, Such as iso-paraffins, which are preferably not

carbons from a Steam cracking process feed Stream by rejected from the process.

adsorptive Separation. The net bottoms stream of line 3 forms the feedstream to

These objectives are met through the use of adsorptive an adsorptive Separation Zone 4. The adsorptive Separation

Separation to fractionate the feedstream into a normal par Zone may be of any Suitable type, that is Swing bed or

affin fraction for the Steam cracking S unit and a non-normal Simulated moving bed, that is appropriate for the Specific

fraction which is passed into a different conversion Zone or Situation of the process. The net bottoms Stream is separated

withdrawn from the process. The objectives are also met in the adsorptive Separation Zone by the Selective retention

through the use of light hydrocarbons, preferably Cs of normal paraffins on a Selective adsorbent located in that

paraffins, recovered from the initial feed Stream as the portion of the Overall adsorptive Separation Zone dedicated

deSorbent in the adsorptive Separation Zone. 25 to adsorption, which is referred to herein as an adsorption

The feedstream to a steam cracking unit can be quite Zone. These normal paraffins remain on the adsorbent until

diverse and can be chosen from a variety of petroleum a stream of desorbent delivered from line 18 passes through

fractions. The feedstream to the Subject process preferably the adsorbent. The desorbent has properties which cause it to

has a boiling point range falling within the naphtha boiling dislodge the heavier, normal paraffins resulting in the for

point range or about 36 to 195 C. It is specifically preferred mation of a stream referred to herein as the extract Stream.

to charge a C-plus fraction to the Steam cracking Zone, The extract Stream comprises the normal paraffins, which

meaning that the feed Stream is Substantially free of hydro were previously Selectively retained on the adsorbent, and a

carbons having five or fewer carbon atoms per molecule. It quantity of the desorbent material. The extract Stream is

is also preferred that the feed Steam does not contain removed from the adsorptive Separation Zone 4 via line 5 and

appreciable amounts, e.g. more than 5 mole %, of C. 35 passed into a Second fractionation Zone 6 referred to in the

hydrocarbons. A representative feed Stream to the Subject art as the extract column. This fractionation Zone is designed

process is a C-C fraction produced by fractional distil and operated to Separate the entering hydrocarbons into a net

lation of a hydrotreated petroleum fraction. Hydrotreating is overhead Stream rich in the Cs desorbent and a net bottoms

desired to reduce the Sulfur and nitrogen content of the feed Stream rich in the C-C normal paraffins of the extract

down to acceptable levels. A Second representative feed is a 40 Stream. These normal paraffins are passed through line 7 into

Similar fraction comprising Cs through Co. hydrocarbons. a Steam cracking Zone 8 operated at Steam cracking condi

The feed will preferably have a carbon number range of at tion effective to convert the paraffins mainly into ethylene

least three. It is within the scope of the subject invention that removed from the proceSS as a product Stream of line 9.

the feed Stream to the process comprise only the heavier In this embodiment the more volatile C. hydrocarbons of

C-plus hydrocarbons. In this case the lightest (most 45 the extract Stream are concentrated into the net overhead

volatile) hydrocarbons, the C hydrocarbons, are concen stream removed from fractionation Zone 6 in line 14. This Cs

trated into a stream which is used as the desorbent in the Stream is admixed with a Second Stream of recycled Cs

adsorptive Separation Zone. The light fraction employed as hydrocarbons from line 13 and then passed into line 15. This

the desorbent preferably contains essentially only hydrocar mixture is then further augmented with the Cs hydrocarbons

bons having the same carbon number e.g. Cs or C hydro 50 flowing through line 19. The total flow of Cs hydrocarbons

carbons. This light fraction will contain a variety of hydro formed in this manner is passed into the adsorptive Separa

carbon types, but preferably contains at least 90 mol-% of tion Zone 4 as the desorbent stream of line 18.

the same carbon number. During the adsorption Step in the Separation Zone 4 the

Referring now to the drawing, a naphtha boiling range non-normal components of the net bottoms Stream of line 3

feedstream enters the overall process through line 1. The 55 pass through the adsorption Zone unaffected and are

feedstream is passed into first fractionation Zone 2. This removed from Zone 4 via line 10 as a process stream referred

fractional distillation Zone is designed and operated to to as the raffinate Stream. The raffinate Stream also contains

function as a depentanizer Separating the entering hydrocar Cs hydrocarbons which previously occupied the Void spaces

bons into a net overhead Stream, which comprises mainly Cs of the adsorbent bed(s) through which it has passed. This is

hydrocarbons, removed through line 16 and a net bottoms 60 deSorbent left from the previous Step in the Separation cycle.

stream which is removed through line 3 which comprises the The raffinate Stream is passed into a third fractionation Zone

remaining hydrocarbons of the feedstream. It is undesirable 11, referred to in the art as the raffinate column. The raffinate

for Cs hydrocarbons to be part of the bottoms stream as this Stream is separated in column 11 into a net overhead Stream

would interfere with the use of Cs hydrocarbons as of line 13 and a bottoms stream of line 12 referred to as the

deSorbent, and it is also quite undesirable for C-plus 65 raffinate product Stream. The overhead Stream is rich in Cs

hydrocarbons to be part of the overhead stream. It is hydrocarbons and is recycled to the adsorptive Separation

therefore desired to perform a good Separation of these Zone 4 as desorbent. The bottoms Stream comprises an

US 6,407.301 B1

S 6

admixture of non-normal paraffins, aromatics and naph ducing ethylene, which process comprises passing a process

thenes and is passed into a catalytic reforming Zone 17 for feed Stream comprising Cs through C hydrocarbons

the production of high octane motor fuel components including Cs through C normal paraffins and Cs through

removed from the process via line 20. C non-normal paraffins into a first fractionation Zone, and

AS with most integrations of Several process units, there Separating the hydrocarbons entering the first fractionation

are numerous optional variations. For instance, line 22 can Zone into a first process stream rich in Cs paraffins and a

be employed to pass all or a portion of the extract Stream of Second process Stream comprising C through C hydro

the adsorption Zone 4 directly to the Steam cracking Zone 8. carbons, passing the Second process Stream into an adsorp

This is an optional procedure, but it is very beneficial and is tion Zone of an adsorptive Separation Zone operated at

a preferred practice if there is Sufficient Cs material in the adsorption conditions, and Selectively retaining normal par

feed stream of line 1 to allow the rejection of Cs hydrocar affins on a quantity of an adsorbent located in the adsorption

bons in this manner. The passage of the entire extract Stream Zone to yield a raffinate Stream comprising Cs normal

directly from the adsorption Zone to the cracking Zone paraffins and non-normal C through C hydrocarbons;

Significantly reduces the cost of the overall process. It passing the first proceSS Stream into a desorption Zone,

eliminates the capital and operating expense of the extract 15 operated at desorption conditions, of the adsorptive Separa

column of the prior art SMB adsorptive separation Zones. tion Zone as at least part of a desorbent Stream, and removing

The cost of constructing and operating this column is normal paraffins from adsorbent present in the desorption

Significant, and its elimination results in a lower cost pro Zone to yield an extract Stream comprising C through C

ceSS. The passage of all or a portion of the extract directly normal paraffins and Cs paraffins, Separating the raffinate

into the ethylene cracking Zone is possible because the Stream in a Second fractionation Zone into a third process

desorbent material is primarily, normally about 85%, normal Stream comprising Cs paraffins and a fourth proceSS Stream

paraffins and thus is a good feed material for the cracking comprising C through C non-normal paraffins; and pass

ZOC. ing at least a portion of the extract Stream directly into a

The application of the Subject invention to a petroleum Steam cracking Zone operated at Steam cracking conditions

refinery having existing catalytic reforming and cracking 25 and producing ethylene.

units which derive their feed from the same Source can cause Each of the fractionation Zones employed in the process

aimbalance in the available feed to the reforming Zone. This preferably comprises a Single fractional distillation column.

is because it is necessary to make up for the removal of the The fractionation or splitting of the various process Streams

non-normals from the feed stream of line 1. That is, it is can, however, be performed in other Suitable equipment if

necessary to increase the flow rate of line 1 to balance out desired. AS noted earlier, the complete recovery of Cs

the removal of non-normal hydrocarbons in Zone 4 and hydrocarbons, or other light hydrocarbon, overhead from all

maintain the Same charge rate through line 7 to the cracking three fractionation Zones will result in a Surplus of Cs

Zone. With a normal distribution of hydrocarbon species this hydrocarbons and a need to draw Some of them out of the

increases the amount of C-plus feed generated for the process. An alternative is to allow Some of the Cs hydro

reforming unit. To counteract this it is preferred to fraction 35 carbons to exit the process in the extract and or raffinate

ate the raffinate Stream of line 12 to remove C and C7 Streams. This can be done by adjustment of the operation of

acyclic paraffins. This can be accomplished by passing the the fractionation Zones or by the use of an inherently leSS

raffinate product Stream into an optional fractional distilla exact separation. The use of a simple flash Zones or of a

tion column 24. The function of this column is to remove the refluxed flash Zone is one example of this optional alterna

lighter C. hydrocarbons and optionally Some or all C7 40 tive Cs rejection technique. This not only directs this light

hydrocarbons. All of the C hydrocarbons are removed in material to a Suitable hydrocarbon consuming process, but

this manner, but the fractionation is preferably adjusted to also reduces the Overall capital and operating costs of the

allow C7 naphthenes to remain in the feed to the reforming feed preparation, thus helping to achieve the objectives of

Zone. This degree of hydrocarbon removal has been deter the invention.

mined Sufficient to normally counteract the increased rate of 45 The Separation Step of the Subject proceSS can be per

reformer feed generated by the overall process. This addi formed in a Single large bed of adsorbent or in Several

tional fractionation has Synergistic effects. The C-C-7 mate parallel beds on a Swing bed basis. However, it has been

rial which is removed is normally good quality gasoline found that Simulated moving bed adsorptive Separation

blending Stock without further processing. In addition, the provides Several advantages Such as high purity and recov

remaining C7-plus material is an even better reforming feed 50 ery. Therefore, many commercial Scale petrochemical Sepa

than the prior art C-plus material. The overall performance rations especially for the recovery of mixed paraffins are

of the reforming Zone is thus also improved in terms of performed using Simulated countercurrent moving bed

octane number and yield loSS. (SMB) technology. The previously sited references are

Zone 17 is a catalytic reforming Zone, but could alterna incorporated for their teaching on the performance of this

tively be an aromatization Zone. Catalytic reforming is 55 process. Further details on equipment and techniques for

described in Part 4 of Handbook of Petroleum Refining, 2" operating an SMB process may be found in U.S. Pat. Nos.

edition, by Robert A. Meyers, McGraw Hill, 1996. The 3,208,833; 3,214,247; 3,392,113; 3,455.815; 3,523,762;

reforming Zone may employ a catalyst comprising platinum 3,617,504; 4,006, 197; 4,133,842; and 4,434,051. A different

and tin on alumina or platinum on a Zeolite, Such as type of Simulated moving bed operation which can be

L-Zeolite. This catalyst may be retained in fixed, moving or 60 performed using Similar equipment, adsorbent and condi

fluidized beds or a combination of these reactor types. tions but which simulates cocurrent flow of the adsorbent

Further information is provided in U.S. Pat. Nos. 6,001,241; and liquid in the adsorption chambers is described in U.S.

6,013,173 and 6,036,845. All four of these references are Pat. Nos. 4,402,832 and 4,498,991.

incorporated for their description of catalytic reforming. Operating conditions for the adsorption chamber used in

A preferred embodiment of the invention, incorporating 65 the Subject invention include, in general, a temperature

this direct passage of extract to the cracking Zone, may be range of from about 20 to about 250 C., with from about 60

characterized as a hydrocarbon conversion process for pro to about 200 C. being preferred. Temperatures from 90° C.

US 6,407.301 B1

7 8

to 160° C. are highly preferred. Adsorption conditions also position. Volatile-free compositions are generally deter

preferably include a pressure Sufficient to maintain the mined after the adsorbent has been calcined at 900 C. in

process fluids in liquid phase, which may be from about order to drive off all volatile matter. The remainder of the

atmospheric to about 600 psig. Desorption conditions gen adsorbent will generally be the inorganic matrix of the

erally include the same temperatures and pressure as used binder present in intimate mixture with the Small particles of

for adsorption conditions. It is generally preferred that an the Silicalite material. This matrix material may be an

SMB process is operated with an A.F flow rate through the adjunct of the manufacturing proceSS for the Silicalite, for

adsorption Zone in the broad range of about 1:1 to 5:0.5 example, from the intentionally incomplete purification of

where A is the volume rate of “circulation” of selective pore the Silicalite during its manufacture.

volume and F is the feed flow rate. The practice of the Those skilled in the art will appreciate that the perfor

Subject invention requires no significant variation in oper mance of an adsorbent is often greatly influenced by a

ating conditions or desorbent composition within the adsor number of factors not related to its composition Such as

bent chambers. That is, the adsorbent preferably remains at operating conditions, feed Stream composition and the water

the Same temperature throughout the proceSS during both content of the adsorbent. The optimum adsorbent composi

adsorption and desorption. 15 tion and operating conditions for the process are therefore

The adsorbent used in the first adsorption Zone preferably dependent upon a number of interrelated variables. One Such

comprises Silica alumina molecular Sieves having relatively variable is the water content of the adsorbent which is

uniform pore diameters of about 5 angStroms. This is expressed herein in terms of the recognized LOSS on Ignition

provided by commercially available type 5A molecular (LOI) test. In the LOI test the volatile matter content of the

sieves produced by the adsorbents group of UOP LLC, Zeolitic adsorbent is determined by the weight difference

formerly the Linde Division of Union Carbide Corporation. obtained before and after drying a Sample of the adsorbent

A Second adsorbent which could be used in the adsorption at 500 C. under an inert gas purge Such as nitrogen for a

Zone comprises Silicalite. Silicalite is well described in the period of time Sufficient to achieve a constant weight. For the

literature. It is disclosed and claimed in U.S. Pat. No. Subject process it is preferred that the water content of the

4,061,724 issued to Grose et al. A more detailed description 25 adsorbent results in an LOI at 900 C. of less than 7.0% and

is found in the article, “Silicalite, A New Hydrophobic preferably within the range of from 0 to 4.0 wt.%.

Crystalline Silica Molecular Sieve,” Nature, Vol. 271, Feb. An important characteristic of an adsorbent is the rate of

9, 1978 which is incorporated herein by reference for its eXchange of the desorbent for the extract component of the

description and characterization of Silicalite. Silicalite is a feed mixture materials or, in other words, the relative rate of

hydrophobic crystalline Silica molecular Sieve having inter desorption of the extract component. This characteristic

Secting bent-orthogonal channels formed with two croSS relates directly to the amount of desorbent material that

Sectional geometries, 6 A circular and 5.1-5.7 A elliptical on must. be employed in the process to recover the extract

the major axis. This gives Silicalite great Selectivity as a size component from the adsorbent. Faster rates of exchange

Selective molecular Sieve. Due to its aluminum free Structure reduce the amount of desorbent material needed to remove

composed of Silicon dioxide Silicalite does not show ion 35 the extract component, and therefore, permit a reduction in

eXchange behavior. Thus Silicalite is not a Zeolite. Silicalite the operating cost of the process. With faster rates of

is also described in U.S. Pat. Nos. 5,262,144, 5,276,246 and eXchange, less desorbent material has to be pumped through

5,292,900. These basically relate to treatments which reduce the proceSS and Separated from the extract Stream for reuse

the catalytic activity of Silicalite to allow its use as an in the process. Exchange rates are often temperature depen

adsorbent. The use of silicalite is not preferred. 40 dent. Ideally, desorbent materials should have a Selectivity

The active component of the adsorbent is normally used equal to about 1 or slightly less than 1 with respect to all

in the form of particle agglomerates having high physical extract components So that all of the extract components can

Strength and attrition resistance. The agglomerates contain be desorbed as a class with reasonable flow rates of desor

the active adsorptive material dispersed in an amorphous, bent material, and So that extract components can later

inorganic matrix or binder, having channels and cavities 45 displace desorbent material in a Subsequent adsorption Step.

therein which enable fluid to access the adsorptive material. U.S. Pat. No. 4,992,618 issued to S. Kulprathipanja

Methods for forming the crystalline powders into such describes the use of a “prepulse' of a desorbent component

agglomerates include the addition of an inorganic binder, in an SMB process recovering normal paraffins. The

generally a clay comprising a Silicon dioxide and aluminum prepulse is intended to improve the recovery of the extract

oxide, to a high purity adsorbent powder in a wet mixture. 50 normal paraffins acroSS the carbon number range of the feed.

The binder aids in forming or agglomerating the crystalline The prepulse enters the adsorbent chamber at a point before

particles. The blended clay-adsorbent mixture may be (downstream) of the feed injection point. A related SMB

extruded into cylindrical pellets or formed into beads which processing technique is the use of "Zone flush.” The Zone

are Subsequently calcined in order to convert the clay to an flush forms a buffer Zone between the feed and extract bed

amorphous binder of considerable mechanical Strength. The 55 lines to keep the desorbent e.g. normal pentane, from

adsorbent may also be bound into irregular shaped particles entering the adsorption Zone. While the use of a Zone flush

formed by Spray drying or crushing of larger masses fol requires a more complicated, and thus more costly rotary

lowed by Size Screening. The adsorbent particles may thus Valve, the use of Zone flush is preferred in the adsorption

be in the form of extrudates, tablets, spheres or granules Zones when high purity extract product are desired. In

having a desired particle range, preferably from about 16 to 60 practice, a quantity of the mixed component desorbent

about 60 mesh (Standard U.S. Mesh) (1.9 mm to 250 recovered overhead from the extract and/or raffinate col

microns). Clays of the kaolin type, water permeable organic umns is passed into a separate splitter column. A high purity

polymers or Silica are generally used as binders. Stream of the lower Strength component of the mixed

The active molecular Sieve component of the adsorbent component desorbent is recovered and used as the Zone flush

will ordinarily be in the form of small crystals present in the 65 Stream. Further information on the use of dual component

adsorbent particles in amounts ranging from about 75 to deSorbents and on techniques to improve product purity Such

about 98-wt.% of the particle based on volatile-free com as the use of flush streams may be obtained from U.S. Pat.

US 6,407.301 B1

9 10

Nos. 3,201,491; 3,274,099; 3,715,409; 4,006,197 and 4,036, Chemical Technology at page 563. The terms “upstream”

745 which are incorporated herein by reference for their and “downstream” are used herein in their normal Sense and

teaching on these aspects of SMB technology. are interpreted based upon the overall direction in which

For purposes of this invention, various terms used herein liquid is flowing in the adsorbent chamber. That is, if liquid

are defined as follows. A “feed mixture' is a mixture is generally flowing downward through a vertical adsorbent

containing one or more extract components and one or more chamber, then upstream is equivalent to an upward or higher

raffinate components to be separated by the process. The location in the chamber.

term “feed Stream' indicates a stream of a feed mixture In an SMB process the Several Steps e.g. adsorption and

which is passed into contact with the adsorbent used in the desorption, are being performed Simultaneously in different

process. An "extract component' is a compound or class of parts of the mass of adsorbent retained in the adsorbent

compounds that is more Selectively adsorbed by the adsor chamber(s) of the process. If the process was being per

bent while a “raffinate component' is a compound or type of formed with more or more adsorbent beds in a Swing bed

compound that is less selectively adsorbed. The term “des System then the StepS may be performed in a Somewhat

orbent material” shall mean generally a material capable of interrupted basis, but adsorption and desorption will most

deSorbing an extract component from the adsorbent. The 15

likely occur at the Same time.

What is claimed is:

term “raffinate stream” or “raffinate output stream” means a 1. A process for preparing a feedstream to be charged to

Stream in which a raffinate component is removed from the a Steam cracking unit producing ethylene, which process

adsorbent bed after the adsorption of extract compounds. comprises:

The composition of the raffinate Stream can vary from a.) passing a process feed stream comprising Cs through

essentially 100% desorbent material to essentially 100% Cohydrocarbons including Cs through Co. normal par

raffinate components. The term “extract stream” or “extract affins into a first fractionation Zone, and Separating the

output Stream” means a stream in which an extract material, hydrocarbons entering the first fractionation Zone into

which has been desorbed by a desorbent material, is a first process Stream rich in Cs paraffins and a Second

removed from the adsorbent bed. The composition of the process Stream comprising C through Co. hydrocar

extract stream can vary from essentially 100% desorbent 25

bons,

material to essentially 100% extract components.

At least portions of the extract Stream and the raffinate b.) passing the Second process stream into an adsorption

Stream are passed to Separation means, typically fractional Zone of an adsorptive Separation Zone and Selectively

distillation columns, where at least a portion of desorbent retaining normal paraffins on an adsorbent located in

material is recovered and an extract product and a raffinate the adsorption Zone to yield a raffinate Stream compris

product are produced. The terms "extract product' and ing non-normal C through Co. hydrocarbons;

“raffinate product” mean Streams produced by the proceSS c.) passing the first process stream into a desorption Zone

containing, respectively, an extract component and a raffi in the adsorptive Separation Zone as at least part of a

nate component in higher concentrations than those found in deSorbent Stream and removing normal paraffins from

the extract stream and the raffinate stream withdrawn from 35 adsorbent present in the desorption Zone to yield an

adsorbent chamber. The extract stream may be rich in the extract stream comprising C through Co. normal par

desired compound or may only contain an increased con affins and Cs paraffins,

centration. The term "rich' is intended to indicate a con d.) Separating the extract Stream in a second fractionation

centration of the indicated compound or class of compounds Zone into a third process Stream comprising Cs paraf

greater than 50 mole percent. 40 fins and a fourth process Stream comprising C through

It has become customary in the art to group the numerous Co normal paraffins; and,

beds in the SMB adsorption chamber(s) into a number of e.) passing the fourth process stream into a cracking Zone

Zones. Usually the process is described in terms of 4 or 5 and producing ethylene.

Zones. First contact between the feed Stream and the adsor 2. The process of claim 1 wherein the third proceSS Stream

bent is made in Zone I, the adsorption Zone. The adsorbent 45 is recycled to the adsorptive Separation Zone as at least part

or Stationary phase in Zone I becomes Surrounded by liquid of Said desorbent Stream.

which contains the undesired isomer(s), that is, with raffi 3. The process of claim 1 wherein the raffinate stream also

nate. This liquid is removed from the adsorbent in Zone II, comprises Cs paraffins, and the raffinate Stream is separated

referred to as a purification Zone. In the purification Zone the in a third fractionation Zone into a fifth process. Stream

undesired raffinate components are flushed from the void 50 comprising Cs paraffins and a heavier Sixth proceSS Stream

volume of the adsorbent bed by a material which is easily comprising non-normal C through Co. hydrocarbons.

Separated from the desired component by fractional distil 4. The process of claim 1 wherein the Second fractionation

lation. In Zone III of the adsorbent chamber(s) the desired Zone comprises a flash or rectified flash Separation Zone.

isomer is released from the adsorbent by exposing and 5. The process of claim 3 wherein at least a portion of the

flushing the adsorbent with the desorbent (mobile phase). 55 Sixth proceSS Stream is passed into a naphtha reforming Zone

The released desired isomer and accompanying desorbent and converted into aromatic hydrocarbons.

are removed from the adsorbent in the form of the extract 6. A hydrocarbon conversion process for producing eth

stream. Zone IV is a portion of the adsorbent located ylene which process comprises:

between Zones I and III which is used to Segregate Zones I a.) passing a process feed stream comprising Cs through

and II. In Zone IV desorbent is partially removed from the 60 C. hydrocarbons including Cs through C normal

adsorbent by a flowing mixture of desorbent and undesired paraffins and Cs through C non-normal paraffins into

components of the feed Stream. The liquid flow through a first fractionation Zone, and Separating the hydrocar

Zone IV. prevents contamination of Zone III by Zone I liquid bons entering the first fractionation Zone into a first

by flow cocurrent to the simulated motion of the adsorbent process Stream rich in Cs paraffins and a Second process

from Zone III toward Zone I. A more thorough explanation 65 Stream comprising C through C hydrocarbons;

of Simulated moving bed processes is given in the Adsorp b.) passing the Second process stream into an adsorption

tive Separation section of the Kirk-Othmer Encyclopedia of Zone of an adsorptive Separation Zone operated at

US 6,407.301 B1

11 12

adsorption conditions, and Selectively retaining normal affins into a first fractionation Zone, and Separating the

paraffins on a quantity of a Selective adsorbent located hydrocarbons entering the first fractionation Zone into

in the adsorption Zone to yield a raffinate Stream a first process stream rich in Cs paraffins and a second

comprising Cs normal paraffins and non-normal C process Stream comprising C through Co. hydrocar

through C hydrocarbons, bons,

c.) passing the first process stream into a desorption Zone, b.) passing the Second process stream into an adsorption

operated at desorption conditions, of the adsorptive Zone of an adsorptive Separation Zone and Selectively

Separation Zone as at least part of a desorbent Stream,

and removing normal paraffins from adsorbent present retaining normal paraffins on an adsorbent located in

in the desorption Zone to yield an extract Stream the adsorption Zone to yield a raffinate Stream compris

comprising C through C normal paraffins and Cs ing non-normal C through Co. hydrocarbons,

paraffins, c.) passing the first process stream into a desorption Zone

d.) Separating the raffinate stream in a second fraction in the adsorptive Separation Zone as at least part of a

ation Zone into a third proceSS Stream comprising Cs 15 deSorbent Stream and removing normal paraffins from

paraffins and a fourth process stream comprising C adsorbent present in the desorption Zone to yield an

through C non-normal paraffins, and, extract Stream comprising C through Co normal par

e.) passing at least a portion of the extract stream directly affins and Cs paraffins,

into a Steam cracking Zone operated at Steam cracking

conditions and producing ethylene. d.) Separating the extract Stream in a second fractionation

7. The process of claim 6 further characterized in that the Zone into a third process Stream comprising Cs paraf

first process stream comprises both Cs normal paraffins and fins and a fourth process Stream comprising C through

Cs isoparaffins. Co normal paraffins, and,

8. The process of claim 6 further characterized in that the e.) passing the fourth process stream into a cracking Zone

fourth process Stream is passed directly into a catalytic 25 and producing ethylene,

naphtha reforming Zone.

9. The process of claim 6 wherein the third process stream f) Separating at least a portion of the raffinate stream in a

is recycled within the proceSS as at least a part of the third fractionation Zone into a fifth process Stream

deSorbent Stream. comprising Chydrocarbons and a sixth proceSS Stream

10. A process for preparing the feedstreams to a catalytic comprising C7-Co non-normal hydrocarbons, and

reforming Zone and to a Steam cracking unit producing g.) passing the Sixth process stream into a catalytic

ethylene, which process comprises: reforming Zone operated at reforming conditions.

a.) passing a proceSS feed Stream comprising Cs through

Cohydrocarbons including Cs through Co. normal par

You might also like

- New Text DocumentDocument3 pagesNew Text DocumentHazeq AzaharNo ratings yet

- Kolo TororitaDocument3 pagesKolo TororitaHazeq AzaharNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentHazeq AzaharNo ratings yet

- A Do Bex ML Forms SamplesDocument10 pagesA Do Bex ML Forms SamplesMuvindu Yahampath MakaveliNo ratings yet

- UpDocument2 pagesUpHazeq AzaharNo ratings yet

- New Text DocumentDocument4 pagesNew Text DocumentHazeq AzaharNo ratings yet

- Start-Up Cost: (1 To 1.5 PAGES)Document3 pagesStart-Up Cost: (1 To 1.5 PAGES)Hazeq AzaharNo ratings yet

- Untitled Document PDFDocument1 pageUntitled Document PDFHazeq AzaharNo ratings yet

- 2 in 1 Correction Highlighter With Pen: Problem/IssuesDocument1 page2 in 1 Correction Highlighter With Pen: Problem/IssuesHazeq AzaharNo ratings yet

- Process Design Site Selection PDFDocument1 pageProcess Design Site Selection PDFHazeq AzaharNo ratings yet

- UpDocument2 pagesUpHazeq AzaharNo ratings yet

- UpDocument2 pagesUpHazeq AzaharNo ratings yet

- United States Patent (10) Patent No.: US 8.471,082 B2Document10 pagesUnited States Patent (10) Patent No.: US 8.471,082 B2Hazeq AzaharNo ratings yet

- UpDocument2 pagesUpHazeq AzaharNo ratings yet

- UpDocument2 pagesUpHazeq AzaharNo ratings yet

- FOOD IRRADIATION BENEFITS AND QUALITY IMPACTSDocument25 pagesFOOD IRRADIATION BENEFITS AND QUALITY IMPACTSChilmy Coklat SusuNo ratings yet

- UpDocument2 pagesUpHazeq AzaharNo ratings yet

- UpDocument2 pagesUpHazeq AzaharNo ratings yet

- Tutorial Network Optimization - Loop & PathDocument2 pagesTutorial Network Optimization - Loop & PathHazeq AzaharNo ratings yet

- Us 6407301Document8 pagesUs 6407301Hazeq AzaharNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentHazeq AzaharNo ratings yet

- R. E. S. H.E.H.S: (12) United States Patent (10) Patent No.: US 6, 177,600 B1Document11 pagesR. E. S. H.E.H.S: (12) United States Patent (10) Patent No.: US 6, 177,600 B1Hazeq AzaharNo ratings yet

- HuhuhihiDocument4 pagesHuhuhihiHazeq AzaharNo ratings yet

- CPE 614 Assignment 1 Pinch Technology AnalysisDocument2 pagesCPE 614 Assignment 1 Pinch Technology AnalysisHazeq AzaharNo ratings yet

- HuhuhihiDocument1 pageHuhuhihiHazeq AzaharNo ratings yet

- Stress, Strain and Relation ExerciseDocument7 pagesStress, Strain and Relation ExerciseHazeq AzaharNo ratings yet

- Time Fe 11022016Document2 pagesTime Fe 11022016Hazeq AzaharNo ratings yet

- 5 Freezing As Low Temperature Cold Processing Preservation MethodDocument26 pages5 Freezing As Low Temperature Cold Processing Preservation MethodHazeq AzaharNo ratings yet

- Experiment 6 - Kla DeterminationDocument4 pagesExperiment 6 - Kla DeterminationHazeq AzaharNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Activated CarbonDocument34 pagesActivated CarbonSanjeeva YedavalliNo ratings yet

- Experiment 8 ElectrochemistryDocument4 pagesExperiment 8 ElectrochemistryRhett Adrian Seduco0% (1)

- Final Product 7 Learning Cycles - 6th Grade MatterDocument46 pagesFinal Product 7 Learning Cycles - 6th Grade Matterapi-310725472No ratings yet

- Ipacs - Report - Thermal Properties of Concrete PDFDocument23 pagesIpacs - Report - Thermal Properties of Concrete PDFRodrigo LameirasNo ratings yet

- Bond Length: Measuring the Average Distance Between Atoms in a Covalent BondDocument9 pagesBond Length: Measuring the Average Distance Between Atoms in a Covalent BondMiteigiNo ratings yet

- Report Gas Adsorption Refrigeration Unit - 2020452596 - Eh2436Document7 pagesReport Gas Adsorption Refrigeration Unit - 2020452596 - Eh2436Nurul Syahida SyafikaNo ratings yet

- Indian Oil's Petrochemical Initiatives at Paradip & Downstream OpportunitiesDocument26 pagesIndian Oil's Petrochemical Initiatives at Paradip & Downstream Opportunitiesabhishek chowdhuryNo ratings yet

- Applications of Isotopes C11!3!01&C11!3!02Document12 pagesApplications of Isotopes C11!3!01&C11!3!02Olivia M OliverNo ratings yet

- Alimentos Funcionais em UanDocument12 pagesAlimentos Funcionais em UanEduardo MartinsNo ratings yet

- Predator Engine 69733Document20 pagesPredator Engine 69733Robin HughesNo ratings yet

- High Temp Grease Technical Data SheetDocument2 pagesHigh Temp Grease Technical Data SheetErickNo ratings yet

- Effects of Doping Yb3 - La3 - Ti4 - Hf4 - Ce4 Cations On - 2019 - Journal of ADocument13 pagesEffects of Doping Yb3 - La3 - Ti4 - Hf4 - Ce4 Cations On - 2019 - Journal of Ahk esatonNo ratings yet

- ReasoningDocument43 pagesReasoningrajkh0786No ratings yet

- Hemoglobin Oxidation-Reduction BiochemistryDocument5 pagesHemoglobin Oxidation-Reduction BiochemistryYasmine AzzackiyahNo ratings yet

- ST TLE Agri. Crop Production 7 NO. 1Document3 pagesST TLE Agri. Crop Production 7 NO. 1Vince Zoi Galvan100% (1)

- Bollhoff HeliCoil Plus ImperialDocument48 pagesBollhoff HeliCoil Plus ImperialAce Industrial SuppliesNo ratings yet

- 2010 Proportional CatalogDocument16 pages2010 Proportional CatalogjondesousaNo ratings yet

- Common polyatomic ions and their formulasDocument16 pagesCommon polyatomic ions and their formulasskyline aviationNo ratings yet

- Lecture 2 - Clinical and Lab Steps - Preliminary Impression-Preliminary Cast (3.03)Document42 pagesLecture 2 - Clinical and Lab Steps - Preliminary Impression-Preliminary Cast (3.03)Ioachim FriedmannNo ratings yet

- Chapter 8Document44 pagesChapter 8Oscar Espinosa BonillaNo ratings yet

- Rotamat® Rok 4 Pumping Stations Screen: WasteDocument4 pagesRotamat® Rok 4 Pumping Stations Screen: WastecrvenicajNo ratings yet

- Physical Properties of SolutionDocument3 pagesPhysical Properties of SolutionRhye Tabaday LopezNo ratings yet

- Dow Carbowax PEGs PDFDocument12 pagesDow Carbowax PEGs PDFMattNo ratings yet

- Latitude Travel Iron: Instructions For UseDocument9 pagesLatitude Travel Iron: Instructions For UseNickNo ratings yet

- Objectives Identify The Two Main Classes of Vitamins. List Seven Minerals Your Body Needs inDocument28 pagesObjectives Identify The Two Main Classes of Vitamins. List Seven Minerals Your Body Needs inyosysilalahiNo ratings yet

- Hardness Desalination1Document18 pagesHardness Desalination1Swati U NaikNo ratings yet

- Cast Steel-Sic Composites As Wear Resistant Materials: Dejan ČikaraDocument5 pagesCast Steel-Sic Composites As Wear Resistant Materials: Dejan ČikaraAna MijatovicNo ratings yet

- Product Information Sheet: Phytotechnology Laboratories®Document1 pageProduct Information Sheet: Phytotechnology Laboratories®Jiovanni AmbNo ratings yet

- 16 ACC Issues and ConcernsDocument11 pages16 ACC Issues and ConcernsShivakumarNo ratings yet

- Queen's University - Mining Engineering - ListDocument3 pagesQueen's University - Mining Engineering - ListNitinkiet103No ratings yet