Professional Documents

Culture Documents

Art 20164655

Uploaded by

Vinod yadavOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Art 20164655

Uploaded by

Vinod yadavCopyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

Experimental Analysis of the Cooling of a

Motorcycle Helmet by Using Phase Change

Material with Forced Convection

Vinod Yadav1, Awadhesh Kumar Yadav2, Nishant Kumar Srivastava3, Pravesh Kumar Srivastava4,

Suresh Kumar Gigoo5

1, 2, 3, 4, 5

Mechanical Engineering Department, Rajarshi Rananjay Sinh Institute of Management and Technology,

Amethi (U.P.),227405, India

Abstract: This paper presents an experimental analysis of the cooling of a motorcycle helmet with the help of phase change material

(PCM) and using air flow circulation through the surface of the phase change material. The heat produced by the head of the wearer is

absorbed and stored by phase change material and stored heat is thrown out with the help of air circulation in the helmet. In this PCM

is placed between the head of the wearer and helmet metal shell. Thus the heat produced by head of the wearer and heat in the helmet

metal shell due to atmospheric high temperature and expanded polystyrene foam (EPF) will be absorbed by the PCM but to increase

the duration of working of the PCM, here we implement the method of forced convection by the installing two fan which removed the

inside heat of the helmet and extend the working time of the PCM. This maintains the wearer head temperature nearly melting point of

PCM temperature and protects the wearer head from discomfort and hot environment. If only PCM will be used then the cooling iis

achieved for few hours only when the PCM is completely melted.

Keywords: Phase change material; Helmet metal shell; Expanded polystyrene foam; Melted

1. Introduction material is also included. Phase change material is absorbing

all the heat of head at a constant temperature by changing its

The motorcycle helmet is used by motorcycle riders. The phase and providing

providing cooling

coolingtotothe

thewearer’s

wearer’shead.

head.The

ThePCM

PCM

main objective of a motorcycle helmet is to provide safety to is placed between the head and helmet. Initially, the PCM is

the rider’s

rider’shead

headduring impact

during [1]. Modern

impact helmets

[1]. Modern are are

helmets in a solid state. When the temperature inside the helmet

generally made from plastics, reinforced with Kevlar or reaches above the melting point temperature of PCM it starts

carbon fiber. Basically, helmet contains two layers of melting by absorbing the heat of the head. But the drawback

protection i.e. outer shell and inner shell, outer shell made of of this system is that it is effective only for nearly two hours

acrylonitrile butadiene styrene (ABS) plastic, fiberglass or (Climsel C28) i.e. its capacity to store the heat is only for

Kevlar and inner shell contains inner liner about one-inch nearly two hours. After Afterevery twotwo

every hourshours

it’s needed

it’s needed

thickness made of EPS “Expanded Polystyrene Foam” and an discharging of stored heat to the ambient. The PCM weight is

outer shell which protects the EPS. An outer shell is used to also an important factor in cooling [7]. To overcome from

prevent puncture of the helmet by any sharp object and to this problem we installed two fans (inlet and exhaust) which

hold the EPS, it is used to absorb the crush during an impact. increase the working duration of the PCM by removing the

The acrylonitrile butadiene styrene (ABS) causes heating interior heat of the helmet [5].

inside the helmet because it acts as insulation and restricts the

transfer of heat from the interior to the outside of the wall. 2. Materials and Methods

This causes discomfort and danger to the rider because the

temperature in the interior of the helmet increases up to 37 to For storage of heat, PCM is a very effective material which

38 C. Due to this, the physiological and psychological effect stores the heat by changing its phase because much higher

on the rider takes place. This causes the deadening of the energy is needed during the phase change. PCM have a

senses and rider loosed its ability to concentrate [2]. As specific phase change temperature for different uses. The use

compared to another body, the head has high skin of PCM materials is depending upon its melting temperature,

temperature because it has highest skin temperature as well freezing temperature, latent heat, liquid thermal conductivity

as large constant volume blood flow [3]. For the comfort of and solid thermal conductivity. In this experiment savER

the head around 34.5 C temperature is required. In hot HS29 are used. savER Phase change materials are organic or

climate condition temperature inside helmet may reach up to inorganic chemical compounds that have a large amount of

45 C if there is no wind and hypothermia can be induced [4]. heat energy stored in the form of latent heat. The PCM

Hence it is necessary to maintain the interior temperature of retains its latent heat without any change in physical or

helmet around the body temperature. So for cooling of the chemical properties over thousand of cycles. Various specific

head, additional features are provided in the helmet like temperatures PCM" are commercially available varying

ventilation for air flow, but this phenomenon is not very between -35 C to 90 C depending upon the applications.

effective in ordinary motorcycle it is effective in racing

motorcycle. Therefore an alternative is required for the

cooling of the helmet in which using of phase change

Volume 6 Issue 1, January 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20164655 2270

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

PCM so that it’s melting temperature is only 7 to 8 C below

the body temperature and non-toxic in nature. One of the

problems regarding the PCM is that when it solidifies it

occupies more space than in liquid state. Hence the size of

the PCM pouch should be large when PCM is in a liquid

state. In this Solid to liquid PCM is used.

In this paper, the main focus is on how to increase the

working time of the PCM by selecting suitable PCM and

changing the interior design of the helmet. Casing of PCM

pouch and heat collector is placed inside of the expanded

polystyrene foam (EPF) between the helmet shell and head of

the wearer.

2.2 Heat collector

For transfer of heat firstly collect the heat released by a head

in a collector so that it is easy to transfer the heat from head

to the PCM pouch. The collector is made up of copper wire

so that it will transfer the maximum amount of heat which is

released by head due to high thermal conductivity of copper

as compared to other materials in respect of their cost. The

heat collector is made of light flexible braided copper wire so

that it is installed easily along the curvature of the helmet and

Figure 1: Classification of PCM head.

The major component of the PCM-cooled helmet includes:

Copper heat collector, casing made of copper, PCM, copper

pipe as outside/inside air channel, electric fan for an air

pump, 12v battery and heat sink with built in electric fan. The

PCM-cooled helmet is designed so that temperature of the

head is maintained near about 30 C. It is designed to increase

the working duration of PCM with transfer of heat by

circulating air inside the casing where PCM is placed and for

air flow we are using two fans, one is for suction of air and

other for the exhaust [6]. The portion of heat collector which

is made of copper for better heat transfer is in direct contact

with the head and absorbing the heat produced by head and

transfers it to the PCM. To hold the PCM, a casing of copper

is fabricated so that transfer of heat takes place effectively to

the PCM and some of the heat also removed by circulation of

air through fan. For suction of air from outside to the casing

of the PCM, double effect pipe is used to feed the air in and

out with the help of suction and exhaust the fan. Both of the Figure 2: Heat Collector

fans are installed at the back side of the helmet and it is

connected with casing with the help of pipe for air So that it easily gets fitted on the head of the wearer and due

circulation. 12 V batteries are used for running of the fan. It to mesh like structure of light and soft copper wire provides a

helps in the feeding of air directly into the helmet. Thus, a comfortable interior for the head to fit in.

higher cooling rate is achieved.

2.3 PCM pouch and its casing

2.1 Conceptual Design of PCM-cooled helmet

The PCM which is used in this research paper is savER HS

In a PCM-cooled helmet, basic component is PCM pouch. 29 is an organic chemical-based PCM having nominal

The problem of overcooling will not occur in a case of PCM freezing and melting temperature of 29 C. It stores thermal

cooling because it maintains the head temperature near the energy as latent heat in its crystalline form. On changing

melting point of the PCM and the head skin temperature will phase this latent heat is released or absorbed, allowing the

never go below the melting temperature of the PCM. While ambient temperature within the systems to be maintained.

in a case of thermoelectric cooling, it causes sensational

overcooling on the head. Due to which rider losing his Technical specification of PCM

concentration and there is also chances of an accident. Hence Series: HS29

for the cooling on the head selection of good PCM material is

important. To avoid overcooling of the head select such a

Volume 6 Issue 1, January 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20164655 2271

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

Description: Mixture of Cacl2 and other salts Hence to increase the duration time of the PCM set up of

Appearance: Grey liquid suspension above 30 C inlet and exhaust fan is mounted on the helmet shown in

fig.6. Due to transfer of air through the inlet fan, the air

HS29 is chemically and thermally stable by using proprietary carries the heat from the PCM and rejects it through the

additives. This is a blend of various organic fatty acids exhaust fan. For running of fan 12 v battery is used which

suspended in the matrix of polymers. The enthalpy graph of supplied the power to fan. As shown in fig. 4 it is exhausting

PCM HS29 in air bath with respect to temperature is shown fan and on reversing its direction it acts as inlet fan. In fig. 5

in graph fig.3. set up of inlet and exhaust fan which is connected to casing

with the help of pipe for air flow.

Figure 3: Enthalpy Graph of HS29

Figure 5: Fan after mounting on helmet

To hold the PCM with air flow circulation there is the

requirement of such a casing which will carry the PCM with 3. Theoretical and Experimental Analyses of

the hole in a casing so that air can be circulated by Cooling of Helmet

connecting the fan with the hole of casing through the pipe.

The Casing is made of copper metal so that higher heat Analysis of motorcycle helmet can be done by following

transfer rate can be achieved so that maximum heat can be methods i.e. theoretical analysis and experimental analysis of

transfer to the PCM for better cooling effect while a large cooling of the motorcycle helmet.

area of the PCM surface is mainly in contact with the heat

collector. In the figure, from the casing, the middle portion is 3.1 Theoretical analysis of cooling of motorcycle helmet

cut out and removed so that direct contact of heat collector to

the PCM can be made for increasing the rate of heat transfer This helmet consist of three layers outer layer which is

from heat collector to PCM. PCM is placed in the casing in exposed to the atmosphere is the metal shell, foam, PCM

such a way so that air can circulate around the PCM pouch then heat collector are consequently the inner layer as

effectively and prevent its leakage from the casing to heat shown in fig.8

collector because air resists the rate of heat transfer which

reduces the effect of cooling.

2.4 Fan and its casing

PCM will the heat by changing its phase however the

limitation of some of the PCM material like Climsel C28 is

that they store heat only for about 2 hours [8] because after

two hour its reaches at saturation state and further it will not

absorb heat.

Figure 6: Cross-section of the helmet showing the PCM

pouch and heat collector

Figure 7: Heat flows through thermal resistance

Fourier law of heat conduction is used to evaluate the value

Figure 4: Set-up of fan with casing of the temperature of wearer’s head theoretically. First,

Volume 6 Issue 1, January 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20164655 2272

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

second and third equation shows the resistance of the shell 3.2.2 After completing the first stage we placed the PCM

(metal shell), foam and collector while fourth and fifth shows inside the helmet and took the readings without starting the

the heat transfer. fan. Now recorded the value of the inside thermocouple

placed on the wearer’s head by increasing the temperature of

the thermocouple placed on the top of the outer surface of the

helmet when the intensity of heat is increasing by increasing

the power of the halogen with the help of regulator.

From equation (5) the temperature of the wearer’s head after

using the PCM can be determine [8].

3.2 Experimental analysis of cooling of motorcycle

helmet

In the experimental set-up, PCM is absorbing the heat of

wearer’s head as well as the hot ambient air around the

helmet which get heated up due to heating of metal shell

which is direct exposed to sun rays. Testing of helmet is Figure 9: Experimental set-up of testing of helmet

completed in three phase:-

Table 2: Thermocouple reading with PCM and without fan

3.2.1 Inn first phase temperature of wearer’s head is

measured without PCM inside helmet and fan. For Thermocouple Placed on Thermocouple placed on the head

measuring the temperature four thermocouples are placed, top surface of helmet with of the wearer with PCM and

one of the thermocouples is placed at the top of the helmet PCM and without fan without fan

to measure surface temperature (T 1) of the helmet while the T1(C) T2(C) T3(C) T4(C)

other three are placed on the head of the wearer to measure 35.7 31.3 31.4 32.1

40.1 31.9 32.4 32.9

the temperature of head when he wears the helmet i.e. T 2, 45.0 32.0 32.7 33.1

T3 and T4. Atmospheric Temperature measured is C. After

wearing of helmet Temperature is measured from readings

of the thermocouples are:

T1 = 29.5 C placed on the surface of the helmet.

T2 = 36.4 C, T3= 36.5 C, T4= 37 C

Table 1: Thermocouple reading without PCM and fan

Thermocouple Placed on Thermocouple placed on the head

top surface of helmet with of the wearer without PCM and

PCM and without fan fan

T1(C) T2(C) T3(C) T4(C) Figure 10: Helmet outer surface (T1) and inner surface

29.5 36.4 36.5 37 temperature (T2, T3 & T4) with PCM and without fan

The result shows that when PCM is used then inside

temperature of the helmet is less than without PCM.

3.2.3 In this we switched on the fan and record the reading.

As shown in the table temperature is nearly constant means

increasing with the little margin with increasing the outer

temperature at large scale.

Figure 8: Helmet outer surface (T1) and inner surface

temperature (T2, T3 & T4) without PCM and the fan

Volume 6 Issue 1, January 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20164655 2273

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2015): 78.96 | Impact Factor (2015): 6.391

Table 3: Thermocouple reading with PCM and fan with forced convection on the cooling of the helmet. PCM

Thermocouple Placed on

Thermocouple placed on the head of

material having melting temperature of 29 C is used for

top surface of helmet with controlling the inside temperature of the helmet. However to

the wearer with PCM and fan

PCM and fan extend the working duration of PCM here forced convection

T1 (C) T2(C) T3(C) T4(C) phenomenon is used by with the help of inlet and exhaust fan.

56.0 32.5 34.4 33.2 Which will extract the heat from inside of the helmet and it

60.2 33.7 35.1 34.1

will increases the melting duration of the PCM.

65.7 34.9 35.8 35.1

References

[1] Bicycle Helmet Safety Institute, Bicycle Helmet Cooling,

an article on <www.bhsi.org>, last revised on 2 January

2005.

[2] Yigit Sezgin, Murat Celik, PCM-cap to provide thermal

comfort for the human head, Extreme Physiol. Med. 4

(Suppl. 1) (2015) A81.

[3] K.C. Parsons, Human Thermal Environments, Taylor and

Francis, 1993.

[4] Gowtham Vigneswaran, L. Arulmurugan, “Improving

Thermal Comfort in Industrial Safety Helmet using Phase

Figure 11: Helmet outer surface (T1) and inner surface Change Material” ISSN 2319-8885 Vol.03,Issue.04,

temperature (T2, T3 & T4) with PCM and the fan April-2014, Pages:0712-0715.

[5] Fresh Air Systems Technologies, Helmet Conversions and

4. Result Air Flow Improvement, an article on

<www.fastraceproducts.com/fresh_air_systems_helmet_c

This paper presented the experimental analysis of testing of onversions.htm>, 2005.

the helmet in three stages [6] Saud Ghani, Esmail Mohame Ali Ahmed ElBialy, Foteini

a) First testing is completed without PCM and the fan, which Bakochristou, Seifelislam Mahmoud Ahmad Gamaledin,

shows that inside temperature of the helmet, is increases Mohammed Mohammed Rashwan, “The “ effect of forced

from 6 to 7 C shown in fig. 8 than atmospheric temperature convection and PCM on helmets thermal performance in

which is also the surface temperature of the helmet. hot and arid environments”, 2016.

When PCM will be installed inside the helmet then the

b)When [7] Roger Masadi, Robert F. Kinney, “Evaluation of Five

temperature of the wearer’s head increases at very low rate Commercial Microcimate Cooling Systems for Military

as shown in fig. 11 while the temperature in inner surface Use” United States Army Natick Research, Development

is also lower than if we compared it to the previous testing 2

and Engineering Center, 1991, pp. 2–8, doi:01760-5000.

this shows that PCM is absorbing the heat and maintaining [8] F.L. Tan, S.C. Fok”, “Cooling of the helmet with phase

the temperature close to the melting point of the PCM due change material”. Appl. Therm. Eng. 26 (17–18)

(17– (2006)

to its phase change capacity. PCM will absorb the heat by 2067–2072,http://dx.doi.org/10.1016/j.applthermaleng.

changing its phase at constant temperature. In the result of 2006.04.022.

the experiment, it shows that the temperature of the

wearer’s head inside helmet in which PCM is placed is Author Profile

lowered up to 5 to 6 C than that of the helmet without

PCM. Vinod Yadav received the B.Tech. degree from

c) When the inlet and exhaust fan is started then it removes Maharana Pratap Engineering College in 2009 and

the inside heat of the helmet with forced convection M.Tech degree from Kamla Nehru Institute of

Technology in 2014 in Mechanical Engineering. He

process resulting in that wearer head temperature increases

now with Rajarshi Rananjay Sinh Institute of Management &

only 2 to 3oC when the surface temperature of the helmet Technology.

reaches 55 to 65oC.

Pravesh Kumar Srivastava received B.E. degree from

On comparing the temperature of thermocouples in fig. 8, 10 Oriental Institute of science & Technology in 2005 and

and 11 it shows that the thermocouple temperature T 1 is M.Tech. in Thermal Engineering from Sam

lower than other thermocouple temperature T 2, T3 & T4. Hagginbottom Institute of Agriculture, Technology &

While in fig. 10 and 11 value of T1 is greater than other Sciences. He now with Rajarshi Rananjay Sinh Institute of

thermocouple which are T2, T3 & T4, and they measure the Management & Technology.

temperature of the thermocouple which is placed on the

Nishant Kumar Srivastava received B.E. degree from

wearer head. From the fig. 11 it shows that the working

Bhopal Institute of Technology & science in 2007 and

duration of the PCM will increased. M.Tech in Mechanical Engineering. He now with

Rajarshi Rananjay Sinh Institute of Management &

5. Conclusion Technology.

An analysis has been carried out to study the effect of PCM

Volume 6 Issue 1, January 2017

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20164655 2274

You might also like

- 7.helmet Paper SoftDocument16 pages7.helmet Paper SoftVivek AnandanNo ratings yet

- Naveen 123Document13 pagesNaveen 123NAVEEN CHUNCHURENo ratings yet

- paraffin with graphene industuel helmotz 2019Document10 pagesparaffin with graphene industuel helmotz 2019hajar.hafsNo ratings yet

- 1 s2.0 S1364032123009218 MainDocument20 pages1 s2.0 S1364032123009218 MainGunashekar KalluriNo ratings yet

- 2a-18 Phase Change MaterialDocument14 pages2a-18 Phase Change MaterialMaheshNo ratings yet

- Conceptual Design of Motor Cycle Helmet To Meet The Requirement of Thermal Comfort, Ergonomics and SafetyDocument7 pagesConceptual Design of Motor Cycle Helmet To Meet The Requirement of Thermal Comfort, Ergonomics and SafetySohail KhanNo ratings yet

- A Review On Phase-Changing Material in Battery Management SystemsDocument7 pagesA Review On Phase-Changing Material in Battery Management SystemsIJRASETPublicationsNo ratings yet

- The Thermal Protection and Comfort Properties of Aerogel and PCM-coated Fabric For Firefighter GarmentDocument15 pagesThe Thermal Protection and Comfort Properties of Aerogel and PCM-coated Fabric For Firefighter GarmentHea TherNo ratings yet

- (D) PCM Cooling Vest For Improving Thermal Comfort in Hot EnvironmentDocument14 pages(D) PCM Cooling Vest For Improving Thermal Comfort in Hot EnvironmentMuhammad Salman100% (1)

- A Review Paper On Gas Turbine Blade Cooling MethodsDocument6 pagesA Review Paper On Gas Turbine Blade Cooling MethodsEditor IJTSRDNo ratings yet

- CFD Analysis of An IC Engine With and Without GrooveDocument12 pagesCFD Analysis of An IC Engine With and Without GrooveIJRASETPublicationsNo ratings yet

- Test Methods R Keep in Mind: From Fibre To Smart Textiles For Thermal Properties A ConclusionDocument2 pagesTest Methods R Keep in Mind: From Fibre To Smart Textiles For Thermal Properties A Conclusiondavide galbiatiNo ratings yet

- Final Report (COMM)Document14 pagesFinal Report (COMM)PhanthumpNo ratings yet

- Optimisation of An Innovative Cooling System For Motorsport ApplicationsDocument14 pagesOptimisation of An Innovative Cooling System For Motorsport Applicationsleone.martellucciNo ratings yet

- Performance of Metal and Non-Metal Coated Phase Change Materials Microcapsules When Used in Compressed Air Energy Storage SystemDocument8 pagesPerformance of Metal and Non-Metal Coated Phase Change Materials Microcapsules When Used in Compressed Air Energy Storage SystemRefat AlshannaqNo ratings yet

- Smart Helmet For Cooling ComfortDocument9 pagesSmart Helmet For Cooling ComfortChandanNo ratings yet

- Extrusion Tank Whitepaper Rev 3 5 12Document5 pagesExtrusion Tank Whitepaper Rev 3 5 12Vamsi GantaNo ratings yet

- Design and Fabrication of Seed Dryer Using Waste Heat of VCR CycleDocument7 pagesDesign and Fabrication of Seed Dryer Using Waste Heat of VCR CycleIJRASETPublicationsNo ratings yet

- Thermal Analysis of Engine BlockDocument6 pagesThermal Analysis of Engine BlockEditor IJTSRDNo ratings yet

- Article - Full Version PCMDocument75 pagesArticle - Full Version PCMNADA KOURAANo ratings yet

- Performance Improvement of Domestic Refrigerator by Using PCM (Phase Change Material) and Refrigerant As A Blend of R290 and R600aDocument6 pagesPerformance Improvement of Domestic Refrigerator by Using PCM (Phase Change Material) and Refrigerant As A Blend of R290 and R600aGirish BhangaleNo ratings yet

- Turbine Blade Film Cooling Research ReviewDocument21 pagesTurbine Blade Film Cooling Research ReviewSaroz ParajuliNo ratings yet

- Numerical Study On The Thermal Performance of A Composite Board inDocument10 pagesNumerical Study On The Thermal Performance of A Composite Board inPedro MuttoniNo ratings yet

- Development of A Heat Exchanger With Integrated Thermal Storage For Spacecraft Thermal Management ApplicationsDocument12 pagesDevelopment of A Heat Exchanger With Integrated Thermal Storage For Spacecraft Thermal Management ApplicationsJuan Fernando Cano LarrotaNo ratings yet

- Simulation Based Interpretation and Recent Trends On Performance Analysis On Automobile Radiator Through Nano Particle FluidsDocument3 pagesSimulation Based Interpretation and Recent Trends On Performance Analysis On Automobile Radiator Through Nano Particle FluidsEditor IJTSRDNo ratings yet

- 1808-Article Text-6268-1-10-20191227Document8 pages1808-Article Text-6268-1-10-20191227Fito MarcelindoNo ratings yet

- Steady and Transient Analysis of Engine Cylinder Head With Fins at 3000C and 5000CDocument11 pagesSteady and Transient Analysis of Engine Cylinder Head With Fins at 3000C and 5000CIJRASETPublicationsNo ratings yet

- Performance Enhancement of Unitary and Packaged Air Conditioners With Phase Change MaterialDocument6 pagesPerformance Enhancement of Unitary and Packaged Air Conditioners With Phase Change MaterialsergioNo ratings yet

- 828-Article Text-6274-3-10-20201224Document12 pages828-Article Text-6274-3-10-20201224Fito MarcelindoNo ratings yet

- Passive Cooling System To Provide Thermal ComfortDocument12 pagesPassive Cooling System To Provide Thermal ComfortIJRASETPublicationsNo ratings yet

- Fabrication Solar Refrigeration System by Peltier Effect Ijariie8926Document6 pagesFabrication Solar Refrigeration System by Peltier Effect Ijariie8926Prachurjya BaruahNo ratings yet

- Review of Air and Liquid Metal Based Cooling of Turbine BladesDocument7 pagesReview of Air and Liquid Metal Based Cooling of Turbine BladesAirwarriorg91No ratings yet

- VolumefiveDocument11 pagesVolumefiveabhishek singhNo ratings yet

- Insulation and Thermal Storage Materials Pre-Publication Draft - 1Document91 pagesInsulation and Thermal Storage Materials Pre-Publication Draft - 1m61367366No ratings yet

- Rani 2017Document9 pagesRani 2017yoshiangelNo ratings yet

- Automatic Fall Protection For Hips Based On Micromechanical Double Gas Cylinder Rapid Puncture and Bionic Capsule InflationDocument4 pagesAutomatic Fall Protection For Hips Based On Micromechanical Double Gas Cylinder Rapid Puncture and Bionic Capsule InflationVarshini MuruganNo ratings yet

- MECHPGCON2019 Conference Reviews Phase Change Materials for Electronics CoolingDocument7 pagesMECHPGCON2019 Conference Reviews Phase Change Materials for Electronics CoolingSachin BelgaonkarNo ratings yet

- The Potentialofusingnanofluids InPEMfuelcellcoolingsystemsDocument17 pagesThe Potentialofusingnanofluids InPEMfuelcellcoolingsystemsMario MandžukićNo ratings yet

- Design and Development of Solar Powered 360degree Automatic Air CoolerDocument6 pagesDesign and Development of Solar Powered 360degree Automatic Air CoolerIJRASETPublicationsNo ratings yet

- Thermal Analysis and Optimization of I.C. Engine Piston Using Finite Element MethodDocument6 pagesThermal Analysis and Optimization of I.C. Engine Piston Using Finite Element MethodAnirudhNo ratings yet

- NEEW Generation Smart TextileDocument13 pagesNEEW Generation Smart Textileabdulkhaliqmohd46No ratings yet

- Phase Change Materials For Smart Textiles - An OverviewDocument15 pagesPhase Change Materials For Smart Textiles - An Overviewpitblau100% (1)

- Design and Thermal Analysis of Disc Brake For Minimizing TemperatureDocument5 pagesDesign and Thermal Analysis of Disc Brake For Minimizing TemperatureAnonymous kw8Yrp0R5rNo ratings yet

- Fin PCM Battery CoolingDocument12 pagesFin PCM Battery Coolingmikajps1933No ratings yet

- Accepted Manuscript: International Journal of RefrigerationDocument38 pagesAccepted Manuscript: International Journal of RefrigerationWinarta AdiNo ratings yet

- Electric Vehicle Battery CoolingDocument4 pagesElectric Vehicle Battery CoolingElizabeta ŽalacNo ratings yet

- Dehumidification For Indoor Swimming PoolsDocument15 pagesDehumidification For Indoor Swimming Poolsmohamed nizmyNo ratings yet

- 155 MM Gu Heat Transfer AnalysisDocument8 pages155 MM Gu Heat Transfer AnalysisgetachewggNo ratings yet

- Rajarambapu Institute of Technology, Sakharale: Solar Water Heating System With Phase Change MaterialDocument20 pagesRajarambapu Institute of Technology, Sakharale: Solar Water Heating System With Phase Change Materialumeshg2157No ratings yet

- Fabrication of two wheeler driver cabin with air conditioningDocument8 pagesFabrication of two wheeler driver cabin with air conditioningNidhish MaheshwariNo ratings yet

- Thermal Analysis of Piston of IC EngineDocument8 pagesThermal Analysis of Piston of IC EnginePinsteritNo ratings yet

- Lecture On PCMDocument51 pagesLecture On PCMWaky Mahmudul HasanNo ratings yet

- Experimental Work On Solar Powered Portable Refrigeration System For Rural AreasDocument9 pagesExperimental Work On Solar Powered Portable Refrigeration System For Rural AreasIJRASETPublicationsNo ratings yet

- Improving Efficiency of Solar Water Heater Using Phase Change MaterialsDocument6 pagesImproving Efficiency of Solar Water Heater Using Phase Change MaterialsSuraj MulayNo ratings yet

- A8117119119 Thermal Protection AnalysisDocument4 pagesA8117119119 Thermal Protection AnalysisYasirNo ratings yet

- Ijest12 04 06 027Document8 pagesIjest12 04 06 027Prasanna KumarNo ratings yet

- Design of Heat Exchanger For Solar Energy Application in Biogas PlantDocument9 pagesDesign of Heat Exchanger For Solar Energy Application in Biogas PlantIJRASETPublicationsNo ratings yet

- Numerical Analysis and Comparison of Film Cooling and Convective Cooling For Turbojet Engine ApplicationDocument4 pagesNumerical Analysis and Comparison of Film Cooling and Convective Cooling For Turbojet Engine Applicationkishore pmNo ratings yet

- Iarjset 2023 104091Document7 pagesIarjset 2023 104091Aditya DoyaleNo ratings yet

- Civil EngineeringDocument3 pagesCivil EngineeringDhaked Shahab67% (3)

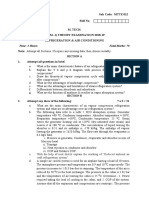

- MTTE 012 Mtech RAC Set 02Document3 pagesMTTE 012 Mtech RAC Set 02Vinod yadavNo ratings yet

- Biogas IntroductionDocument75 pagesBiogas IntroductionRohan JindalNo ratings yet

- Small-Scale Electricity Generation From Biomass Part-1Document22 pagesSmall-Scale Electricity Generation From Biomass Part-1dominguezvNo ratings yet

- MTTE 012 Mtech RAC Set 01Document3 pagesMTTE 012 Mtech RAC Set 01Vinod yadavNo ratings yet

- Printed Pages: Sub Code: MTEE033 Paper Id Roll No. M.Tech. (Sem - Ii) Theory Examination 2019-20 RoboticsDocument2 pagesPrinted Pages: Sub Code: MTEE033 Paper Id Roll No. M.Tech. (Sem - Ii) Theory Examination 2019-20 RoboticsVinod yadavNo ratings yet

- Printed Pages: Sub Code: MTCS051 Paper Id Roll No. M.Tech. (Sem - Ii) Theory Examination 2019-20 Optimization TechniquesDocument3 pagesPrinted Pages: Sub Code: MTCS051 Paper Id Roll No. M.Tech. (Sem - Ii) Theory Examination 2019-20 Optimization TechniquesVinod yadavNo ratings yet

- Bharata RatnaDocument1 pageBharata RatnaVinod yadavNo ratings yet

- Equator Passes Through 13 Countries These AreDocument11 pagesEquator Passes Through 13 Countries These AreVinod yadavNo ratings yet

- Time: 2 Hours Total Marks: 70: Mechanical System Analysis?Document2 pagesTime: 2 Hours Total Marks: 70: Mechanical System Analysis?Vinod yadavNo ratings yet

- Time: 2 Hours Total Marks: 70Document3 pagesTime: 2 Hours Total Marks: 70Vinod yadavNo ratings yet

- Rac CT2Document3 pagesRac CT2Vinod yadavNo ratings yet

- Printed Pages: Sub Code: MTEE033 Paper Id Roll No. M.Tech. (Sem - Ii) Theory Examination 2019-20 RoboticsDocument2 pagesPrinted Pages: Sub Code: MTEE033 Paper Id Roll No. M.Tech. (Sem - Ii) Theory Examination 2019-20 RoboticsVinod yadavNo ratings yet

- Time: 2 Hours Total Marks: 70Document3 pagesTime: 2 Hours Total Marks: 70Vinod yadavNo ratings yet

- M.Tech Optimization Techniques ExamDocument3 pagesM.Tech Optimization Techniques ExamVinod yadavNo ratings yet

- M.Tech Computer Aided Analysis of Mechanical Systems ExamDocument2 pagesM.Tech Computer Aided Analysis of Mechanical Systems ExamVinod yadavNo ratings yet

- Rac CT2Document3 pagesRac CT2Vinod yadavNo ratings yet

- RCH 064 Intellectual Property Rights & Standardization Set BDocument2 pagesRCH 064 Intellectual Property Rights & Standardization Set BVinod yadavNo ratings yet

- Discuss Irreversible Thermodynamics Elements in DetailDocument2 pagesDiscuss Irreversible Thermodynamics Elements in DetailVinod yadavNo ratings yet

- Rac PutDocument2 pagesRac PutVinod yadavNo ratings yet

- Put Math 2018Document2 pagesPut Math 2018Vinod yadavNo ratings yet

- RAC - ME 3rd YearDocument2 pagesRAC - ME 3rd YearVinod yadavNo ratings yet

- Rajarshi Rananjay Sinh Institute of Management & Technology refrigeration examDocument2 pagesRajarshi Rananjay Sinh Institute of Management & Technology refrigeration examVinod yadavNo ratings yet

- HMT Put Final 2018-18Document2 pagesHMT Put Final 2018-18Vinod yadavNo ratings yet

- Rajarshi Rananjay Sinh Institute of Management and TechnologyDocument3 pagesRajarshi Rananjay Sinh Institute of Management and TechnologyVinod yadavNo ratings yet

- PUT Computer Aided Design (CAD)Document2 pagesPUT Computer Aided Design (CAD)Vinod yadavNo ratings yet

- B.Tech Mechatronics and Microprocessor Exam QuestionsDocument3 pagesB.Tech Mechatronics and Microprocessor Exam QuestionsVinod yadavNo ratings yet

- Thermodynamics 2 E7Document41 pagesThermodynamics 2 E7taya699No ratings yet

- Power Plant EngineeringDocument91 pagesPower Plant EngineeringknikhileshNo ratings yet

- Second Law of ThermodynamicsDocument40 pagesSecond Law of ThermodynamicscaptainhassNo ratings yet

- Vietnam & Angkor Wat (PDFDrive) PDFDocument306 pagesVietnam & Angkor Wat (PDFDrive) PDFChristine TranNo ratings yet

- Weekly Report 52Document196 pagesWeekly Report 52Erceanu DanNo ratings yet

- Making Soap From WoodDocument6 pagesMaking Soap From WoodmastabloidNo ratings yet

- Class-III English Notes-WsDocument6 pagesClass-III English Notes-WsManu SinghNo ratings yet

- Alberta Highway and Flood Projects 2016-2019Document37 pagesAlberta Highway and Flood Projects 2016-2019Anonymous QRCBjQd5I7No ratings yet

- How To Use Dr. Foster's Essentials: Essential Oils and BlendsDocument5 pagesHow To Use Dr. Foster's Essentials: Essential Oils and BlendsemanvitoriaNo ratings yet

- Boutique Olive Oil Machines Catalogue ENG5Document33 pagesBoutique Olive Oil Machines Catalogue ENG5Younesse EL BraiNo ratings yet

- Sing 2Document64 pagesSing 2WindsurfingFinnNo ratings yet

- Avh p6050dvd EngDocument119 pagesAvh p6050dvd EngcaimanaterNo ratings yet

- CalderaDocument56 pagesCalderaEsteban TapiaNo ratings yet

- STP Manual Final PDFDocument862 pagesSTP Manual Final PDFrudiNo ratings yet

- Analytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeDocument2 pagesAnalytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeJhon dave SurbanoNo ratings yet

- Aac Block Adhesive: Product DescriptionDocument2 pagesAac Block Adhesive: Product DescriptionmaznahNo ratings yet

- Service and Repair Instructions: Water & WastewaterDocument72 pagesService and Repair Instructions: Water & WastewaterLa Marina Mantenimiento100% (1)

- Tyco TY8281 TFP680 - 03 - 2023Document17 pagesTyco TY8281 TFP680 - 03 - 2023First LAstNo ratings yet

- Anhydrous Ammonia Unloading Station & Storage/Vaporizer SystemDocument2 pagesAnhydrous Ammonia Unloading Station & Storage/Vaporizer SystemWalter Rigamonti100% (1)

- STPM Chemistry Topic 16 Haloalkanes Short Notes PDFDocument2 pagesSTPM Chemistry Topic 16 Haloalkanes Short Notes PDFbendanNo ratings yet

- Perreaux E220 200W Stereo Power Amplifier from 1994Document2 pagesPerreaux E220 200W Stereo Power Amplifier from 1994joaoraffa raffaNo ratings yet

- Hufenus 2006 Geotextiles GeomembranesDocument18 pagesHufenus 2006 Geotextiles Geomembranesbkollarou9632No ratings yet

- Pricelist Mobil Area Jabodetabek Semester 2 2022 TerbaruDocument108 pagesPricelist Mobil Area Jabodetabek Semester 2 2022 TerbarutonymuzioNo ratings yet

- ChecklistsDocument1 pageChecklistsnotme2120No ratings yet

- Anorexia NervosaDocument2 pagesAnorexia NervosaDhea Mae MadisNo ratings yet

- Cryptography 01092014Document19 pagesCryptography 01092014Anshu MittalNo ratings yet

- Water System BOQ 16.12.2023 R0Document144 pagesWater System BOQ 16.12.2023 R0moinu85No ratings yet

- 2021 Vallourec Universal Registration DocumentDocument368 pages2021 Vallourec Universal Registration DocumentRolando Jara YoungNo ratings yet

- October 14, 2011 Strathmore TimesDocument28 pagesOctober 14, 2011 Strathmore TimesStrathmore TimesNo ratings yet

- LearnEnglish Video Zone How These Women Changed Science ForeverDocument3 pagesLearnEnglish Video Zone How These Women Changed Science ForeverDaniella MensatoNo ratings yet

- Guía Fallas para Ricoh Aficio 220Document31 pagesGuía Fallas para Ricoh Aficio 220desechableNo ratings yet

- Production of Natural Bamboo Fibers-1: Experimental Approaches To Different Processes and AnalysesDocument13 pagesProduction of Natural Bamboo Fibers-1: Experimental Approaches To Different Processes and AnalysesrabiulfNo ratings yet

- 2tak Vs 4takDocument3 pages2tak Vs 4takTaufiq AlhakimNo ratings yet