Professional Documents

Culture Documents

Concrete Mix Design Specification

Uploaded by

Anıl ÖzpirinçiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Mix Design Specification

Uploaded by

Anıl ÖzpirinçiCopyright:

Available Formats

2.

3 CONCRETE MIX DESIGN

A. General Contractor shall prepare concrete mix designs from representative samples of the

materials to be used to produce the concrete for each "type" of concrete required.

1. A new "type" of concrete exists whenever any one or more of the following parameters change:

a. Source or kind of any ingredient.

b. Type or source of cement.

c. Design strength.

d. Proportioning of ingredients.

e. Placing method (pumping vs. gravity).

2. The Contractor shall design or verify mixes for each "type" of concrete in accordance with the trial

mixture method or field experience method of ACI 318 Article

3. Test results of trial mixes shall be submitted to Engineer for acceptance prior to concreting. Each mix

shall clearly state the location where mix is to be used. The proportion of ingredients shall be selected

by the Contractor to produce proper place ability, durability, strength, and to produce a mixture which

will work readily into the corners and angles of forms and around reinforcement by methods of

placement and consolidation employed on the work, but without permitting materials to segregate or

permitting excessive free water to collect on surface. Comply with recommendations of ACI 211.1,

211.2 and 302.1R.

4. When a source, type, kind or brand of each constituent has been established and approved for the

project mixes, it shall not be changed throughout the duration of the concreting. Batch all constituents

including admixtures at the central batch plant.

B. Concrete Durability:

1. Below-grade reinforced concrete casting: Concrete mixture for below grade reinforced

concrete mixtures shall be designed to meet the requirements specified in this section and the following

additional requirements:

a. Reference standard: Refer to ACI 318-05, Chapter 4\ “Durability Requirements”

b. Exposure: As indicated in Geotechnical Report

c. Cement Type: As recommended in Geotechnical Report, drawings or BOQ .

- CONCRETE DURABILITY CRITERIA AND TESTS

- AIR CONTENT 1 – 1.5 % MAXIMUM

- BLEEDING NIL

- CONCRETE STRENGTH AFTER 28 DAYS 45 MPA (as mentioned In Structure drawings)

- WATER CEMENT RATIO (W/ C) FROM 0.36 UP TO 0.4

- WATER ABSORPTION AT HARDENED STATE:

SUBSTRUCTURE 1.5 % MAXIMUM

Document No. MP0094 PO2018001 ZZZ SP 0001 001 Rev. No. B Page No. 20 of 44

WHEN PRINTED, THIS DOCUMENT BECOMES UNCONTROLLED

Copyright Sharjah Waste to Energy Company, LLC. 2018. This document is the property of Sharjah Waste to Energy Co. LLC. All rights reserved.

CIVIL WORKS

ARCHITECT & CIVIL REQUIREMENTS - APPENDIX.2

Sharjah WTE Project - Phase 1

SUPER STRUCTURE 2 % MAXIMUM

- WATER PENETRATION

- SUB STRUCTURE 8 mm MAXIMUM

- SUPER STRUCTURE 20 mm MAXIMUM

- RAPID CHOLORIDE PENETRATION (RCP)

- SUB STRUCTURE 1000 COULOMBS

- SUPER STRUCTURE 2500 COULOMBS

- INITIAL SURFACE ABSORPTION TEST (ISAT)

- AFTER 10 MINUTES

- SUB STRUCTURE 0.15 ML/ M2 / SEC

- SUBER STRUCTURE 0.25 ML / M2 / SEC

- AFTER 30 MINUTES 0.17 ML / M2 / SEC

- AFTER 60 MINUTES 0.1 ML / M2 / SEC

- CHOLORIDE CONTENT/ CEMENTITIOUS 0.20 %

- SO3 CONTENT / CEMENTITIOUS 4%

C. Admixtures

Concrete mixes with admixture dosages exceeding 2.4 kilograms per cubic meter of concrete shall

have free water content of concrete mix reduced by aqueous portion of admixtures in order to adhere

to water-to-cement ratio requirements.

1. A water-reducing admixture or high-range water reducing admixture shall be used in all mix

designs.

2. A high-range, water-reducing admixture shall be used when any of the conditions below apply.

Minimum slump shall be 190 + / - 3millimeters, maximum 220 millimeters.

a. Water-to-cement ratio is 0.4 or less.

b. Concrete is to be pumped.

c. When requested by the Contractor and accepted by the Engineer in concrete mix design

3. A water-reducing, retarding admixture shall be used when concrete is to be placed during hot

weather as defined by ACI 305R.

4. Fly ash shall be used as an admixture for all lightweight concrete to be pumped.

D. Mix Requirements:

Concrete mixes shall be designed to provide for all of the requirements given in this Specification and

on the Drawings even if strength or any other criteria must be exceeded to meet other criteria.

1. Strength requirements given on the Drawings shall be based on 28-days Cube compressive

strength unless a different test age is specified.

2. Normal weight concrete shall have a maximum water-to-cement ratio, by weight, of 0.40 and a

minimum strength of 45 MPa U.O.N. in the general notes.

Document No. MP0094 PO2018001 ZZZ SP 0001 001 Rev. No. B Page No. 21 of 44

WHEN PRINTED, THIS DOCUMENT BECOMES UNCONTROLLED

Copyright Sharjah Waste to Energy Company, LLC. 2018. This document is the property of Sharjah Waste to Energy Co. LLC. All rights reserved.

CIVIL WORKS

ARCHITECT & CIVIL REQUIREMENTS - APPENDIX.2

Sharjah WTE Project - Phase 1

3. Concrete to be exposed to brackish water, or to salt laden air in service shall have a maximum

water-to-cement ratio, by weight, of 0.40, a minimum strength of 45 MPa, a minimum cement

content of 390 kilograms per cubic meter.

4. All concrete required to be watertight shall have a maximum water-to

5. Concrete mixes to be exposed to earth or weather shall have a maximum water soluble chloride

ion content of 0.20 percent by weight of cement.

Document No. MP0094 PO2018001 ZZZ SP 0001 001 Rev. No. B Page No. 22 of 44

WHEN PRINTED, THIS DOCUMENT BECOMES UNCONTROLLED

Copyright Sharjah Waste to Energy Company, LLC. 2018. This document is the property of Sharjah Waste to Energy Co. LLC. All rights reserved.

You might also like

- Volume-2 SpecificationDocument26 pagesVolume-2 SpecificationRamsha YasirNo ratings yet

- LANL Project I.D. Miscellaneous Cast-in-Place Concrete (Rev. 8, June 29, 2015) 03 3053-1Document8 pagesLANL Project I.D. Miscellaneous Cast-in-Place Concrete (Rev. 8, June 29, 2015) 03 3053-1081382991318No ratings yet

- Dr. S. K. Dubey, Professor (Structures), Deptt. of Civil Engineering., M.A.N.I.T.Document7 pagesDr. S. K. Dubey, Professor (Structures), Deptt. of Civil Engineering., M.A.N.I.T.NeelNo ratings yet

- 5.3.6 Minimum Requirements To Concrete Mix: 5.3.6.1 Durability and Structural Design RequirementsDocument2 pages5.3.6 Minimum Requirements To Concrete Mix: 5.3.6.1 Durability and Structural Design Requirementsahmed alyNo ratings yet

- R. Nagendra - Paper On Mix Proportioning As Per Is 10262-2009Document31 pagesR. Nagendra - Paper On Mix Proportioning As Per Is 10262-2009Vinod JogurNo ratings yet

- IRS Guidelins HPCDocument12 pagesIRS Guidelins HPCsaritasohamNo ratings yet

- Civil Guidelines and SpecificationsDocument65 pagesCivil Guidelines and SpecificationshardikNo ratings yet

- IS 456 Comparison of 1978 Vs 2000Document9 pagesIS 456 Comparison of 1978 Vs 2000man.drakeNo ratings yet

- Sample QuestionsDocument5 pagesSample Questionsmohd khajaNo ratings yet

- Concrete Specifications Rev ADocument15 pagesConcrete Specifications Rev ABdteam T2No ratings yet

- Blucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Document4 pagesBlucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Rajiv SingalNo ratings yet

- Methodolgy For Structural ConcreteDocument38 pagesMethodolgy For Structural Concretevenkateswara rao PothinaNo ratings yet

- Structural SpecificationDocument16 pagesStructural SpecificationMIKENo ratings yet

- Mix Design With Superplasticizers: by Er. Kaushal Kishore, Materials Engineer, RoorkeeDocument12 pagesMix Design With Superplasticizers: by Er. Kaushal Kishore, Materials Engineer, RoorkeeSantoshNo ratings yet

- 15-355-2014 Division 03Document18 pages15-355-2014 Division 03Otceliban SarlNo ratings yet

- Portland Cement ConcreteDocument15 pagesPortland Cement ConcreteIm ChinithNo ratings yet

- Irc SP 105 2015 Explanatory Handbook To Irc 112 2011Document36 pagesIrc SP 105 2015 Explanatory Handbook To Irc 112 2011vivekNo ratings yet

- Technical SPECIFICATION FOR PILESDocument13 pagesTechnical SPECIFICATION FOR PILESgopal sudhirNo ratings yet

- S Aa Civ Concrete (Rev.0 2010)Document17 pagesS Aa Civ Concrete (Rev.0 2010)santanudas2001in9040No ratings yet

- Azuker Sugar PresentationDocument24 pagesAzuker Sugar Presentationomkar ladNo ratings yet

- ML-15 - Concrete Coating PDFDocument13 pagesML-15 - Concrete Coating PDFDeepakNo ratings yet

- S-AAA-CIV-CONCRETE (Rev.0-2015) PDFDocument16 pagesS-AAA-CIV-CONCRETE (Rev.0-2015) PDFSwathish SivaprasadNo ratings yet

- Concrete Mix Design C30 - MKICO SITEDocument7 pagesConcrete Mix Design C30 - MKICO SITEMitendra Kumar Chauhan0% (1)

- Shotcrete RequirementsDocument16 pagesShotcrete Requirementstinz_3100% (2)

- Annex 4.1 - Technical Specifications - Civil WorksDocument6 pagesAnnex 4.1 - Technical Specifications - Civil WorksMW ALSABRINo ratings yet

- Mix Design PresentationDocument12 pagesMix Design Presentationdsuresh_ch20029057No ratings yet

- Microfine Cement and Portland Cement With A High-Range Water-Reducing AgentDocument5 pagesMicrofine Cement and Portland Cement With A High-Range Water-Reducing AgentwassimmahfouzNo ratings yet

- Sec689 - Cementitious Patch Repair of ConcreteDocument9 pagesSec689 - Cementitious Patch Repair of ConcreteAmr Adel HameedNo ratings yet

- 06 82 00 GRP LINING TO THE CONCRETE TANK OkDocument3 pages06 82 00 GRP LINING TO THE CONCRETE TANK OkshajbabyNo ratings yet

- BALLAST-spec-Nov 2014Document39 pagesBALLAST-spec-Nov 2014princebh3No ratings yet

- MS 158 - Method Statement For Sub-Grade Construction of Parallel RoadsDocument11 pagesMS 158 - Method Statement For Sub-Grade Construction of Parallel Roadsthushara100% (1)

- Mix DesignDocument27 pagesMix DesignSoni Mishra TiwariNo ratings yet

- Iptc-19770-Abstract Password RemovedDocument8 pagesIptc-19770-Abstract Password Removed叶芊No ratings yet

- House SpecDocument6 pagesHouse SpecJuan CarlosNo ratings yet

- Experimental Studies On Performance of SDocument6 pagesExperimental Studies On Performance of SMr. Mark B.No ratings yet

- Marine Concrete Specs-HkDocument5 pagesMarine Concrete Specs-HkMohammed Faisal TNo ratings yet

- BALLAST SpecDocument35 pagesBALLAST SpecshujaNo ratings yet

- Roller Compacted Concrete For DamsDocument16 pagesRoller Compacted Concrete For Damsabhineet srivastavaNo ratings yet

- Manhole-Bench Mix DesignDocument5 pagesManhole-Bench Mix DesignAhmadNo ratings yet

- Method Statement Water ProofingDocument16 pagesMethod Statement Water ProofingVinod MasaniNo ratings yet

- Specification For Pre Stressed Cement Concrete PolesDocument10 pagesSpecification For Pre Stressed Cement Concrete PolesNagabhushanam PayapalleNo ratings yet

- Basics of Concrete Technology: by Prakash Channappagoudar, VP (Structural Designs), SKA/TEBSDocument61 pagesBasics of Concrete Technology: by Prakash Channappagoudar, VP (Structural Designs), SKA/TEBSprakashcg123No ratings yet

- 03 31 00 Structural ConcreteDocument10 pages03 31 00 Structural ConcreteJonathanPobletePerezNo ratings yet

- Grout Rev.c PDFDocument6 pagesGrout Rev.c PDFMithun UdayanarayanaNo ratings yet

- Water Tightness Test SpecDocument2 pagesWater Tightness Test SpecKAKANo ratings yet

- ShotcreteDocument10 pagesShotcreteHemaNo ratings yet

- Grade of ConcreteDocument10 pagesGrade of ConcreterddlfcbeauditNo ratings yet

- PBG SpesifikasiDocument19 pagesPBG SpesifikasikaryantoherlambangNo ratings yet

- Central Business District of The New Adminis Trative CapitalDocument7 pagesCentral Business District of The New Adminis Trative Capitallf chNo ratings yet

- Masterroc Hca 20: Liquid Hydration Inhibitor For ConcreteDocument3 pagesMasterroc Hca 20: Liquid Hydration Inhibitor For Concretez_sheriNo ratings yet

- Durability Characteristics OF Self Compacting Concrete: Presentation ONDocument26 pagesDurability Characteristics OF Self Compacting Concrete: Presentation ONMonika DhaklaNo ratings yet

- Self Compacting Concrete 1Document34 pagesSelf Compacting Concrete 1Anonymous I5w5hCCNo ratings yet

- 293-1-Spc-002 Specification For Grouting, Rev. ADocument10 pages293-1-Spc-002 Specification For Grouting, Rev. ABasitNo ratings yet

- BALLAST SpecificationsDocument39 pagesBALLAST SpecificationsRajaram KulapakaNo ratings yet

- 3 Concrete Mix DesignDocument28 pages3 Concrete Mix DesignPraveen BhandariNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- HSE RecordDocument1 pageHSE RecordAnıl ÖzpirinçiNo ratings yet

- You Can Use EQMS Risk Manager To Identify, Monitor and ReviewDocument8 pagesYou Can Use EQMS Risk Manager To Identify, Monitor and ReviewAnıl ÖzpirinçiNo ratings yet

- MSheet Manual 7.1Document359 pagesMSheet Manual 7.1Anıl ÖzpirinçiNo ratings yet

- Continuos Improvement Processes Internal Audit ProcessDocument1 pageContinuos Improvement Processes Internal Audit ProcessAnıl ÖzpirinçiNo ratings yet

- Najmant Development - Master Plan PDFDocument1 pageNajmant Development - Master Plan PDFAnıl ÖzpirinçiNo ratings yet

- A100-1 - Site PlanDocument1 pageA100-1 - Site PlanAnıl ÖzpirinçiNo ratings yet

- Project Hse Compliance: Initial RequirementsDocument4 pagesProject Hse Compliance: Initial RequirementsAnıl ÖzpirinçiNo ratings yet

- Main Flow ChartDocument1 pageMain Flow ChartAnıl ÖzpirinçiNo ratings yet

- 905 029 2 Grouting enDocument12 pages905 029 2 Grouting enAnıl ÖzpirinçiNo ratings yet

- LEEA Lifting Appointed Person - 2Document6 pagesLEEA Lifting Appointed Person - 2Anıl Özpirinçi100% (1)

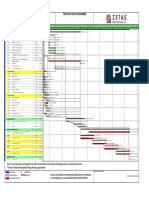

- Foundation Piling Works: Maryam Beach Residence On Plot No.844 Tentative Work ProgrammeDocument1 pageFoundation Piling Works: Maryam Beach Residence On Plot No.844 Tentative Work ProgrammeAnıl ÖzpirinçiNo ratings yet

- BS 5975 1996 FalseworkDocument16 pagesBS 5975 1996 FalseworkAnıl Özpirinçi0% (1)

- General Information: Please Find Here Below The General Information Related To This ITBDocument1 pageGeneral Information: Please Find Here Below The General Information Related To This ITBAnıl ÖzpirinçiNo ratings yet

- Convert Easting Norting To Lat Long Google MapDocument5 pagesConvert Easting Norting To Lat Long Google MapAnıl ÖzpirinçiNo ratings yet

- LTR 1100Document2 pagesLTR 1100Anıl ÖzpirinçiNo ratings yet

- Civil Calculation: EC2: Lap Length of ReinforcementsDocument3 pagesCivil Calculation: EC2: Lap Length of ReinforcementsAnıl ÖzpirinçiNo ratings yet

- GCH Notes PDFDocument18 pagesGCH Notes PDFAnıl Özpirinçi100% (1)

- 5 Steps To Risk AssessmentDocument22 pages5 Steps To Risk AssessmentAnıl Özpirinçi50% (2)

- 17-0404 - Mariam Beach Residence - Submittal LogDocument6 pages17-0404 - Mariam Beach Residence - Submittal LogAnıl ÖzpirinçiNo ratings yet

- IMMO Prestige Residential Tower Development - 'AAA' Values & Notification Strategy - 30072018 PDFDocument1 pageIMMO Prestige Residential Tower Development - 'AAA' Values & Notification Strategy - 30072018 PDFAnıl ÖzpirinçiNo ratings yet

- Lecture 9 Indutrial CitiesDocument13 pagesLecture 9 Indutrial CitiesDeepa AnoopNo ratings yet

- Economic Profile Ontario Oil Gas and Salt Resources IndustryDocument40 pagesEconomic Profile Ontario Oil Gas and Salt Resources IndustryRossana CairaNo ratings yet

- List EemuaDocument2 pagesList EemuaRafiqKuNo ratings yet

- Air-Cooled Diesel Generator Owner S Manual: This Manual Contains Important Safety InformationDocument17 pagesAir-Cooled Diesel Generator Owner S Manual: This Manual Contains Important Safety Informationfredy buitragoNo ratings yet

- 2ar FeDocument69 pages2ar Feroberto cruz100% (5)

- D - Internet - Myiemorgmy - Intranet - Assets - Doc - Alldoc - Document - 5762 - Jurutera July 2014 PDFDocument47 pagesD - Internet - Myiemorgmy - Intranet - Assets - Doc - Alldoc - Document - 5762 - Jurutera July 2014 PDFDiana MashrosNo ratings yet

- Shear Wall Analysis - New Modelling, Same AnswersDocument11 pagesShear Wall Analysis - New Modelling, Same AnswersGururaj AshritNo ratings yet

- MIPAC MPA App Note SAG MillsDocument2 pagesMIPAC MPA App Note SAG MillsTanaji_maliNo ratings yet

- BREF LargeVolInorgChemicals Vdez06Document446 pagesBREF LargeVolInorgChemicals Vdez06Luís Miguel Castro100% (1)

- NFPA 1, 2009 EditionDocument10 pagesNFPA 1, 2009 EditionAshutosh KambleNo ratings yet

- Comp Env 2007 Chp4Document94 pagesComp Env 2007 Chp4Robin ShergillNo ratings yet

- Final Exam For EeDocument3 pagesFinal Exam For EeVenkata DineshNo ratings yet

- AlloysDocument4 pagesAlloyslinguy007No ratings yet

- Operation and Installation: Residential/Commercial Generator SetsDocument52 pagesOperation and Installation: Residential/Commercial Generator SetsStevenNo ratings yet

- SGS MIN WA308 Coal Petrographic Analysis en 11Document1 pageSGS MIN WA308 Coal Petrographic Analysis en 11Nilesh SinghalNo ratings yet

- CM List of Reference BooksDocument2 pagesCM List of Reference BooksPiyush BhandariNo ratings yet

- Demolition: Medan Ikan Bakar Sabar Awor, Bandar Maharani, Muar, Johor Darul TakzimDocument10 pagesDemolition: Medan Ikan Bakar Sabar Awor, Bandar Maharani, Muar, Johor Darul TakzimShafiek IsmailNo ratings yet

- RS20 20,000lb Reel StandDocument14 pagesRS20 20,000lb Reel StandComstar SupplyNo ratings yet

- 2007 Technical HandbookDocument148 pages2007 Technical HandbookeriklangeveldNo ratings yet

- Capping Machines Technical GuideDocument12 pagesCapping Machines Technical Guidekaniappan sakthivelNo ratings yet

- Manual Toshiba ClimDocument22 pagesManual Toshiba ClimalelicuNo ratings yet

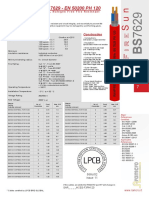

- Ramfireco CableDocument1 pageRamfireco CableahsanNo ratings yet

- Pattern Samples PDFDocument3 pagesPattern Samples PDFm0211No ratings yet

- Icemake Catalogue IBTDocument32 pagesIcemake Catalogue IBTRamhesh BabuNo ratings yet

- Isoladores Polimericos para Ancoragem Ou Suspensao IngDocument2 pagesIsoladores Polimericos para Ancoragem Ou Suspensao IngRenzo Romero ArenasNo ratings yet

- SOP For Changeovers Carried Out in Manufacturing and Packing AreaDocument2 pagesSOP For Changeovers Carried Out in Manufacturing and Packing Areareflectprakash3610No ratings yet

- Ac550 - Ac4250 Operators Manual 3390502393Document56 pagesAc550 - Ac4250 Operators Manual 3390502393Deno Manuel LudzanNo ratings yet

- CASR PART 43 Amdt. 1 PDFDocument21 pagesCASR PART 43 Amdt. 1 PDFarbypratamax66100% (1)

- Bajaj Light PDFDocument8 pagesBajaj Light PDFrajeshbehura1989_119No ratings yet

- Dywidag Post Tensioning Catalogue 7Document1 pageDywidag Post Tensioning Catalogue 7PrateekNo ratings yet