Professional Documents

Culture Documents

Prediction of Strength Characteristics of Fly Ash Concrete Using Artificial Neural Networking

Uploaded by

KeerthiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prediction of Strength Characteristics of Fly Ash Concrete Using Artificial Neural Networking

Uploaded by

KeerthiCopyright:

Available Formats

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

RESEARCH ARTICLE ISSN: 2321-7758

PREDICTION OF STRENGTH CHARACTERISTICS OF FLY ASH CONCRETE USING

ARTIFICIAL NEURAL NETWORKING

NAYANA MANOHARI T.K1, KEERTHI GOWDA B.S2, VINAYAK P.VIJAPUR3

1

Post graduation student (Structural Engineering), Government Engineering College, Haveri,

Karnataka. India

2

Lecturer, civil Engineering, DACG Government polytechnic, Chickmagalore, Karnataka, India

3

Assistant Professor of Civil Engineering Department, Government Engineering College, Haveri,

Karnataka. India

Article Received: 28/08/2013 Article Revised on: 02/09/2013 Article Accepted on:08/09/2013

ABSTRACT

An exhaustive literature survey shows that a little effort has been done towards artificial

neural network (ANN) approach in the area of concrete technology. In the present

investigation, development of ANN approach to predict strength characteristics of fly ash

concrete in lieu of conventional laboratory approach. The traditional lab approach

attracts some drawbacks such as manual involvement, time consuming, chances of

creeping of human errors, uncertain prediction and always invasive in nature. Hence to

reduce above drawbacks, this study is undertaken to develop an ANN between concrete

NAYANA MANOHARI T.K mix ingredients and compressive, tensile, shear, flexure strength of mix. The work deals

Author for with collection of huge input data’s by conducting experiments, ANN’s training and its

Correspondence testing are adopted to fix appropriate weighted matrix which in turn predict strength

E-mail: characteristics of fly ash concrete.

nayanamanohari27@gmail. Keywords: ANN, Fly ash concrete, Prediction, Performance, Topology.

com

INTRODUCTION

Fly ash is a by-product from burning pulverized requirement for obtaining a given consistency.

coal in electric power generating plants. During Good fly ash can act as a super plasticizing

combustion, mineral impurities in the coal (clay, admixture when used in high-volume. The

feldspar, quartz, and shale) fuse in suspension and phenomenon is attributable to three mechanisms.

float out of the combustion chamber with the First, fine Particles of fly ash get absorbed on the

exhaust gases. As the fused material rises, it cools oppositely charged surfaces of cement particles

and solidifies into spherical glassy particles called and prevent them from flocculation. The cement

fly ash. It is generally observed that a partial particles are thus effectively dispersed and will

substitution of Portland cement by fly ash in a trap large amounts of water means that the

mortar or concrete mixture reduces that water system will have a reduced water requirement to

163 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

achieve a given consistency. Secondly, the ANN takes data samples rather than entire data

spherical shape and the smooth surface of fly ash sets to arrive at solutions, which saves both time

particles help to reduce the inter-particle friction and money. ANNs are considered fairly simple

and thus facilitate mobility. Thirdly, the “particle mathematical models to enhance existing data

packing effect” is also responsible for the reduced analysis technologies.

water demand in plasticizing the system. It may be ANNs have three layers that are interconnected.

noted that both Portland cement and fly ash The first layer consists of input neurons. Those

contribute particles that are mostly in the 1 to 45μ neurons send data on to the second layer, which

size range, and therefore serve as excellent fillers in turn sends the output neurons to the third

for the void space within the aggregate mixture. In layer. Training an artificial neural network involves

fact, due to its lower density and higher volume choosing from allowed models for which there are

per unit mass, fly ash is a more efficient void-filler several associated algorithms. The general

than Portland cement. computational ANN model is always represented

IS: 10262-2009 the code recommended by the by a topology which represents number of

Bureau of Indian standards to design a concrete neurons in input layer, hidden layer and output

mix proportions, because of its complex graphs, layer. However the numbers of neurons in the

tables, it requires high knowledge of interpolation, input layer and output layer are determined based

graph reading and so on. At last it also requires a on the problem domain depending upon number

more human resource involvement and time of input variables and numbers of output or target

consuming. This is very tedious and uneconomical variables. The number of hidden layers and

for small and moderate projects. In the present neurons in hidden layer are fixed during the

work, an attempt is made to eliminate those training process.

difficulties by adopting ANN approaches which is

basically data driven approach rather than

equation. The basic philosophy of ANN is that it

learns by known examples and results are stored

as experienced knowledge in the form of

weighted matrix. This weighted matrix is used for

future prediction for unknown examples. This

Fig.1 Structure of neural network

basic concept is used in this study to estimate the

Learning and training

strength characteristics of fly ash concrete.

A network can learn when training is used or the

ARTIFICIAL NEURAL NETWORKING THEORY

network can learn also in the absence of training.

An artificial neuron network (ANN) is a

Two barrowed categories of the network learning

computational model based on the structure and

are supervised and unsupervised learning.

functions of biological neural networks.

Supervised learning provides the outputs to

Information that flows through the network

compare, while unsupervised does not. During

affects the structure of the ANN because a neural

supervised training, external prototypes are used

network changes or learns, in a sense - based on

as target output and the network is given a

that input and output. ANNs are considered

learning algorithm to follow and calculate new

nonlinear statistical data modeling tools where

connection weights and bring the output closer to

the complex relationships between input and

the target output.

outputs or modeled or patterns are found ANN is

Methodology

also known as a neural network. ANN is used as a

1) Casting of specimens, 2) Curing of specimens, 3)

random function approximation tool. These types

Testing of specimens, 4) Collection of test results,

of tools help estimate the most cost-effective and

5) Training, testing, validation were done using

ideal methods for arriving at solutions while

ANN to generate weighted matrix and 6)

defining computing functions or distributions.

164 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Predicted values were compared with the specified error tolerance. Once this number is

experimental values. attained the program is terminated even if

Topology of ANN model used for predicting the error tolerance is not met.

strength of fly ash concrete Among the total number of data, 85% of the

The network architecture used in this study is 8-5- total data used for training and remaining

st nd

1, where the 1 digit is the number of inputs, 2 15% for testing.

rd

digit is the number of hidden neurons and 3 digit A learning rate is set to 0.7.

is the number of outputs. Levenberg-Marquardt algorithm is used.

The maximum number of training epochs, Performance of ANN model is based on Mean

which is chosen as 1000 to achieve the Squared Error.

Table 1 Input and output data used in prediction of compressive strength of fly ash concrete

Training output

Training input data

data

Fly Coarse Fine Fly Compressive

Slump Cement Water No. of

ash aggregate aggregate W/C ash in strength

(mm) in kG in kG days 2

(%) in kG in kG kG N/mm

0 50 4.65 2.7 1.50 0.75 0.5 0.00 7 30.22

10 50 4.65 2.7 1.35 0.75 0.5 0.15 7 30.36

20 50 4.65 2.7 1.20 0.75 0.5 0.30 7 30.51

30 50 4.65 2.7 1.05 0.75 0.5 0.45 7 29.92

40 50 4.65 2.7 0.90 0.75 0.5 0.60 7 29.64

50 50 4.65 2.7 0.75 0.75 0.5 0.75 7 29.22

0 50 4.65 2.7 1.50 0.75 0.5 0.00 28 35.10

10 50 4.65 2.7 1.35 0.75 0.5 0.15 28 35.25

20 50 4.65 2.7 1.20 0.75 0.5 0.30 28 35.40

30 50 4.65 2.7 1.05 0.75 0.5 0.45 28 34.80

40 50 4.65 2.7 0.90 0.75 0.5 0.60 28 34.51

50 50 4.65 2.7 0.75 0.75 0.5 0.75 28 34.07

Graphical representation of predicted compressive strength of fly ash concrete

Fig.2 Training performance of ANN (Levenberg-Marquardt Algorithm)

165 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Fig.3 Experimental value v/s predicted value of compressive strength in training

Fig.4 Comparison of experimental and predicted values of 7 days compressive strength

Fig.5 Comparison of experimental and predicted values of 28 days compressive strength

164 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Table 2 Training input and output data used in prediction of tensile strength of fly ash concrete

Training

Training input data

output data

Fly Coarse Fine Tensile

Slump Cement Water Fly ash No. of

ash in aggregate aggregate W/C strength

(mm) in kG in kG in kG days 2

% in kG in kG N/mm

0 50 7.30 4.24 2.33 1.17 0.5 0.000 7 2.40

10 50 7.30 4.24 2.12 1.17 0.5 0.235 7 2.49

20 50 7.30 4.24 1.88 1.17 0.5 0.471 7 2.58

30 50 7.30 4.24 1.65 1.17 0.5 0.707 7 2.44

40 50 7.30 4.24 1.41 1.17 0.5 0.943 7 2.35

50 50 7.30 4.24 1.17 1.17 0.5 1.179 7 2.21

0 50 7.30 4.24 2.33 1.17 0.5 0.000 28 2.82

10 50 7.30 4.24 2.12 1.17 0.5 0.235 28 2.92

20 50 7.30 4.24 1.88 1.17 0.5 0.471 28 3.01

30 50 7.30 4.24 1.65 1.17 0.5 0.707 28 2.87

40 50 7.30 4.24 1.41 1.17 0.5 0.943 28 2.77

50 50 7.30 4.24 1.17 1.17 0.5 1.179 28 2.63

Graphical representation of predicted tensile strength of fly ash concrete

Fig.6 Training Performance of ANN (Levenberg-Marquardt Algorithm)

165 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Fig.7 Experimental value v/s predicted value of tensile strength in training

Fig.8 Comparison of experimental and predicted values of 7 days tensile strength

Fig.9. Comparison of experimental and predicted values of 28 days tensile strength

166 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Table 3 Training input and output data used in prediction of shear strength of fly ash concrete

Training

Training input data

output data

Fly Coarse Fine Shear

Slump Cement Water Fly ash No. of

ash aggregate aggregate W/C strength

(mm) in kG in kG in kG days 2

in % in kG in kG N/mm

0 50 3.537 2.05 1.464 0.57 0.5 0.000 7 2.77

10 50 3.537 2.05 1.350 0.57 0.5 0.114 7 2.95

20 50 3.537 2.05 0.912 0.57 0.5 0.228 7 3.14

30 50 3.537 2.05 0.798 0.57 0.5 0.342 7 2.58

40 50 3.537 2.05 0.684 0.57 0.5 0.456 7 2.03

50 50 3.537 2.05 0.570 0.57 0.5 0.570 7 1.84

0 50 3.537 2.05 1.646 0.57 0.5 0.000 28 3.33

10 50 3.537 2.05 1.350 0.57 0.5 0.114 28 3.48

20 50 3.537 2.05 0.912 0.57 0.5 0.228 28 3.64

30 50 3.537 2.05 0.798 0.57 0.5 0.342 28 3.14

40 50 3.537 2.05 0.684 0.57 0.5 0.456 28 2.59

50 50 3.537 2.05 0.570 0.57 0.5 0.570 28 2.41

Graphical representation of predicted shear strength of fly ash concrete

Fig.10 Training Performance of ANN (Levenberg-Marquardt Algorithm)

167 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Fig.11 Experimental value v/s predicted value of shear strength in training

Fig.12 Comparison of experimental and predicted values of 7 days shear strength

Fig.13 Comparison of experimental and predicted values of 28 days shear strength

168 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Table 4 Training input and output data used in prediction of flexure strength of fly ash concrete

Training

Training input data output

data

Fly Coarse Fine Flexure

Slump Cement Water Fly ash No. of

ash aggregate aggregate W/C strength

(mm) in kG in kG in kG days 2

in % in kG in kG N/mm

0 50 6.94 4.0 2.24 1.112 0.5 0.000 7 7.50

10 50 6.94 4.0 2.02 1.112 0.5 0.224 7 7.83

20 50 6.94 4.0 1.79 1.112 0.5 0.448 7 8.00

30 50 6.94 4.0 1.57 1.112 0.5 0.672 7 7.66

40 50 6.94 4.0 1.34 1.112 0.5 0.896 7 7.33

50 50 6.94 4.0 1.12 1.112 0.5 1.120 7 7.00

0 50 6.94 4.0 2.24 1.112 0.5 0.000 28 9.00

10 50 6.94 4.0 2.02 1.112 0.5 0.224 28 9.40

20 50 6.94 4.0 1.79 1.112 0.5 0.448 28 9.50

30 50 6.94 4.0 1.57 1.112 0.5 0.672 28 9.16

40 50 6.94 4.0 1.34 1.112 0.5 0.896 28 8.83

50 50 6.94 4.0 1.12 1.112 0.5 1.120 28 8.50

Graphical representation of predicted flexure strength of fly ash concrete

Fig.14 Training Performance of ANN (Levenberg-Marquardt Algorithm)

169 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Fig.15 Experimental value v/s predicted value of flexure strength in training

Fig.16 Comparison of experimental and predicted values of 7 days flexure strength

Fig.17 Comparison of experimental and predicted values of 28 days flexure strength

170 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Fig.18 Predicted values of compressive strength of fly ash concrete for 7 days

Fig.19 Predicted values of compressive strength of fly ash concrete for 28 days

Fig.20 Predicted values of tensile strength of fly ash concrete for 7 days

171 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Fig.21 Predicted values of tensile strength of fly ash concrete for 28 days

Fig.22 Predicted values of shear strength of fly ash concrete for 7 days

Fig.23 Predicted values of shear strength of fly ash concrete for 28 days

172 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

Fig.24 Predicted values of flexure strength of fly ash concrete for 7 days

Fig.25 Predicted values of flexure strength of fly ash concrete for 28 days

CONCLUSIONS concrete without using complicated

1. ANN approach avoids memorization of equations and laboratory experiments.

equations and generalizes the problem REFERENCES

domain. [1]. Keerti Gowda B.S., Dr. Easwara Prasad G.L., Dr.

2. The predicted compressive, tensile, shear, Velmurgan R. “Prediction of optimized Cantilever

and flexure strength of fly ash concrete Earth Retaining wall by ANN”, International

show lesser error. Journal of Emerging Trends in Engineering and

3. The present dissertation work Development, vol-6, September (2012), pp. 328-

demonstrates that all the predicted values 333.

of compression, tensile, shear and flexure [2]. Duan Z.H., Kou S.C., Poon C.S “Prediction of

strength of fly ash concrete are well within compressive strength of recycled aggregate

permissible limit. concrete using artificial neural networks”,

4. The developed ANN model will guide to Construction and Building Materials (2012).

get the values of compression, tensile

shear, and tensile strength of fly ash

173 NAYANA MANOHARI T.K et al

International journal of Engineering Research-Online

A Peer Reviewed International Journal Vol.1., Issue.2., 2013

Articles available onlne http://www.ijoer.in

[3]. Muhammad N.S. Hadi “Neural networks

applications in concrete structures”, Computers

and Structures 81 (2003), pp. 373–381.

[4]. Yaoyao Peia, Yuanyou Xia “Design of Reinforced

Cantilever Retaining Walls using Heuristic

Optimization Algorithms”, Procedia Earth and

Planetary Science 5, (2012), pp.32-36.

[5]. IS: 10262 – 2009 Specifications for plain and

reinforced concrete.

[6]. IS: 456-2000 Specifications for plain and reinforced

concrete.

[7]. IS: 8112 - 1989 Specifications for plain and

reinforced concrete.

[8]. http://rspublication.com/ijeted/ijeted%20sep%20

12/23.pdf

[9]. http://link.springer.com/content/pdf/10.1007/s10

518-009-9117-6.pdf

[10]. http://www.concreteconstruction.net/concrete-

construction/what-is-fly-ash.aspx

174 NAYANA MANOHARI T.K et al

You might also like

- Civil - Ijcseierd - Estimation of Shear Strength - Abeer Abduljabaar Abdulabaas - OpaidDocument10 pagesCivil - Ijcseierd - Estimation of Shear Strength - Abeer Abduljabaar Abdulabaas - OpaidTJPRC PublicationsNo ratings yet

- Prediction Concrete Strength Neuronal NetworkDocument6 pagesPrediction Concrete Strength Neuronal NetworkolazagutiaNo ratings yet

- Optimal Design Prediction of Singly Reinforced Concrete Beam Steel Using Artificial Neural NetworkDocument7 pagesOptimal Design Prediction of Singly Reinforced Concrete Beam Steel Using Artificial Neural NetworksrijanNo ratings yet

- A Review On Application of Artificiial Intelligence To Predict Strength of ConcreteDocument3 pagesA Review On Application of Artificiial Intelligence To Predict Strength of ConcreteTanmay KalolaNo ratings yet

- 1 s2.0 S1359836823006029 MainDocument16 pages1 s2.0 S1359836823006029 MainZrar IsqeliNo ratings yet

- A Review On Artificial Neural Network Concepts in Structural EngineeringDocument6 pagesA Review On Artificial Neural Network Concepts in Structural EngineeringAravind H B Engineering CivilNo ratings yet

- Behaviour Analysis of Multilayer Perceptronswith MDocument7 pagesBehaviour Analysis of Multilayer Perceptronswith MJosé Geraldo De Souza SilvaNo ratings yet

- Back Propagation Neural NetworkDocument10 pagesBack Propagation Neural NetworkAhmad Bisyrul HafiNo ratings yet

- Predicting The Ingredients of Self Compacting Concrete Using Artificial Neural NetworkDocument10 pagesPredicting The Ingredients of Self Compacting Concrete Using Artificial Neural NetworkPablo Cesar TrejoNo ratings yet

- Artificial Neural Networks and Their Applications: June 2005Document6 pagesArtificial Neural Networks and Their Applications: June 2005sadhana mmNo ratings yet

- 181-Article Text-292-1-10-20200406Document10 pages181-Article Text-292-1-10-20200406Nhi NguyễnNo ratings yet

- A Review of Artificial Neural Networks in The Constitutive Modeling of Composite MaterialsDocument15 pagesA Review of Artificial Neural Networks in The Constitutive Modeling of Composite MaterialsGiuseppeNo ratings yet

- PXC 3886594Document6 pagesPXC 3886594Lionel LapuzNo ratings yet

- Ai FeDocument8 pagesAi Fevivashwanth paiNo ratings yet

- PDF 154051 80482Document7 pagesPDF 154051 80482Hani BenguesmiaNo ratings yet

- Implementation of Deep Neural Network Using VLSI BDocument8 pagesImplementation of Deep Neural Network Using VLSI BKhang Truong NguyenNo ratings yet

- Simple Hardware Implementation of Neural Networks For Instruction in Analog ElectronicsDocument12 pagesSimple Hardware Implementation of Neural Networks For Instruction in Analog ElectronicsGeraud Russel Goune ChenguiNo ratings yet

- Hidden Neurons PDFDocument12 pagesHidden Neurons PDFmanojaNo ratings yet

- Project Assignment TBWDocument6 pagesProject Assignment TBWMuzaffar IqbalNo ratings yet

- Prediction of Compressive Strength of Composite Fiber Reinforced Concrete (FRC) Using Artificial Neural NetworkDocument8 pagesPrediction of Compressive Strength of Composite Fiber Reinforced Concrete (FRC) Using Artificial Neural NetworkRachida KrachaiNo ratings yet

- Time Domain Structural Health Monitoring With Magnetostrictive Patches Using Five Stage Hierarchical Neural NetworksDocument7 pagesTime Domain Structural Health Monitoring With Magnetostrictive Patches Using Five Stage Hierarchical Neural NetworksDebiprasad GhoshNo ratings yet

- Artificial Neural Networks: An Overview: August 2023Document11 pagesArtificial Neural Networks: An Overview: August 2023LoneSamuraiNo ratings yet

- Convolutional Neural Network For Flow Over SingleDocument59 pagesConvolutional Neural Network For Flow Over SingleBS GOURISARANNo ratings yet

- Neural Network Prediction forRectangularR - CExteriorEdgeColumnSubjectedtoTorsionEffectDocument16 pagesNeural Network Prediction forRectangularR - CExteriorEdgeColumnSubjectedtoTorsionEffectOrhan YanyatmazNo ratings yet

- SPE 28394 A Methodological Approach For Reservoir Heterogeneity Characterization Using Artificial Neural NetworksDocument5 pagesSPE 28394 A Methodological Approach For Reservoir Heterogeneity Characterization Using Artificial Neural NetworkskapereshemNo ratings yet

- Synthesis of Mechanical Linkages Using Artificial Neural Networks and OptimizationDocument5 pagesSynthesis of Mechanical Linkages Using Artificial Neural Networks and OptimizationSatyajit Halder me18s052No ratings yet

- Evaluation of Dump Slope Stability of A Coal Mine Using Artificial Neuralnetwork 2168 9806 1000128Document5 pagesEvaluation of Dump Slope Stability of A Coal Mine Using Artificial Neuralnetwork 2168 9806 1000128Abhijeet Dutta100% (1)

- AI Concrete StrengthDocument8 pagesAI Concrete StrengthpdhurveyNo ratings yet

- (I Articulo) 2014 Application-Of-Artificial-Neural-Network-In-Predicting-The-Weld-Quality-Of-A-Tungsten-Inert-Gas-Welded-Mild-Steel-Pipe-Joint PDFDocument9 pages(I Articulo) 2014 Application-Of-Artificial-Neural-Network-In-Predicting-The-Weld-Quality-Of-A-Tungsten-Inert-Gas-Welded-Mild-Steel-Pipe-Joint PDFEsteban MerinoNo ratings yet

- Neural Networks Application in PavementDocument20 pagesNeural Networks Application in PavementLucas Cavalcante de AlmeidaNo ratings yet

- Quality Prediction in Object Oriented System by Using ANN: A Brief SurveyDocument6 pagesQuality Prediction in Object Oriented System by Using ANN: A Brief Surveyeditor_ijarcsseNo ratings yet

- RM Assign1Document7 pagesRM Assign1Sushant BhargavaNo ratings yet

- Study of Nano-Systems For Computer SimulationsDocument7 pagesStudy of Nano-Systems For Computer SimulationsFalak KoliNo ratings yet

- Electronics 10 02689 v2Document43 pagesElectronics 10 02689 v2Koripella UsharaniNo ratings yet

- Mitra2021 Article DeterminationOfStableStructureDocument12 pagesMitra2021 Article DeterminationOfStableStructurepinakiNo ratings yet

- Ijaest: Use of Artificial Bee Colony (ABC) Algorithm in Artificial Neural Network SynthesisDocument10 pagesIjaest: Use of Artificial Bee Colony (ABC) Algorithm in Artificial Neural Network Synthesisz1111234No ratings yet

- Data Optimization With Multilayer Perceptron Neural Network and Using New Pattern in Decision Tree ComparativelyDocument8 pagesData Optimization With Multilayer Perceptron Neural Network and Using New Pattern in Decision Tree ComparativelyAkshita dammuNo ratings yet

- Artificial Intelligence Applications in Civil Construction Architectural Engineering EducationDocument10 pagesArtificial Intelligence Applications in Civil Construction Architectural Engineering EducationGovindasamy ChinnuNo ratings yet

- Multiple Harmonic Source Detection and Equipment Identification With Cascade Correlation NetworkDocument8 pagesMultiple Harmonic Source Detection and Equipment Identification With Cascade Correlation NetworkmicapesacNo ratings yet

- Artificial Neural Networks in Structural Dynamics: A New Modular Radial Basis Function Approach vs. Convolutional and Feedforward TopologiesDocument16 pagesArtificial Neural Networks in Structural Dynamics: A New Modular Radial Basis Function Approach vs. Convolutional and Feedforward Topologiesvicto1111No ratings yet

- Applications of Artificial Neural Networks in Foundation EngineeringDocument25 pagesApplications of Artificial Neural Networks in Foundation Engineeringgreenday3No ratings yet

- Artificial Neural Network in Rapid PrototypingDocument9 pagesArtificial Neural Network in Rapid Prototypingpurushothaman sinivasanNo ratings yet

- Forecasting The Production of Fully-Mechanised Coal Face by Meta-Synthetic AI MethodDocument4 pagesForecasting The Production of Fully-Mechanised Coal Face by Meta-Synthetic AI Methodazimi32No ratings yet

- Artificial Bee Colony-Based Neural Network For The Prediction of The Fundamental Period of Infilled Frame StructuresDocument11 pagesArtificial Bee Colony-Based Neural Network For The Prediction of The Fundamental Period of Infilled Frame StructuresNitin DahiyaNo ratings yet

- Prediction of Compressive Strength of Concrete: Machine Learning ApproachesDocument11 pagesPrediction of Compressive Strength of Concrete: Machine Learning ApproachesShemin T JohnNo ratings yet

- Editorial Artificial Neural Networks To Systems, Man, and Cybernetics: Characteristics, Structures, and ApplicationsDocument7 pagesEditorial Artificial Neural Networks To Systems, Man, and Cybernetics: Characteristics, Structures, and Applicationsizzul_125z1419No ratings yet

- Comparison of Neural Network Architectures For Machinery Fault DiagnosisDocument10 pagesComparison of Neural Network Architectures For Machinery Fault DiagnosiselshafeiNo ratings yet

- EM ML SurveyDocument4 pagesEM ML SurveysomedoodNo ratings yet

- (2018) Probabilistic Damage Detection of A Steel Truss Bridge Model by Optimally Designed Bayesian Neural NetworkDocument16 pages(2018) Probabilistic Damage Detection of A Steel Truss Bridge Model by Optimally Designed Bayesian Neural NetworkTao YinNo ratings yet

- Application of ANN To Predict Reinforcement Height of Weld Bead Under Magnetic FieldDocument5 pagesApplication of ANN To Predict Reinforcement Height of Weld Bead Under Magnetic FieldInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- DB 86 FbeeDocument14 pagesDB 86 FbeeFanevaNo ratings yet

- Fuzzy Logic-Based Spike Sorting System: Journal of Neuroscience MethodsDocument10 pagesFuzzy Logic-Based Spike Sorting System: Journal of Neuroscience MethodsAlparslan OnderNo ratings yet

- Exact Algorithms For A Task Assignment Problem: Parallel Processing Letters September 2009Document16 pagesExact Algorithms For A Task Assignment Problem: Parallel Processing Letters September 2009Rahim Ali QamarNo ratings yet

- Scour PaperDocument6 pagesScour Papermohammedasim1999No ratings yet

- Convolutional Neural Network For Image RecognitionDocument8 pagesConvolutional Neural Network For Image RecognitionIJRASETPublicationsNo ratings yet

- Classification of Faults in A Transmission Line Using Artificial Neural NetworkDocument5 pagesClassification of Faults in A Transmission Line Using Artificial Neural Networkdavid CameloNo ratings yet

- Explicit Formulation of Drying and Autogenous Shrinkage of Concretes With Binary and Ternary Blends of Silica Fume and Fly AshDocument9 pagesExplicit Formulation of Drying and Autogenous Shrinkage of Concretes With Binary and Ternary Blends of Silica Fume and Fly AshMohamed ArbiliNo ratings yet

- Analysis of A Triangulation Based Approach For SpeDocument12 pagesAnalysis of A Triangulation Based Approach For SpechotuNo ratings yet

- Modeling Ready Mix Concrete Slump Using Artificial Neural NetworkDocument9 pagesModeling Ready Mix Concrete Slump Using Artificial Neural NetworkPradeep SharmaNo ratings yet

- Structural Analysis Systems: Software — Hardware Capability — Compatibility — ApplicationsFrom EverandStructural Analysis Systems: Software — Hardware Capability — Compatibility — ApplicationsRating: 5 out of 5 stars5/5 (1)

- LISTA PRECIOS CORPORATIVOS - Garantia en Partes de Diez (10) MesesDocument10 pagesLISTA PRECIOS CORPORATIVOS - Garantia en Partes de Diez (10) MesesJavier DavidNo ratings yet

- Camber For Construction StageDocument18 pagesCamber For Construction StageOanh PhanNo ratings yet

- Arthashastra: Citation NeededDocument4 pagesArthashastra: Citation NeededtusharNo ratings yet

- Mobile HardwereDocument19 pagesMobile Hardwereanil8481No ratings yet

- 10 - Chapter 4 PDFDocument143 pages10 - Chapter 4 PDFKalyan ChakravarthyNo ratings yet

- Abb Sattcon ComliDocument17 pagesAbb Sattcon Comlilgrome73No ratings yet

- NASA Facts Explorer XVI The Micrometeoroid SatelliteDocument4 pagesNASA Facts Explorer XVI The Micrometeoroid SatelliteBob AndrepontNo ratings yet

- Buchholz Relay OperationDocument71 pagesBuchholz Relay Operationlinus abrahamNo ratings yet

- Astrophysics QuestionsDocument19 pagesAstrophysics QuestionsMauzoom AliNo ratings yet

- Fpls 12 764103Document10 pagesFpls 12 764103Pawan MishraNo ratings yet

- PDF Sensors Air Conditioning Automotive AN1Document5 pagesPDF Sensors Air Conditioning Automotive AN1Karthik RajaNo ratings yet

- Punching Shear PDFDocument13 pagesPunching Shear PDFmohamedadel100No ratings yet

- Three-Dimensional Lithium-Ion Battery ModelDocument35 pagesThree-Dimensional Lithium-Ion Battery ModelmortezagashtiNo ratings yet

- Optimum Policy ControlDocument4 pagesOptimum Policy ControlKimberly VargasNo ratings yet

- Rules, Scripts and BeanshellDocument7 pagesRules, Scripts and BeanshelltgudyktzxNo ratings yet

- EMDCSS DatasheetDocument5 pagesEMDCSS DatasheetHoracio UlloaNo ratings yet

- Column Design With ExcelDocument40 pagesColumn Design With ExcelMatiur Rahman BasumNo ratings yet

- Mozart Symphony 6 TimpaniDocument2 pagesMozart Symphony 6 Timpaniגיל עברוןNo ratings yet

- Cronje Chemical 2010 PDFDocument569 pagesCronje Chemical 2010 PDFPara MoreNo ratings yet

- Applications of Heat PipeDocument17 pagesApplications of Heat PipeManikantaNaupadaNo ratings yet

- Asset Failure Detention Codes (ICMS - PAM - ZN - SECR 312)Document5 pagesAsset Failure Detention Codes (ICMS - PAM - ZN - SECR 312)mukesh lachhwani100% (1)

- SAE-J1850 Communication Protocol Conformity Transmission Controller For Automotive LANDocument59 pagesSAE-J1850 Communication Protocol Conformity Transmission Controller For Automotive LANMa Ngoc TrungNo ratings yet

- 11Document47 pages11Felipe Retamal100% (1)

- LSMW To Update Customer Master Records With Standard ObjectDocument9 pagesLSMW To Update Customer Master Records With Standard ObjectShahid_ONNo ratings yet

- Entity Framework Interview Questions With AnswersDocument16 pagesEntity Framework Interview Questions With AnswersShivprasad Koirala100% (5)

- CSTR in SeriesDocument3 pagesCSTR in SeriesDhananjay KadamNo ratings yet

- Instruction Manual B-Tronic SystemDocument35 pagesInstruction Manual B-Tronic SystemYipper ShnipperNo ratings yet

- Chapter 9 Deflections of Beams: X Axis and The Tangent To The DeflectionDocument5 pagesChapter 9 Deflections of Beams: X Axis and The Tangent To The DeflectionRimon GawandeNo ratings yet

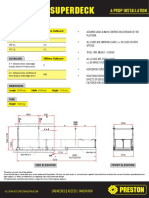

- SuperDeck All ModelsDocument12 pagesSuperDeck All Modelsarthur chungNo ratings yet

- MADNotes J2MEDocument34 pagesMADNotes J2MEKanchana MorumpalliNo ratings yet