Professional Documents

Culture Documents

Motion Electronics in Avionics

Uploaded by

Murat GörükmezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motion Electronics in Avionics

Uploaded by

Murat GörükmezCopyright:

Available Formats

APPLICATION NOTE

Motion Electronics in Avionics

Several transducer types, including synchros, resolvers, linear/rotary variable differential

transformers (LVDT/RVDT) are key building blocks in flight control and navigation

dynamics. This article will address the systems that utilize these transducers, de-mystify

the workings of these AC analog transducers and associated conversion electronics,

describe the testing and simulation of these signal types and discuss some common

troubleshooting failure mechanisms.

Synchros & Resolvers

Synchros have been used in a wide variety of military and commercial systems for

many years. They have traditionally been the transducer of choice where reliability is

critical, and where harsh environmental conditions exist. The simplicity of their

connection, combined with today’s modern (and relatively inexpensive) Synchro-to-

Digital and Digital-to-Synchro converter boards (such as those from North Atlantic

Industries) make the synchro a very attractive component.

Typical applications include:

• fire control • flight surface positioning

• inertial navigation reference units (gyro, • cockpit simulators

compass) • jet engine control

• automatic direction finder (ADF) • antenna pedestal control

• omni-range system (VOR, very high • cockpit indicators

frequency omni-directional range) • landing gear positioning and control

• distance measurement equipment (DME) • flap actuators

In an ADF, for example, the resolver RESOLVER

or synchro is used to drive an

indicator. As the aircraft turns, the FIXED COIL

ROTATING COIL

amount of coupling in the transducer

TO RECEIVER

changes proportionally as illustrated LOOP ANTENNA

in figure 1. The analog waveforms INPUT

FIXED LOOP

generated by these transducers,

and their characteristics, are INDICATOR

detailed in the ARINC407

MOTOR

specification (ARINC Synchro

System Manual), but how do FROM

RECEIVER

synchros and resolvers work

specifically?

Fig. 1 – Automatic Direction Finder (ADF)

North Atlantic Industries, Inc.

110 Wilbur Place, Bohemia, NY 11716 631.567.1100 / 631.567.1823 (fax) www.naii.com / e-mail:sales@naii.com

Theory of Operation

S3 S2

Synchros and resolvers are World War II era

120o

technology that is still widely used in modern day

electronic motion control applications. They are

essentially transformers. Just like a traditional

transformer, they have a primary winding and R1

multiple secondary windings, and just like a 120o

transformer, their primary is driven by an AC

signal. Synchros and resolvers are very similar. R2

However, there are some differences. As shown

in figure 2, a synchro has:

• 2 primary windings Output voltage

S1 relationships

• 3 secondary windings, with each secondary

winding mechanically oriented 120º apart Fig. 2 – Synchro Rotor/Stator Configuration

S1

In contrast, as shown in figure 3, a resolver has:

• 2 primary windings

• 2 secondary windings, which are oriented at S2 S4

90º to each other R1

While a synchro and a resolver are electrically

very similar to a transformer, they are S3

mechanically more like a motor. The primary

R4

winding in a synchro or a resolver can be R2

physically rotated with respect to the secondary

windings. For this reason, the primary winding is Output voltage

called the rotor. The secondary windings (which R3

relationships

are fixed) are called stators. Because of this

Fig. 3 – Resolver Rotor/Stator Configuration

similarity, the term "synchro" will be used to refer

to both Synchros and resolvers for the remainder of this article, unless otherwise noted.

Synchros are often used to track the rotary output angle of a closed-loop system, which

uses feedback to achieve accuracy and repeatability. A synchro can be turned

continuously and, since its secondary winding outputs are analog signals, provide

"infinite" resolution output. As the shaft of a synchro transmitter is turned, the angular

position of its rotor winding changes with respect to its secondary (stator) windings. The

relative amplitude of the resulting AC output signals from the secondary (stator)

windings indicates the rotary position of the transmitter’s shaft.

A synchro is excited by an AC reference voltage applied to its rotor winding. This

reference signal is typically one of two possible voltages:

• 115 VRMS @ 60 Hz or 400 Hz

• 26 VRMS @ 400 Hz

400 Hz signal is used in aircraft applications, where size and weight are important

factors. Reducing the size and weight of a synchro reduces the size of its magnetic

core. A small magnetic core saturates when driven with 60 Hz. For that reason, small

aircraft synchros are excited with 400 Hz signal.

North Atlantic Industries, Inc.

110 Wilbur Place, Bohemia, NY 11716 631.567.1100 / 631.567.1823 (fax) www.naii.com / e-mail:sales@naii.com

Synchro-to-Digital Conversion

Synchros generate analog output signals, and those outputs must typically be converted

to digital form. This can be accomplished by using a synchro-to-digital converter. It

might seem logical to use a set of conventional A/D converters to simultaneously

sample the AC voltages on the outputs of a synchro. The relative magnitudes of these

samples could then be used to determine the rotary position of the synchro’s shaft at

the time the samples where taken.

However, this does not work well for several reasons:

• Synchros have inductive

characteristics, which must be

taken into account

• Synchro output signals can be

heavily distorted, due to the

nonlinearities in the Synchro

• Synchro output signals often

contain a lot of noise because

of the environment they work in.

In addition, if the inputs and the outputs of a The 64C2 6U VME multifunction board contains

synchro are not galvanically isolated from up to 6 independent module slots, each of which

each other (and from the signal ground) can be populated with a function specific

common mode noise can dramatically affect module. The S Module features 4 channels of

Synchro-to-Digital conversion; therefore the

the accuracy of conversion. To avoid these 64C2 is capable of providing up to 24 channels

problems, an S/D converter board must of Synchro-to-Digital conversion.

employ transformer-isolated inputs and

outputs, thus significantly reducing the effects of common mode noise and ground

loops.

LVDTs and RVDTs

LVDTs and RVDTs are electromagnetic displacement

transducers designed to provide output voltages

proportional to linear and rotary displacement,

respectively. These transducers consist of three basic VP

elements: a primary winding, two secondary windings PRIMARY

and a movable armature made of a soft OUT IN

ferromagnetic material, as illustrated in figure 4. This ARMATURE

transducer type would be typical of flight surface

measurement (e.g. flaps, slats, rudder, aileron) or SECONDARY

B

SECONDARY

A

landing gear positioning and control. As differential or

VA VB

ratiometric devices they are particularly insensitive to

common-mode noise and temperature effects and VA - VB

are therefore ideal for harsh aircraft environments.

ARINC608 (Standard Modular Avionics Repair and Fig. 4 – LVDT/RVDT Configuration

Test System) describes interface to many signal

types including synchro/resolvers and LVDTs.

North Atlantic Industries, Inc.

110 Wilbur Place, Bohemia, NY 11716 631.567.1100 / 631.567.1823 (fax) www.naii.com / e-mail:sales@naii.com

Avionic Test Equipment must therefore address the means to both measure and

simulate these signal types. Typical rack and stack instrumentation might include angle

position indicators (API), synchro/resolver simulators (SIM) and phase angle voltmeters

(PAV) to enable measurement or simulation of phase-sensitive signals.

Modern ATE has migrated to VXIbus

technology with a combination of

synchro/resolver measurement and

simulation (e.g. NAI model 5390) that

may be integrated into an overall

instrumentation test stand. Similarly,

LVDT signals may be measured by a

phase angle voltmeter either rack-

and-stack or VXIbus configurations.

These signal types may also be

configured in a VMEbus environment, The 65CS4 is a multichannel, Instrument/Embedded Grade

common to flight simulators, or a single slot VXI “C”-size card. It incorporates up to four

PCbus architecture. Multi-channel Synchro/Resolver-to-Digital conversion channels, as well as

implementations are typical and 4 channels of Digital-to-Synchro/Resolver simulation.

hardware is tailored to meet specific

voltage and frequency requirements. Such instruments and cards are essential tools to

the measurement, control, simulation and test of motion electronics.

Testing and troubleshooting

Synchro and LVDT signals require specialized test equipment for accurate

measurement and calibration. Several parameters need to be considered as all of these

will invariably affect the performance and integrity of the of the avionics system as a

whole.

• Accuracy

• Phase shift and quadrature

• Resolution

• Dynamic characteristics

• Distortion and noise

Accuracy and verification of a

synchro/resolver transmitter signals are

most easily and best accomplished

using an Angle Position Indicator (API)

such as the North Atlantic Model 8810A

or 8500. These instruments can read the

synchro signal directly in degrees and

decimal degrees. An API automatically

The 8810A is a highly accurate Synchro/Resolver

compensates for phase shift, noise and Angle Position Indicator (API) used for calibration and

distortion. Due to their transformer test functions of components, assemblies and systems.

coupled inputs, common mode effects

are reduced to a minimum.

North Atlantic Industries, Inc.

110 Wilbur Place, Bohemia, NY 11716 631.567.1100 / 631.567.1823 (fax) www.naii.com / e-mail:sales@naii.com

For calibration grade accuracy of up to 2 arc seconds a synchro/resolver bridge (such

as the Model 540) and Phase Angle

Voltmeter (PAV), such as the Model

2250 or 2251 is required. The PAV is

also used to measure phase shift and

total (rms), fundamental, quadrature

and in-phase voltage. The PAV is

specifically designed to measure these

parameters accurately in the presence

of highly distorted and noisy signals NAI’s 2250 Digital Phase Angle Voltmeter presents a

(such as those encountered in new level of accuracy and versatility in AC

synchro/resolver systems) t

To accurately simulate a synchro/resolver signal or to drive a synchro/resolver receiver

a standard such as the North Atlantic Model 5330 or 5300 is needed. It is important to

understand the load requirements of the unit under test and to make sure that these fall

within the output drive capability of the simulator. These instruments are designed to

generate signals with enough

resolution, speed and drive capability

to dynamically and statically test most

common devices that accept 3

(synchro) or 4 (resolver) wire inputs.

LVDT/RVDT signals must be tested

using a phase angle voltmeter such as

the Model 2250 or 2251. Key

measurements to be made are

ratiometric characteristics, voltage

linearity and phase shift. North Atlantic NAI’s 5330A is the latest in Digital Synchro/Resolver

also offers LVDT/RVDT signal Simulation technology. Intelligent DSP design allows

generators in VXI, VME and PC based all programming via touch-screen or mouse interface.

formats.

Conclusion

Synchros, resolvers and LVDT/RVDTs are important and reliable elements of avionics

systems. The operation and interface of these transducers enables navigation and flight

surface control feedback. Consequently, the operational characteristics, typical failure

mechanisms and available equipment for measurement, control, simulation and test of

these transducer types are essential elements to the design of on-board systems, flight

simulators and ATE.

North Atlantic Industries, Inc.

110 Wilbur Place, Bohemia, NY 11716 631.567.1100 / 631.567.1823 (fax) www.naii.com / e-mail:sales@naii.com

You might also like

- ServomechanismsDocument25 pagesServomechanismsEgor85No ratings yet

- Electronic Flight Instrument SystemDocument14 pagesElectronic Flight Instrument SystemBookMaggotNo ratings yet

- Airbus AC A320 Jan16Document390 pagesAirbus AC A320 Jan16simon100% (1)

- Aircraft Structures and System 1Document9 pagesAircraft Structures and System 1Zjian Wai100% (1)

- Thrust Reversers Aircraft SystemsDocument20 pagesThrust Reversers Aircraft SystemsShaurya GuptaNo ratings yet

- 787 Report Final - March 19, 2014Document71 pages787 Report Final - March 19, 2014Evan Buxbaum, CircaNo ratings yet

- TSM 32-31-00-810-820-A PDFDocument4 pagesTSM 32-31-00-810-820-A PDFMoc JetsmartNo ratings yet

- GeneralDocument48 pagesGeneralParag Alamyan100% (1)

- NEW Oral Practical Questions (Powerplant)Document35 pagesNEW Oral Practical Questions (Powerplant)Juan C Balderas100% (1)

- Module 14 NOTEDocument72 pagesModule 14 NOTEASHIS MAHARANANo ratings yet

- Airbus A318 A319 A320 A321Document24 pagesAirbus A318 A319 A320 A321HelloWorldNo ratings yet

- Arinc Standards LN - 13Document14 pagesArinc Standards LN - 13M S PrasadNo ratings yet

- Automatic Flight Control SystemDocument50 pagesAutomatic Flight Control SystemZay Yar100% (1)

- Fault IsolationDocument226 pagesFault Isolationfarazh.oneNo ratings yet

- Garmin GPS 165 Installation ManualDocument43 pagesGarmin GPS 165 Installation ManualCAOSORIO2004No ratings yet

- 06 ATA29 Hydraulics 2012Document17 pages06 ATA29 Hydraulics 2012Jack AzadNo ratings yet

- Passenger Aircraft SubsystemsDocument79 pagesPassenger Aircraft Subsystemsraymun c100% (3)

- CAT B1 Module 05 Master PDFDocument438 pagesCAT B1 Module 05 Master PDFNouman LatifNo ratings yet

- S65-5366 L-BandDocument1 pageS65-5366 L-Bandkkpatel87No ratings yet

- Master Minimum Equipment List: U.S. Department of Transportation Federal Aviation AdministrationDocument203 pagesMaster Minimum Equipment List: U.S. Department of Transportation Federal Aviation AdministrationHetskuniNo ratings yet

- CAR 66 Module 5.4 Data BusesDocument24 pagesCAR 66 Module 5.4 Data Busespontoo100% (1)

- AvionicsDocument57 pagesAvionicsMoses Devaprasanna100% (1)

- Ac 21-99Document399 pagesAc 21-99georgeclima4103100% (2)

- ARINC 429 CommentaryDocument22 pagesARINC 429 CommentaryIsaac MoraNo ratings yet

- Flying The Jet City Aircraft Md-90: PreparationDocument10 pagesFlying The Jet City Aircraft Md-90: PreparationCharles SingerNo ratings yet

- EASA Mod 13 BK 44 Landing GearDocument42 pagesEASA Mod 13 BK 44 Landing GearDavid OwenNo ratings yet

- Use of MEDLINKDocument4 pagesUse of MEDLINKAli Ismail MuhiddinNo ratings yet

- Avionics Bus - DA - CPDocument31 pagesAvionics Bus - DA - CPM S Prasad100% (1)

- Airbus AbbreviationDocument46 pagesAirbus Abbreviationyeung875No ratings yet

- M11 Aerodynamcis, Structures and Instruments 1 of 2Document913 pagesM11 Aerodynamcis, Structures and Instruments 1 of 2kls07037667% (3)

- PDF N Fcom Sva TF N Eu 20130101 DSC 22 30Document138 pagesPDF N Fcom Sva TF N Eu 20130101 DSC 22 30JP ZemogNo ratings yet

- Module 13.docx ADMALDocument40 pagesModule 13.docx ADMALMohamad Nor Iman100% (1)

- Introduction of EASA Part 66Document10 pagesIntroduction of EASA Part 66Siswa EmasNo ratings yet

- CRJ 700Document2 pagesCRJ 700Arie Wibowo100% (1)

- 06 - Wwamm RDocument21 pages06 - Wwamm RPedroRodriguezNo ratings yet

- Baker Airframe 1Document36 pagesBaker Airframe 1Idris IbrahimNo ratings yet

- CAR 66 Module 5.12 Electrostatics Sensitive DeviceDocument12 pagesCAR 66 Module 5.12 Electrostatics Sensitive Devicepontoo100% (1)

- 02 - Basic - AhrsDocument40 pages02 - Basic - AhrsGazi JayedNo ratings yet

- Vapor Cycle System (VCS) : Effectivity:AllDocument16 pagesVapor Cycle System (VCS) : Effectivity:AllclebersjcNo ratings yet

- DTA Guidelines For Antenna InstallationsDocument60 pagesDTA Guidelines For Antenna InstallationsivanfernandorodriguezNo ratings yet

- TheAvionicsHandbook Cap 31 PDFDocument16 pagesTheAvionicsHandbook Cap 31 PDFfernandoabel01No ratings yet

- EASA Mod 9A BK 1 Human Factors 1 PDFDocument75 pagesEASA Mod 9A BK 1 Human Factors 1 PDFRam C HumagainNo ratings yet

- ARINc 629 PDFDocument9 pagesARINc 629 PDFM S PrasadNo ratings yet

- Aircraft Flight Control SystemDocument187 pagesAircraft Flight Control SystemTahnia AyshiNo ratings yet

- Cl600 Easa-Mmel Rev01 2Document198 pagesCl600 Easa-Mmel Rev01 2Philippe TORNENo ratings yet

- 2.1 Introduction To Flight Control SystemsDocument38 pages2.1 Introduction To Flight Control SystemsFanhang ZhangNo ratings yet

- Soft Afdx (Avionics Full Duplex Switched Ethernet) End System Implementation With Standard PC and Ethernet CardDocument121 pagesSoft Afdx (Avionics Full Duplex Switched Ethernet) End System Implementation With Standard PC and Ethernet CardMarian RotaruNo ratings yet

- Boeing Phase II - Main Doc 1Document10 pagesBoeing Phase II - Main Doc 1api-530918428No ratings yet

- Aircraft Electrical GeneratorDocument714 pagesAircraft Electrical GeneratorPIYUSH100% (1)

- Airbus - A320 A330 A340 Families - Cabin Crew PDFDocument33 pagesAirbus - A320 A330 A340 Families - Cabin Crew PDFMuhammad HassanNo ratings yet

- AirFranceIndustries CourseCatalog PDFDocument107 pagesAirFranceIndustries CourseCatalog PDFNimesh DelanNo ratings yet

- Resumen Atr A ColorDocument26 pagesResumen Atr A ColorDoberman06No ratings yet

- Feedback 2 2016 enDocument40 pagesFeedback 2 2016 enshaotao guoNo ratings yet

- KHF 1050 Feature ComparisonDocument8 pagesKHF 1050 Feature ComparisonMy Agung SuryadiNo ratings yet

- Entry AC43.13-1BDocument35 pagesEntry AC43.13-1Bjuan_o_620100% (1)

- An Analysis and Correlation of Aircraft Wave Drag - HarrisDocument70 pagesAn Analysis and Correlation of Aircraft Wave Drag - HarrisTRFNo ratings yet

- Design Considerations For Pressure Sensing IntegrationDocument6 pagesDesign Considerations For Pressure Sensing IntegrationMurat GörükmezNo ratings yet

- SmartProbeR Air Data SystemsDocument4 pagesSmartProbeR Air Data SystemsMurat GörükmezNo ratings yet

- Video System Upgrade On Aerial Support Aircraft Case StudyDocument2 pagesVideo System Upgrade On Aerial Support Aircraft Case StudyMurat GörükmezNo ratings yet

- TouchscreenTechnology Comparison EsterlineDocument2 pagesTouchscreenTechnology Comparison EsterlineMurat GörükmezNo ratings yet

- ICCE Presentation On VESA Display PortDocument40 pagesICCE Presentation On VESA Display Porthithot2008No ratings yet

- Haptics For TouchsenseDocument3 pagesHaptics For TouchsenseMurat GörükmezNo ratings yet

- Choosing An Embedded File SystemDocument2 pagesChoosing An Embedded File SystemMurat GörükmezNo ratings yet

- XCOM Aerial Dummies GuideDocument9 pagesXCOM Aerial Dummies Guide@macNo ratings yet

- Avionics Architectures and ComponentsDocument10 pagesAvionics Architectures and ComponentsMurat GörükmezNo ratings yet

- Fundamentals of Aviation and Space TechnologyDocument172 pagesFundamentals of Aviation and Space TechnologySfarleaza100% (1)

- Part 66 Basic Training 20090211 PDFDocument50 pagesPart 66 Basic Training 20090211 PDFCharbel EL SayyarNo ratings yet

- Open Systems Integrated Modular Avionics - The Real Thing - : René L.C. EveleensDocument22 pagesOpen Systems Integrated Modular Avionics - The Real Thing - : René L.C. EveleenssaeedbabaNo ratings yet

- Understanding Required Navigation Performance (RNP) and Area Navigation (RNAV) OperationsDocument8 pagesUnderstanding Required Navigation Performance (RNP) and Area Navigation (RNAV) OperationsaleNo ratings yet

- Basic Principles of Inertial NavigationDocument22 pagesBasic Principles of Inertial NavigationSai VishwanathNo ratings yet

- Safety Critical CommunicationDocument63 pagesSafety Critical CommunicationMurat GörükmezNo ratings yet

- M8 BasicAerodynamicsDocument16 pagesM8 BasicAerodynamicsBig FloresNo ratings yet

- Basic Principles of Inertial NavigationDocument22 pagesBasic Principles of Inertial NavigationSai VishwanathNo ratings yet

- A380 Integrated Modular AvionicsDocument45 pagesA380 Integrated Modular AvionicsHugues de Payens100% (4)

- Introduction of Glass Cockpit Avionics PDFDocument91 pagesIntroduction of Glass Cockpit Avionics PDFMurat GörükmezNo ratings yet

- Garmin G500 - Pilot Guide PDFDocument354 pagesGarmin G500 - Pilot Guide PDFMurat GörükmezNo ratings yet

- Avionic Displays: Branko LivadaDocument10 pagesAvionic Displays: Branko LivadaMurat GörükmezNo ratings yet

- Robinson - Maintenance Manual PDFDocument130 pagesRobinson - Maintenance Manual PDFMurat GörükmezNo ratings yet

- GARMIN Flight Deck - SolutionsDocument12 pagesGARMIN Flight Deck - SolutionsMurat Görükmez100% (2)

- Image Fusion For Tactical ApplicationsDocument11 pagesImage Fusion For Tactical ApplicationsMurat GörükmezNo ratings yet

- Understanding EDID - Extended Display Identification Data PDFDocument5 pagesUnderstanding EDID - Extended Display Identification Data PDFMurat GörükmezNo ratings yet

- Safety Critical CommunicationDocument63 pagesSafety Critical CommunicationMurat GörükmezNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- ADISept05 PDFDocument5 pagesADISept05 PDFMurat GörükmezNo ratings yet

- 4.11 Radar Cross-Section (RCS)Document5 pages4.11 Radar Cross-Section (RCS)hariramrmNo ratings yet

- Eep000090 14700510 Mearr 0036 - 01 PDFDocument1 pageEep000090 14700510 Mearr 0036 - 01 PDFডঃ শুভম চ্যাটার্জীNo ratings yet

- Commercial Loads Calculation NECDocument9 pagesCommercial Loads Calculation NECRudanek100% (1)

- Determination of the viscosity coefficient of glycerin.: v= g (ρ ρ - v= s tDocument2 pagesDetermination of the viscosity coefficient of glycerin.: v= g (ρ ρ - v= s tفاطمة محمد الزهرانيNo ratings yet

- Module 6 - Laws of MotionDocument9 pagesModule 6 - Laws of MotionTOP ERNo ratings yet

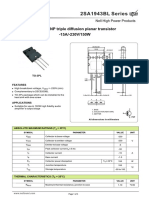

- 2SA1943BL Series: Silicon PNP Triple Diffusion Planar Transistor - 15A/-230V/150WDocument3 pages2SA1943BL Series: Silicon PNP Triple Diffusion Planar Transistor - 15A/-230V/150WYukie Vaie JoeNo ratings yet

- CSB HR1234WF2 - Hoja de DatosDocument1 pageCSB HR1234WF2 - Hoja de DatosGermanYPNo ratings yet

- Dian Eka Prasetyawan - Design of Electrical Setting Protection Indarung VI Cement Plant PT Semen Padang (New Format) EnglishDocument13 pagesDian Eka Prasetyawan - Design of Electrical Setting Protection Indarung VI Cement Plant PT Semen Padang (New Format) EnglishDian PrasetyawanNo ratings yet

- Physics On The Guitar - Jim Overhiser & Luke Donev PDFDocument19 pagesPhysics On The Guitar - Jim Overhiser & Luke Donev PDFValter DiasNo ratings yet

- 5.DEMADEM AV10859650 enDocument6 pages5.DEMADEM AV10859650 enEngineering TFINo ratings yet

- Is.6209.2006 Indian Standard Methods For Partial Discharge MeasurementsDocument35 pagesIs.6209.2006 Indian Standard Methods For Partial Discharge Measurementsjuanete29No ratings yet

- IR NsuDocument50 pagesIR NsuTahsin AhmedNo ratings yet

- Submittal Wilo 01Document28 pagesSubmittal Wilo 01Shaik Bepari JakeerNo ratings yet

- 49 Meridian Sections 1 2Document6 pages49 Meridian Sections 1 2lavaganciaNo ratings yet

- Visible Light: Color Temperature Is A Characteristic ofDocument3 pagesVisible Light: Color Temperature Is A Characteristic ofRhona MerinNo ratings yet

- Objectives Electrical EngineeringDocument21 pagesObjectives Electrical Engineeringvan eric lardizabalNo ratings yet

- Answer CK 12 PhysicsDocument263 pagesAnswer CK 12 PhysicsZeinab Elkholy100% (1)

- Thermodynamics PDFDocument347 pagesThermodynamics PDFVishal PrajapatiNo ratings yet

- Exercises March 2021Document4 pagesExercises March 2021Giang HươngNo ratings yet

- Minireview Aquaporin Water Channels: Molecular Mechanisms For Human Diseases1Document13 pagesMinireview Aquaporin Water Channels: Molecular Mechanisms For Human Diseases1GrenlyKerehNo ratings yet

- Handbook On Earthing System For Power Supply Installations PDFDocument82 pagesHandbook On Earthing System For Power Supply Installations PDFPavan100% (4)

- Material Testing MethodsDocument6 pagesMaterial Testing MethodsFebrian JhaNo ratings yet

- Flexible Options Comfortable FunctionsDocument2 pagesFlexible Options Comfortable FunctionsDavid Gnana DuraiNo ratings yet

- Cat DVRDocument68 pagesCat DVRhomayoun100% (6)

- Chapter 03 - Mesh AnalysisDocument21 pagesChapter 03 - Mesh AnalysisHidayah KamaludinNo ratings yet

- Henry Dave D. Demorito Problem Set 1Document4 pagesHenry Dave D. Demorito Problem Set 1Henry Dave DemoritoNo ratings yet

- Parameter Adaptation of Reduced Order Models For Three-Dimensional Flutter AnalysisDocument9 pagesParameter Adaptation of Reduced Order Models For Three-Dimensional Flutter AnalysisAtsis PapadopoulosNo ratings yet

- AKROLEN® PP ICF 30 AM Black (8344) - Akro-PlasticDocument3 pagesAKROLEN® PP ICF 30 AM Black (8344) - Akro-PlasticalkhalidibaiderNo ratings yet

- Metrology Course 2-1441-1442 Part 2Document54 pagesMetrology Course 2-1441-1442 Part 2OSAMA ALRIFAINo ratings yet

- Potential Distribution Over Suspension Insulator S PDFDocument4 pagesPotential Distribution Over Suspension Insulator S PDFsmitajanaNo ratings yet

- (2015) Design Optimization of Front and Rear Aerodynamic Wings of A High Performance CarDocument6 pages(2015) Design Optimization of Front and Rear Aerodynamic Wings of A High Performance CarBảo Toàn LêNo ratings yet