Professional Documents

Culture Documents

Ms Aode: Master Solenoid Kit

Uploaded by

Guilherme ZoboliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ms Aode: Master Solenoid Kit

Uploaded by

Guilherme ZoboliCopyright:

Available Formats

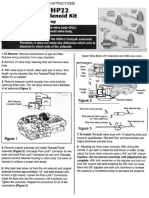

INSTAllATION INSTRUCTIONS

MS AODE

Master Solenoid Kit

FITS AODE/4R70W

'92 -'94 (some '95)

AODE SHIFT SOLENOID DUAL PACK loosen the inner nut. Slide the manual shaft partially out of the

76919 20 to 40 ohms case to complete removal of the inner nut.

AODE MCCC LOCK-UP SOLENOID 5. Remove manual shaft, rooster comb, and park pawl rod

76918 1 to 3 ohms from case.

1.To Remove: 6. Remove one 8mm bolt holding the EPC (Electronic Pressure

\.\. Control) Solenoid Bracket and discard OEM retaining bracket.

Remove the old

dual shift Disconnect EPC wires and remove solenoid.

solenoid by first

unplugging the ~_o

0

'8 R- 7. To Install: Before attempting to install the EPC solenoid

grease the snout to prevent a-rings from

harness from

the old solenoid. Dual Pack

/C!: rolling off. Install EPC with Teckpak's

retaining bracket (Figure 4). Reuse the

Remove the two Shift Solenoid .I~ OEM bolt. Connect vehicle wiring harness

bolts holding the MCCC (Lock-up) to the new 76923 EPC Solenoid.

old solenoid to Solenoid

8. Reinstall manual shaft and rooster comb

the valve body.

This bolt secures with park pawl rod in the case. Install inner

One of the bolts

Figure both solenoids nut on manual shaft. Using a 13/16"

may secure

open-end wrench, tighten the inner nut

both the dual solenoid and the MCCC (Lock-up). Pull the

while holding the manual shaft with a 1mm wrench.

dual solenoid directly out and discard. Remove the MCCC

Lock-up Solenoid. - 9. Make sure the manual valve and the rooster comb are

properly lined up, and install the manual shaft retaining pin.

2. To Install: Insert the new Teckpak

Install manual lever detent spring and roller with one 8mm

MCCC solenoid (Figure 2). Then, install

retaining bolt.

the Dual Shift Solenoid into the valve body

10. Install MLPS and adjust according to the manufacturer's

as shown in Figure 1. Tighten the bolts to

specification. Plug the OEM harness

:J--- specifications.

Figure 2

connector into the center of the new Dual 11. Test drive the vehicle to perform shift test.

Shift solenoid, and connect the MCCC Lock-up solenoid.

12. Adjust the force motor solenoid. After driving the vehicle,

AODE EPC if you wish to make the shift firmer or softer, simply adjust the

76923 2.48 to 5.66 ohms force motor solenoid using a 3/8" and 5/8" wrench. Caution:

Do not remove wrenches until adjustments are complete.

1.To Remove: Removetwo 8 mm bolts retainingmanual

With both wrenches on the adjuster and lock nut, hold 3/8"

lever positionsensor (MLPS)to case. RemoveMLPSfrom

wrench still while breaking the 5/8" lock nut loose. Move the

manualshaft(Figure 3). 3/8" adjuster one-sixth turn clockwise to increase the

2. Removeone 8mm bolt retainingmanuallever detent pressure or counterclockwise to decrease the pressure.

springand roller .

Helalnlng DDlt Line Pressure:

I .

assemblyto the ";!JJ.

valve body. Helalmng

r .Manual srun

50-75:

80-120:

P, D, N (closed throttle position)

Reverse (closed throttle position)

bracket retaining pin

3. Removemanual 160-210: P, 0, N (open throttle position)

.Manual lever

shaftroll pin. position 220-280: Reverse (open throttle position)

sensor

4. Usinga 13/16" If you experience high line pressure in "PARK", a-ring may

Rooster comb

open-endwrenchon have rolled during installation. An extra a-ring is provided for a

the innernutanda Figure3~~~~~ ~ second attempt. Please grease the snout. High line pressure

12mmwrenchon the problems can also occur when using the OEM bracket.

manualshaftflats,

~

~

You might also like

- Msaode 95 PDFDocument1 pageMsaode 95 PDFGuilherme ZoboliNo ratings yet

- Master Solenoid Kit: MS KM-175 93Document1 pageMaster Solenoid Kit: MS KM-175 93Guilherme ZoboliNo ratings yet

- MS 4L80E Master Solenoid KitDocument1 pageMS 4L80E Master Solenoid KitGuilherme ZoboliNo ratings yet

- SKI Elec Tronic Reverse (Line-Up) - Supplement mmr2017-121 enDocument9 pagesSKI Elec Tronic Reverse (Line-Up) - Supplement mmr2017-121 enErne Lange OlsenNo ratings yet

- Ma 1500000 WMDocument7 pagesMa 1500000 WMCarlos ReyesNo ratings yet

- 2005 S60 Front Cig Socket RemoveDocument2 pages2005 S60 Front Cig Socket RemoveЙордан ПетровNo ratings yet

- Maintenance: OS030EC (C801) OS/SS030BE (D826)Document10 pagesMaintenance: OS030EC (C801) OS/SS030BE (D826)Hector PuacNo ratings yet

- STARTER 02 01 srm0106 PDFDocument16 pagesSTARTER 02 01 srm0106 PDFcarlos maradiaga100% (1)

- Steering SystemDocument12 pagesSteering Systemluis tocoraNo ratings yet

- Master Solenoid Kit: (Figure 1)Document1 pageMaster Solenoid Kit: (Figure 1)Guilherme ZoboliNo ratings yet

- Civic 1996 2000 D16Y5 D16D8 B16A2Document176 pagesCivic 1996 2000 D16Y5 D16D8 B16A2Juan David RamirezNo ratings yet

- Master Solenoid Kit: MS KM-175Document1 pageMaster Solenoid Kit: MS KM-175Guilherme ZoboliNo ratings yet

- Electric BrakeDocument14 pagesElectric BrakeHector Puac100% (1)

- Proximity Switch InstallationDocument3 pagesProximity Switch InstallationSaleh AlomariNo ratings yet

- Semi Solid Link Solenoid Installation Instructions 50MT Motor 12V and 24VDocument2 pagesSemi Solid Link Solenoid Installation Instructions 50MT Motor 12V and 24VAbu Naufal HanifahNo ratings yet

- S80 Replace Shift SolenoidDocument38 pagesS80 Replace Shift SolenoidZulkifli Zainal RampakNo ratings yet

- Valve Body F4A222 PDFDocument1 pageValve Body F4A222 PDFSanun Automatictranmission100% (1)

- In-Vehicle Repair: Output Shaft Speed (OSS) SensorDocument11 pagesIn-Vehicle Repair: Output Shaft Speed (OSS) SensorAlex Maceira GraterolNo ratings yet

- Assembly and Use of GEMO Contactless Ignition System Model D-04Document9 pagesAssembly and Use of GEMO Contactless Ignition System Model D-04Manuel Ćulibrk100% (1)

- Semi Solid Link Solenoid Installation Instructions 37mt, 41mt and 42mt Starters 12v and 24vDocument6 pagesSemi Solid Link Solenoid Installation Instructions 37mt, 41mt and 42mt Starters 12v and 24vElfego Ortega GarciaNo ratings yet

- A2201 PDFDocument12 pagesA2201 PDFhamzaNo ratings yet

- 37, 41, 42MT SSL Solenoids PDFDocument4 pages37, 41, 42MT SSL Solenoids PDFjuanNo ratings yet

- EnertorkDocument22 pagesEnertorkTj Bro BroNo ratings yet

- MS 4T60E: Master Solenoid KitDocument1 pageMS 4T60E: Master Solenoid KitGuilherme ZoboliNo ratings yet

- Weldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitDocument12 pagesWeldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitMark trahanNo ratings yet

- Prestige - Medical - 2100 - Service - Manual Steam SterilizerDocument13 pagesPrestige - Medical - 2100 - Service - Manual Steam SterilizerGigi CostelusNo ratings yet

- KC22/32 SERIES Sealless Non-Metallic Centrifugal Pumps Installation and Maintenance Instructions AssemblyDocument6 pagesKC22/32 SERIES Sealless Non-Metallic Centrifugal Pumps Installation and Maintenance Instructions AssemblyEdwin Collado FigueroaNo ratings yet

- Assembly Gemo d05 enDocument9 pagesAssembly Gemo d05 enbergsten532No ratings yet

- 2cv Manual3Document9 pages2cv Manual3alfonsoNo ratings yet

- Honeywell 40003916 Powerhead InstallDocument4 pagesHoneywell 40003916 Powerhead InstallbarryNo ratings yet

- Electronic Pressure Control (EPC) Solenoid: RemovalDocument2 pagesElectronic Pressure Control (EPC) Solenoid: RemovalJavier MgzNo ratings yet

- Magpower Clutch Model CDocument4 pagesMagpower Clutch Model CJuan CaceresNo ratings yet

- Ati Manual Reverse Valve BodyDocument4 pagesAti Manual Reverse Valve BodyPaul OfsthunNo ratings yet

- A111 89ND-NGSDocument17 pagesA111 89ND-NGSMuhammad Idrees ArainNo ratings yet

- Iql Electric Linear Actuator Installation and Maintenance ManualDocument7 pagesIql Electric Linear Actuator Installation and Maintenance ManualretrogradesNo ratings yet

- Kalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io)Document151 pagesKalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io)ValeriNo ratings yet

- Kc11 Series Sealless Non-Metallic Centrifugal Pumps Installation & Maintenance InstructionsDocument5 pagesKc11 Series Sealless Non-Metallic Centrifugal Pumps Installation & Maintenance InstructionsEdwin Collado FigueroaNo ratings yet

- Motor Operating Device UEMC 40 A - , B - , D - : Installation, Operating and Recycling GuideDocument38 pagesMotor Operating Device UEMC 40 A - , B - , D - : Installation, Operating and Recycling GuidecepchileNo ratings yet

- Ferrari - Cap6.3 Manutenzione F121618 EDocument23 pagesFerrari - Cap6.3 Manutenzione F121618 EJoseph VasquezNo ratings yet

- MSD 4151Document8 pagesMSD 4151rxhughesNo ratings yet

- Park/Neutral Position Switch Assy (Atm) : ReplacementDocument3 pagesPark/Neutral Position Switch Assy (Atm) : ReplacementluisNo ratings yet

- ABB Power Distribution: Motor Operating Device UEMC 40 A - , B - , D - Installation and Operating GuideDocument33 pagesABB Power Distribution: Motor Operating Device UEMC 40 A - , B - , D - Installation and Operating GuideivanramljakNo ratings yet

- Brake System PDFDocument9 pagesBrake System PDFdiego diaz100% (1)

- 6-RELA-ABT Boton de Aborto PDFDocument2 pages6-RELA-ABT Boton de Aborto PDFAndres Rodriguez ArevaloNo ratings yet

- 6-RELA-ABT Boton de AbortoDocument2 pages6-RELA-ABT Boton de AbortoAndres Rodriguez ArevaloNo ratings yet

- Asco - Solenoide Ef8017g1 Red HatDocument4 pagesAsco - Solenoide Ef8017g1 Red HatMariano DomenechNo ratings yet

- Points Eliminator: Conversion Part No. 2030Document2 pagesPoints Eliminator: Conversion Part No. 2030masakpNo ratings yet

- Ip-7700 Infusion Pump: Service ManualDocument20 pagesIp-7700 Infusion Pump: Service ManualSkywalker_92No ratings yet

- Sps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Document7 pagesSps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Zahira Yadira Arévalo MéndezNo ratings yet

- 700R4 Manual Reverse Valve Body: Installation InstructionsDocument4 pages700R4 Manual Reverse Valve Body: Installation InstructionsAbbode HoraniNo ratings yet

- EIC5000 Electronic Indicator Control Installation and Operation InstructionsDocument8 pagesEIC5000 Electronic Indicator Control Installation and Operation InstructionsАртемNo ratings yet

- Sec8 LHDDocument375 pagesSec8 LHDEzequiel SkirzinskiNo ratings yet

- 1953 Lucas Dynamos E3L E3LM E3NDocument7 pages1953 Lucas Dynamos E3L E3LM E3NedelapolloNo ratings yet

- MG 3 Cylinder Head Bolt Torque Settings PDFDocument2 pagesMG 3 Cylinder Head Bolt Torque Settings PDFMikeNo ratings yet

- 93ZJ Secc 8S Power WindowsDocument4 pages93ZJ Secc 8S Power WindowsBLAZEPSINo ratings yet

- Installation Instructions For The FT-10 Network Genset LonWorks Card With PCC3200Document7 pagesInstallation Instructions For The FT-10 Network Genset LonWorks Card With PCC3200Nguyen SonNo ratings yet

- Pinion Clearance - Adjust: Shutdown SIS Previous ScreenDocument3 pagesPinion Clearance - Adjust: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Antrieb Actuators O & M CatalogueDocument12 pagesAntrieb Actuators O & M Catalogueysr3ee6926100% (3)

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationFrom EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationRating: 4 out of 5 stars4/5 (1)

- Fundamentals of Automation and Remote Control: International Series of Monographs in Automation and Automatic ControlFrom EverandFundamentals of Automation and Remote Control: International Series of Monographs in Automation and Automatic ControlRating: 5 out of 5 stars5/5 (1)

- A604 A606 42rleDocument2 pagesA604 A606 42rleGuilherme ZoboliNo ratings yet

- A604 A606 42rle PDFDocument2 pagesA604 A606 42rle PDFGuilherme Zoboli100% (2)

- Axode Ax4sDocument2 pagesAxode Ax4sGuilherme ZoboliNo ratings yet

- Subaru 4EATDocument2 pagesSubaru 4EATGuilherme ZoboliNo ratings yet

- Mazda R4-AEL, R4AXEL (929) : Transmission Code: 131Document2 pagesMazda R4-AEL, R4AXEL (929) : Transmission Code: 131Guilherme ZoboliNo ratings yet

- Allison 1000/2000: SOLENOID TEST: (Engine Off)Document2 pagesAllison 1000/2000: SOLENOID TEST: (Engine Off)Guilherme ZoboliNo ratings yet

- Allison WTEC II PDFDocument2 pagesAllison WTEC II PDFGuilherme ZoboliNo ratings yet

- ToyotaDocument2 pagesToyotaGuilherme ZoboliNo ratings yet

- Ms Axode 91: Master Solenoid KitDocument1 pageMs Axode 91: Master Solenoid KitGuilherme ZoboliNo ratings yet

- 01m PDFDocument2 pages01m PDFGuilherme Zoboli67% (3)

- 01 MDocument2 pages01 MGuilherme ZoboliNo ratings yet

- Master Solenoid Kit: (Figure 1)Document1 pageMaster Solenoid Kit: (Figure 1)Guilherme ZoboliNo ratings yet

- Master Solenoid Kit: MS KM-175Document1 pageMaster Solenoid Kit: MS KM-175Guilherme ZoboliNo ratings yet

- MS 4T60E: Master Solenoid KitDocument1 pageMS 4T60E: Master Solenoid KitGuilherme ZoboliNo ratings yet

- MS Master Solenoid Kit: Shift Solenoid 2 Violet Blue:::::... Violet . - Shift Solenoid 1Document1 pageMS Master Solenoid Kit: Shift Solenoid 2 Violet Blue:::::... Violet . - Shift Solenoid 1Guilherme ZoboliNo ratings yet

- Focus 2009 MC9S12XHZ512 Modelo 2Document3 pagesFocus 2009 MC9S12XHZ512 Modelo 2Guilherme ZoboliNo ratings yet

- Modulo e Comtrole BCM Ix35Document2 pagesModulo e Comtrole BCM Ix35Guilherme ZoboliNo ratings yet

- Aliment A CaoDocument1 pageAliment A CaoGuilherme ZoboliNo ratings yet

- Quick Start Guide: Digital Camera D7000Document2 pagesQuick Start Guide: Digital Camera D7000foosome12No ratings yet

- Myanmar Power SystemDocument4 pagesMyanmar Power Systemkayden.keitonNo ratings yet

- BC-5000&BC-5150 - Service Training Material - V1.0 - EN (REV)Document137 pagesBC-5000&BC-5150 - Service Training Material - V1.0 - EN (REV)iisputNo ratings yet

- PESTLE Analysis - KenyaDocument4 pagesPESTLE Analysis - KenyaJoseph0% (1)

- V$SESSIONDocument8 pagesV$SESSIONCristiano Vasconcelos BarbosaNo ratings yet

- BOB SO Information HandoutDocument5 pagesBOB SO Information HandoutKabya SrivastavaNo ratings yet

- A Modified Vince Gingery PlasticDocument13 pagesA Modified Vince Gingery PlasticgeppaNo ratings yet

- DominosDocument11 pagesDominosApril MartinezNo ratings yet

- H S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolDocument58 pagesH S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolCRISTIANNo ratings yet

- NNH4-65C-R6-V2: Electrical SpecificationsDocument4 pagesNNH4-65C-R6-V2: Electrical SpecificationsAntony López GálvezNo ratings yet

- Congelador - Frigidaire GLFC1326FW1 - Man - Eng - PartsDocument7 pagesCongelador - Frigidaire GLFC1326FW1 - Man - Eng - Partsfelix bazanNo ratings yet

- 8 Candidate Quiz Buzzer Using 8051Document33 pages8 Candidate Quiz Buzzer Using 8051prasadzeal0% (1)

- GSM Network Hash CodesDocument5 pagesGSM Network Hash CodesMd.Bellal HossainNo ratings yet

- Micronta 12VDC Power Adapter 273-1653A InstructionsDocument2 pagesMicronta 12VDC Power Adapter 273-1653A Instructions240GL guyNo ratings yet

- Is 803Document98 pagesIs 803Gaurav BedseNo ratings yet

- Android VersionsDocument7 pagesAndroid VersionsEdna Mae Salas GarciaNo ratings yet

- Gudenaaparken (Randers) - All You Need To Know BEFORE You GoDocument8 pagesGudenaaparken (Randers) - All You Need To Know BEFORE You GoElaine Zarb GiorgioNo ratings yet

- Is 13687 1993Document15 pagesIs 13687 1993ADIPESHNo ratings yet

- CS 201 1 PDFDocument7 pagesCS 201 1 PDFMd AtharNo ratings yet

- OTL R12 ImplementationDocument288 pagesOTL R12 ImplementationSarah Kay MortelNo ratings yet

- Trial On CompresorDocument3 pagesTrial On CompresorA JNo ratings yet

- Falcon 7X CommunicationsDocument105 pagesFalcon 7X Communicationsjunmech-1No ratings yet

- Cooling Tower 3DTrasar ManualDocument90 pagesCooling Tower 3DTrasar ManualArevaLemaNo ratings yet

- David Beard Composer CV ShortDocument2 pagesDavid Beard Composer CV ShortEhsan KarimyNo ratings yet

- ITP For Pipeline (Sampel)Document5 pagesITP For Pipeline (Sampel)Reza RkndNo ratings yet

- Weapon Lights and Targeting LasersDocument3 pagesWeapon Lights and Targeting LasersバラモスまさゆきNo ratings yet

- Advanced English Communication Skills LaDocument5 pagesAdvanced English Communication Skills LaMadjid MouffokiNo ratings yet

- Process Engineering ChiyodaDocument65 pagesProcess Engineering ChiyodaSean Choi100% (10)

- Bloomberg Certification FAQ BMC (Bloomberg Market Concepts) : Goizueta Business LibraryDocument3 pagesBloomberg Certification FAQ BMC (Bloomberg Market Concepts) : Goizueta Business LibrarySarah Raquel Bozo Herrera100% (1)

- ERJ 145 InfoDocument11 pagesERJ 145 InfoMarcus100% (1)