Professional Documents

Culture Documents

Leo Tolstoy, Translated by Wilks, Briggs and McDuff - The Death of Ivan Ilyich and Other Stories-Penguin Classics (2008)

Uploaded by

NK NKCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leo Tolstoy, Translated by Wilks, Briggs and McDuff - The Death of Ivan Ilyich and Other Stories-Penguin Classics (2008)

Uploaded by

NK NKCopyright:

Available Formats

s an emerging technol- Fabrication process the distinction between complex

A

ogy, MEMs has been a MEMS is a manufacturing technolo- mechanical systems and integrated cir-

hot topic at various gy; that is a new way of making com- cuit electronics.

conferences over the plex electromechanical systems. It uses While some Asian approaches may

past decade or so. The batch fabrication techniques—similar be different, the US approach to MEMS

MEMS acronym stands to the way integrated circuits (ICs) are fabrication involves the repetitive

for Micro-Electro-Mechanical Systems. made—and makes the electromechani- process of designing, fabrication, pack-

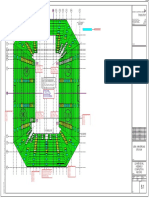

These devices and systmes range in size cal elements along with electronics. aging and testing, as shown in Fig. 1.

from a few microns to a few millime- (1) Design: There are soft-

ters. The field is called by a wide vari- ware packages available for the

ety of names by different people,e.g. design and simulation of MEMS

Micro-Electro-Mechanical Systems devices.

(MEMS), Micromechanics, Micro (2) Fabrication: While the

System Technology (MST) and Nano electronics are fabricated using

technology. This field, which encom- integrated circuit (IC) process

passes all aspects of science and tech-

nology, is involved with things on a

smaller scale. Things behave substan-

MEMS sequences, the micromechanical

components are fabricated using

compatible “micromachining”

tially differently in the processes. The MEMS materials

micro domain. Forces are typically restricted to those

related to volume, like used in the IC process. MEMS

weight and inertia, promise to revolutionize nearly

tend to decrease in sig- every product category by bring-

nificance. Forces relat- ing together silicon-based micro-

ed to surface area, electronics with micromachining tech-

such as friction and nology. This makes possible the realiza-

electrostatics, tend to tion of complete systems-on-a-chip.

become large. And

forces like surface ten-

sion that depend upon

an edge become enor-

mous.

MEMS may also be

regarded as the inte-

A quick look

gration of micro-

electronics and at a

micromechanics, Matthew Sadiku

and sometimes

micro-optics and

breakthrough

micromagnetics. It

combines conventional technology

semiconductor elec-

tronics with beams,

gears, levers, switches,

sensors, accelerome-

ters, diaphragms, and

heat controllers, all of (3) Packaging: MEMS packaging is

© PHOTODISC COMPOSITE: D. CANTILLO

them microscopic in an application-specific task. It accounts

size. MEMS technolo- for the largest fraction of the cost of the

gies make devices MEMS device. Packaging should avoid

ranging in size from a transferring mechanical strain, heat,

dozen millimeters to a pressure, etc. to the device in the pack-

dozen microns. For age. MEMS introduce new interfaces,

example, MEMS tech- processes and materials foreign to the

nology has enabled IC packaging industry.

electrically-driven (4) Testing: The testing of MEMS

motors smaller than devices is more complex than that of

the diameter of a human hair (about 80 This new manufacturing technology ICs because of the integrated electronic

(m) to be realized. Thus, MEMS tech- has several distinct advantages. First, and mechanical character of MEMS.

nology lets scientists and engineers MEMS is an extremely diverse technol- Since MEMS devices are manufac-

build things that have been impossible ogy that potentially could significantly tured using batch fabrication tech-

or prohibitively expensive with other impact every category of commercial niques, similar to ICs, unprecedented

technologies. and military products. Second, it blurs levels of functionality, reliability and

4 0278-6648/02/$17.00 © 2002 IEEE IEEE POTENTIALS

sophistication can be placed on a small emerge, expanding beyond that which is • W. S. Trimmer, Micromechanics

silicon chip at a relatively low cost. currently identified or known. and MEMS: Classic and Seminal

Papers to 1990. New York: IEEE Press,

Applications Need for MEMS engineers 1997.

MEMS technology has emerged as Traditionally, the training of MEMS • M. Gad-El-Hak, Ed., The MEMS

very useful in telecommunications with engineers and scientists has entailed a Handbook. Boca Raton, FL: CRC

major applications particularly in opti- graduate education at one of a few Press, 2001.

cal switching. Applications are in the research universities. Even then, the stu-

large terabit network switches and other dent works under the direction of an About the author

equipment used in metropolitan and experienced faculty member to design, Matthew N. O. Sadiku received his

wide-area networks. In such systems, fabricate and test a MEMS device. As a B. Sc. degree in 1978 from Ahmadu

the efficiency of keeping the optical sig- result, the graduate education in MEMS Bello University, Zaria, Nigeria and his

nals as light provides significant perfor- technology is very costly and compara- M.Sc. and Ph.D. degrees from

mance gains and better overall cost sav- tively time-consuming. Consequently, Tennessee Technological University,

ings. Satellite and spacecraft also bene- the current output from US universities Cookeville, TN in 1982 and 1984,

fit from MEMS technology. For exam- of technical persons trained in MEMS respectively. He was a professor at

ple, the picosats weigh less than 280 technology is much smaller than the Florida Atlantic University, Boca

grams each and comprise little more number required to support the project- Raton, FL and Temple University,

than a small radio. Such MEMS-based ed growth of MEMS industry. The out- Philadelphia, PA. Since July 2001, he

satellites with negligible mass, size and put of well-trained MEMS engineers has been a senior scientist with Boeing

power consumption can easily be piggy- and scientists needs to increase. Satellite Systems in Los Angeles, CA.

backed onto conventional satellites or If your university offers classes in He is the author of over 100 profession-

launched using small launch vehicles. MEMS, take as many of them as possi- al papers and over 20 books. He was the

Another area for using MEMS tech- ble. Better still, if your university has a recipient of the 2000 McGraw-

nology is transportation, in particular, laboratory on MEMS, you may consider Hill/Jacob Millman Award for outstand-

making mechanical parts for the automo- doing your senior design or your gradu- ing contributions in the field of electri-

tive industry. Motors, pivots, linkages, ate thesis in this area. That should pre- cal engineering.

sensors, microswitches and other pare you well enough for the job market.

mechanical devices can be made to fit

inside this circle O. These devices are Conclusion

also inexpensive. For example, using sili- MEMS technology has already taken

con surface micromachining, a gear cap- root firmly in today’s world. It is des-

tivated on a pivot can be made for less tined to become a hallmark 21st-century

than one cent (U.S.). Micromechanical manufacturing technology with numer- MEMS Design

parts tend to be rugged, respond rapidly, ous and diverse applications. MEMS

use little power, occupy a small volume, will have a dramatic impact on every-

and are often much less expensive than thing from aerospace technology to

conventional macro parts. For example, biotechnology. As a breakthrough tech-

MEMS sensors measure pressure, nology allowing unparalleled synergy

strain, acceleration, temperature, fluid between apparently unrelated fields of

flow and more. endeavor such as biology and microelec- Fabrication

In addition to telecommunications tronics, MEMS is forecasted to have a

and transportation, other areas of MEMS commercial and defense market growth

application include microwave/RF similar to its parent IC technology.

switches and relays; printers, where ink-

jet technology is revolutionizing a Read more about it

booming field; optical systems where • D. J. Nagel and M. E. Zaghloul,

new actuated mirror- and lens- systems “MEMS: Micro Technology, Mega

Packaging

are being exploited for display; informa- Impact,” IEEE Circuits Devices Mag.,

tion storage in which much increased pp. 14-25, Mar. 2001.

density at increased speed and reduced • K. W. Markus and K. J. Gabriel,

cost; and medical applications where “MEMS: The Systems Function

MEMS promise truly revolutionary sys- Revolution,” IEEE Computer, pp. 25-

tems. Yet these examples only scratch 31, Oct. 1990.

the surface of what the future holds. • J. R. Gabriel, “Integrating CAD

Future MEMS applications will be Tools for MEMS Design,” IEEE Testing

dictated by processes that enable greater Computer, April 1998, pp. 99-101.

functionality through higher levels of • K. W. Markus, “Developing

electronic-mechanical integration and Infrastructure to Mass-Produce

more mechanical components. The vari- MEMS,” IEEE Comput. Sci. Eng.,

ety of available mechanical microde- Mag., pp. 49-54, Jan. 1997.

vices and their applications will grow. • S. Cass, “MEMS In Space,” IEEE Fig. 1 Flow diagram for the fabrica-

Many new MEMS applications will Spectr., pp. 56-61, July 2001. tion of MEMS devices

FEBRUARY/MARCH 2002 5

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The New Order of BarbariansDocument39 pagesThe New Order of Barbariansbadguy100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tharoor Shashi India From MidnigDocument410 pagesTharoor Shashi India From MidnigNK NK100% (2)

- Mecha World Compendium Playbooks BWDocument12 pagesMecha World Compendium Playbooks BWRobson Alves MacielNo ratings yet

- Words of Radiance: Book Two of The Stormlight Archive - Brandon SandersonDocument6 pagesWords of Radiance: Book Two of The Stormlight Archive - Brandon Sandersonxyrytepa0% (3)

- Catheter Related InfectionsDocument581 pagesCatheter Related InfectionshardboneNo ratings yet

- Tuma Research ManualDocument57 pagesTuma Research ManualKashinde Learner Centered Mandari100% (1)

- How We Found The Missing Memristor - Stanley Williams PDFDocument8 pagesHow We Found The Missing Memristor - Stanley Williams PDFNK NKNo ratings yet

- Quality Control of Rigid Pavements 1Document58 pagesQuality Control of Rigid Pavements 1pranjpatil100% (1)

- Highlights ASME Guides Preheat PWHT IDocument4 pagesHighlights ASME Guides Preheat PWHT IArul Edwin Vijay VincentNo ratings yet

- Institutional Group Agencies For EducationDocument22 pagesInstitutional Group Agencies For EducationGlory Aroma100% (1)

- Project Quality Plan (JFJS-788)Document18 pagesProject Quality Plan (JFJS-788)mominNo ratings yet

- ESD SadikuDocument3 pagesESD SadikuNK NKNo ratings yet

- E C G Sudarshan PDFDocument39 pagesE C G Sudarshan PDFNK NKNo ratings yet

- Verilog Coding Guideline: Author: TrumenDocument51 pagesVerilog Coding Guideline: Author: TrumenNK NKNo ratings yet

- Jugdutt SinghDocument1 pageJugdutt SinghNK NKNo ratings yet

- A Survey Analysis On CMOS Integrated Cir PDFDocument4 pagesA Survey Analysis On CMOS Integrated Cir PDFNK NKNo ratings yet

- CHP 2Document38 pagesCHP 2NK NKNo ratings yet

- SRAM Variation PDFDocument44 pagesSRAM Variation PDFNK NKNo ratings yet

- Learning Your First JobDocument12 pagesLearning Your First JobNK NKNo ratings yet

- Decoder2001 Armatur HorowitzDocument10 pagesDecoder2001 Armatur HorowitzNK NKNo ratings yet

- Two Kinds of Metal-Semiconductor ContactsDocument19 pagesTwo Kinds of Metal-Semiconductor ContactsNK NKNo ratings yet

- ScalingDocument32 pagesScalingNK NKNo ratings yet

- Gate Oxide Leakage Current Analysis and Reduction For VLSI CircuitsDocument12 pagesGate Oxide Leakage Current Analysis and Reduction For VLSI CircuitsNK NKNo ratings yet

- Worst of Autocall Certificate With Memory EffectDocument1 pageWorst of Autocall Certificate With Memory Effectapi-25889552No ratings yet

- IM1 Calculus 2 Revised 2024 PUPSMBDocument14 pagesIM1 Calculus 2 Revised 2024 PUPSMBEunice AlonzoNo ratings yet

- The Turning Circle of VehiclesDocument2 pagesThe Turning Circle of Vehiclesanon_170098985No ratings yet

- KLA28 ProductsapplicationpresetDocument2 pagesKLA28 ProductsapplicationpresetcarxmozNo ratings yet

- Culture 2007 2013 Projects Overview 2018-03-18Document133 pagesCulture 2007 2013 Projects Overview 2018-03-18PontesDeboraNo ratings yet

- Arithmetic QuestionsDocument2 pagesArithmetic QuestionsAmir KhanNo ratings yet

- AIIMS 2015 Solved PaperDocument436 pagesAIIMS 2015 Solved PaperSurya TejaNo ratings yet

- 220245-MSBTE-22412-Java (Unit 1)Document40 pages220245-MSBTE-22412-Java (Unit 1)Nomaan ShaikhNo ratings yet

- Kissoft 15,69,0.4Document10 pagesKissoft 15,69,0.4Daggupati PraveenNo ratings yet

- Geotechnical PaperDocument16 pagesGeotechnical PaperTxavo HesiarenNo ratings yet

- PD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsDocument20 pagesPD3 - Strategic Supply Chain Management: Exam Exemplar QuestionsHazel Jael HernandezNo ratings yet

- Isi Rumen SBG Subtitusi HijauanDocument3 pagesIsi Rumen SBG Subtitusi HijauanBagas ImamsyahNo ratings yet

- Galgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesDocument2 pagesGalgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesRohit Singh BhatiNo ratings yet

- Tangerine - Breakfast Set Menu Wef 16 Dec UpdatedDocument3 pagesTangerine - Breakfast Set Menu Wef 16 Dec Updateddeveloper louNo ratings yet

- GPP Calendar of Activities 2022 23 SdoDocument5 pagesGPP Calendar of Activities 2022 23 SdoRomel GarciaNo ratings yet

- Ej. 1 Fin CorpDocument3 pagesEj. 1 Fin CorpChantal AvilesNo ratings yet

- Test Physics Chapter# 12,13,14 (2 Year) NameDocument1 pageTest Physics Chapter# 12,13,14 (2 Year) NameStay FocusedNo ratings yet

- Mcdaniel Tanilla Civilian Resume Complete v1Document3 pagesMcdaniel Tanilla Civilian Resume Complete v1api-246751844No ratings yet

- Nizkor Project Fallacies - LabossierDocument77 pagesNizkor Project Fallacies - Labossierapi-3766098100% (1)

- СV Nestor RodriguezDocument28 pagesСV Nestor RodriguezKate BrownNo ratings yet

- SDSSSSDDocument1 pageSDSSSSDmirfanjpcgmailcomNo ratings yet