Professional Documents

Culture Documents

Material Selection For Swimming Pools

Uploaded by

Mandar KadamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Selection For Swimming Pools

Uploaded by

Mandar KadamCopyright:

Available Formats

Technical Bulletin

Stainless Steel Selection for Swimming Pool Environments

Swimming pool water may appear to be quite passive to the casual user, but the specifier

needs to take adequate precautions to ensure any drainage, fittings and fixtures around the

pool are manufactured from the correct materials to prevent corrosion.

Corrosion factors

There are many variable factors in swimming pool environments that contribute towards

possible corrosion of drainage components:

Temperature of the pool water

pH level of pool water

Pool water type: saltwater or fresh water

Chlorination level of pool: dosing from hypochlorite (fresh water) or electrolysis (salt

water)

Pool use regularity

Proximity of drain to pool: constantly wetted (lapped by the pool), splash zone, change

rooms etc.

If indoors, the temperature of the room, ventilation and humidity

Grades of stainless steel and finishing

There are many grades of stainless steel available, but the most common grades used in

swimming pool environments are 304 and 316.

Pickle passivation is a surface finishing process for stainless steel that removes surface

impurities introduced during welding and the fabrication process and provides a protective

passive oxide film. It is particularly important to apply this process as a minimum requirement

in swimming pool applications.

Electropolishing is an additional optional finishing process that provides stainless steel with a

natural polished lustre. This process strengthens the passive film and microscopically flattens

the surface material, therefore reducing chloride traps, thereby reducing the risk of pitting

corrosion. Electropolishing is recommended for pool environments.

Fresh water pools

Typically for public swimming pools, the pool water temperature will be approximately 24°C,

pH levels between 7.2 and 7.8 and chlorine levels between 1 and 2 parts per million (ppm).

For private swimming pools, the temperature may rise to around 30°C (and higher in

hydrotherapy pools).

Chlorine or sodium hypochlorite is often used to disinfect swimming pool water and it is the

chlorides contained in these chemicals that will create a corrosive environment – even

Bulletin No.: TB200804 – rev 1 ACO Polycrete Pty Ltd

Date: 23 February 2017 134-140 Old Bathurst Road

Issued By: KJ Emu Plains NSW 2750

Telephone (02) 4747 4000

Facsimile (02) 4747 4040

U:\Technical Services\Product Launches\New Product Releases\Official Releases\Technical Bulletins\TB

Page 1 of 3 Drafts\TB200804\TB200804.doc Email: technical@acoaus.com.au

© 2011 COPYRIGHT ACO POLYCRETE PTY LTD. All reasonable care has been taken in compiling the information in this technical bulletin. All recommendations and suggestions on the use of ACO products are made

without guarantee since the conditions of use are beyond the control of the company. It is the customer’s responsibility to ensure that the product is fit for its intended purpose and that the actual conditions of use are suitable.

ACO Polycrete pursues a policy of continuous product development and reserves the right to amend specifications without notice.

though they are used at very low levels. ACO recommends that drainage products in

chlorinated fresh water swimming pool environments be manufactured from pickle passivated

316 grade stainless steel to prevent corrosion. For specific application advice, contact ACO.

Saltwater pools

Saltwater pools are typically more aggressive than chlorine pools. ACO recommends that

drainage products in saltwater pool environments be manufactured from grade 316 stainless

steel and both pickle passivated and electropolished. For specific application advice, contact

ACO.

Proximity of drain to pool: material and finishing selection

Applications where the drainage channel is installed against or on a pool’s edge often have a

lap effect of the grate being in constant contact with the pool water.

Pool Drain

Channel and grate installed on pool edge

Often, the water only laps over half of the grate

leaving residual water on the further half of the grate,

which can evaporate and become more corrosive as

it concentrates. As the grate is not continuously

exposed to water, the available oxygen in a partially

wetted environment can give rise to an increased risk

of pitting corrosion. To avoid this risk, electropolished

grade 316 stainless steel should be selected.

Constantly wetted

Fig 1

A drain can also be positioned in areas where it is subject to occasional splash. This too can

leave residual water on the grate and channel, which can cause pitting corrosion and brown

spots. Pickle passivated and electropolished grade 316 stainless steel is recommended for

this application.

Pool Drain

Occasional splash

Fig 2

ACO Polycrete Pty Ltd

Technical Bulletin No.: TB201001 Page 2 of 3

Date: 23 February 2017

Where the drain will be subject to fresh water only and in areas well away from the pool water

and pool atmosphere, (for example, change rooms), 304 stainless steel is perfectly adequate.

Pool Drain

Drainage in other areas of swimming pool environment Fig 3

Preventing corrosion

Good management of the pool environment is required to minimise corrosion. Swimming pool

decks and drainage systems must be washed down daily with fresh water and regularly

inspected. Regular and consistent checking of the pools’ chemical balance is vital.

The material recommendations in this document are of a general nature only. For

specific application advice, please contact ACO.

ACO Polycrete Pty Ltd

Technical Bulletin No.: TB201001 Page 3 of 3

Date: 23 February 2017

You might also like

- Principles of Heat Treating of SteelsDocument30 pagesPrinciples of Heat Treating of Steelssatish_trivediNo ratings yet

- OSMB Technical Handbook Iss3Document92 pagesOSMB Technical Handbook Iss3halder_kalyan9216No ratings yet

- Differential AerationDocument1 pageDifferential AerationPradeepNo ratings yet

- Detailed Rolling MillsDocument167 pagesDetailed Rolling MillsMd.zubairNo ratings yet

- 1 Introduction (Compatibility Mode)Document45 pages1 Introduction (Compatibility Mode)Steven KuaNo ratings yet

- Heat Treatment: Prepared by Approved byDocument20 pagesHeat Treatment: Prepared by Approved byBhanu Pratap ChoudhuryNo ratings yet

- FAC ChemistryDocument6 pagesFAC ChemistrymarydaughterNo ratings yet

- Boronizing AVIONDocument37 pagesBoronizing AVIONManwi Khandelwal100% (1)

- Mechanics of Cold Rolling of Thin StripDocument25 pagesMechanics of Cold Rolling of Thin StripcristobalmonopeluoNo ratings yet

- On The Fabrication of Metallic Single Crystal Turbine Blades With A Commentary On Repair Via Additive ManufacturingDocument28 pagesOn The Fabrication of Metallic Single Crystal Turbine Blades With A Commentary On Repair Via Additive Manufacturingmrkshitij.sNo ratings yet

- Nonferrous Alloys Al-6069Document16 pagesNonferrous Alloys Al-6069FMMServicesNo ratings yet

- Modern High Strength Niobium Microallyed Structural SteelsDocument26 pagesModern High Strength Niobium Microallyed Structural SteelsimetallurgyNo ratings yet

- En8 080M40Document1 pageEn8 080M40sulemankhanNo ratings yet

- Surface & Coatings Technology: A. Rico, J. Gómez-García, C.J. Múnez, P. Poza, V. UtrillaDocument8 pagesSurface & Coatings Technology: A. Rico, J. Gómez-García, C.J. Múnez, P. Poza, V. UtrillaJhonatan GomezNo ratings yet

- Alloy Guide PDFDocument12 pagesAlloy Guide PDFArjed Ali ShaikhNo ratings yet

- Austempered Ductile Cast IronDocument10 pagesAustempered Ductile Cast Ironhrk100No ratings yet

- TMT Bars (Friends ISI) PDFDocument3 pagesTMT Bars (Friends ISI) PDFPiyushiNo ratings yet

- Advanced Boiler TubeDocument2 pagesAdvanced Boiler TubeShailendra WaniNo ratings yet

- Atlas 3CR12 DatasheetDocument3 pagesAtlas 3CR12 DatasheettridatylNo ratings yet

- Advanced Coating Solutions For The OilDocument4 pagesAdvanced Coating Solutions For The OilManivannanMudhaliarNo ratings yet

- China's Bayi Steel Pickling Line and Tandem Cold MillDocument12 pagesChina's Bayi Steel Pickling Line and Tandem Cold MillJJNo ratings yet

- 05 - Ltend - Mac, RLC and PDCPDocument47 pages05 - Ltend - Mac, RLC and PDCPLuigi RambaldiNo ratings yet

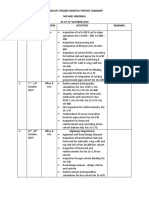

- Graduate Trainee Monthly Report SummaryDocument2 pagesGraduate Trainee Monthly Report Summarymichael100% (1)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- BS3100 A2Document11 pagesBS3100 A2AlexNo ratings yet

- ABS Approved Still Mill PDFDocument84 pagesABS Approved Still Mill PDFJanuar Target Willyam0% (1)

- BOMA 1 Introduction AIADocument70 pagesBOMA 1 Introduction AIAConstantin FlorescuNo ratings yet

- Outokumpu Supra Range DatasheetDocument12 pagesOutokumpu Supra Range DatasheetMichelNo ratings yet

- Duplex Stainless Steel 329 or 1.4460 PDFDocument2 pagesDuplex Stainless Steel 329 or 1.4460 PDFtien100% (1)

- 1045 Steel Flat BarDocument4 pages1045 Steel Flat BarFebri SSNo ratings yet

- PN 2013-05 Swimming Pools and Spas and Safety BarriersDocument7 pagesPN 2013-05 Swimming Pools and Spas and Safety BarrierskhjhfghfNo ratings yet

- Effects of Alloying Elements in SteelDocument12 pagesEffects of Alloying Elements in SteelyatheendravarmaNo ratings yet

- Pickling and PassivationDocument2 pagesPickling and PassivationKalpesh JainNo ratings yet

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Document5 pagesSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiNo ratings yet

- SMS Casting BreakoutsDocument20 pagesSMS Casting BreakoutsShubham KaushikNo ratings yet

- World Oil CorrosionDocument4 pagesWorld Oil CorrosionmutemuNo ratings yet

- Riview On Cold Drawing Process PDFDocument7 pagesRiview On Cold Drawing Process PDFAmandeep Singh GujralNo ratings yet

- 03HighSpeedCastingNucor DanieliDocument29 pages03HighSpeedCastingNucor DanielialfonsomendietaNo ratings yet

- Scarfing Steel Slabs TechniqueDocument9 pagesScarfing Steel Slabs TechniquecamableNo ratings yet

- XOMOX JacketedPlugValveDocument14 pagesXOMOX JacketedPlugValvedsiucNo ratings yet

- Accelerated CoolingDocument7 pagesAccelerated CoolingHarikrishnan N SivaprasadNo ratings yet

- Forgingforging ProcessDocument13 pagesForgingforging Processpatel ketanNo ratings yet

- Electric and Automation - Ladle Management A-323eDocument4 pagesElectric and Automation - Ladle Management A-323eSantosh UpadhyayNo ratings yet

- Technologies For The Production of Pharmaceutical Grade Sodium ChlorideDocument13 pagesTechnologies For The Production of Pharmaceutical Grade Sodium ChlorideAmyNo ratings yet

- Reduction Ratio Chart in Steel Rolling MillDocument1 pageReduction Ratio Chart in Steel Rolling MillSoumyo Broto DasNo ratings yet

- ERNiCr 3Document1 pageERNiCr 3Cemal NergizNo ratings yet

- Galvanizing HistoryDocument6 pagesGalvanizing HistorySreedhar Patnaik.MNo ratings yet

- Steel Pickling in Challenging Conditions: Mika MaanonenDocument40 pagesSteel Pickling in Challenging Conditions: Mika MaanonenRohit SharmaNo ratings yet

- Brochure English - Pickling, Cleaning, PassivatingDocument4 pagesBrochure English - Pickling, Cleaning, PassivatingSerge1976100% (1)

- Aalco Metals LTD Stainless Steel 1.4003 Nirosta 4003 3CR12 96Document2 pagesAalco Metals LTD Stainless Steel 1.4003 Nirosta 4003 3CR12 96Xingfeng HanNo ratings yet

- A New Role For Microalloyed SteelsDocument11 pagesA New Role For Microalloyed SteelsMuhammed SulfeekNo ratings yet

- 1221 Hot Gas and Extrusion Welding Jan 2016Document2 pages1221 Hot Gas and Extrusion Welding Jan 2016ibnu.asad984No ratings yet

- Hastelloy Alloy B3 UNS N10675 Welding Rod Manufacturer in IndiaDocument3 pagesHastelloy Alloy B3 UNS N10675 Welding Rod Manufacturer in IndiaOZAIRTRADELINKNo ratings yet

- 304 VS 316Document2 pages304 VS 316Sheikh ZakirNo ratings yet

- Turret Bearing Deflection MonitoringDocument1 pageTurret Bearing Deflection MonitoringVinay RajputNo ratings yet

- FARO Quote 20014448 Focus 130 SystemDocument4 pagesFARO Quote 20014448 Focus 130 SystemCarlos SanchezNo ratings yet

- SIHI Applications and Products E 092011Document9 pagesSIHI Applications and Products E 092011Menze de JongeNo ratings yet

- Longtermoxidationbehaviour PDFDocument10 pagesLongtermoxidationbehaviour PDFAnonymous lmCR3SkPrKNo ratings yet

- Pickling (Metal)Document2 pagesPickling (Metal)alphadingNo ratings yet

- CPCCBC4013A - Student Assessment Task 2 ResourcesDocument15 pagesCPCCBC4013A - Student Assessment Task 2 ResourcesRavi MadaanNo ratings yet

- The Iron Puddler My life in the rolling mills and what came of itFrom EverandThe Iron Puddler My life in the rolling mills and what came of itNo ratings yet

- Fine Bubble Diffusers & Ozone Contactor Chambers For Water TreatmentDocument1 pageFine Bubble Diffusers & Ozone Contactor Chambers For Water TreatmentachmadinNo ratings yet

- Good Practice Guide No. 120: Avoidance of Corrosion in Plumbing SystemsDocument16 pagesGood Practice Guide No. 120: Avoidance of Corrosion in Plumbing SystemsMochamad Irvan MaulanaNo ratings yet

- MTDC Resort Reservation ReceiptDocument1 pageMTDC Resort Reservation ReceiptMandar KadamNo ratings yet

- Revised TDS TCS Rate ChartDocument3 pagesRevised TDS TCS Rate ChartMandar KadamNo ratings yet

- VEMC HYPN ReferancesDocument4 pagesVEMC HYPN ReferancesMandar KadamNo ratings yet

- Sanghvi Estella BycullaDocument6 pagesSanghvi Estella BycullaMandar KadamNo ratings yet

- Cab - Wit Vm250 Part2Document1 pageCab - Wit Vm250 Part2Mandar KadamNo ratings yet

- Ashwatha Insignia Dadar WestDocument6 pagesAshwatha Insignia Dadar WestMandar KadamNo ratings yet

- Wadhwa Wise City PanvelDocument6 pagesWadhwa Wise City PanvelMandar KadamNo ratings yet

- Mechanical PermitDocument2 pagesMechanical PermitjbonvierNo ratings yet

- The Church of The Holy CrossDocument3 pagesThe Church of The Holy Crossren nishiNo ratings yet

- d36978010 S5000vsa Tps r1 9Document71 pagesd36978010 S5000vsa Tps r1 9t111938No ratings yet

- Combination Wall Oven Installation GuideDocument2 pagesCombination Wall Oven Installation Guidejulio ariasNo ratings yet

- Historical Research About MPR-DPR BuildingDocument17 pagesHistorical Research About MPR-DPR BuildingTERRYNA SAFIRANo ratings yet

- Arun &associatesDocument12 pagesArun &associatesSujaa SaravanakhumaarNo ratings yet

- Conseal 250Document2 pagesConseal 250Rabih GergesNo ratings yet

- GRI 8450-3 Data SheetDocument4 pagesGRI 8450-3 Data SheetJMAC SupplyNo ratings yet

- RCC Bundled BarsDocument7 pagesRCC Bundled BarsVSMS8678No ratings yet

- 4.2.1 MiTek Training Schedule 2018Document10 pages4.2.1 MiTek Training Schedule 2018Tino TiriNo ratings yet

- Structural Design and Construction Lecture 1Document26 pagesStructural Design and Construction Lecture 1Chong Ting ShengNo ratings yet

- High Capacity Fully Removable Soil Anchors A D Barley D A Bruce M e Bruce J C Lang and H Aschenbroich 2003Document9 pagesHigh Capacity Fully Removable Soil Anchors A D Barley D A Bruce M e Bruce J C Lang and H Aschenbroich 2003Kenny CasillaNo ratings yet

- Architectural Projects: Work StagesDocument2 pagesArchitectural Projects: Work StagesMykael_p0% (1)

- Multiprogramming With Fixed Number of Tasks MFTDocument16 pagesMultiprogramming With Fixed Number of Tasks MFTJs JsNo ratings yet

- What Is MapReduce in Hadoop - Architecture - ExampleDocument7 pagesWhat Is MapReduce in Hadoop - Architecture - Examplejppn33No ratings yet

- AMX NX 3200.QuickStartGuideDocument2 pagesAMX NX 3200.QuickStartGuideDat TranNo ratings yet

- Lifetime Support Applications 069216Document57 pagesLifetime Support Applications 069216logiuxNo ratings yet

- PowerElectronics Class6Document26 pagesPowerElectronics Class6Keyur PatelNo ratings yet

- Method Statement For Temporary OpeningDocument1 pageMethod Statement For Temporary Openingvaibhav_sparshNo ratings yet

- Concrete Phasing Plan MGQDocument4 pagesConcrete Phasing Plan MGQJhundel Factor PajarillagaNo ratings yet

- Other Art Forms: Industrial Art (Raw Materials Forming SignificantDocument10 pagesOther Art Forms: Industrial Art (Raw Materials Forming Significantjohn mark dionidoNo ratings yet

- Geo Perform XDocument4 pagesGeo Perform Xthermosol5416No ratings yet

- Software EngineeringDocument27 pagesSoftware EngineeringAnurag KumarNo ratings yet

- Beginner Programming Lesson: Introduction To The EV3 Brick and SoftwareDocument12 pagesBeginner Programming Lesson: Introduction To The EV3 Brick and SoftwareMenandro JumpaladNo ratings yet

- Aax2024iqm01 ADocument344 pagesAax2024iqm01 APhani ArvapalliNo ratings yet