Professional Documents

Culture Documents

Design Report

Uploaded by

Nhut NguyenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Report

Uploaded by

Nhut NguyenCopyright:

Available Formats

Examination for the Bachelor of Engineering (Chemical)

Semester 1, 2010

105527 CHEMICAL ENGINEERING APPLICATIONS A

CHEMENG 3035

Official Reading Time: 10 mins

Writing Time: 180 mins

Total Duration: 190 mins

Part Questions Time Marks

A Answer all 1 question 60 mins 60 marks

B Answer all 3 questions 120 mins 120 marks

180 Total

Instructions

Part A is a Closed Book examination – Calculators are not permitted.

Part B is an Open Book examination during which reference material may be

consulted, and calculators may be used.

Part A must be handed in before commencing Part B.

Part B may be attempted early provided that Part A has been handed in.

Answer Parts A and B in separate books.

Begin each question on a new page.

The marks for each question are indicated.

Write your name and Student ID number on all loose diagrams/papers.

Examination materials must not be removed from the examination room.

Materials

Course notes and text books are permitted for Part B.

Calculator is permitted for Part B.

The use of a dictionary is permitted.

Attachments:

1. Drag coefficient – Reynolds number chart

2. Batch solids flux data

DO NOT COMMENCE WRITING UNTIL INSTRUCTED TO DO SO

Examination 2010 2 CHEMENG 3035 (105527)

PART A. CLOSED BOOK

Question 1 (60 marks)

Give brief answers to the following questions. Marks for individual questions are as

indicated.

a. Give three (3) definitions of equivalent sphere diameters that are used to

describe sizes of non-spherical particles. Illustrate the application of each term

with a practical example. [6]

b. Define the surface-volume number mean diameter (dSVn) for a powder

containing spherical particles. Explain how dSVn can be calculated from size

distribution data based on (A) particle number measurement, and (B) particle

mass measurement. [4]

c. How do you know if the particle sizes of a particulate solid follow log-normal

size distribution? What are the key features of this size distribution function? [3]

d. Under what condition does hindered settling occur? Describe the

characteristics of this type of settling behaviour, and explain how the hindered

settling velocity can be determined experimentally and analytically. [4]

e. Describe the effects of surface tension and gravity on the shape and terminal

velocity of an air bubble rising in water. [3]

f. For flow through porous media, give the definitions and applications of define

the following terms, and show that they are equivalent characteristic dimensions

of a porous medium: [6]

- Hydraulic diameter

- Surface-volume diameter

- Specific surface area per unit volume of solids

g. Consider a porous medium initially filled by a liquid. A gas is then introduced

under pressure in order to displace the liquid from the medium. Describe the

flow behaviour of both fluid phases in terms of relative permeability as a

function of saturation. Discuss also the effects of wettability and surface

tension on the mobility of the fluids. [5]

Question 1 continues on the next page

Chemical Engineering Applications A

Examination 2010 3 CHEMENG 3035 (105527)

h. Consider counter-current flows of a gas and a liquid through a packed column.

Describe how the frictional pressure drop across the packing varies with the gas

and liquid flow rates. Define the critical conditions referred to as loading and

flooding, and explain how design of such a system is carried out. [5]

i. Describe incipient fluidisation, and explain how the minimum fluidising

velocity can be determined experimentally and analytically for beds containing

(1) uniform particles and (2) particles of different sizes? [4]

j. According to Geldart classification of powder, what are the main characteristics

of group A, group B and group D powders? What are the likely modes of

fluidisation when these powders are fluidised by air? [4]

k. What is solids flux plot? Describe the procedure used to construct the solids

flux plot from batch settling data. [4]

l. What are the four possible zones in a type II settling slurry? Show how the

movements of these zones can be predicted from batch solids flux data. [5]

m. The general filtration equation is usually given in the following form:

C R dV

P S2 V m

A A dt

A. Explain the meaning of all terms, and outline the basic steps involved

in the development of the above equation. [4]

B. Describe how the specific cake resistance of a compressible material

can be determined from constant-pressure filtration experiments. [3]

END OF PART A

Chemical Engineering Applications A

Examination 2010 4 CHEMENG 3035 (105527)

PART B. OPEN BOOK

Question 2 (40 marks)

A 2-m diameter bed of catalyst (s.g. = 1.9, sphericity = 0.81) with size distribution given

below is to be fluidized using a gas of density 1.2 kg/m3 and viscosity 1.8x10-5 Pa.s.

Under quiescent condition, the bed is 1.0 m high with voidage of 0.46.

Volume Diameter (m) Mass

from to (g)

50 75 68

75 105 92

100 150 83

150 215 57

a. Calculate the minimum gas flow rate necessary to fluidise the bed of catalyst. The

bed voidage at incipient fluidization may be assumed to be 0.5.

b. Determine the highest gas flow rate that can be used to safely fluidise the bed.

c. The bed is fluidised using a gas superficial velocity of 0.08 m/s. Determine the bed

voidage, bed expansion and frictional pressure drop under this condition. State any

assumptions made.

d. In actual operation, process requirements may demand a gas flow rate higher than

that calculated in (b). If the bed is fluidised with a gas flow rate of 1500 m3/h,

calculate the largest size of catalyst particles that would be permanently entrained

in the exit gas from a bed of uniform diameter of 2 m.

e. In order to contain all particles in the bed, the fluidising section needs to be

tapered, i.e. with increasing cross section in the vertical direction. For an operating

fluidising gas rate of 1500 m3/h, what should be the minimum diameter at the upper

end of the bed, if the base has a diameter of 2 m?

Chemical Engineering Applications A

Examination 2010 5 CHEMENG 3035 (105527)

Question 3 (40 marks)

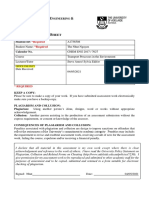

A mineral tailings slurry containing 25 wt% solids in water is concentrated by gravity

sedimentation to remove as much water as possible before being pumped to

disposal. The slurry is fed to a continuous thickener at a rate of 400 m3/h, and the

thickened underflow is discharged at 200m3/h. The thickener has a cross sectional

area of 200m2 in the vertical section. The specific gravity is 1.7 for the solids and 1.0

for water. Laboratory batch solids flux plot for the slurry is attached (Attachment 2).

a. By means of the continuous solids flux method, assess the performance of the

thickener by determining the solids concentrations in the underflow, the

overflow and in the thickening zone below the feed line of the thickener.

b. Although the current operation may be satisfactory, the underflow slurry is not

concentrated enough. Your manager has proposed two options to increase the

underflow concentration further:

Option 1: increasing the feed rate by 35%, keeping the underflow rate the

same;

Option 2: decreasing the underflow rate by 35%, keeping the feed rate

constant.

Which of the above options is feasible and how much increase in the underflow

concentration can be achieved? Present your case with detailed calculations of

the solids concentrations of all streams leaving the thickener.

Chemical Engineering Applications A

Examination 2010 6 CHEMENG 3035 (105527)

Question 4 (40 marks)

Filtration of a slurry is normally carried out in a plate and frame filter press having 20

frames, each with dimensions 0.3 m x 0.3 m square and 0.05 m thick. At a constant

pressure differential of 200 kPa, filtration takes 20 minutes to complete when the frames

are full. Washing the filter cake follows under the constant-pressure (200 kPa) condition.

Cake washing takes 15 minutes, and requires a volume of wash water equal to half of

the total filtrate volume collected. Dismantling, cleaning and refitting of the filter take 15

minutes.

a. Determine the volume of filtrate collected per filtration cycle.

b. Calculate the average cake resistance () and the filter medium resistance (Rm).

It is proposed to replace the filter press with a continuous rotary drum filter, which is 2 m

long and 1 m in diameter. Filtration will be carried out at a constant pressure difference

of 150 kPa, and the filter will operate with 25 per cent of the drum submerged in the feed

slurry at any instant. Assume that the filter cake is incompressible and has the same

specific resistance* as that of the filter press cake, and that the medium resistance may

be neglected.

c. Calculate the speed of rotation of the drum which will result in the same overall

rate of filtration as obtained with the filter press.

d. Calculate the average thickness of the filter cake formed with the drum filter.

* Note: If you had difficulties calculating in part (b), assume = 1.41010 m/kg.

Data: Feed slurry concentration: 20 wt% solids

Solid density: 3000 kg/m3

Filtrate density & viscosity: 1000 kg/m3, 1 cp

Average filter cake voidage: 0.6

END OF PART B

END OF THE PAPER

Chemical Engineering Applications A

Examination 2010 7 CHEMENG 3035 (105527)

ATTACHMENT 1: Drag Coefficient – Reynolds Number chart

Chemical Engineering Applications A

Examination 2010 8 CHEMENG 3035 (105527)

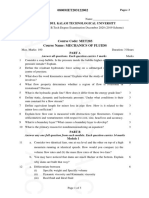

ATTACHMENT 2: Batch Solids Flux Data for Question 3

0.14

Solids flux, (mm/s)

0.12

0.1

0.08

0.06

0.04

0.02

0

0 0.1 0.2 0.3 0.4 0.5

Solids volume fraction, c

0.14

Solids flux, (mm/s)

0.12

0.1

0.08

0.06

0.04

0.02

0

0 0.1 0.2 0.3 0.4 0.5

Solids volume fraction, c

Chemical Engineering Applications A

You might also like

- Civil Engineering FormulasDocument6 pagesCivil Engineering FormulasJonathan100% (2)

- Helicopter AerodynamicsDocument1 pageHelicopter AerodynamicsSatyavinaykumar TokalaNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Fluid Statics Problem Set 3aDocument11 pagesFluid Statics Problem Set 3aRyan Shane Langit50% (2)

- Pressure Vessel Assessment SpreadsheetDocument3 pagesPressure Vessel Assessment SpreadsheetrawirabbatNo ratings yet

- Principles of HydrotherapyDocument21 pagesPrinciples of Hydrotherapyvaishali jagtap100% (6)

- Agglomeration Methods for Fine ParticlesDocument19 pagesAgglomeration Methods for Fine ParticlesNhut NguyenNo ratings yet

- Driving PSM Performance Beyond Kpi Metrics BehieDocument37 pagesDriving PSM Performance Beyond Kpi Metrics BehieNhut NguyenNo ratings yet

- EM 1110-2-1416 River HydraulicsDocument176 pagesEM 1110-2-1416 River Hydraulicsdyc123100% (1)

- Pump Maintenance EssentialsDocument29 pagesPump Maintenance EssentialsnaushadmnnitNo ratings yet

- SedimentationDocument41 pagesSedimentationGailNo ratings yet

- Cavitation Analysis CFDDocument4 pagesCavitation Analysis CFDshdjjfNo ratings yet

- M4-1-SMS - Aerodrome - Safety Performance and MonitoringDocument43 pagesM4-1-SMS - Aerodrome - Safety Performance and MonitoringNhut NguyenNo ratings yet

- r050210801 Fluid Mechanics For Chemical EngineeringDocument7 pagesr050210801 Fluid Mechanics For Chemical EngineeringSrinivasa Rao GNo ratings yet

- Global Upstream Tier 1 and 2 Process Safety Event Classification Guidance 2015Document19 pagesGlobal Upstream Tier 1 and 2 Process Safety Event Classification Guidance 2015MIGUELONOFRENo ratings yet

- Fixed and Fluidized Bed ExperimentDocument9 pagesFixed and Fluidized Bed Experimentsunlias50% (2)

- Chem Eng Exam Primary 2017Document11 pagesChem Eng Exam Primary 2017Octave008No ratings yet

- Fluid Flow and Mechanical OperationsDocument8 pagesFluid Flow and Mechanical OperationsShiavm PatelNo ratings yet

- Instructions:: University of Pune Polymer/Petroleum/Petrochemical) Momentum TransferDocument42 pagesInstructions:: University of Pune Polymer/Petroleum/Petrochemical) Momentum TransferEkugum Pascal ChinedumNo ratings yet

- The University of Nottingham Malaysia CampusDocument5 pagesThe University of Nottingham Malaysia CampusDnesh NairNo ratings yet

- Instructions To CandidatesDocument4 pagesInstructions To Candidateskivumbi AchileoNo ratings yet

- r050210801 Fluid Mechanics For Chemical EngineersDocument8 pagesr050210801 Fluid Mechanics For Chemical Engineersprakash.paruchuri100% (2)

- Pyq 2020-2021Document7 pagesPyq 2020-2021Rai MinNo ratings yet

- 2009 S1 ExamDocument21 pages2009 S1 Exam赵一伦No ratings yet

- r05310804 Mass Transfer Operations IDocument8 pagesr05310804 Mass Transfer Operations ISrinivasa Rao GNo ratings yet

- FMM Question BankDocument6 pagesFMM Question BanktagoreboopathyNo ratings yet

- Transport - Phenomena - Suggestions - October - 2016.docx - Filename - UTF-8''Transport Phenomena - Suggestions - October, 2016Document10 pagesTransport - Phenomena - Suggestions - October - 2016.docx - Filename - UTF-8''Transport Phenomena - Suggestions - October, 2016J S M MahediNo ratings yet

- R09 Set No. 2Document4 pagesR09 Set No. 2Samiullah MohammedNo ratings yet

- Btech Ce 3 Sem Fluid Mechanics Rce303 2019Document3 pagesBtech Ce 3 Sem Fluid Mechanics Rce303 2019shivchauhan0507No ratings yet

- Mechanics of Fluids r05220302Document8 pagesMechanics of Fluids r05220302Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Geotechnical Engineering-I PDFDocument8 pagesGeotechnical Engineering-I PDFMopidevi Vijaya KishoreNo ratings yet

- 9a23303-Fluid Flow in Bio ProcessesDocument4 pages9a23303-Fluid Flow in Bio ProcessessivabharathamurthyNo ratings yet

- FLUID MECHANICS MODEL QUESTION PAPERDocument4 pagesFLUID MECHANICS MODEL QUESTION PAPERPraveen Reddy ReddyNo ratings yet

- Code No: 43011/43012Document7 pagesCode No: 43011/43012SRINIVASA RAO GANTANo ratings yet

- SCH2108201612 Transport PhenomenaDocument5 pagesSCH2108201612 Transport PhenomenaAljebre MohmedNo ratings yet

- r7320101 Geotechnical EngineeringDocument4 pagesr7320101 Geotechnical Engineeringvamsi253No ratings yet

- BE1603 - May Exam Paper - 2020-21Document8 pagesBE1603 - May Exam Paper - 2020-21zain khuramNo ratings yet

- 882 Question PaperDocument2 pages882 Question PaperDharmanshu SharmaNo ratings yet

- Previous Papers 2Document28 pagesPrevious Papers 2REVANTH KUMAR KNo ratings yet

- r050210104 Fluid MechanicsDocument10 pagesr050210104 Fluid MechanicsSrinivasa Rao G100% (1)

- II B. Tech I Semester, Supplementary Examinations, May - 2012 Fluid Mechanics & Hydraulic MachinesDocument44 pagesII B. Tech I Semester, Supplementary Examinations, May - 2012 Fluid Mechanics & Hydraulic MachineshvrkNo ratings yet

- 525 PQDocument7 pages525 PQPromise OkekeNo ratings yet

- Transport Phenomena 2021-I Exam 30 AprilDocument3 pagesTransport Phenomena 2021-I Exam 30 AprilSebastian calle uribeNo ratings yet

- WWW - Manaresults.co - In: Geotechnical Engineering - IDocument2 pagesWWW - Manaresults.co - In: Geotechnical Engineering - Iसोनू जगतापNo ratings yet

- r050212102 Mechanics of FluidsDocument8 pagesr050212102 Mechanics of FluidsSrinivasa Rao GNo ratings yet

- Ch8551 Mass Transfer-I Unit I - (Diffusion) C303.1: Department of Chemical Engineering, VSBECDocument12 pagesCh8551 Mass Transfer-I Unit I - (Diffusion) C303.1: Department of Chemical Engineering, VSBECSaravanan SundaramNo ratings yet

- FFODocument31 pagesFFOBhakti Mahbubani0% (1)

- 03 Catalyst CharacterizationDocument39 pages03 Catalyst CharacterizationMegan TorresNo ratings yet

- Exam+sol 2005-2013 HJDocument14 pagesExam+sol 2005-2013 HJSamad Ali SiddiquiNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityShivam PanchalNo ratings yet

- Batch Sedimentation Experiment to Determine Particle SizeDocument4 pagesBatch Sedimentation Experiment to Determine Particle SizeJade Dhalle Encarnacion100% (1)

- 9A23303 Fluid Flow in Bio ProcessesDocument4 pages9A23303 Fluid Flow in Bio ProcessessivabharathamurthyNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityvifaket581No ratings yet

- Screenshot 2023-10-09 at 3.54.38 AMDocument5 pagesScreenshot 2023-10-09 at 3.54.38 AMhnsm9bwtqrNo ratings yet

- Tribology QP & Syllabus Vtu PRASHANTHDocument21 pagesTribology QP & Syllabus Vtu PRASHANTHpachieduNo ratings yet

- HydraulicsDocument5 pagesHydraulicsAmit GhadeNo ratings yet

- Consolidation Test1Document6 pagesConsolidation Test1Ramesh BabuNo ratings yet

- Internal Test - Compensatory: Shri Ramswaroop Memorial UniversityDocument2 pagesInternal Test - Compensatory: Shri Ramswaroop Memorial UniversityAmit Kumar SinghNo ratings yet

- 9A23303 Fluid Flow in BioprocessesDocument4 pages9A23303 Fluid Flow in BioprocessessivabharathamurthyNo ratings yet

- Momentum TransferDocument2 pagesMomentum TransferrahulNo ratings yet

- 09 - 05 Geotechnical Engineering - IDocument1 page09 - 05 Geotechnical Engineering - IMURALI KRISHNANo ratings yet

- Fluid Mechanics Rce 303Document2 pagesFluid Mechanics Rce 303Raju RøyNo ratings yet

- Advanced FM Paper PDFDocument1 pageAdvanced FM Paper PDFRavindra MamgainNo ratings yet

- 07a60101 Geotechnical EngineeringDocument8 pages07a60101 Geotechnical EngineeringSatish KumarNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityShivam PanchalNo ratings yet

- 2020 Dec. MET203-ADocument3 pages2020 Dec. MET203-Ared18ggmuNo ratings yet

- 06 ME 36B/ 06 ME 46B: (Answer Any FIVE Questions Selecting at Least Two From Each Part)Document4 pages06 ME 36B/ 06 ME 46B: (Answer Any FIVE Questions Selecting at Least Two From Each Part)Ravi karanNo ratings yet

- NR 310105 GeotechnicalEngineeringDocument8 pagesNR 310105 GeotechnicalEngineeringSrinivasa Rao G100% (1)

- Fluid Dynamics in Complex Fractured-Porous SystemsFrom EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- CE4014-2019-FBS-GP15A4 r0 NAW Oct 2019Document4 pagesCE4014-2019-FBS-GP15A4 r0 NAW Oct 2019Nhut NguyenNo ratings yet

- Risk Analysis and Assessment Methodologies in Work SitesDocument49 pagesRisk Analysis and Assessment Methodologies in Work SitesNhut NguyenNo ratings yet

- Process Safety Performance IndicatorsDocument11 pagesProcess Safety Performance IndicatorsNhut NguyenNo ratings yet

- Process Safety Performance IndicatorsDocument11 pagesProcess Safety Performance IndicatorsNhut NguyenNo ratings yet

- Classification of PSM Barriers I Travers P McCullochDocument9 pagesClassification of PSM Barriers I Travers P McCullochNhut NguyenNo ratings yet

- UL WP Final Using Leading and Lagging Safety Indicators To Manage Workplace Health and Safety Risk V7 LR1Document10 pagesUL WP Final Using Leading and Lagging Safety Indicators To Manage Workplace Health and Safety Risk V7 LR1Nhut NguyenNo ratings yet

- Gestión de Controles CriticosDocument60 pagesGestión de Controles CriticosEdward MendozaNo ratings yet

- Barrier Vulnerability On Bow TiesDocument2 pagesBarrier Vulnerability On Bow TiesNhut NguyenNo ratings yet

- Developing System Based Leading IndicatorsDocument80 pagesDeveloping System Based Leading IndicatorsManishNo ratings yet

- Ellingham Diagrams: Understanding Relative Stabilities of Metal OxidesDocument14 pagesEllingham Diagrams: Understanding Relative Stabilities of Metal OxidesNhut NguyenNo ratings yet

- Determination of Leading and Lagging Indicators Utilizing The BowTie MethodDocument10 pagesDetermination of Leading and Lagging Indicators Utilizing The BowTie MethodNhut NguyenNo ratings yet

- Pyrometallurgy Lecture 3 Fluid Bed RoastingDocument18 pagesPyrometallurgy Lecture 3 Fluid Bed RoastingNhut NguyenNo ratings yet

- Pyrometallurgy Lecture 1. Introduction and Roasting ThermodynamicsDocument22 pagesPyrometallurgy Lecture 1. Introduction and Roasting ThermodynamicsNhut NguyenNo ratings yet

- Pyrometallurgy Lecture 4 Chlorination RoastingDocument16 pagesPyrometallurgy Lecture 4 Chlorination RoastingNhut NguyenNo ratings yet

- Lecture Notes Iron Making (Pcmt4307) - 6th Sem Btech 2020 1602282032Document159 pagesLecture Notes Iron Making (Pcmt4307) - 6th Sem Btech 2020 1602282032Nhut NguyenNo ratings yet

- Lecture Notes Iron Making (Pcmt4307) - 6th Sem Btech 2020 1602282032Document159 pagesLecture Notes Iron Making (Pcmt4307) - 6th Sem Btech 2020 1602282032Nhut NguyenNo ratings yet

- Molecular Weight (G/mol) Benzene 78 DDT 354.5 2,4 - D 221 T 25Document5 pagesMolecular Weight (G/mol) Benzene 78 DDT 354.5 2,4 - D 221 T 25Nhut NguyenNo ratings yet

- Assignment 5 - The Nhut NguyenDocument5 pagesAssignment 5 - The Nhut NguyenNhut NguyenNo ratings yet

- Small Gas Processing FacilityDocument5 pagesSmall Gas Processing FacilityNhut NguyenNo ratings yet

- Tutorial 5 - Partitioning 2021Document2 pagesTutorial 5 - Partitioning 2021Nhut NguyenNo ratings yet

- Small Gas Processing FacilityDocument5 pagesSmall Gas Processing FacilityNhut NguyenNo ratings yet

- Assignment 1Document14 pagesAssignment 1Nhut NguyenNo ratings yet

- Data Given Calculation Concentration in Air 100 PPM H in Water 3.8 Ug/l KAW T 25 Oc P 1 AtmDocument17 pagesData Given Calculation Concentration in Air 100 PPM H in Water 3.8 Ug/l KAW T 25 Oc P 1 AtmNhut NguyenNo ratings yet

- Tutorial 1 - Powder Storage and Particulate Mixing (Unmarked)Document16 pagesTutorial 1 - Powder Storage and Particulate Mixing (Unmarked)Nhut NguyenNo ratings yet

- Beach EnergyDocument2 pagesBeach EnergyNhut NguyenNo ratings yet

- Para Calculo de Tirantes ConjugadosDocument122 pagesPara Calculo de Tirantes ConjugadosFlavio Cesar Alvitez VasquezNo ratings yet

- Friction LossDocument22 pagesFriction LossChungath LineshNo ratings yet

- AREMA Volume 1, Chapter 1, Part 4, Section 4.8 HDPE PDFDocument20 pagesAREMA Volume 1, Chapter 1, Part 4, Section 4.8 HDPE PDFpquiroga2100% (2)

- Non-Newtonian Fluids ExplainedDocument14 pagesNon-Newtonian Fluids ExplainedLuis Felipe Gutierrez MarcantoniNo ratings yet

- Common Temperature Scales: Basis: Freezing Point of WaterDocument16 pagesCommon Temperature Scales: Basis: Freezing Point of WaterJohnNo ratings yet

- Covection Heat TransferDocument24 pagesCovection Heat TransfersampathsiddamNo ratings yet

- FLUENT-Intro 14.0 WS07b Vortex SheddingDocument39 pagesFLUENT-Intro 14.0 WS07b Vortex Sheddingyoners1691No ratings yet

- Classification of Flows Applied Computational Fluid DynamicsDocument32 pagesClassification of Flows Applied Computational Fluid DynamicsMarcelo MartinezNo ratings yet

- LINDEBURG ESAS Terms Compilation PART 1 TO 12Document47 pagesLINDEBURG ESAS Terms Compilation PART 1 TO 12christinesarah0925No ratings yet

- Chapter Summary and Study Guide for Control Volume Analysis Using EnergyDocument24 pagesChapter Summary and Study Guide for Control Volume Analysis Using Energykrntomboy25% (4)

- Characterization of Velocity and Shear Rate Distribution in A Continuous MixerDocument104 pagesCharacterization of Velocity and Shear Rate Distribution in A Continuous Mixerm_luchianNo ratings yet

- Transport PhenomenaDocument8 pagesTransport PhenomenawaqaskhanNo ratings yet

- CFD Analysis of Conical and Bell NozzlesDocument5 pagesCFD Analysis of Conical and Bell NozzlesKunal RaikarNo ratings yet

- Naval Engineering Modeling and Optimization Program (NEMO)Document54 pagesNaval Engineering Modeling and Optimization Program (NEMO)Leandro MeiliNo ratings yet

- Fluid Mechanics EquationsDocument13 pagesFluid Mechanics EquationsBhushan VermaNo ratings yet

- Turbomachinery Design and Theory - R. S. R. Gorla and A. A. KhanDocument179 pagesTurbomachinery Design and Theory - R. S. R. Gorla and A. A. KhanaliNo ratings yet

- Take Test - Fluid Mechanics - Section 04 Quiz Questions - ..Document8 pagesTake Test - Fluid Mechanics - Section 04 Quiz Questions - ..MAJ kNo ratings yet

- Unit-3 Dimensional AnalysisDocument65 pagesUnit-3 Dimensional AnalysisS PrathebaNo ratings yet

- Design of Kaplan Turbine RunnerDocument48 pagesDesign of Kaplan Turbine RunnerNathan ThomsonNo ratings yet

- Report of The Results For KCS Resistance & Self-Propulsion (Case 2-1, 2-5, and 2-7)Document42 pagesReport of The Results For KCS Resistance & Self-Propulsion (Case 2-1, 2-5, and 2-7)Adin SugiarsoNo ratings yet

- Lecture 25 Design of Stack: Key Words: Stack, Chimney, Draft, Natural Draft What Is Stack EffectDocument3 pagesLecture 25 Design of Stack: Key Words: Stack, Chimney, Draft, Natural Draft What Is Stack Effectkarthikraja21No ratings yet