Professional Documents

Culture Documents

Antisismicos 010PHD

Uploaded by

YopoGas Ingenieria & ServiciosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Antisismicos 010PHD

Uploaded by

YopoGas Ingenieria & ServiciosCopyright:

Available Formats

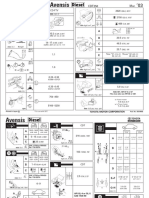

S WAY B RACE F ITTINGS

FUNCTION: Designed for bracing pipe against sway and seismic disturbance. The

pipe attachment component of a sway brace system used in conjunction

Fig. 010

with a PHD Manufacturing structural attachment fitting, and joined

together with a bracing pipe element forms a complete sway brace SWAY BRACE

assembly. Sway brace assemblies are intended to be installed in

accordance with NFPA 13 and the manufacturer’s installation PIPE ATTACHMENT

instructions.

SIZE: Pipe size 1" thru 6".

Pipe size used for bracing 1" or 1 1⁄4" Schedule 40 IP.

FINISH: Electro-galvanized

MATERIAL: Low Carbon Steel

INSTALL: Place over the pipe to be braced, adjust brace angle, and insert bracing

pipe through opening leaving a minimum of 1" extending from

attachment. Brace pipe can be installed on top or bottom of pipe to be

braced but must be a minimum of 6" away from a pipe joint. Tighten nuts

down evenly until hex heads break off.

APPROVALS: Underwriters Laboratories listed for US and Canada

Factory Mutual approved

Listed for use with NFPA and PHD sway brace components only

FM Maximum Design Load

ORDERING: Specify figure number, brace pipe size, and sprinkler pipe size

Brace Pipes 1” or 1 1/4”

UL Maximum Design Load (GB/T3091, EN10255H, or JISG3454)

Weight Ea. Pipe Size Brace Angle

1” (25mm) 1 1/4” (32mm) SCH 10, 40 From Vertical

Brace Pipe Brace Pipe & Flow Pipe (Degrees) lbs. kN

Pipe Size 30°-44° 340 (1.51)

SCH 40 lbs. kN lbs. kg lbs. kg

45°-59° 480 (2.13)

*1 (25) 1000 (4.45) 0.71 (0.32) 0.75 (0.34) 1 (25)

60°-74° 590 (2.62)

1 1/4 (32) 1000 (4.45) 0.76 (0.34) 0.79 (0.36) 75°-90° 660 (2.93)

1 1/2 (40) 1000 (4.45) 0.79 (0.36) 0.82 (0.37) 30°-44° 350 (1.55)

45°-59° 500 (2.22)

2 (50) 1000 (4.45) 0.84 (0.38) 0.88 (0.40) 1 1/4 (32)

60°-74° 610 (2.71)

2 1/2 (65) 1000 (4.45) 0.90 (0.41) 0.94 (0.43) 75°-90° 680 (3.02)

3 (80) 1000 (4.45) 0.98 (0.44) 1.02 (0.46) 30°-44° 290 (1.28)

45°-59° 420 (1.86)

4 (100) 1000 (4.45) 1.10 (0.50) 1.14 (0.52) 1 1/2 (40)

60°-74° 510 (2.26)

6 (150) 1600 (7.12) N/A N/A 1.40 (0.63) 75°-90° 570 (2.53)

30°-44° 390 (1.73)

* Restraint only

45°-59° 550 (2.44)

2 (50)

60°-74° 670 (2.98)

75°-90° 750 (3.33)

30°-44° 440 (1.95)

45°-59° 620 (2.75)

2 1/2 (65)

60°-74° 760 (3.38)

75°-90° 850 (3.78)

30°-44° 470 (2.09)

45°-59° 660 (2.93)

3 (80)

60°-74° 810 (3.33)

75°-90° 910 (4.04)

30°-44° 430 (1.91)

45°-59° 610 (2.71)

4 (100)

60°-74° 750 (3.33)

75°-90° 840 (3.73)

30°-44° 250 (1.11)

45°-59° 350 (1.55)

*6 (150)

60°-74° 430 (1.91)

75°-90° 480 (2.13)

* 1 1/4” brace size only

Unless otherwise specified, all dimensions on drawings and in charts are in inches and dimensions shown in parentheses are in millimeters.

PHD Manufacturing, Inc.

PHD Manufacturing, Inc.

44018 Columbiana-Waterford Road

Columbiana, Ohio 44408-9481

Phone: 800-321-2736 • 330-482-9256

Fax: 330-482-2763

Web: www.phd-mfg.com

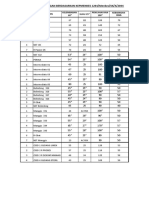

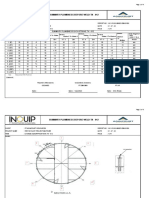

FIG. 010 SWAY BRACE PIPE ATTACHMENT

Pipe Braced: 1”, 1 1/4”, 1 1/2”, 2”, 2 1/2”, 3”, 4”, 6”

Bracing: 1” Or 1 1/4” SCH40 steel pipe

Function: Designed for bracing pipe against sway and seismic disturbance. The pipe attachment component of

a sway brace system used in conjunction with a PHD Manufacturing structural attachment fitting,

and joined together with a bracing pipe element forms a complete sway brace assembly. Sway brace

assemblies are intended to be installed in accordance with NFPA 13 and the manufacturer’s

installation instructions.

Approvals: Underwriters Laboratories listed for US and Canada (1” system pipe size listed as a restraint only)

Factory Mutual approved

Listed for use with NFPA and PHD sway brace components only

Material: Low Carbon Steel

Installation: Place over the pipe to be braced, adjust brace angle, and insert bracing pipe through opening leaving

a minimum of 1" extending from attachment. Brace pipe can be installed on top or bottom of pipe to

be braced but must be a minimum of 6" away from a pipe joint. Tighten nuts down evenly until hex

heads break off.

UL Maximum Design Loads

Brace Pipe

Pipe Size Size

Schedule 40 Schedule 40 lbs.

1* 1 & 1 1/4 1000

1 1/4 1 & 1 1/4 1000

1 1/2 1 & 1 1/4 1000

2 1 & 1 1/4 1000

2 1/2 1 & 1 1/4 1000

3 1 & 1 1/4 1000

4 1 & 1 1/4 1000

6 1 1/4 1600

* UL listed as a restraint device only.

FM Approved Loads

Allowable Horizontal Capacity

Per Installation Angle (lbs.) Brace Pipe

Pipe Brace Angle From Vertical Size

Orientation Pipe Size Schedule 30° - 44° 45° - 59° 60° - 74° 75° - 90° Schedule 40

Lateral 1 LW, 10, 40 340 480 590 660 1” or 1 1/4”

Lateral 1 1/4 LW, 10, 40 350 500 610 680 1” or 1 1/4”

Lateral 1 1/2 LW, 10, 40 290 420 510 570 1” or 1 1/4”

Lateral 2 LW, 10, 40 390 550 670 750 1” or 1 1/4”

Lateral 2 1/2 LW, 10, 40 440 620 760 850 1” or 1 1/4”

Lateral 3 LW, 10, 40 470 660 810 910 1” or 1 1/4”

Lateral 4 LW, 10, 40 430 610 750 840 1” or 1 1/4”

Lateral 6 LW, 10, 40 250 350 430 480 1 1/4”

NOTE: LW above refers to FM Approved Lightwall pipe, commonly referred to as Schedule 7.

These ratings may also be applied to EN10220 and GB/T 8163 pipe. Schedule 10 above may be

applied to GB/T 3091, GB/T 3092, EN 10255 M and H, JIS G3452. Schedule 40 above may be

applied to GB/T3091, EN10255H or JISG3454 brace pipe.

The Complete Line of Pipe Supports and Devices

Pipe Hangers ▲ Strut & Accessories ▲ Pipe Clamps ▲ Beam Clamps ▲ Shields

You might also like

- WAY Race Ittings: Fig. 010 Sway Brace Pipe AttachmentDocument1 pageWAY Race Ittings: Fig. 010 Sway Brace Pipe AttachmentJORGE LUIS VALENCIA CHIRINOSNo ratings yet

- Aerospace Grade Oils and Greases: Product InformationDocument4 pagesAerospace Grade Oils and Greases: Product InformationPeter BennetNo ratings yet

- Lri Nomogram NichaminDocument3 pagesLri Nomogram NichaminMiminNo ratings yet

- Ebf 8251 Спецификация На Распредвалы 3116-С7Document4 pagesEbf 8251 Спецификация На Распредвалы 3116-С7DyxovnikNo ratings yet

- Lab # 5-Impact of A Jet - FillableDocument8 pagesLab # 5-Impact of A Jet - Fillablehussain ghaziNo ratings yet

- Rasco - MV - Medium Velocity Directional Spray Nozzle - B.106-Aug21Document39 pagesRasco - MV - Medium Velocity Directional Spray Nozzle - B.106-Aug21Ary SetiawanNo ratings yet

- Product Datasheet Product Datasheet SF CIRC 400 V 24W 840 IP44Document6 pagesProduct Datasheet Product Datasheet SF CIRC 400 V 24W 840 IP44Catalin DulceataNo ratings yet

- PRO144EXDocument2 pagesPRO144EXALIOUI MontassirNo ratings yet

- Sling Angle ChartsDocument1 pageSling Angle ChartsAgung WitonoNo ratings yet

- Land Cruiser 100 - DieselDocument2 pagesLand Cruiser 100 - DieselJair GonzalezNo ratings yet

- Kubota V3300 SM-068-072Document5 pagesKubota V3300 SM-068-072yeferson mora guerreroNo ratings yet

- Technical Data Sheet Mpt16La 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet Mpt16La 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantmustafaNo ratings yet

- CertMaterialTestReport E6010 Fletweld SP 1-8Document1 pageCertMaterialTestReport E6010 Fletweld SP 1-8gerosuca800No ratings yet

- Attachment - 5 Technical Documents: Numen Engineering Pte - LTD (Stahl Lightings)Document11 pagesAttachment - 5 Technical Documents: Numen Engineering Pte - LTD (Stahl Lightings)Budi Putra NasutionNo ratings yet

- Appendix T AbleDocument16 pagesAppendix T AbleEmad M. NaguibNo ratings yet

- Tuerca A194 2H 1 1.4 HDGDocument1 pageTuerca A194 2H 1 1.4 HDGMiguel dextreNo ratings yet

- Katalog Komposisi Lengkap New VersionDocument8 pagesKatalog Komposisi Lengkap New VersionSontani PurnamaNo ratings yet

- Novaseptic Valve Sp1139en MsDocument2 pagesNovaseptic Valve Sp1139en MsmiliNo ratings yet

- Nylatron MC 901: Iso AstmDocument2 pagesNylatron MC 901: Iso AstmIrwan SaputraNo ratings yet

- Kubota v3600 SMDocument16 pagesKubota v3600 SMyeferson mora guerreroNo ratings yet

- Table 4B1 and 4E4ADocument2 pagesTable 4B1 and 4E4Ahachan100% (2)

- Sky Water ProductsDocument1 pageSky Water ProductsCarlos Fernando Parra DiazNo ratings yet

- ASTM Standard (SCH) UPVC Pipes and Fitting CatalogDocument1 pageASTM Standard (SCH) UPVC Pipes and Fitting CatalogPUSHPENDRA SINGHNo ratings yet

- c4nr04192e1Document5 pagesc4nr04192e1Abril GaarNo ratings yet

- Danfoss GU45TG R134a 200 50Document5 pagesDanfoss GU45TG R134a 200 50Dadan KurniaNo ratings yet

- LED Office Lighting Specifications and Performance DataDocument3 pagesLED Office Lighting Specifications and Performance DataJonathan MaldonadoNo ratings yet

- Ertalon 6 Pla Nylatron MC 907 Pds Glob e 19092016Document2 pagesErtalon 6 Pla Nylatron MC 907 Pds Glob e 19092016Rashid Mohammed100% (1)

- Avensis DieselDocument2 pagesAvensis DieselzoltanpolyakNo ratings yet

- Hardness conversions chart with Brinell, Rockwell, Vickers & Tensile valuesDocument1 pageHardness conversions chart with Brinell, Rockwell, Vickers & Tensile valuesVeronika SinagaNo ratings yet

- Colli Specification Cutter Dredger B1200: Dredging Depth 10mDocument4 pagesColli Specification Cutter Dredger B1200: Dredging Depth 10mMD shawonNo ratings yet

- GPY14RDa compressor technical data sheetDocument4 pagesGPY14RDa compressor technical data sheetjose el wachoNo ratings yet

- Low Profile Self-Sealing B NutsDocument2 pagesLow Profile Self-Sealing B NutsEagle1968No ratings yet

- BETE_NDocument1 pageBETE_NDenaibeliNo ratings yet

- 3175 Maintenance Checks (CK3175) Lo-Res PDFDocument2 pages3175 Maintenance Checks (CK3175) Lo-Res PDFclaudioNo ratings yet

- Data Sheet: Rd520 Axius® Rupture DiscDocument3 pagesData Sheet: Rd520 Axius® Rupture DiscbondsivamaniNo ratings yet

- Duplex Yayın 1Document10 pagesDuplex Yayın 1Hüseyin ZenginNo ratings yet

- RC7 Data Sheet MD15 DN100-150 @enDocument2 pagesRC7 Data Sheet MD15 DN100-150 @enAmeneh KhajehaliNo ratings yet

- XFC160 ErpDocument1 pageXFC160 ErpBanupriya BalasubramanianNo ratings yet

- Radwin 5000 Ant RW-9061-2002Document2 pagesRadwin 5000 Ant RW-9061-2002Nguyen Xuan NhuNo ratings yet

- Jadwal SwapntauDocument56 pagesJadwal Swapntauyusuf BakhtiarNo ratings yet

- Q1Display 15843280Document3 pagesQ1Display 15843280Oscar BasantesNo ratings yet

- Remote industrial thermometers with 4.5Document1 pageRemote industrial thermometers with 4.5Isidro RODRIGUEZ VILLEGASNo ratings yet

- Summary Report Plumbness - TK - 012Document2 pagesSummary Report Plumbness - TK - 012yuwantoniNo ratings yet

- Product Datasheet Product Datasheet DP VAL 600 9 W 4000 K IP65Document5 pagesProduct Datasheet Product Datasheet DP VAL 600 9 W 4000 K IP65Catalin DulceataNo ratings yet

- Rolling Stock Current Rating EN50355Document2 pagesRolling Stock Current Rating EN50355Angelo SilvaNo ratings yet

- Zytel: D D D DDocument5 pagesZytel: D D D DIsi-journals PublisherNo ratings yet

- ResultsDocument6 pagesResultsNora ZuraNo ratings yet

- Lower Unit and Electrical SpecificationsDocument1 pageLower Unit and Electrical SpecificationsPHUONG NGUYENNo ratings yet

- Jan 2022-CLB20403 Results Exp 1-Exp 4 Group 6Document10 pagesJan 2022-CLB20403 Results Exp 1-Exp 4 Group 6Ahmad DanialNo ratings yet

- Tds Dowcal N PDFDocument2 pagesTds Dowcal N PDFChoice OrganoNo ratings yet

- FR530Document7 pagesFR530rocaoNo ratings yet

- keepflo_refrigerant_distributors_catalogDocument20 pageskeepflo_refrigerant_distributors_catalog霍广东No ratings yet

- NUY90NRa - R290 - 115 - 60Document5 pagesNUY90NRa - R290 - 115 - 60Glorimar RojasNo ratings yet

- Calibración Del Sensor de OxigenoDocument6 pagesCalibración Del Sensor de OxigenogabrielNo ratings yet

- Serie 740Document4 pagesSerie 740Mabeli MartinezNo ratings yet

- Surfd 2 oDocument5 pagesSurfd 2 oadlinkNo ratings yet

- Corolla engine specifications optimized for SEODocument2 pagesCorolla engine specifications optimized for SEOjuan carlos diaz cardozoNo ratings yet

- Novaseptic Valve Valve Body, Tank Outlet Valve 90, Elbow 45 TCDocument3 pagesNovaseptic Valve Valve Body, Tank Outlet Valve 90, Elbow 45 TCJustin GeorgeNo ratings yet

- VLV Prueba y Drenaje Con VisorDocument2 pagesVLV Prueba y Drenaje Con VisorYopoGas Ingenieria & Servicios100% (1)

- Malleable Iron Pipe Fittings GuideDocument12 pagesMalleable Iron Pipe Fittings GuideGuillermo Catter FarroNo ratings yet

- Valv Check Aleum DGC Riser CheckDocument1 pageValv Check Aleum DGC Riser CheckYopoGas Ingenieria & ServiciosNo ratings yet

- Valv Check Aleum DGC Riser CheckDocument1 pageValv Check Aleum DGC Riser CheckYopoGas Ingenieria & ServiciosNo ratings yet

- VLV Prueba y Drenaje Con VisorDocument2 pagesVLV Prueba y Drenaje Con VisorYopoGas Ingenieria & Servicios100% (1)

- Valv Compuerta Sin Vastago Asc Brida X BridaDocument1 pageValv Compuerta Sin Vastago Asc Brida X BridaYopoGas Ingenieria & ServiciosNo ratings yet

- Valv Compuerta Sin Vastago Asc Brida X BridaDocument1 pageValv Compuerta Sin Vastago Asc Brida X BridaYopoGas Ingenieria & ServiciosNo ratings yet

- Soporte Tipo Pera PHD ManufacturingDocument1 pageSoporte Tipo Pera PHD ManufacturingYopoGas Ingenieria & ServiciosNo ratings yet

- Two-Piece Recessed Escutcheons and Protective Paint Caps For Automatic Sprinkler Recessed Installation General DescriptionDocument4 pagesTwo-Piece Recessed Escutcheons and Protective Paint Caps For Automatic Sprinkler Recessed Installation General DescriptionYopoGas Ingenieria & ServiciosNo ratings yet

- V27, K5.6 300 Psi/2068 Kpa High Pressure Models V2753 and V2754Document4 pagesV27, K5.6 300 Psi/2068 Kpa High Pressure Models V2753 and V2754buixuando11No ratings yet

- Antisismicos 010PHDDocument2 pagesAntisismicos 010PHDYopoGas Ingenieria & Servicios100% (1)

- 400A NTC Series OK INGLESDocument4 pages400A NTC Series OK INGLESYopoGas Ingenieria & ServiciosNo ratings yet

- VLV Prueba y Drenaje Con VisorDocument2 pagesVLV Prueba y Drenaje Con VisorYopoGas Ingenieria & Servicios100% (1)

- E-17 MODEL L60-6D WROUGHT 6D 60o ELBOW PDFDocument4 pagesE-17 MODEL L60-6D WROUGHT 6D 60o ELBOW PDFKikist ErsNo ratings yet

- VCCT For Abaqus PDFDocument14 pagesVCCT For Abaqus PDFFelipe Dornellas SilvaNo ratings yet

- Shear Modulus at Room Temperature: Standard Test Method ForDocument5 pagesShear Modulus at Room Temperature: Standard Test Method ForROHITNo ratings yet

- Thermodynamics Problems PDFDocument21 pagesThermodynamics Problems PDFSubhash KorumilliNo ratings yet

- Complete EDM Handbook - 14Document12 pagesComplete EDM Handbook - 14soheil gazeranNo ratings yet

- AC PRICE QUOTEDocument4 pagesAC PRICE QUOTEFaizal Septia HadiNo ratings yet

- 9.9 Diaphragms-With-Interior-Shearwalls PDFDocument4 pages9.9 Diaphragms-With-Interior-Shearwalls PDFnickNo ratings yet

- TWI Control of Welding DistortionDocument12 pagesTWI Control of Welding DistortionClaudia Mms100% (2)

- Enviro Processtanks® & Manholes®: Request Catalogue (/index - Php/Technical-Support-And-Catalogues)Document1 pageEnviro Processtanks® & Manholes®: Request Catalogue (/index - Php/Technical-Support-And-Catalogues)ssdprojects RexNo ratings yet

- Mom 1Document25 pagesMom 1Husnain ShahidNo ratings yet

- Bostik Low Voc Catalogue-A4-Nov20Document24 pagesBostik Low Voc Catalogue-A4-Nov20Stefano CamillucciNo ratings yet

- Aropol LP 67400Document2 pagesAropol LP 67400Ahmed ZamanNo ratings yet

- Air Cooled Heat Exchnger FormatedDocument43 pagesAir Cooled Heat Exchnger FormatedMustafa Anwar50% (2)

- Chapter 8 Ion Implantation - IIDocument33 pagesChapter 8 Ion Implantation - IIkbkkrNo ratings yet

- Rubber RecyclingDocument15 pagesRubber RecyclingEhab Attia SelimNo ratings yet

- Bernt - EC3 1 5Document44 pagesBernt - EC3 1 5Rosario BlancaNo ratings yet

- Chimney FoundationDocument19 pagesChimney Foundationamass esmNo ratings yet

- 10 1016@j Istruc 2019 02 018Document10 pages10 1016@j Istruc 2019 02 018shak543No ratings yet

- The Effects of Abrasives On Electrical Submersible Pumps: Brown L. WilsonDocument5 pagesThe Effects of Abrasives On Electrical Submersible Pumps: Brown L. WilsonAnonymous VNu3ODGavNo ratings yet

- E21-G02 - 1 Identification of Circuit Conductor & Phase RelationDocument6 pagesE21-G02 - 1 Identification of Circuit Conductor & Phase RelationMuhammad IrfanNo ratings yet

- FAG Rolling Bearing LubricationDocument69 pagesFAG Rolling Bearing LubricationSam ChengNo ratings yet

- Seismic HotelDocument6 pagesSeismic HotelThesis ConsultantNo ratings yet

- Access Scaffolding CalculationDocument8 pagesAccess Scaffolding CalculationSarah HaiderNo ratings yet

- Ebara 3M IE3 UKDocument19 pagesEbara 3M IE3 UKAfraz ShaikhNo ratings yet

- M. Doors and WindowsDocument6 pagesM. Doors and WindowsTharaka PereraNo ratings yet

- Piping Material Specification 2010014 00 l0 Gs 001Document215 pagesPiping Material Specification 2010014 00 l0 Gs 001Wilson Xavier Orbea Bracho100% (1)

- TPI FacadeDocument17 pagesTPI FacadeSohel DalalNo ratings yet

- EvaporatorDocument9 pagesEvaporatorLin Xian Xing100% (1)

- Romold Domestic Grease TrapDocument1 pageRomold Domestic Grease Traprajkumar_chinniahNo ratings yet

- Powder Chopped Stand Mats: General PurposeDocument1 pagePowder Chopped Stand Mats: General Purposehamza OUADINo ratings yet