Professional Documents

Culture Documents

PF 32 11 034 06

Uploaded by

ubaidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PF 32 11 034 06

Uploaded by

ubaidCopyright:

Available Formats

Flavor encapsulation

Spray Drying

An in-depth look at the steps in spray drying and the different options available to

flavorists

Mike Porzio, McCormick & Co.

A

good percentage of flavors formulated by a properties, dry easily and form a glassy amorphous pow-

flavorist will be encapsulated. While a variety of der upon drying. No single material meets all of these

encapsulation technologies have been developed criteria.

34 and are commercially employed, the majority of

encapsulated flavors are spray dried.1–4 T-1 presents

Carrier systems are usually formulated by combining

a number of water-soluble components. The first of these

some commercial flavor encapsulation options available components are the water-soluble polymers. Two classes

to the flavorist along with an estimated degree of industry of food polymers used almost exclusively are gum arabic

usage and preferred state for the encapsulated flavor- and the OSAN-starches. Gum arabics are hydrocolloid

carrier material. Spray drying remains the predominant gums, obtained from Acacia trees of the Leguminosae

encapsulation process because it handles both water- family, alternately referred to as gum arabic, gum aca-

soluble and oil-soluble flavor systems equally well, is cost- cia, gum Senegal or Turkey gum. These plant exudates

effective and easily scaled from pilot plant to commercial have the advantage of being natural, providing excellent

production. Over the past 70 years encapsulation of emulsifying and film-forming properties while exhibiting

flavors by spray drying has become so routine and relatively low solution viscosities even at 35–40% dis-

standardized that some of the nuances and options solved solids in solution. On the negative side, they suffer

VOL. 32 NOVEMBER 2007

available to flavorists may no longer be obvious and thus from large swings in ingredient cost, as well as quality

are worth reviewing. and availability issues. The gum arabic sourced from the

sub-Saharan region is also subject to climate change vari-

Factors in Spray Drying ability and political instability in the harvesting areas. To

Flavor encapsulation employing the spray drying process avoid some of these issues, acacia tree farms have been

involves a large number of interactive factors. These established and supply significant quantities of gum arabic

include: the flavor, the flavor cosolvent, the carrier com- to the trade.

position, the emulsion solids-to-water ratio, emulsion The alternate food polymers used in spray drying

preparation and lipid particle size distribution, as well as are the octenylsuccinnic acid anhydride (OSAN) modi-

the dryer system and the operational drying conditions. fied starches. The precursor starches are derivatized by

The encapsulation process starts with the formulated reaction with octenylsuccinnic anhydride. This process

flavor (i.e., a compounded flavor, flavor extract, flavor adds octenylsuccinate side groups to the starch polymer

oil or reaction flavor) designed to meet the organoleptic chain and the modification generates the surface active

character of the flavor brief. As the flavorist compounds properties needed to emulsify and stabilize lipid-flavor

the flavor, the choice of cosolvent will also influence the droplets. Upon homogenization this polymer will generate

ultimate quality of the encapsulated flavor. For water- and stabilize 0.5–2 micron-sized oil droplets in an emul-

soluble flavors, use of ethanol or propylene glycol will not sion. The advantages of the OSAN-starches include low

have as big an effect on the final product relative to the cost, uninterruptible availability and reduced viscosities at

cosolvent selected for oil-soluble flavor systems. Since fla- higher concentrations, in addition to good emulsification

PERFUMER & FLAVORIST

vor chemicals vary greatly in water and oil solubility (their and lipid-droplet-stabilization properties. All the OSAN

partitioning character), volatility and chemical reactivity, carriers are acidic with solution pHs ranging from 3.0 to

the flavor cosolvent and carrier will affect the final sensory 5.6, depending upon OSAN-starch type and source. A

character. number of second generation hydrolyzed OSAN-starches

are becoming available and are blander and less acidic

The Spray Dry Carrier than the initial generation of dextrinized OSAN-starches.

The carrier composition is the most critical component in Other food polymers that have been suggested for use

the spray dry encapsulation system. The preferred carrier in spray drying include larch gum, modified celluloses,

material should dissolve easily, be water-soluble, bland, corn fiber gum, milk proteins and, most recently, an

inexpensive, have excellent oil-emulsifying and droplet- OSAN-modified gum arabic.5 T-2 lists a number of food

stabilizing properties, exhibit low solution viscosities at polymers used in spray drying, their trade names, suppli-

higher dissolved solids levels, have excellent film-forming ers and the pHs of 10% (w/w) solutions.

PF0711_Porzio.fcx.indd 34 10/1/07 1:07:24 PM

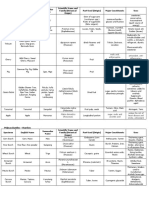

Commercial encapsulation systems T-1

Encapsulation system Relative contribution (%)a Preferred physical state

Spray drying ~80–85 Glassy solid—fine powder

Lipid–spray chilling 5–10 b‑Polymorph—fine particles

Melt extrusion 2–3 Glassy solid—particulates

Lipid–flakes 1 b‑Polymorph—flakes

Melt injection/solvent cooling 2 Glassy solid—threads

b-Cyclodextrin molecular complex 1 Crystalline complex

Complex coacervation < 1 Cross‑linked polymer membrane

surrounding flavor droplet

Co‑crystallization < 1 Crystalline sucrose with occluded flavor

apersonal communication–F. Paulicka

case, a uniform emulsion is prepared and the feed stream

35

Polymer solution pH’s T-2 metered into the dryer chamber. The ratio of carrier and

flavor to aqueous component is balanced to reach a com-

promise between a maximum practical emulsion viscosity

Trade name/source Polymer type pH of 10% and the reduced water levels leading to improved drying

solution efficiencies.

Emulgum a gum arabic 4.88 As noted in T-2, several of the OSAN-starches have

Capsule b OSAN-starch 3.10 pHs of approximately 3 in solution. This pH range can

Capsul TA b OSAN-starch 3.26 cause acid-catalyzed reactions with specific acid-sensitive

Miracap c OSAN-starch 3.07 flavor compounds such as citral or acetal. Also, this low

Emcap 12634 d OSAN-starch 4.80 pH becomes more of a concern with commercial pro-

Hicap 100 b OSAN-starch 4.00 duction where emulsions must be prepared and held for

Emcap 12639 d OSAN-starch 5.64 extended periods of time or held at high temperatures in

Emser 555 e sodium caseinate 6.51 the plant feed tank.

aColloidesNaturels; bNational Starch; cTate & Lyle; dCargill; eMain Street

Ingredients

The Dryer and the Drying Process

A general schematic of a spray dryer is shown in F-1.

While the flavorist generally does not get involved in the

Food polymers are not generally used as a single car- spray dryer systems used in the preparation of flavor sam-

rier component but are blended with maltodextrins, corn ples, those interested in the number and types of drying

syrup solids and sugars. This approach reduces cost-in- systems can consult the text by Masters.6 The spray drying

use while improving carrier functionality. Maltodextrin process can be broken down into a number of operational

provides a low-cost, bland-food polymer component, and steps. These include preparation of aqueous carrier phase;

corn syrup solids, or mono and disaccharides, improve emulsification or solubilization of the flavor; delivery of

the glassy state character by the mechanism of molecular the emulsion/flavor as a fine particle stream into the dryer;

packing in the dried matrix (see below). and drying under controlled rates and drying tempera-

tures to obtain the product—a dried encapsulated flavor

particulate.

Flavor Emulsion Referring to F-1, the flavor emulsion is prepared by

Efficient formation of the flavor emulsion starts with

first dissolving the carrier in the mixing tank [1]. The

dispersion of the carrier solids in water. The water source

flavor is added and the emulsion generated by passage of

should be devoid of contaminates, such as pro-oxidant

the flavor through a homogenizing unit [2], which is then

ions (Fe+++ or Cu ++) and chemical odors. A deionized

fed into a surge tank [3]. This flavor emulsion is metered

water source would be ideal. Alternately, a metal-com-

into the drying chamber [10] that has a preheated hot air

plexing agent such as disodium EDTA may be added to

stream, set at a predetermined temperature, within the

the water preceding emulsion preparation. The carrier

160–220°C range. The liquid flavor-carrier emulsion drop-

solids must be fully hydrated and dissolved before the fla-

lets are dispersed by the centrifugal head atomizer (or

vor component is added and dispersed. High shear mixing

nozzle atomizer) into the heated air within the chamber

is generally employed to disperse flavor oil droplets fol-

plenum at a specific rate. The droplets are almost instan-

lowed by homogenization using a two-stage homogenizer.

taneously heated to 100°C. Each liquid droplet rapidly

With nozzle dryers the homogenization step can also be

gives up moisture at the air-liquid interface forming a film

performed by passage through the dryer nozzle. In either

on the outer droplet surface. Water molecules rapidly

PF0711_Porzio.fcx.indd 35 10/1/07 1:07:24 PM

Flavor encapsulation

diffuse out of the droplet, increasing the solids content The Glassy State and Encapsulated Flavor

of the particle as it dries. Evaporative cooling protects Whenever a water-soluble flavor carrier system is spray

the flavor and the increasing solids retain the entrapped dried, the result is an amorphous powder. The amorphous

aromatic flavor molecules. By balancing the air-outlet powder will be in either the glassy state or the rubbery

temperature with air-inlet temperature by the liquid feed state, the former being preferred (T-1). The glassy state is

rates, the particles can be held at 100°C—the wet bulb more effective in preventing diffusion and loss of water-

temperature—during the full drying process. Ultimately, soluble flavor actives than the rubbery amorphous state.

the fully dried particles are swept out of the chamber into More details regarding the glassy state in food systems can

the cyclone [11] and collected in the receiving chamber be found in a number of articles.7–9

[12]. The recovered encapsulated flavor-carrier matrix will As a general rule the mixture of a food polymer—an

be an amorphous solid and based upon the carrier com- intermediate weight carbohydrate, such as maltodextrin or

position and drying dynamics; the solid should be in the corn syrup solids, and the mono and disaccharides—gives

desired glassy state. These particulates are usually 10–120 an optimum glass transition character (DCp) and a higher

microns in size and resemble collapsed soccer balls when glass transition temperature (Tg) at lower final moisture

viewed under a scanning electron microscope (SEM). levels. It is worth noting that when an oil-soluble flavor is

In some flavor houses, the flavorist will compound a fla- encapsulated within a glassy matrix, the lipid droplets are

vor, choosing the appropriate cosolvent and specifying the dispersed within the solid matrix. These lipid (solvent-

36 carrier composition in the formula system. In larger flavor flavor) droplets containing the flavor actives are still able

houses, the flavorist may only be required to compound to undergo normal liquid phase chemistries (i.e., cycliza-

the flavor and supply the formula to the process staff. The tions, inter-esterifications, isomerizations, ketal or acetal

choice of the carrier will be made from a carrier library formation in the presence of alcohols or polyols, conden-

developed and optimized for specific flavor systems. Still sation reactions, etc.).10 In essence, the droplets can act as

in some flavor houses, multiple forms of the spray dried microreactors. The significant advantage of a glassy matrix

encapsulated flavor utilizing a number of carriers may be is in prevention of oxygen permeation into the lipid,

prepared and returned to the flavorist for sensory evalua- which could initiate terpene oxidation or other oxidative

tion and the resulting best formula identified. flavor-degrading reactions.

VOL. 32 NOVEMBER 2007

A general schematic of a spray dryer F-1

PERFUMER & FLAVORIST

PF0711_Porzio.fcx.indd 36 10/1/07 1:07:24 PM

Flavor Carrier Systems Alternate Systems

A number of patents have been issued describing spray For water-soluble flavor extracts the spray dry carrier

dry flavor encapsulation systems. In US Patent 3,971,852, does not require a surface active polymer. A simpler (and

Brenner describes a polymer—low molecular weight less expensive) carrier based upon maltodextrin, corn

plasticizer carrier composition for encapsulation of large syrup solids and mono/disaccharides can be formulated.

ratios of lipid (flavor) relative to the carrier.11 With a When employed with simple water-alcohol-based extracts,

sophisticated understanding and control of the dynam- such as vanilla extracts, this carrier yields a clean-tasting

ics of drying, Brenner designed a carrier matrix that material. Even with such a simple system the physical

remained fully plasticized during the full drying range. chemistry of the flavor components should be considered.

In this way, the partially dried particle does not crack or For example, it is well-known that crystalline vanillin has

collapse during drying while retaining the increased load significant vapor pressure as a solid at ambient conditions.

of lipid (flavor) phase. Saleeb and Pickup disclosed in US Sublimation of vanillin is one process that can affect the

Patent 4,532,145 a spray drying carrier for the encapsula- impact of the vanillin character over time. The encapsu-

tion of acetaldehyde.12 This carrier

is composed of a high molecular

weight component (molecular

weight range of 1000–6000 Daltons)

and a lower molecular weight com- 37

ponent (molecular weight range of

90–500 Daltons) with the specifica-

tion that the carrier be composed of

70–90% of higher molecular weight

component and 10–30% of lower

molecular weight agent. However,

no disclosure on the extended reten-

tion stability of the encapsulated

acetaldehyde was supplied.

In US Patent 5,124,162, Boskovic

et al. disclosed a carrier system

designed for citrus based oils.13

Here, the dried particle was char-

acterized as a dense product with at

least 0.5 g/cc bulk density, exhibit-

ing < 20% voids and existing in the

glassy state. His carrier was based

upon a composition of 10–35% food

polymer (gum arabic, gum acacia,

OSAN-starch), 25–50% film-form-

ing carbohydrate (maltodextrins)

and 22–45% mono- and disaccha-

rides where the mono/disaccharide

is primarily maltose. The glassy

state particle’s physical character

was designed to protect citrus oils

from oxygen perfusing into the

matrix and initiating oxidative reac-

tions. Levine and Slade employed

similar carrier formulas to improve

stability of spray dried flavors in a

double encapsulation process as

disclosed in US Patent 5,087,461.14

The flavor was spray dried using a

carrier composition consisting of

40–80% OSAN-starch, 10–40%

maltodextrin, 5–20% corn syrup

solids or polydextrose and 5–20 %

mono- or disaccharide. The spray

dried encapsulated flavor was then

re-encapsulated in a carbohydrate

carrier by melt extrusion.

PF0711_Porzio.fcx.indd 37 10/1/07 1:07:26 PM

Flavor encapsulation

lated vanillin present in a folded vanilla extract may still approach is in essence “formulating to the dryer.” Using

sublime over time in its final amorphous state. A practical an iterative process, the unbalanced flavor becomes more

approach when spray drying a folded vanilla extract would balanced with the proper formula adjustments until the

be to assay the initial vanillin level of the extract, the volatile loss results in a final level to supply the desired

resulting level in the spray dried material and the stability organoleptic character in the spray dried flavor.

level of the vanillin in the stored material. A more efficient approach might be considered. This

Volatile aromatic chemicals such as acetaldehyde, approach is based on the concept of encapsulating a

ethanol, diacetyl and dimethylsulfide are very sensitive to single flavor chemical and then post-blending the encap-

the spray drying process. Compounded fruit and allium sulated active into the remaining spray dried flavor. The

flavors containing significant levels of acetaldehyde as a carrier for the single volatile agent would be selected for

“fresh” top note will lose significant levels of this key com- optimized load retention and stability. For example, a top-

pound upon drying. One approach in compounding with noted fruit flavor needs to be designed and encapsulated

these volatiles employs the use of increased levels of the for a dry drink mix. If the flavor was originally formulated

agent to act as overages to account for drying losses. This at 10% by weight acetaldehyde in the compounded flavor

actives, and the flavor fraction is

set at 20% flavor in the spray dry

product, then the acetaldehyde

38 component would be at a 2% level

assuming no loss in the encapsula-

tion process. If the resulting spray

dried flavor was to be formulated

(arbitrarily) at 5% in the drink

mix, then a final acetaldehyde

level would be estimated at 0.1%.

Knowing this, the flavorist or the

encapsulation specialist, could

prepare the drink mix by first

having the acetaldehyde at much

lower concentrations spray dried

VOL. 32 NOVEMBER 2007

using a re-optimized carrier and

process conditions. The initial

acetaldehyde level would be

lowered to approximately 2% for

safety issues. After drying and

recovery of the acetaldehyde,

addition of 5 parts by weight

encapsulated acetaldehyde with

approximately 4.9 parts final

spray dried flavor is formulated to

yield the drink mix blend. These

parallel spray drying steps will

add additional process costs but

should result in a balanced and

more stable flavored drink mix.

Other strategies may be used

in spray drying flavor systems to

enhance flavor quality and deliv-

PERFUMER & FLAVORIST

ery. Dairy-based flavors could be

encapsulated utilizing sodium

caseinate, nonfat dry milk, whey

protein or blends of these ingre-

dients with lactose. This system

would yield a flavor-compatible

carrier system, which would

encapsulate the dairy oils/flavors

as well as generate a glassy matrix.

See Rothenberg in US Patent

5,601,760 for a specific teaching

on the use of milk protein carriers

and spray drying.15

PF0711_Porzio.fcx.indd 38 10/1/07 1:07:27 PM

The constraints involved in the spray dry formularies 7. H Levine and L Slade, Water Relationships in Foods, New York,

Plenum Press (1991)

preclude a simple route to controlled release functional-

ity in the encapsulated flavor. This limitation derives from 8. Amorphous Food and Pharmaceutical Systems, H Levine, ed, Royal

the fact that water-soluble carriers used in spray dried Society of Chemistry (2002)

encapsulates easily release the flavor upon rehydration. 9. H Levine and L Slade, Thermomechanical Properties of Small

There are alternate methods to overcome these restraints. Carbohydrate- Water-Glasses and Rubbers, J Chem Soc Faraday Trans

184(8) 2169–2633 (1988)

However, combining control-release functionality into a

spray dry carrier elevates the technology into the field of 10. M Porzio, Flavor Encapsulation: A Convergence of Science and Art,

control release. For this objective, alternate routes may Food Tech 58(7) 40–47 (2004)

be designed such as a double encapsulation process or a 11. US Patent 3,971,852, Process of encapsulating an oil and product

phase irreversible process. For the former, the spray-dried produced thereby, J Brenner et al. (July 27, 1976)

flavor is the starting point for additional processes, such as 12. US Patent 4,532,145, Fixing volatiles in an amorphous substrate and

agglomeration followed by lipid coating or melt encap- product therefrom, Z Saleeb and G Pickup (June 30, 1985)

sulation, as noted in US Patent 5,087,461.14 A reverse 13. US Patent 5,124,162, Spray-dried fixed flavorants in a carbohydrate

encapsulation spray dry process is another option. Here, substrate and process, M Boskovic et al. (June 23, 1992)

a complex coacervate of an oil-based flavor might initially 14. US Patent 5,087,461, Double-encapsulated composition containing

be prepared. Following cross-linking of the protein- volatile and/or labile components, and process for preparation and

hydrocolloid membrane, additional carbohydrate carriers use thereof, H Levine, L Slade et al. (Feb 11, 1992) 39

would be added to the original reaction solution and the 15. US Patent 5,601,760, Milk derived whey protein-based microencaps

total polydispersed mixture spray dried. ulating agents and a method of use, M Rosenberg, (Feb 11, 1997)

Another proposed approach for thermal protection

of a spray dried flavor would utilize a phase irreversible To purchase a copy of this article or others,

process. This system employs a protein that denatures visit www.PerfumerFlavorist.com/articles.

at or below the approximate 100°C droplet temperature

reached during the drying process. A lipid-stabilizing,

water-soluble protein with thermo-gelling or thermal-

denaturing properties solubilizes in the original aqueous

carrier, then the emulsion formed and the system spray

dried. Assuming the protein denatures and still effectively

encapsulates the flavor droplets during denaturing transi-

tions, the protein would remain in the dried product as a

barrier to provide functionality.

These and a number of potential encapsulation options

can be explored if the flavorist and encapsulation special-

ist leverage their understanding of the physical chemistry

of flavor-carrier-drying interactions and dynamics.

However, for routine spray drying of most flavors, under-

standing the principals of the spray drying encapsulation

process and utilizing selected carriers and process condi-

tions will ensure a flavor can be delivered in a quality

manner.

Address correspondence to Mike Porzio, McCormick & Co., Technical

Center, 204 Wight Ave., Hunt Valley, MD 21031; e-mail: mike_porzio@

mccormick.com.

References

1. G Reineccius, S Anandarman, and W Bangs, Spray Drying of Food

Flavors: I. Theory of Flavor Retention, Perf Flav 7(4) 1–6 (1982)

2. Microencapsulation in Methods and Industrial Applications, S Benita,

ed, Marciel Dekker, New York (1996)

3. Source Book of Flavors, 2nd edn, G Reineccius, ed, Springer (1998)

4. B Gibbs, S Kermasha, I Alli and C Mulligan, Encapsulation in the

Food Industry: A Review, Int J Food Sci Nutr 50 213–224 (1999)

5. US Patent 6,455,512, Water-soluble esterified hydrocolloids, F Ward,

(Sep 24, 2002)

6. Spray Drying Handbook, 5th edn, K Masters, ed, New York: Longman

Scientific and Technical Publishers (1991)

PF0711_Porzio.fcx.indd 39 10/1/07 1:07:28 PM

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Complying With ISO 17025 A Practical GuidebookDocument122 pagesComplying With ISO 17025 A Practical Guidebookyes17025100% (8)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 46 AdhesivesDocument132 pages46 AdhesivesChiNgo100% (1)

- Gum-Jellie ZdsDocument59 pagesGum-Jellie ZdsSri. SiriNo ratings yet

- Natural Gums and Resins Market SurveyDocument18 pagesNatural Gums and Resins Market SurveyJefferson ThiamNo ratings yet

- Offset Printing - The Dampening System PDFDocument87 pagesOffset Printing - The Dampening System PDFNBA100% (2)

- AllAboutColor EbookDocument157 pagesAllAboutColor EbookMihaela Vasiliu100% (1)

- Tem-290 Process Validation Protocol Template SampleDocument5 pagesTem-290 Process Validation Protocol Template SampleJonatan Dominguez Perez100% (2)

- Tem-290 Process Validation Protocol Template SampleDocument5 pagesTem-290 Process Validation Protocol Template SampleJonatan Dominguez Perez100% (2)

- The Effectiveness of Using Rosa Rose Hibiscus Gumamela and Bougainvillearevised in Making InkDocument11 pagesThe Effectiveness of Using Rosa Rose Hibiscus Gumamela and Bougainvillearevised in Making InkWarren PagsuyuinNo ratings yet

- Plant Gum ReviewDocument10 pagesPlant Gum ReviewHaroon RahimNo ratings yet

- The Spatula Ink FormularyDocument183 pagesThe Spatula Ink Formularyjimmyboy111100% (1)

- Ferric GumDocument13 pagesFerric GumMichal SlavíčekNo ratings yet

- Review of Related Literature Charcoal BriquettesDocument6 pagesReview of Related Literature Charcoal BriquettesGrace N Malik67% (9)

- Flavor and Fragrance AnalysisDocument1 pageFlavor and Fragrance AnalysisubaidNo ratings yet

- 582 1749 1 PBDocument5 pages582 1749 1 PBamerican_guy10No ratings yet

- A Food Coloring Guide: All About ColorsDocument4 pagesA Food Coloring Guide: All About ColorsubaidNo ratings yet

- Multiple Choice Questions ECONOMICSDocument3 pagesMultiple Choice Questions ECONOMICSubaidNo ratings yet

- Adamjee Insurance ClaimDocument2 pagesAdamjee Insurance ClaimubaidNo ratings yet

- 582 1749 1 PBDocument5 pages582 1749 1 PBamerican_guy10No ratings yet

- Fundamentals of Macroeconomics - Mcqs With Answers - Part IDocument4 pagesFundamentals of Macroeconomics - Mcqs With Answers - Part IubaidNo ratings yet

- Gcse Bus Revised Support 9697Document15 pagesGcse Bus Revised Support 9697ubaidNo ratings yet

- MannitolDocument1 pageMannitolubaidNo ratings yet

- God Made Man and Tailor Made GentlemanDocument1 pageGod Made Man and Tailor Made GentlemanubaidNo ratings yet

- The Complete List of Emulsifier CodesDocument8 pagesThe Complete List of Emulsifier CodesubaidNo ratings yet

- Cefixime and Palpitations - From FDA ReportsDocument3 pagesCefixime and Palpitations - From FDA ReportsMuhammad UbaidNo ratings yet

- Arabic Gum Basic InformationDocument3 pagesArabic Gum Basic InformationFthr RachmanNo ratings yet

- General CharacteristicsDocument145 pagesGeneral CharacteristicsMuhammad Akbar SiddiqNo ratings yet

- How to make homemade panjiriDocument3 pagesHow to make homemade panjirisabreynaNo ratings yet

- Lakk StatisztikaDocument84 pagesLakk StatisztikavajdazitaNo ratings yet

- 1 s2.0 S0963996911006417 Main PDFDocument12 pages1 s2.0 S0963996911006417 Main PDFDiego AiresNo ratings yet

- Formulation and Comparison of Suspending Properties Ofdifferent Natural Polymers Using Paracetamol Suspension PDFDocument6 pagesFormulation and Comparison of Suspending Properties Ofdifferent Natural Polymers Using Paracetamol Suspension PDFchandrakelik2No ratings yet

- LPLP PDFDocument12 pagesLPLP PDFAnand100% (1)

- Carbohydrates and Related Compounds: Unit 3Document19 pagesCarbohydrates and Related Compounds: Unit 3Gerald AquinoNo ratings yet

- Hidrocoloides en La Industria de AlimentosDocument23 pagesHidrocoloides en La Industria de AlimentosANAHI AUQUI AROTOMANo ratings yet

- Food Hydrocolloids: Eric DickinsonDocument13 pagesFood Hydrocolloids: Eric DickinsonAndres Felipe Rojas RodriguezNo ratings yet

- Working Paper Econ of Pastoral LivestockDocument22 pagesWorking Paper Econ of Pastoral LivestockFeinstein International CenterNo ratings yet

- AllAboutColor EbookDocument157 pagesAllAboutColor EbookCésar Zamora0% (1)

- Gum Arabic / Gum Acacia: The Dried Exudate (Gum) From Acacia Senegal and Related Species (Acacia Seyal)Document29 pagesGum Arabic / Gum Acacia: The Dried Exudate (Gum) From Acacia Senegal and Related Species (Acacia Seyal)Abdrahman AkubaNo ratings yet

- Assessment of Foundry Properties of Steel Casting Sand Moulds Bonded With The Grade 4 Nigerian Acacia Species (Gum Arabic)Document4 pagesAssessment of Foundry Properties of Steel Casting Sand Moulds Bonded With The Grade 4 Nigerian Acacia Species (Gum Arabic)Ardani AsaNo ratings yet

- Natural HydrogelsDocument21 pagesNatural HydrogelsMaksym LobodenkoNo ratings yet

- 2017foam Mat Drying Technology A ReviewDocument14 pages2017foam Mat Drying Technology A ReviewDimas DwisardiNo ratings yet

- Natural Gums of Plant Origin As Edible Coatings For Food Industry ApplicationsDocument16 pagesNatural Gums of Plant Origin As Edible Coatings For Food Industry ApplicationslunosicaNo ratings yet

- Biopolymers From Crop Plants: R 2019 Elsevier Inc. All Rights ReservedDocument10 pagesBiopolymers From Crop Plants: R 2019 Elsevier Inc. All Rights ReservedM HNo ratings yet

- Exporting CountriesDocument47 pagesExporting CountriesastuteNo ratings yet

- CarbohydratesDocument4 pagesCarbohydratesNina Del RosarioNo ratings yet