Professional Documents

Culture Documents

2 0L Sdi

Uploaded by

Mohd FairusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 0L Sdi

Uploaded by

Mohd FairusCopyright:

Available Formats

Service Training

6.14

Edition 05.02.2004

The 2.0 ltr./51 kW SDI engine

Trainer information (GB)

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

List of contents

Subject Page

1 Introduction 4

1.1 Development aims 4

1.2 Technical data 5

1.3 Performance and torque development curve of 2.0 ltr./51 kW SDI engine 6

2 Engine mechanics 7

2.1 "Lightweight crank drive" 7

2.1.1 Crankshaft 7

2.1.2 Pistons 8

2.1.3 Piston pin 8

2.1.4 Conrods 8

2.2 Camshaft 9

2.2.1 Valve seat ring 9

2.3 Intake manifold 10

3 Engine management 11

3.1 Crankshaft seal with integrated engine speed sender wheel 11

3.1.1 Engine speed sender 12

3.1.2 Sender wheel 12

3.2 Hall sender G40 (camshaft) 13

3.2.1 Camshaft sender wheel 13

3.2.2 Signal pattern during normal operation 14

3.2.3 Signal pattern during emergency operation 15

VK-21/sm//T0614_D.doc 2/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

List of contents

Subject Page

3.2.4 Emergency operation 16

3.3 Exhaust gas recirculation 17

3.3.1 Exhaust gas recirculation valve 18

4 Differences between 2.0 ltr./51 kW SDI engine

and 2.0 ltr./55 kW SDI engine 19

VK-21/sm//T0614_D.doc 3/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

1 Introduction

1.1 Development aims The 2.0 ltr./51 kW SDI engine is offered as an entry-level diesel engine with

emissions standard EU 3 among the range of engines available for the Caddy 2004.

This engine is a further development of the 1.9 ltr./74 kW TDI engine with unit injector

technology.

The greater capacity compared to the 1.9 ltr/74 kW TDI engine is thanks to an increase

in cylinder bore from 79.5 mm to 81.0 mm.

Another version of the engine is the 2.0 ltr./55 kW SDI engine, which is installed in

the passenger vehicle category in the Golf 2004. This engine will fulfil the emissions standard

EU 4.

VK-21/sm//T0614_D.doc 4/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

1.2 Technical data

Engine code BDK BDJ

(51 kW (55 kW

engine) engine)

Displacement 1968 cm³

Stroke 95.5 mm

Bore 81.0 mm

Type 4-cylinder inline engine

Valves per cylinder 2

Compression ratio 19 :1

Max. output 51 kW at 4200 rpm

55 kW at 4200 rpm

Max. torque 140 Nm at 1800 rpm

Engine management Bosch EDC 16

Fuel Diesel at least 51 CN

Exhaust treatment Exhaust gas

recirculation and

oxidizing catalyst

Emissions standard EU 3 (51 kW engine)

EU 4 (55 kW engine)

VK-21/sm//T0614_D.doc 5/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

1.3 Performance and torque development curve of 2.0 ltr./51 kW SDI engine

VK-21/sm//T0614_D.doc 6/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

2 Engine mechanics

2.1 "Lightweight crank The pistons, conrods and also the crankshaft are lighter in weight compared with the

drive" 1.9 ltr./74 kW TDI engine. This was possible due the combustion pressure in the SDI engine

being less than the TDI engine. The SDI engine operates at 90 bar and the TDI engine operates

at 120 bar.

2.1.1 Crankshaft • The crankshaft only has 4 balance weights

as opposed to 8. This allows a weight saving

of the crankshaft by 3 kg. This was made

possible due to the fact that the engine

speed sender wheel is no longer installed

directly on the crankshaft but is integrated in

the crankshaft sealing flange.

VK-21/sm//T0614_D.doc 7/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

2.1.2 Pistons The individual pistons from the SDI engine

weigh 180 grams less than the pistons of the

basic engine.

2.1.3 Piston pin The piston pins are 4 mm smaller in diameter

than those of the basic engine.

The piston pins are mounted in an aluminium

piston pin boss in the piston. Due to the low

combustion pressure compared to the TDI

engine, there is no requirement for the piston

pins to be mounted in brass sleeves in the

piston pin bosses.

2.1.4 Conrods The conrods in the SDI engine are overall

narrower and 8 mm longer than those of the

TDI engine.

VK-21/sm//T0614_D.doc 8/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

2.2 Camshaft The cam profiles, and thereby also the valve timing, have been modified compared to the 1.9 ltr.

engine. The modified timing ensures the correct quantity of air is drawn in for combustion in the

powerful SDI engine.

The timing modifications can be seen as follows:

SDI engine TDI engine

Inlet valve opens 21.4° CA bTDC Inlet valve opens 15.8° CA bTDC

Exhaust valves closes 25.4° CA aBDC Exhaust valves closes 25.3° CA aBDC

Exhaust valve opens 43.4° CA bBDC Exhaust valve opens 28.2° CA bBDC

Exhaust valve closes 9.4° CA aTDC Exhaust valve closes 18.7° CA aTDC

2.2.1 Valve seat ring Inline with legal requirements that come into force from 2006, the valve seat rings no longer

contain any cadmium. Molybdenum is added to the material in place of cadmium.

VK-21/sm//T0614_D.doc 9/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

2.3 Intake manifold The intake manifold of the 2.0 ltr./51 kW SDI engine was taken over from the 1.9 ltr./47 kW SDI

engine of the Polo 2002.

To reiterate: The so-called "snail intake manifold" was developed from the overhead intake

manifold from the SDI engine of the Golf 1998. Due to small installation dimensions in the Polo

2002, the intake pipe length of the overhead intake manifold is "wound up" (snail) in the snail

intake manifold.

VK-21/sm//T0614_D.doc 10/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

3 Engine management

3.1 Crankshaft seal with The crankshaft seal on the flywheel side is combined with the engine speed sender wheel. The

integrated engine speed seal in the sealing flange is made of polytetrafluoroethylene (PTFE).

sender wheel

1 Seal

2 Engine speed sender

3 Crankshaft flange

VK-21/sm//T0614_D.doc 11/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

3.1.1 Engine speed sender The engine speed sender is of the Hall sender

type. It is screwed into the housing of the

crankshaft sealing flange.

3.1.2 Sender wheel The sender wheel comprises of a steel ring

onto which a rubber composite material is

sprayed. In this rubber composite material is a

large number of metal filings, which are

magnetised alternately to north and south. As a

reference mark for the engine speed sender

there are two large north poles on the sender

wheel. The sender wheel thereby has a ratio of

60-2-2. The sender wheel is clipped onto the

crankshaft flange.

1 Sender wheel

2 Engine speed sender

VK-21/sm//T0614_D.doc 12/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

3.2 Hall sender G40 The Hall sender G40 is of the so-called static type. It detects a segment or gap as soon as the

(camshaft) ignition is switched "ON".

External identification marks: The colour of the connector housing is GREY.

3.2.1 Camshaft sender wheel The sender wheel on the camshaft is of a new

design. In conjunction with the Hall sender G40

(camshaft), an emergency running feature is

provided, which allows the engine to continue

running in the event of engine speed sender

failure. Restarting of the engine is also

possible.

Around the circumference of the sender wheel

are 4 segments at 6°, 12°, 18° and 24° spacing

for camshaft angle to cylinder allocation. A

further segment with a 45° camshaft angle gap

serves as an aid to improve pickup of segments

6° and 12° for starting purposes.

VK-21/sm//T0614_D.doc 13/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

3.2.2 Signal pattern during Signal pattern of Hall sender G40 (camshaft) and engine speed sender G28 during normal

normal operation operation

1 = One camshaft rotation

2 = One crankshaft rotation

VK-21/sm//T0614_D.doc 14/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

3.2.3 Signal pattern during Signal pattern of Hall sender G40 (camshaft) and engine speed sender G28 during

emergency operation emergency operation

Note: To provide clarity, the "missing" or "implausible" signal during emergency operation from

the engine speed sender is also shown in this diagram.

VK-21/sm//T0614_D.doc 15/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

3.2.4 Emergency operation

Unlike previous TDI engines, the engine will continue to run in the event of missing or implausible

signals from the engine speed sender.

When the engine is switched off it can also be restarted.

In emergency running mode, the engine control unit evaluates only rising flanks of the segments.

Oscillations that are caused during starting result in the engine control unit identifying too many

segment flanks. The high number means that the segment flanks are difficult to allocate. To

detect TDC of no. 3 cylinder, the 45° segment serves as a reference mark.

During emergency running:

• The engine speed is limited to 3000 rpm.

• The volume of injection is limited.

• Starting takes longer (slower).

VK-21/sm//T0614_D.doc 16/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

3.3 Exhaust gas On the 2.0 ltr./51 kW SDI engine, exhaust gas recirculation is controlled by the EGR map in the

recirculation engine control unit. There is no control of exhaust gas recirculation by means of an air mass

meter. To fulfil emission standard EU 3, the 2.0 ltr./51 kW SDI engine does not need an air mass

meter.

The EGR rate is determined by the exhaust gas recirculation map based on the quantity of

injection and engine speed. For control of the exhaust gas recirculation volume, the pneumatic

exhaust gas recirculation valve (2 stage) and electric intake manifold flap are actuated by the

engine control unit.

VK-21/sm//T0614_D.doc 17/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

3.4 Exhaust gas recirculation The exhaust gas recirculation valve is monitored by the engine control unit in EOBD (Euro

valve Onboard Diagnosis) when in the "EGR valve open" or "EGR valve closed" positions.

For a predetermined load at a predetermined intake manifold flap position and opened EGR

valve, there is a specified intake manifold pressure stored in a map.

A faulty exhaust gas recirculation valve (EGR valve stuck in "closed" position) is detected if the

actual intake manifold pressure transmitted by the intake manifold pressure sender is not

comparable with the specified intake manifold pressure stored in the map.

The specified intake manifold pressure is calculated from:

• Engine speed

• Quantity of injection

• Surrounding air pressure

• Intake manifold temperature

• Coolant temperature

• Defined intake manifold flap position

• EGR valve in "open" position

VK-21/sm//T0614_D.doc 18/20 03.02.2004

Service Training

Trainer information, 2.0 ltr./51 kW SDI engine, 06.14 (GB)

4 Differences between • Emissions standard

2.0 ltr./51 kW SDI The 2.0 ltr./51 kW SDI engine will be installed in the Caddy 2004 with emissions standard EU 3.

The 2.0 ltr./55 kW SDI engine will be installed in the Golf 2004 with emissions standard EU 4.

engine and

2.0 ltr./55 kW SDI • Exhaust gas recirculation

engine On the 2.0 ltr./51 kW SDI engine, the recirculated exhaust gas is not cooled.

The 2.0 ltr./55 kW SDI engine has an exhaust gas recirculation cooler (cannot be selected

manually).

• Unit injectors

The flow rate of the unit injectors (5-hole injectors) is fine tuned to the specific engine.

• Preglow system

The 2.0 ltr./55 kW SDI engine features a quick start preglow system made by BERU (GSK 3).

Information about the quick start preglow system can be found in self-study programme no. 316

"The 2.0 ltr. TDI engine".

• Acoustics

The 2.0 ltr./51 kW SDI engine does not feature a special acoustic bonnet with foam elements.

VK-21/sm//T0614_D.doc 19/20 03.02.2004

Service Training

For internal use only

Volkswagen AG, Service Training, VK-21, Brieffach 1995

All rights reserved, including the right to make technical alterations.

Technical status 02.2004

You might also like

- SSP 100 16 L Tdi and 20 L Tdi Engines With The Common Rail Injection System Ea288 Design SeriesDocument60 pagesSSP 100 16 L Tdi and 20 L Tdi Engines With The Common Rail Injection System Ea288 Design SeriesSamad100% (1)

- 1 9 Tdi PDDocument21 pages1 9 Tdi PDMohd Fairus100% (1)

- Himalayan 1 PDFDocument20 pagesHimalayan 1 PDFJulian GallegoNo ratings yet

- Himalayan Engine Ls 410 - Service ManualDocument130 pagesHimalayan Engine Ls 410 - Service ManualNitin Chandavar100% (1)

- Himalayan 1 PDFDocument20 pagesHimalayan 1 PDFJulian Gallego100% (1)

- 317 GB 0009Document192 pages317 GB 0009kashif AliNo ratings yet

- 317 Training Manual 0704Document219 pages317 Training Manual 0704mliugong100% (4)

- Training Manual ProvisionalDocument524 pagesTraining Manual ProvisionalArriola Sergio50% (2)

- Service Manual - Royal Enfield 500/535 EFI ABS - Feb 2017Document301 pagesService Manual - Royal Enfield 500/535 EFI ABS - Feb 2017Guilherme Biancarelli100% (3)

- Imv3 Rev4 Master Book 29dec08Document95 pagesImv3 Rev4 Master Book 29dec08rvozgovNo ratings yet

- MAN V28/33D STC Marine Engine SpecsDocument1 pageMAN V28/33D STC Marine Engine Specsghostt123No ratings yet

- Pres NeoDocument52 pagesPres Neonikko50% (2)

- V04 - C03 - Andina Ball Mill Op Manual - 3BHS235454 - EN - Rev - CertDocument115 pagesV04 - C03 - Andina Ball Mill Op Manual - 3BHS235454 - EN - Rev - CertJuan100% (1)

- Operating instructions for gearboxes AFM 04, AFM 05, AFM 06Document20 pagesOperating instructions for gearboxes AFM 04, AFM 05, AFM 06Bang OchimNo ratings yet

- Linde 357 05 Service Training Manual 17-12-09Document20 pagesLinde 357 05 Service Training Manual 17-12-09mark98% (47)

- DC Genset: For BACK UP (PV or Grid)Document4 pagesDC Genset: For BACK UP (PV or Grid)eddywidjaya9No ratings yet

- 7907 Ela80-3000 Rev - 7 PDFDocument54 pages7907 Ela80-3000 Rev - 7 PDFDavid デビッドブエノ BuenoNo ratings yet

- 1.4 ltr./132 KW TSI Petrol Engine: Self-Study ProgrammeDocument48 pages1.4 ltr./132 KW TSI Petrol Engine: Self-Study ProgrammeAndrei Baluse100% (3)

- 357-03 Series TrainingDocument638 pages357-03 Series TrainingQuốc Viêtj Huỳnh100% (1)

- Marine Installation Manual - Volume 3Document24 pagesMarine Installation Manual - Volume 3Святослав ВороновNo ratings yet

- Citytrac 4200Document112 pagesCitytrac 4200h45xlmNo ratings yet

- Engine Manual - ClarkDocument65 pagesEngine Manual - ClarkMiguel100% (4)

- Service: 2.0, 1.6, 1.2 - Litre Diesel EnginesDocument44 pagesService: 2.0, 1.6, 1.2 - Litre Diesel EnginesGeorgiu Claudiu100% (1)

- Dvigatel Mtu 12v1600g20f PDFDocument141 pagesDvigatel Mtu 12v1600g20f PDFLuis Cunha100% (2)

- MK18 MKE18: Compact MotorsDocument20 pagesMK18 MKE18: Compact MotorsAlexxxLeoNo ratings yet

- 2 SFG15T series engine第二章 SFG15T系列发动机Document96 pages2 SFG15T series engine第二章 SFG15T系列发动机Cesare GiulioNo ratings yet

- Electronic Engines Support 7 8 0 Global GuideDocument686 pagesElectronic Engines Support 7 8 0 Global Guidejason100% (1)

- Electronic Engines Support 7.9.0 Global-Guide 2022-06Document728 pagesElectronic Engines Support 7.9.0 Global-Guide 2022-06Thomas VeldinkNo ratings yet

- Owner'S Manual: Air-Cooled Diesel Engine Generator Set Dg4Le / Dg6LeDocument40 pagesOwner'S Manual: Air-Cooled Diesel Engine Generator Set Dg4Le / Dg6LePedja BekicNo ratings yet

- DG4LEDG6LEDocument38 pagesDG4LEDG6LEkinosiNo ratings yet

- 29 1551-Lza7016011 1uen CMDocument217 pages29 1551-Lza7016011 1uen CMGhizlane MounjimNo ratings yet

- SSP 556 The Development-goal-For-The 7 Speed-Dual Clutch Gearbox-0GC VWDocument32 pagesSSP 556 The Development-goal-For-The 7 Speed-Dual Clutch Gearbox-0GC VWFarid Mch100% (3)

- SSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Document60 pagesSSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Jose Ramón Orenes ClementeNo ratings yet

- TurbochargerDocument95 pagesTurbochargerCurtler PaquibotNo ratings yet

- C100 Service Training Manual: Instructor GuideDocument6 pagesC100 Service Training Manual: Instructor GuideDangLuyenNo ratings yet

- Reduction Gearbox Manual & Spare Parts ListDocument50 pagesReduction Gearbox Manual & Spare Parts ListPhan Cao An TruongNo ratings yet

- K 98 MCC 7Document389 pagesK 98 MCC 7Kapil ChetiaNo ratings yet

- Operating Instructions MS150049 - 02E C10 - 10R - 11 - 11R - 20 - 20R - 21 - 21RDocument155 pagesOperating Instructions MS150049 - 02E C10 - 10R - 11 - 11R - 20 - 20R - 21 - 21RVictorAstakhovNo ratings yet

- Service Bulletin Trucks: SpecificationsDocument34 pagesService Bulletin Trucks: SpecificationsKha KharNo ratings yet

- GM Ecotec Engine: Generation IDocument20 pagesGM Ecotec Engine: Generation Iroberto100% (1)

- JGC 320GS-L.L Technical DescriptionDocument33 pagesJGC 320GS-L.L Technical Descriptionlaiquz zaman100% (1)

- Operation and Maintenance Instructions Manual: Ju/Jw/Jx Models Electronic Engines FORDocument79 pagesOperation and Maintenance Instructions Manual: Ju/Jw/Jx Models Electronic Engines FORJorge LoraNo ratings yet

- IS.20. Especificaciones D13A. Edicion 5.enDocument36 pagesIS.20. Especificaciones D13A. Edicion 5.enjaimeNo ratings yet

- Electronic Engines Support 8 0 0 Global GuideDocument818 pagesElectronic Engines Support 8 0 0 Global GuideRamanathpura Venkannachar KiranNo ratings yet

- Kessler Linde Drive AxleDocument51 pagesKessler Linde Drive Axlemliugong100% (2)

- MG34S302Document246 pagesMG34S302Herry SusiloNo ratings yet

- Man s70mc6Document363 pagesMan s70mc6Karim Sowley DelgadoNo ratings yet

- Capacities (Refill) : Operation and Maintenance ManualDocument2 pagesCapacities (Refill) : Operation and Maintenance ManualERIC ERICNo ratings yet

- Cat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Document4 pagesCat Engine Specifications 2.0 G/BHP-HR Nox (Nte)avinash_1229100% (1)

- Service Manual For SC11CB EngineDocument92 pagesService Manual For SC11CB Enginegustavo100% (6)

- K 98 MCC 7Document383 pagesK 98 MCC 7Мария ЗинченкоNo ratings yet

- Doosan Engine Brochure PDFDocument7 pagesDoosan Engine Brochure PDFHawdang BabanNo ratings yet

- The Engine For Construction Equipment.: 60 - 155 KW at 1500 - 2500 RPMDocument6 pagesThe Engine For Construction Equipment.: 60 - 155 KW at 1500 - 2500 RPMAinal MuchlisNo ratings yet

- Man B&W S70Mc-C8-Tii: Project Guide Camshaft Controlled Two Stroke EnginesDocument405 pagesMan B&W S70Mc-C8-Tii: Project Guide Camshaft Controlled Two Stroke EnginesAndreyNo ratings yet

- SSP 455 2.0l TDI Engines in The T5 2010Document48 pagesSSP 455 2.0l TDI Engines in The T5 2010pedpabagu100% (1)

- DK-28e Instruction Manual Operation ChapterDocument571 pagesDK-28e Instruction Manual Operation ChapterЕвгений50% (2)

- Service Training CT CM CC PDFDocument112 pagesService Training CT CM CC PDFelucubraNo ratings yet

- Essential maintenance checks for vehiclesDocument58 pagesEssential maintenance checks for vehiclesMohd FairusNo ratings yet

- Optimize diesel engines with common rail technologyDocument49 pagesOptimize diesel engines with common rail technologyMohd FairusNo ratings yet

- 4.0 Course Registration 30-01-2014Document13 pages4.0 Course Registration 30-01-2014TeckYing TanNo ratings yet

- Civacon Manifold Intallation and Parts Breakdowns 27 Pages PDFDocument27 pagesCivacon Manifold Intallation and Parts Breakdowns 27 Pages PDFMohd Fairus0% (1)

- 1992 NoAm Protege ServiceDocument1,164 pages1992 NoAm Protege Servicecyberbeam100% (2)

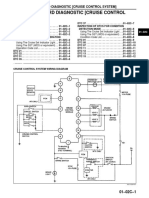

- On-Board Diagnostic (Cruise Control System)Document12 pagesOn-Board Diagnostic (Cruise Control System)Mohd FairusNo ratings yet

- On-Board Diagnostic (Engine Control System (FS) )Document155 pagesOn-Board Diagnostic (Engine Control System (FS) )Mohd FairusNo ratings yet

- Optimize diesel engines with common rail technologyDocument49 pagesOptimize diesel engines with common rail technologyMohd FairusNo ratings yet

- Liquip Tanker Terminal Loading-Arm Opw CatalgoueDocument174 pagesLiquip Tanker Terminal Loading-Arm Opw Catalgouefuransu777No ratings yet

- L10-Electrical Diagnostic Tools PDFDocument9 pagesL10-Electrical Diagnostic Tools PDFMaximiliano MasNo ratings yet

- 1990 EA 4WD SuppDocument677 pages1990 EA 4WD Suppcyberbeam100% (2)

- 1990 NoAm 4WD SuppDocument728 pages1990 NoAm 4WD SuppcyberbeamNo ratings yet

- Analog Vs Digital MetersDocument0 pagesAnalog Vs Digital Metersjnachum9465No ratings yet

- 00-00 General InfoDocument31 pages00-00 General InfodongvacNo ratings yet

- 01 02a PDFDocument146 pages01 02a PDFJGAR2009No ratings yet

- Engine mechanical guideDocument166 pagesEngine mechanical guideMohd FairusNo ratings yet

- Bosch Abs 5 3Document32 pagesBosch Abs 5 308088338100% (2)

- Automotive Vehicle MaintenanceDocument61 pagesAutomotive Vehicle MaintenanceMohd FairusNo ratings yet

- Etacs BLDocument74 pagesEtacs BLMohd FairusNo ratings yet

- Workshop Manual MPIDocument372 pagesWorkshop Manual MPIPhil ProfiliNo ratings yet

- BL AbagDocument74 pagesBL AbagMohd FairusNo ratings yet

- Alhambra 20V MotronicDocument19 pagesAlhambra 20V MotronicMohd FairusNo ratings yet

- BL 4WD EST & TOD GuideDocument106 pagesBL 4WD EST & TOD Guidealeksejik1_604843622100% (5)

- LR OMEGAS METANO 3 - 4 Cil Nuovi Iniettori GBDocument47 pagesLR OMEGAS METANO 3 - 4 Cil Nuovi Iniettori GBMohd FairusNo ratings yet

- 2013 Nissan Altima 45947 PDFDocument1,000 pages2013 Nissan Altima 45947 PDFMohd Fairus100% (1)

- 2.0 Fsi Engine 1Document16 pages2.0 Fsi Engine 1Mohd FairusNo ratings yet

- 2.0 Fsi Engine 1 PDFDocument15 pages2.0 Fsi Engine 1 PDFMohd Fairus100% (1)

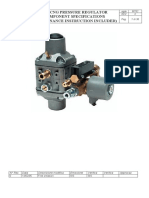

- NG1-2 RegulatorDocument5 pagesNG1-2 RegulatorMohd FairusNo ratings yet

- NG2 RegulatorDocument22 pagesNG2 RegulatorMohd FairusNo ratings yet

- Machinery Used in Power Generation SubstationDocument116 pagesMachinery Used in Power Generation SubstationEjlal HassanNo ratings yet

- MIET2076 L7 Balance LleungDocument78 pagesMIET2076 L7 Balance LleungGabrielle ChengNo ratings yet

- H.N. Gupta - Fundamentals of Internal Combustion Engines-PHI Learning Private Limited (2013)Document675 pagesH.N. Gupta - Fundamentals of Internal Combustion Engines-PHI Learning Private Limited (2013)suspiria100% (3)

- PVL Quick Reference PDFDocument2 pagesPVL Quick Reference PDFJoel Cazalla PuyolNo ratings yet

- Tad 532geDocument2 pagesTad 532geHumberto Carrasco Gutierrez100% (1)

- TM1934 - 120C Excavator Engine Harness (W20) Wiring DiagramDocument1 pageTM1934 - 120C Excavator Engine Harness (W20) Wiring Diagramwilmar_tovar_1No ratings yet

- Psi Engines Product Sheet PDFDocument2 pagesPsi Engines Product Sheet PDFDaniel DelgadoNo ratings yet

- Manual Tool Change Electrospindles Increase Machine EfficiencyDocument5 pagesManual Tool Change Electrospindles Increase Machine EfficiencyM. MUBASHARNo ratings yet

- Torque Converter CDM835Document3 pagesTorque Converter CDM835bakrimoh0% (1)

- Chrysler Corporation: Service Manual 1995 JEEP Grand CherokeeDocument59 pagesChrysler Corporation: Service Manual 1995 JEEP Grand Cherokeeอัตตา ไม่มาหาNo ratings yet

- Engine Zna RichDocument40 pagesEngine Zna RichEMILIO “ER NEGRO MECANICO” GONZALEZ100% (9)

- Manitou MRT1432 PARTS MANUALDocument628 pagesManitou MRT1432 PARTS MANUALSerge100% (2)

- Engine DisplacementDocument3 pagesEngine DisplacementKARTHICKRAJ KANDASAMYNo ratings yet

- Inyectores CRI y CRIN TeoriaDocument21 pagesInyectores CRI y CRIN TeoriaLuis Alarcón100% (1)

- SD 110 Step 1 Training EngineDocument62 pagesSD 110 Step 1 Training Enginemliugong97% (34)

- Custom Monitoring Selection Menu for ExcavatorDocument5 pagesCustom Monitoring Selection Menu for ExcavatorKevine KhaledNo ratings yet

- John Deere 6-cylinder diesel engine specsDocument2 pagesJohn Deere 6-cylinder diesel engine specsMiguelNo ratings yet

- Siemens Dynamic Fuel Blending for Biogas EnginesDocument1 pageSiemens Dynamic Fuel Blending for Biogas EnginesVenkateswara RamakrishnanNo ratings yet

- Est Sg4851 From Rovsco Asia Pte. Ltd. 17396Document5 pagesEst Sg4851 From Rovsco Asia Pte. Ltd. 17396muhamadrafie1975No ratings yet

- Perkins 1103 and 1104c Engines Systems Operation Testing and AdjustingDocument56 pagesPerkins 1103 and 1104c Engines Systems Operation Testing and AdjustingSyed Azhar Hussain97% (33)

- Throttle Body Dan TPS Corolla 88-97Document4 pagesThrottle Body Dan TPS Corolla 88-97Fitri Wibowo100% (1)

- Failure Analysis of Engine Valve Using ANSYSDocument5 pagesFailure Analysis of Engine Valve Using ANSYSMomina AliNo ratings yet

- Daihatsu Ficha Haynes G102 PDFDocument1 pageDaihatsu Ficha Haynes G102 PDFNelsonLeonNo ratings yet

- Engine Performance Measures ExplainedDocument40 pagesEngine Performance Measures ExplainedSiraj BusseNo ratings yet

- SteamE MuncasterDocument29 pagesSteamE MuncasterchopenNo ratings yet

- Manual Kawasaki FA 76-130-210Document35 pagesManual Kawasaki FA 76-130-210pipiiiiiiiNo ratings yet

- 10-1 - Engine Numbering & IdentificationDocument13 pages10-1 - Engine Numbering & IdentificationRiddhi DasNo ratings yet

- Turbo Garrett2009turboCatalogDocument84 pagesTurbo Garrett2009turboCatalogmywifeNo ratings yet

- Air Enters The Compressor of A Gas Turbine at 1...Document4 pagesAir Enters The Compressor of A Gas Turbine at 1...Juan DiegoNo ratings yet

- 4 Stroke Diesel Engine ArslanDocument5 pages4 Stroke Diesel Engine ArslanMuhammad Arslan AfzalNo ratings yet