Professional Documents

Culture Documents

TABLES Mixture Design Properties: Mogawer and Stuart

Uploaded by

varun persadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TABLES Mixture Design Properties: Mogawer and Stuart

Uploaded by

varun persadCopyright:

Available Formats

Mogawer and Stuart 7

RESULTS AND ANALYSIS generally linear. Only three binder contents were used in designing

the SMA mixtures.

Mixture Design The SMA TWG recommends a minimum of 6 percent binder by

mass of mixture (2). Table 5 shows that increasing the coarse aggre-

The Marshall mixture design results are presented in Table 5. For gate content increased the optimum asphalt content of the SMA

the same gradation, the Interfibe and Styrelf mixtures with lime- mixtures.

stone had similar OAC. Also, for the same gradation the OAC of The SMA TWG recommends a minimum VMA of 17. All dia-

the Interfibe and Styrelf mixtures with diabase were close. There base mixtures satisfied this recommendation, whereas none of the

was a trend for increasing binder content and voids in mineral limestone mixtures did,. In an associated study that is evaluating the

aggregate (VMA) with an increase in coarse aggregate. A decrease same mixtures, extractions were performed to determine whether

in stability and an increase in the voids filled with asphalt (VFA) the Marshall hammer broke the aggregates. The extraction results

were associated with this trend. The flow increased with an increase showed that the increase in the amount passi~g the 4.75-mm sieve

in coarse aggregate content, except for the Interfibe mixture with was higher for the limestone aggregate than for the diabase aggre-

limestone using Gradation I. The flow and stability values were gate (Stuart and Mogawer, in a paper in this Record). This is due

higher for Styrelf mixtures than for lnterfibe mixtures. The percent to the high L.A. abrasion weight loss of the limestone aggregate.

binder increased more when the coarse aggregate content was The limestone L.A. abrasion weight loss was 35.4 percent. (The

increased from 70 to 80 percent than when it was increased from 60 maximum recommended by the SMA TWG is 30 percent.)

to 70 percent. The VMAs of each SMA did not vary with the binder Because the limestone aggregate particles fractured more than the

content, and the air voids versus binder content relationships were diabase particles, it was hypothesized that the lower VMAs of the

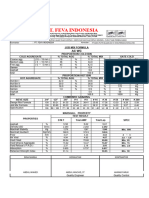

TABLES Mixture Design Properties

Diabase Limestone

I· II III I II III

Interf ibe Mixtures

OAC, by mass 7.5 6.3 5.7 6.7 5.7 5.6

OAC, % by

volume 17.6 15.1 13.8 14.5 12.6 12.3

Ef f OAC, % by

volume 16.7 14.1 13.3 12.5 10.9 10.6

Air Voids, % 3.5 3.5 3.5 3.5 3.5 3.5

VAM, % 20.2 17.7 16.8 16.1 14.4 14.0

VFA, %. 80.2 80.2 79.3 78.3 75.8 75.2

Flow, 0.25 mm 17.7 17.7 14.7 18.1 19.8 17.4

Stability, N 7 819 7 819 9 000 7 633 8 404 10 498

Styrelf Mixtures

OAC, % by

mass 8.4 6.6 6.2 6.8 5.7 5.5

OAC, % by

volume 19.5 15.6 14.7 14.7 12.6 12.2

Ef f OAC, % by

volume 18.5 14.7 13.9 12.8 10.8 10.5

Air voids, % 3.5 3.5 3.5 3.5 3.5 3.5

VMA, % 22.2 18.4 17.6 16.4 14.4 14.0

VFA, % 84.2 81. 0 80.2 78.7 75.8· 75.1

Flow, 0.25 mm 31. 4 28.3 27.6 25.2 24.1 22.9

Stability, N 8 756 10 33·7 13 390 9 547 12 094 12 193

OAC: Optimal Asphalt (Binder) Content.

Ef f OAC: Effective Optimum Asphalt (Binder) Content.

VMA: Voids in the Mineral Aggregate.

VFA: Voids Filled with Asphalt.

You might also like

- Slide FinalDocument24 pagesSlide Finalprinting 234No ratings yet

- Marshall Mix DesignDocument2 pagesMarshall Mix DesignTakdir Satria NandaNo ratings yet

- 130Document6 pages130andi103No ratings yet

- Marshall Mix Design MethodDocument11 pagesMarshall Mix Design MethodAndrea TapingNo ratings yet

- Density Analysis and Marshall Mix MethodDocument22 pagesDensity Analysis and Marshall Mix MethodOmar AbdelnabyNo ratings yet

- SOL - Matriz BCG - AJEPERDocument1 pageSOL - Matriz BCG - AJEPERAntony CoroNo ratings yet

- Chapter 4Document13 pagesChapter 4Farjana BariNo ratings yet

- AC WC MAT. KERING. KURIPAN PROB, RevDocument137 pagesAC WC MAT. KERING. KURIPAN PROB, RevBudi KarsonoNo ratings yet

- Pavement Materials: Highway and Transportation Engineering (Faculty of Engineering)Document38 pagesPavement Materials: Highway and Transportation Engineering (Faculty of Engineering)atharNo ratings yet

- Geopolymer An OverviewDocument16 pagesGeopolymer An OverviewmayaNo ratings yet

- MS 02 Asphalt Mix Design, 7th Edition, 2014Document2 pagesMS 02 Asphalt Mix Design, 7th Edition, 2014Shafiqullah GowharyNo ratings yet

- Exercise HighwayDocument7 pagesExercise HighwayOmar AbdelnabyNo ratings yet

- Uk-C: Marshall Mix Design Method (Astm D 1559 or JKR Method)Document5 pagesUk-C: Marshall Mix Design Method (Astm D 1559 or JKR Method)AiniHazwaniNo ratings yet

- Marshal Mix Design BATCHING, MIXING AND COMPACTION 16th January 2015Document11 pagesMarshal Mix Design BATCHING, MIXING AND COMPACTION 16th January 2015Bernard Kitosi100% (1)

- Zain Ali Zain L1F17BSCE0003 Pavement and Foundation Engineering Lab Experiment # 03Document5 pagesZain Ali Zain L1F17BSCE0003 Pavement and Foundation Engineering Lab Experiment # 03zain aliNo ratings yet

- Universidad Catolica Santa Maria La Antigua: Materia: Ingeniería de TransporteDocument10 pagesUniversidad Catolica Santa Maria La Antigua: Materia: Ingeniería de TransporteAnonymous Y1zdqYh7hNo ratings yet

- Term Project PavementDocument14 pagesTerm Project PavementMohammad AlmafrajiNo ratings yet

- Lecture Design of Bituminous Mixtures by Marshall MethodDocument26 pagesLecture Design of Bituminous Mixtures by Marshall MethodKEZIAH JANE SULAPASNo ratings yet

- Flakiness Index Done DOC-20181030-WA0010Document7 pagesFlakiness Index Done DOC-20181030-WA0010kundayi shavaNo ratings yet

- Form Poa q4 2023 Teddy RevisiDocument384 pagesForm Poa q4 2023 Teddy RevisiFirdan FauzanYtNo ratings yet

- Lampiran BAB 8 Baru Banget-10Document1 pageLampiran BAB 8 Baru Banget-10476 875Hanif AbiyyuNo ratings yet

- 15 - 477 Damper EfficiencyDocument2 pages15 - 477 Damper EfficiencyLuis MartinezNo ratings yet

- Optimum Bitumen Content For Bituminous MixesDocument1 pageOptimum Bitumen Content For Bituminous MixesSasanka SekharNo ratings yet

- Sample Information: Asphalt Test Certification ReportDocument5 pagesSample Information: Asphalt Test Certification ReportweamNo ratings yet

- Utilization of Waste Ash Wood Powder As A Filler Hot Rolled Sheet - Base (Hrs-Base)Document24 pagesUtilization of Waste Ash Wood Powder As A Filler Hot Rolled Sheet - Base (Hrs-Base)Sabar UdinNo ratings yet

- The Effect of Volumetric Properties of Asphalt Concrete Mixture To Wheel Track Rutting With Respect To EN and BS Rutting Test MethodsDocument9 pagesThe Effect of Volumetric Properties of Asphalt Concrete Mixture To Wheel Track Rutting With Respect To EN and BS Rutting Test MethodsthanoseeNo ratings yet

- September 2007 Mega Manila RatingsDocument3 pagesSeptember 2007 Mega Manila Ratingsapi-3696796No ratings yet

- Flatbed 2500X1200Document3 pagesFlatbed 2500X1200Udaan Art LLPNo ratings yet

- Taller MarshallDocument1 pageTaller MarshallAndres Camilo Jimenez GalvisNo ratings yet

- PLN Presentasi HKIDocument38 pagesPLN Presentasi HKIAgus TampubolonNo ratings yet

- Chapter 6 - ConclusionDocument2 pagesChapter 6 - ConclusionBisham HurreeramNo ratings yet

- Shear Susceptibility of Asphalts in Relation To Pavement PerformanceDocument27 pagesShear Susceptibility of Asphalts in Relation To Pavement PerformanceProf. Prithvi Singh Kandhal100% (1)

- TABEL ANSAR Kelompok 13Document51 pagesTABEL ANSAR Kelompok 13Muhammad Dewangga RamadanNo ratings yet

- Bearing CapasityDocument2 pagesBearing CapasityAsad AliNo ratings yet

- USTER-2007 Standards Ready Reckenor Compiled by Vijayewari Textiles-India Technical TeamDocument4 pagesUSTER-2007 Standards Ready Reckenor Compiled by Vijayewari Textiles-India Technical Teamselvapdm67% (6)

- APEL Aqua Patch Test Data 6e8ded7733Document10 pagesAPEL Aqua Patch Test Data 6e8ded7733Adelina GeorgianaNo ratings yet

- Capstone Trial 1 Round 2Document14 pagesCapstone Trial 1 Round 2Tanmay SinghNo ratings yet

- 357-RUGC Manuscript-8263-1-10-20200909Document4 pages357-RUGC Manuscript-8263-1-10-20200909JIHAD EL MAKAOUINo ratings yet

- FR Bec Calorific Value Vs Moisture Content V20a 2013-1Document9 pagesFR Bec Calorific Value Vs Moisture Content V20a 2013-1cuiNo ratings yet

- Deficit: BUDGET DEFICIT (Excluding Grants) / GDP RATIO IN 2002 AND 2003Document10 pagesDeficit: BUDGET DEFICIT (Excluding Grants) / GDP RATIO IN 2002 AND 2003Mayank GargNo ratings yet

- A Segment C C C C C C: Chart TitleDocument21 pagesA Segment C C C C C C: Chart TitleKrishna KumarNo ratings yet

- 2017-06 Refratechnik - Bricks CF SeriesDocument12 pages2017-06 Refratechnik - Bricks CF SeriesSyed Kazam Raza100% (1)

- Stability Test Curves and GraphDocument3 pagesStability Test Curves and GraphTALHA SHAHIDNo ratings yet

- 26 DuranDocument14 pages26 DuranRenato Del CidNo ratings yet

- 6.summary of Mix DesignDocument2 pages6.summary of Mix DesignAnkur ShrivastavNo ratings yet

- Eightcheck 32240823Document5 pagesEightcheck 32240823Andreas avellinus dwi noviyantoNo ratings yet

- Matecconf Agmts2014 01004Document5 pagesMatecconf Agmts2014 01004rihab.ramdane9No ratings yet

- Marshall Mix DesignDocument3 pagesMarshall Mix DesignHasanur Rahman Mishu33% (3)

- Servirenting New 9.5mm Sample 1Document1 pageServirenting New 9.5mm Sample 1madeirastelioNo ratings yet

- Example of Chap 4Document10 pagesExample of Chap 4Alex manNo ratings yet

- Sheet Wearing Course (HRS-WC) : Pengaruh Pemakaian Additive Wetfix-Be Terhadap Karakteristik Campuran Hot RolledDocument15 pagesSheet Wearing Course (HRS-WC) : Pengaruh Pemakaian Additive Wetfix-Be Terhadap Karakteristik Campuran Hot RolledAgus MelanusNo ratings yet

- Strategy SisDocument65 pagesStrategy SisVarunNo ratings yet

- 13 CHAPTER 3 MyDocument24 pages13 CHAPTER 3 Myh zNo ratings yet

- Percent of Bitumen (Of Total Mix) : Sieve Size Percent Passing Percent Passing Percent Retained Batch WeightDocument7 pagesPercent of Bitumen (Of Total Mix) : Sieve Size Percent Passing Percent Passing Percent Retained Batch WeighttasniaNo ratings yet

- 16 - 795 Damper EfficiencyDocument2 pages16 - 795 Damper EfficiencyLuis MartinezNo ratings yet

- Density Void AnalysisDocument9 pagesDensity Void Analysisshuvobosu262No ratings yet

- Gainful Utilization of Sugarcane Bagasse Ash (Paper 5-Paper 8)Document19 pagesGainful Utilization of Sugarcane Bagasse Ash (Paper 5-Paper 8)nishu mangalNo ratings yet

- Lithium-Ion Capacity and CostDocument1 pageLithium-Ion Capacity and CosthuskyjackNo ratings yet

- Gainful Utilization of Sugarcane Bagasse Ash (Paper 5-Paper 8)Document19 pagesGainful Utilization of Sugarcane Bagasse Ash (Paper 5-Paper 8)nishu mangalNo ratings yet

- TABLE 3 Percent Flat and Elongated Particles: Ihi KnessDocument1 pageTABLE 3 Percent Flat and Elongated Particles: Ihi Knessvarun persadNo ratings yet

- Asphalt Fines From AASHTO FP96Document1 pageAsphalt Fines From AASHTO FP96varun persadNo ratings yet

- Length TQ: Mogawer and StuartDocument1 pageLength TQ: Mogawer and Stuartvarun persadNo ratings yet

- SMADocument1 pageSMAvarun persadNo ratings yet

- Effect of Coarse Aggregate Content On Stone Matrix Asphalt Rutting and Drain DownDocument1 pageEffect of Coarse Aggregate Content On Stone Matrix Asphalt Rutting and Drain Downvarun persadNo ratings yet

- TABLE 1 Physical Properties of The Binders: Transportation Research Record 1492Document1 pageTABLE 1 Physical Properties of The Binders: Transportation Research Record 1492varun persadNo ratings yet

- Inc VmaDocument1 pageInc Vmavarun persadNo ratings yet

- 10.2.2 Repeated Shear Test at Constant HeightDocument1 page10.2.2 Repeated Shear Test at Constant Heightvarun persadNo ratings yet

- Feb 15 TLA Asphalt Cement Viscosity - Temp CHARTDocument1 pageFeb 15 TLA Asphalt Cement Viscosity - Temp CHARTvarun persadNo ratings yet

- X 2 X ! 2 1 5 2 N X 2 1 5 2 ! 2 1: 5. Basis of Statistical Criteria For OutliersDocument1 pageX 2 X ! 2 1 5 2 N X 2 1 5 2 ! 2 1: 5. Basis of Statistical Criteria For Outliersvarun persadNo ratings yet

- Mixing and Compaction Temperature ChartDocument1 pageMixing and Compaction Temperature Chartvarun persadNo ratings yet

- FIG. X1.1 Power Law Shear Stress Versus Shear Rate RelationshipDocument1 pageFIG. X1.1 Power Law Shear Stress Versus Shear Rate Relationshipvarun persadNo ratings yet

- Material Transfer VehicleDocument1 pageMaterial Transfer Vehiclevarun persadNo ratings yet

- Stockpile CalculationsDocument6 pagesStockpile Calculationsvarun persad100% (2)

- Pages From Structural Behavior of Asphalt PavementsDocument13 pagesPages From Structural Behavior of Asphalt Pavementsvarun persadNo ratings yet

- FHWA KS 12 8 - FinalDocument29 pagesFHWA KS 12 8 - FinalNatalieNo ratings yet

- C 3-GD - Highway CS Elements PDFDocument48 pagesC 3-GD - Highway CS Elements PDFvarun persadNo ratings yet

- Asphalt Volumetric AnalysisDocument6 pagesAsphalt Volumetric Analysisvarun persadNo ratings yet

- Faa Ac150-5370-2gDocument95 pagesFaa Ac150-5370-2gvarun persadNo ratings yet

- Marshall Teoria y Ejercicios PDFDocument30 pagesMarshall Teoria y Ejercicios PDFYuliana Meriño TNo ratings yet

- Prime Tack Coats FHWA July 2005Document18 pagesPrime Tack Coats FHWA July 2005mzaimNo ratings yet

- Marshall Method of Asphalt-Concrete Mix DesignDocument16 pagesMarshall Method of Asphalt-Concrete Mix DesignfitrianiNo ratings yet

- Present Perfect Tense ExerciseDocument13 pagesPresent Perfect Tense Exercise39. Nguyễn Đăng QuangNo ratings yet

- BDRRM Sample Draft EoDocument5 pagesBDRRM Sample Draft EoJezreelJhizelRamosMendozaNo ratings yet

- Alem Ketema Proposal NewDocument25 pagesAlem Ketema Proposal NewLeulNo ratings yet

- 8. Nguyễn Tất Thành- Kon TumDocument17 pages8. Nguyễn Tất Thành- Kon TumK60 TRẦN MINH QUANGNo ratings yet

- DS SX1280-1-2 V3.0Document143 pagesDS SX1280-1-2 V3.0bkzzNo ratings yet

- Resolution: Owner/Operator, DocketedDocument4 pagesResolution: Owner/Operator, DocketedDonna Grace Guyo100% (1)

- CAMEL Model With Detailed Explanations and Proper FormulasDocument4 pagesCAMEL Model With Detailed Explanations and Proper FormulasHarsh AgarwalNo ratings yet

- 24 Inch MonitorDocument10 pages24 Inch MonitorMihir SaveNo ratings yet

- Capital Structure and Leverage: Multiple Choice: ConceptualDocument53 pagesCapital Structure and Leverage: Multiple Choice: ConceptualArya StarkNo ratings yet

- Maintenance Performance ToolboxDocument6 pagesMaintenance Performance ToolboxMagda ScrobotaNo ratings yet

- Brachiocephalic Artery: AnteriorDocument37 pagesBrachiocephalic Artery: AnteriorFarah FarahNo ratings yet

- Corporate Valuation WhartonDocument6 pagesCorporate Valuation Whartonebrahimnejad64No ratings yet

- Letter Writing: An Informative Powerpoint About LetterDocument11 pagesLetter Writing: An Informative Powerpoint About LetterMalik KamranNo ratings yet

- Harley Davidson U S Reportedly Uses Risk Sharing Agreements With Its Foreign SubsidiariesDocument1 pageHarley Davidson U S Reportedly Uses Risk Sharing Agreements With Its Foreign Subsidiariestrilocksp SinghNo ratings yet

- M.T Nautica Batu Pahat: Clean Product Tanker 4,497 BHPDocument1 pageM.T Nautica Batu Pahat: Clean Product Tanker 4,497 BHPSuper 247No ratings yet

- Differential Calculus ExamDocument6 pagesDifferential Calculus ExamCaro Kan LopezNo ratings yet

- Ajsl DecisionMakingModel4RoRoDocument11 pagesAjsl DecisionMakingModel4RoRolesta putriNo ratings yet

- Engineering Mathematics John BirdDocument89 pagesEngineering Mathematics John BirdcoutnawNo ratings yet

- RELATION AND FUNCTION - ModuleDocument5 pagesRELATION AND FUNCTION - ModuleAna Marie ValenzuelaNo ratings yet

- The Function and Importance of TransitionsDocument4 pagesThe Function and Importance of TransitionsMarc Jalen ReladorNo ratings yet

- Virtual Feeder Segregation Using IIoT and Cloud TechnologiesDocument7 pagesVirtual Feeder Segregation Using IIoT and Cloud Technologiespjgandhi100% (2)

- D15 Hybrid P1 QPDocument6 pagesD15 Hybrid P1 QPShaameswary AnnadoraiNo ratings yet

- Human Capital PlanningDocument27 pagesHuman Capital Planningalokshri25No ratings yet

- Chapter 12Document15 pagesChapter 12kk5522No ratings yet

- Starbucks Progressive Web App: Case StudyDocument2 pagesStarbucks Progressive Web App: Case StudyYesid SuárezNo ratings yet

- Accounting System (Compatibility Mode) PDFDocument10 pagesAccounting System (Compatibility Mode) PDFAftab AlamNo ratings yet

- Firing OrderDocument5 pagesFiring OrderCurtler PaquibotNo ratings yet

- Teacher'S Individual Plan For Professional Development SCHOOL YEAR 2020-2021Document2 pagesTeacher'S Individual Plan For Professional Development SCHOOL YEAR 2020-2021Diether Mercado Padua100% (8)

- Laporan Keuangan TRIN Per Juni 2023-FinalDocument123 pagesLaporan Keuangan TRIN Per Juni 2023-FinalAdit RamdhaniNo ratings yet

- NDT HandBook Volume 10 (NDT Overview)Document600 pagesNDT HandBook Volume 10 (NDT Overview)mahesh95% (19)