Professional Documents

Culture Documents

MyPaperIJET V4I1P61 PDF

Uploaded by

girdhari kushwahaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MyPaperIJET V4I1P61 PDF

Uploaded by

girdhari kushwahaCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/326606437

Design and Application of D.C. Vacuum Cleaner using Axial Flow Fan

Research · July 2018

DOI: 10.29126/23951303/IJET-V4I1P61

CITATIONS READS

0 2,555

3 authors, including:

Vijit Vinod Gajbhiye

Yeshwantrao Chavan College of Engineering

1 PUBLICATION 0 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Design and Application of D. C. Vacuum Cleaner View project

All content following this page was uploaded by Vijit Vinod Gajbhiye on 25 July 2018.

The user has requested enhancement of the downloaded file.

International Journal of Engineering and Techniques - Volume 4 Issue 1, Jan – Feb 2018

RESEARCH ARTICLE OPEN ACCESS

Design and Application of D.C. Vacuum Cleaner

using Axial Flow Fan

Vijit Gajbhiye1, Naved Ahmad2, M. S. Tufail3

1(P.G. Scholar, Department of Mechanical Engineering, Yeshwantrao Chavan College of Engineering, Nagpur)

2(B.E., Department of Mechanical Engineering, Anjuman College of Engineering and Technology, Nagpur)

3(Asst. Prof., Department of Mechanical Engineering, Yeshwantrao Chavan College of Engineering, Nagpur)

Abstract:

Use of Fossil Fuels in Power Generation has its adverse environmental impact. And due to growing

population there is a scarcity of Fossil Fuels in today’s world. To cope up with this problem this paper

suggests the Design of D. C. Operated Vacuum Cleaner using Axial Flow Fan, which is capable of

producing a Suction Pressure of 0.17 Bar. And it is more efficient in Cleaning and has less D. C. Power

Consumption. This Vacuum Cleaner is wireless leading to better approach in cleaning the floor. As this

Vacuum Cleaner is Eco-Friendly, looking forward to use a cleaner source of energy for the betterment of

mankind, planet earth and environment.

Keywords — D. C. Operated, Axial Flow Fan, Vacuum Cleaner, Suction Pressure

. INTRODUCTION iii. Suction Mouth

iv. Dust Collecting Hose

There are various types of Vacuum Cleaners v. Axial Flow Fan

such as Upright Vacuum Cleaners, Stick Vacuum vi. Suction Cylinder

Cleaners and Hand-held Vacuum Cleaners. And all vii. Battery

these Vacuum Cleaners generally use Electrical viii. Gear

Energy as a source of Power. This paper suggests ix. Chain

the use of Battery Operated Vacuum Cleaner using

Axial Flow Fan for Suction Pressure generation. A powered horizontal brush is used to

accumulate garbage in the suction mouth area. It is

An Axial Flow Fan is used to generate the a hand driven type vacuum cleaner, which has a

Suction Pressure to suck the garbage, dust or dirt handle to steer the vacuum cleaner and to move it at

[1]. As the outward flow of Axial Flow Fan creates the desired position with the help of wheels.

a low pressure than the ambient pressure inside the

Vacuum Cleaner, results in the suction of the . LITERATURE REVIEW

garbage.

Reference [1], [2] show a method to set up the

It consists of the following parts: market position of the product through the image

scale and subsequently by 5W1H and tree diagram

i. Brush method, and clarifies the problems and the direction

ii. Brush Motor of the design goals. The following step, according

ISSN: 2395-1303 http://www.ijetjournal.org Page 467

International Journal of Engineering and Techniques - Volume 4 Issue 1, Jan – Feb 2018

to Morphological Analysis and Finite Structure below the Pressure level outside the Ambient Air

method (FSM), arranges the positions of the major Pressure.

components of the product, and shapes the forms

for developing the possible alternatives. Then, it is This creates suction, a partial Vacuum inside the

the most suitable for the consumers that using Vacuum Cleaner. The Ambient Air pushes itself

PUGH several times to choose the final solution. into the Vacuum Cleaner through the Suction

Reference [3] demonstrates the predicted

Mouth as air pressure inside the Vacuum Cleaner is

performance for power, flow rate, pressure, and

efficiency using the present method agreed well lower than the outside Pressure.

with the experimental results obtained for an

equivalent system within 2% difference at best

efficiency point. Three models of the fan-motor

assembly (S1, S2 and S3) were analyzed at the

component level and the decrease in efficiency

produced by flow resistance was estimated to be

1% (S1 and S3 models) or 4.7% (S2 model) using

the developed method.

Reference [4] shows the Pro-EnDurAncE

indicators are applicable to investigate the

durability of products in several different scenarios

and they are robust and flexible since the

assessment based on a large number of parameters

and different scenarios. These indicators can be

used to assess product at the design stage or to

support policy measures to promote more durable

products.

Reference [5], [6] and [7] show the developed

robot can perform sweeping and mopping task. RF

Fig. 1: Circuit diagram

modules have been used for wireless

communication between remote (manual mode) and

robot and having range 50m. From the results of

experiments, it is found that a cleaning robot system

. COMPONENTS OF VACUUM CLEANER

which works through interaction with equipment in

the home and does not disturb humans can become A. Brush

a reality.

The brush is a tool with filaments of Nylon used

. WORKING for cleaning or accumulating the dirt. This Brush is

fitted in the Suction Mouth. Here the Horizontal

When the Vacuum Cleaner is switched ON, the type of rotary Brush is used. The brush is rotated by

Fan blades turn, the air is forced forward towards the Brush Motor. While rotating in a clockwise

the exhaust port. As the air moves forward, the direction the brush carries the dirt with its

density of air increases in front side of the Fan and filaments. Due to this the dirt gets carried towards

density decreases behind the Fan. the Dust Collecting Hose. Like this the Brush works

There is Pressure drop behind the Fan. Thus

Pressure level in the area behind the fan drops

ISSN: 2395-1303 http://www.ijetjournal.org Page 468

International Journal of Engineering and Techniques - Volume 4 Issue 1, Jan – Feb 2018

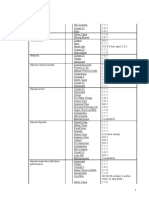

TABLE

SPECIFICATIONS OF BRUSH MOTOR

Sr. Particulars Details

No.

1 Current rating 2 Amp

2 Voltage rating 12 Volts

3 Power consumption 24 Watts

4 Speed of motor 35 rpm

C. Suction Mouth

. The Suction Mouth is a part which provides

Fig. 2: Brush

Suction Surface Area and covers the required

surface of the floor which is to be cleaned, to create

TABLE the desired Suction Pressure. The Suction Mouth

SPECIFICATIONS OF BRUSH

Sr. PARTICULARS Details has two components connected to it: Brush and

No. Dust Collecting Hose. This Suction Mouth is a

1 Filament material Nylon

2 Brush width 30 cm combination of two Geometries: Half Cylinder and

3 Filament diameter 0.3 cm Rectangular Cross-section. The Suction Mouth is

employed to cover Suction surface to make the

B. Brush Motor suction effective.

The Brush Motor is a D.C. operated motor,

providing the rotary motion of the Brush. This

Brush Motor has a rotary motion which is coupled

to the Brush through the chain drive mechanism.

This chain drive gives rotary motion to the Brush

shaft, hereby rotating the brush.

Fig. 4: Suction Mouth

TABLE

SPECIFICATION OF SUCTION MOUTH

Sr. Particulars Details

No.

1 Material Tin

Fig. 3: Brush Motor 2 Gauge size 22

3 Width 30 cm

4 Cylinder radius 15cm

ISSN: 2395-1303 http://www.ijetjournal.org Page 469

International Journal of Engineering and Techniques - Volume 4 Issue 1, Jan – Feb 2018

D. Dust Collecting Hose

The Dust Collecting Hose is an important part as

it is the only medium through which the Sucked dirt

is sent to the Suction Cylinder. The Dust Collecting

Hose is a flexible part whose length can be adjusted

according to the desire.

Fig. 6: Axial Flow Fan

TABLE

SPECIFICATIONS OF AXIAL FLOW FAN

Sr. Particulars Details

No.

1 Current rating 10 Amp

2 Voltage rating 12 Volts

3 Power consumption 120 Watts

4 Speed of Axial flow fan 3000 rpm

Fig. 5: Dust Collecting Hose

F. Suction Cylinder

TABLE The Suction Cylinder consists of the Axial Flow

SPECIFICATIONS OF DUST COLLECTING HOSE Fan fitted inside it. Half of the Suction Cylinder

Sr. Particulars Details

No. acts as the storage tank. As the Suction Pressure is

1 Material PVC produced in the Cylinder due to the Axial Flow Fan

2 Diameter 15.24 cm

3 Length 91.44 cm

rotation, the Dirt or Garbage is sucked inside the

Cylinder and gets stored into the Cylinder bottom

due to self weight of the Garbage.

E. Axial Flow Fan

The storage capacity of the storage tank is of 79

The Axial Flow Fan is the main motor which litres, which makes it able to store more Garbage.

creates lower pressure inside the Suction Cylinder And also the number of times of removing dust bag

resulting in Suction of the dirt. This Fan is fitted reduces due to more storage capacity.

into the Suction Cylinder top. As the Fan rotates it

produces Suction Pressure in the Suction Cylinder

[1]. This Fan is also a D.C. operated Fan, operated

by Battery.

ISSN: 2395-1303 http://www.ijetjournal.org Page 470

International Journal of Engineering and Techniques - Volume 4 Issue 1, Jan – Feb 2018

TABLE

SPECIFICATIONS OF BATTERY

Sr. Particulars Details

No.

1 Current rating 26 Ah

2 Voltage rating 12 Volts

. DESIGN

A. Volumetric Flow Rate of Suction Fan

Volumetric flow rate

of suction fan (Q) = π × D × L ×N

Fig. 7: Suction Cylinder

= π × 0.4572 × 0.0762 × 300

(Q) = 328.34m3/min

TABLE

SPECIFICATIONS OF SUCTION CYLINDER B. Storage Capacity of Cylinder

Sr. Particulars Details

No.

1 Material Mild Steel

Storage capacity of cylinder= π × R² × L

2 Gauge size 21 =3.14 × (0.225)² × 0.45

3 Diameter 45 cm

4 Height 90 cm

= 79 lit

C. Total Power Consumption(PT)

G. Battery 1) Power consumed by suction fan(PF)= 12 × 10

= 120 Watts

The Battery used in this project is the main source

of Power to run the Axial Flow Fan which is 2) Power consumed by brush motor (PM)= 12 × 2

responsible for the production of Suction Pressure. = 24 Watts

The Battery used is of 12V/26Ah rating.

3) Total power consumption (PT) = 120 + 24

= 144 Watts

D. Design of gear [12]

Rated power of brush motor (PR) = 24 Watts

1) Design Power to drive the gear (Pd),

Pd= PR × KL

where,

KL = Load Factor

Type of Load = Light Shock (intermittent or 3 hrs/day)

KL = 1

Fig. 8: Battery Pd = PR × KL

= 24 × 1

Pd = 24 Watts

ISSN: 2395-1303 http://www.ijetjournal.org Page 471

International Journal of Engineering and Techniques - Volume 4 Issue 1, Jan – Feb 2018

2) Static Condition, Vp = 0.0586 × 1.125

Vp = 0.065 m/sec

Ft ≤ FB Ft = Fd / Vp

where, = 24 / (0.0586 × 1.125)

Ft = Tangential Tooth Load Ft = 364.05 N

FB= Bending Tooth Load

a) Ft = Pd / Vp Velocity Factor,

where, Cv = 3 / (3 + Vp)

Vp = Pitch line velocity of gear = 3 / (3 + 0.065)

Cv = 0.978

Vp = (π × Dp × Np) / 60 b = 10 × 1.125

where, b = 11.25

Dp = Pitch diameter

Dp = mo × Tp Ft = FB

where, 364.05 = So × Cv × b × Y × mo

mo = Module 364.05 = 350 × 0.4 × b × 0.382 × 1.125

Tp = Number of teeth on pinion b = 6.05 mm

Tp = 28

Check,

Dp = 28 mo 8.5 mo ˂ b ˂ 12.5

Vp = (π × 28 mo × 40) / 60 9.56 mo ˂ b ˂ 14.06 mm

Speed of pinion (Np) = 40 rpm Hence Face Width,

Vp = 58.64 × mo b = 6.05 mm is not within the range

Vp = 0.0586 mo m/sec Hence selecting Face Width,

b = 11.25 mm

b) Bending Load Therefore, Ft ˂ FB

FB = So × Cv × b × Ym

Hence Design is Safe.

Selecting SAE 2320 Case Hardened Alloy Steel as the

material for Pinion and Gear [12] TABLE

SPECIFICATIONS OF GEAR DESIGN

Basic strength (So) = 350 MPa Sr. Particulars Details

No. Pinion Gear

Assuming

1 Module (Mo) 1.125 1.125

Velocity factor (Cv) = 0.4 2 Face width (b) 11.25 mm 11.25 mm

Face Width (b) = 10 × mo 3 Number of teeth Tp = 28 Tg = 28

Modified Lewis Factor, 4 Velocity (Vp) 0.065 0.065

m/sec m/sec

Yp = 0.485 – 2.87 / Tp

5 Velocity factor (Cv) 0.978 0.978

Yp = 0.485 – 2.87 / 28 6 Lewis factor (Y) 0.382 0.382

Yp = 0.382 7 Pitch diameter (Dp) 35 mm 35 mm

FB = 350 × 0.4 × 10 mo × 0.382 mo

FB = 534.8 mo2

Therefore from Strength Criteria, E. Design of Chain[13]

Ft = FB 1) Design Power,

(24 / 0.0586 mo) = 534.8 mo2

mo = 0.914 Pd = PR × K1

Hence selecting Standard Module, Where,

mo = 1.125 mm K1 = Load Factor

Dp = 28 mo

K1=1

Dp = 35 mm

Pd = 24 × 1

Vp = 0.0586 × mo

ISSN: 2395-1303 http://www.ijetjournal.org Page 472

International Journal of Engineering and Techniques - Volume 4 Issue 1, Jan – Feb 2018

Pd = 24 Watts where,

Pd = 24 / 746 $

C = Dp2 +

Pd = 0.032 HP

%.

Chain No.25 = 49.86 +

Pitch = 6.25 mm C = 74.79 mm

T1 = 25 " ×' .'% . ( # )

Lp = + +

Dp1 = . ×' .'%

( ) Lp = 48.93 mm

Lp ≅ 49 mm

.

=

( )

F. Calculations of suction pressure

Dp1 = 49.86 mm

Vp = π × Dp1 × N1 γ × γ ×

= π × 49.86 × 40 × 10-3 γ#

× ρ (

+ (

= × ρ ( + (

γ)*

Vp = 6.25 m/min

= 3.5(P2 - P1) = 50434.57

{V1 = 71.82 m/sec, V2 = 298.69 m/sec}

= P2 - P1 = 17409.87 N/m2

T2 = 25 P2 - P1 = 0.174 Bar (Vacuum pressure)

Dp2 =

( )

Dp2 = 49.86 mm . EXPERIMENTATION

2) Power Capacity (P), When the developed vacuum cleaner was

applied for the cleaning the floor, it successfully

P=p2 [ - (26 – 25 cos ( ))] created the required suction pressure and the

where, following results were obtained as mentioned in

p = Chain pitch in mm table [8], [9].

T = Number of teeth on smaller sprocket

V = Pitch line velocity Therefore, the developed vacuum cleaner is

P = 6.25 mm effectively applicable in the workshop of an

V = 0.104 m/sec

engineering college, railway station platforms,

T1 = 25

. . premises of college for cleaning the floors. With

P = (6.25)2 [ – (26 – 25 cos( )]

due generation of suction pressure of 0.17 Bar, it

P = 0.035 KW

can be successfully employed in the above

P = 35.4 Watts

mentioned places for cleaning purpose.

3) Number of strands, TABLE

RESULTS OF THE PROJECT MODEL

Number of Strand =

Sr. No. Particulars Details

1 Suction pressure 17 KPa or

0.17 Bar

= 2 Time required to suck 0.15 kg of 25 sec

.

Garbage

= 0.67 3 Surface area cleaned in 1 second 0.073 m2

≅1

4) Length of Chain in Pitches,

" ( # )

Lp = + +p

ISSN: 2395-1303 http://www.ijetjournal.org Page 473

International Journal of Engineering and Techniques - Volume 4 Issue 1, Jan – Feb 2018

Level Analysis of a Fan-Motor Design for a Vacuum

Cleaner’, Part C-Journal of Mechanical Engineering

Science, Vol. 231(20), pp. 3840-3854, October 2017.

4. Bobba, S (Bobba, Silvia); Ardente, F (Ardente, Fulvio)

and Mathieux, F (Mathieux, Fabrice), ‘Environmental

and Economic Assessment of Durability of Energy-using

Products: Method and Application to a Case-Study

vacuum cleaner’, Journal of Cleaner Production, Vol.

137, pp. 762-776, November 2016.

5. Prof. Swati Pawar, Naman Aggarwal, Piyusha

Chaudhari, Akshay Mahalkar and Anshul Mishra,

‘Review Paper Based on Cleaning Robot’, IJER, Vol. 03-

No. 05, pp. 06-08, May 2016.

6. Manreet Kaur and Preeti Abrol, ‘Design and

Development of Floor Cleaner Robot’, International

Fig. 9: Project model

Journal of Computer Applications (0975 – 8887), Volume

97– No.19, pp. 32-34, July 2014.

7. Abhishek Pandey, Anirudh Kaushik and Amit Kumar Jha,

CONCLUSION ‘A Technological Survey on Autonomous Home Cleaning

Robot’, April 2014.

The developed vacuum cleaner has wheels and 8. Gunho Ha, Eungdal Kim, Youngsoo Kim, Jaekeun Lee,

can be moved from one position to desired position Youngchull Ahn and Donggyu Kim, ‘A Study on the

Optimal Design of a Cyclone System for Vacuum Cleaner

manually, by applying push force to move it. It has

with the Consideration of House Dus’, Journal of

a handle to steer the vacuum cleaner. With regard Mechanical Science and Technology, March 2011.

of references taken into consideration the developed 9. Young Chull Ahn, Hoi Kil Jeong, Yu Jin Hwang,

vacuum cleaner works satisfactorily. Gil Tae Kim, Seong Ir Cheong and Jae Keun Lee,

‘Design and Performance Evaluation of Vacuum

The developed vacuum cleaner generates the Cleaners using Cyclone Technology’, Vol. 23(6), pp.

suction pressure of 17 KPa and this generated 925–930, November 2006.

Min-Chie Chiu, Long-Jyi Yeh and Y. C. Lin, ‘The Design

suction pressure is within the range of suction 10.

and Application of a Robotic Vacuum Cleaner’, Journal

pressure of the available vacuum cleaners according of Information & Optimization Sciences, pp. 01–24, 2008.

to our research and analysis [2], [4]. 11. Iwan R. Ulrich, Francesco Mondada and J. D. Nicoud,

‘Robotics and Autonomous Systems’, Vol. 19(3), March

REFERENCES 1997.

12. M/s. Kalaikathir Achchagam, ‘PSG Design Data Book’,

1. Hsiao, SW (Hsiao, Shih-Wen) and Yeh, TA (Yeh, Ting-

pp. 8.1-8.18.

An), ‘Application of Collaborative Design Strategy on

13. B. D. Shiwalkar, ‘Design Data for Machine Elements’,

Redesign of the Cordless Household Vacuum Cleaner’,

Denett & Co., pp. 150-173.

International Conference on Organizational Innovation

(ICOI 2017), Vol. 131, pp. 211-222, 2017.

2. Hsiao, SW (Hsiao, Shih-Wen) and Chen, YC (Chen, Yi-

Chin), ‘Concurrent Design Strategy in Vacuum Cleaner

Development’, International Conference on

Organizational Innovation (ICOI 2017), Vol. 131, pp.

234-241, 2017.

3. Park, C (Park, Changhwan); Jun, S (Jun, Sangook);

Park, K (Park, Kyunghyun); Lee, S (Lee, Sangjong) and

Chang, K (Chang, Kyoungsik), ‘Methodology for System-

ISSN: 2395-1303 http://www.ijetjournal.org Page 474

View publication stats

You might also like

- Design and Development of A Low Cost Handheld Vacuum CleanerDocument6 pagesDesign and Development of A Low Cost Handheld Vacuum CleanerEditor IJTSRDNo ratings yet

- Fabrication of Switch Operated Sweeping and Floor Cleaning MachineDocument10 pagesFabrication of Switch Operated Sweeping and Floor Cleaning MachineEditor IJTSRDNo ratings yet

- Report On Spray PumpDocument36 pagesReport On Spray Pumpakash nikamNo ratings yet

- Design and Fabrication of Low Cost Portable Vehicle WasherDocument4 pagesDesign and Fabrication of Low Cost Portable Vehicle WasherInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Assembly of Prototype of Automatic Rail Track Cleaning MachineDocument3 pagesDesign and Assembly of Prototype of Automatic Rail Track Cleaning MachineGirishZopeNo ratings yet

- Iaetsd-Jaras-Cfd Simulation of Twin Screw Vacuum Pump WithDocument4 pagesIaetsd-Jaras-Cfd Simulation of Twin Screw Vacuum Pump WithiaetsdiaetsdNo ratings yet

- Energization of Boundary Layer Over Wing SurfaceDocument7 pagesEnergization of Boundary Layer Over Wing SurfaceInternational Journal of Innovative Science and Research Technology100% (1)

- Solar Powered Semi-Automatic Pesticide Sprayer For Use in VineyardsDocument4 pagesSolar Powered Semi-Automatic Pesticide Sprayer For Use in VineyardsBasha'a KTNo ratings yet

- Ijiset V2 I4 11Document9 pagesIjiset V2 I4 11girmayNo ratings yet

- Effects of Impeller Design On The Characteristics of Centrifugal PumpsDocument11 pagesEffects of Impeller Design On The Characteristics of Centrifugal PumpsAhmed ShawkiNo ratings yet

- Design, Construction and Performance Test of A Foot Pump SprayerDocument6 pagesDesign, Construction and Performance Test of A Foot Pump SprayerneivenNo ratings yet

- Engineering Tools As A Support in Suction Cups Applications in Order To Increase Energy Efficiency-2007 DSC ThessalonikiDocument7 pagesEngineering Tools As A Support in Suction Cups Applications in Order To Increase Energy Efficiency-2007 DSC ThessalonikiIvana MilenkovicNo ratings yet

- Design and Analysis of U-Shaped Ribbon Blender With Screw ConveyorDocument9 pagesDesign and Analysis of U-Shaped Ribbon Blender With Screw ConveyorPhượng NguyễnNo ratings yet

- Design and Analysis of U-Shaped Ribbon Blender With Screw ConveyorDocument9 pagesDesign and Analysis of U-Shaped Ribbon Blender With Screw ConveyorAasawari MahagaonkarNo ratings yet

- Analyzing Effect of Impeller Width On Mass Flow Rate of Centrifugal Blower Using CFDDocument3 pagesAnalyzing Effect of Impeller Width On Mass Flow Rate of Centrifugal Blower Using CFDtroopersNo ratings yet

- Design and Fabrication of Solar Powered Air PurifierDocument7 pagesDesign and Fabrication of Solar Powered Air PurifierKala JattNo ratings yet

- Pure Electric Sweeper Performance Analysis and TesDocument18 pagesPure Electric Sweeper Performance Analysis and Tesaqilirfan863No ratings yet

- Modeling and Simulation of A Micro Pump and Its PerformanceDocument15 pagesModeling and Simulation of A Micro Pump and Its PerformancemrahmedNo ratings yet

- Comparison of Pumped Air Characteristics From A Rotary Atomizer With Different WheelsDocument6 pagesComparison of Pumped Air Characteristics From A Rotary Atomizer With Different WheelssanketNo ratings yet

- Analysis and Development of Restrictor For Parallel Twin Engine in FSAE CarsDocument4 pagesAnalysis and Development of Restrictor For Parallel Twin Engine in FSAE Carsbritisha2610No ratings yet

- Cavitation in Hydraulic TurbinesDocument7 pagesCavitation in Hydraulic TurbinesAsif HasanliNo ratings yet

- Impact Sprinkler Pattern Modification: KincaidDocument7 pagesImpact Sprinkler Pattern Modification: Kincaidsbalu12674No ratings yet

- Effectof Geometric Parametersonthe Performanceof CycloneDocument6 pagesEffectof Geometric Parametersonthe Performanceof Cyclone43No ratings yet

- Review - Investigation of Pressure Swirl Atomisation PDFDocument5 pagesReview - Investigation of Pressure Swirl Atomisation PDFDr. Nandakumar K. Director Research - ADMINNo ratings yet

- Design and Fabrication of Solar Operated Sprayer For Agricultural PurposeDocument4 pagesDesign and Fabrication of Solar Operated Sprayer For Agricultural PurposeEzenwa ChiomaNo ratings yet

- Optimum Design and Performance Evaluation of A Micro-Bubble GeneratorDocument8 pagesOptimum Design and Performance Evaluation of A Micro-Bubble GeneratorRobert ThanhNo ratings yet

- Numerical Simulation of The Working Process in The Twin Screw Vacuum PumpDocument11 pagesNumerical Simulation of The Working Process in The Twin Screw Vacuum PumprezaNo ratings yet

- Design and CFD Analysis of Centrifugal Pump IJERTCONV9IS10007Document5 pagesDesign and CFD Analysis of Centrifugal Pump IJERTCONV9IS10007muhammad faisalNo ratings yet

- Development of Modified System For Round Ring Cloth Peg AssemblyDocument3 pagesDevelopment of Modified System For Round Ring Cloth Peg AssemblyEditor IJTSRDNo ratings yet

- Volume 3 Wet DedustersDocument37 pagesVolume 3 Wet Dedusterscymy0% (1)

- Hydraulic Analysis of Multistage Vertical Turbine Pump: Prof Jvalant Trivedi, Prof Nitinchandra Patel, Jaydeep TrivediDocument7 pagesHydraulic Analysis of Multistage Vertical Turbine Pump: Prof Jvalant Trivedi, Prof Nitinchandra Patel, Jaydeep TrivediJvalant TrivediNo ratings yet

- Design of A New Improved Intake Manifold For F-Sae Car: January 2016Document6 pagesDesign of A New Improved Intake Manifold For F-Sae Car: January 2016İlker EnesNo ratings yet

- In Tech Open 72530 Pipe InletDocument17 pagesIn Tech Open 72530 Pipe InletMemet Can TosunerNo ratings yet

- Automatic Drain Cleaner Machine PaperDocument4 pagesAutomatic Drain Cleaner Machine PaperVikram PanchalNo ratings yet

- Design of Pneumatic Press Machine For 250 Page Bundle Book Based On Microcontroller Arduino Uno Design of Pneumatic Press Machine For 250 Page Bundle Book Based On Microcontroller..Document11 pagesDesign of Pneumatic Press Machine For 250 Page Bundle Book Based On Microcontroller Arduino Uno Design of Pneumatic Press Machine For 250 Page Bundle Book Based On Microcontroller..Jehuda Titahelu - UsmanyNo ratings yet

- Ijri Me 01 003Document5 pagesIjri Me 01 003ijripublishersNo ratings yet

- Elsiver Paper #2 PDFDocument9 pagesElsiver Paper #2 PDFSiva NarayanaNo ratings yet

- Industrial Centrifugal Compressors Design Validation, Using Rapid Method Evolutionary Algorithms To Predict Map Characteristics EvaluationDocument12 pagesIndustrial Centrifugal Compressors Design Validation, Using Rapid Method Evolutionary Algorithms To Predict Map Characteristics EvaluationMustafa AliosmanoğluNo ratings yet

- Field Evaluation of Tractor Mounted Boom Sprayer: March 2018Document14 pagesField Evaluation of Tractor Mounted Boom Sprayer: March 2018vodounnouNo ratings yet

- Fabrication of Automated Pneumatic Board Cleaning SystemDocument7 pagesFabrication of Automated Pneumatic Board Cleaning SystemVignesan MechNo ratings yet

- Design and Development of Car Wash SteamerDocument4 pagesDesign and Development of Car Wash SteamerVIVA-TECH IJRINo ratings yet

- New Project PDFDocument27 pagesNew Project PDFsampath kumar K NNo ratings yet

- New Project PDFDocument27 pagesNew Project PDFsampath kumar K NNo ratings yet

- Momin 2017 IOP Conf. Ser.: Mater. Sci. Eng. 197 012050Document11 pagesMomin 2017 IOP Conf. Ser.: Mater. Sci. Eng. 197 012050Sivi NallamothuNo ratings yet

- Wind MillDocument11 pagesWind Millrebid.burlier-0hNo ratings yet

- Water - Jet Cutting - A Precise Method For ManufactDocument5 pagesWater - Jet Cutting - A Precise Method For ManufactBooms MastersNo ratings yet

- Control of BLDocument13 pagesControl of BLابراهيم اسامهNo ratings yet

- Experiment Study of Vaned Diffuser Effects On Overall Performance and Flow Field of A Centrifugal CompressorDocument8 pagesExperiment Study of Vaned Diffuser Effects On Overall Performance and Flow Field of A Centrifugal CompressorBrahimABDNo ratings yet

- Numerical Investigation of Three-Dimensional Separation Control in An Axial Compressor CascadeDocument7 pagesNumerical Investigation of Three-Dimensional Separation Control in An Axial Compressor CascadeMohammad OmidiNo ratings yet

- HHHHBBDocument4 pagesHHHHBBThinesh Rau KrishnamurtyNo ratings yet

- Cleaning-Cum-Wiping MachineDocument2 pagesCleaning-Cum-Wiping MachineijaertNo ratings yet

- Working of Road Cleanig MachineDocument47 pagesWorking of Road Cleanig MachineKannan MNo ratings yet

- Centrifugal PumpDocument3 pagesCentrifugal PumpJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Design and Fabrication of Automatic Dishwasher Machine: January 2017Document7 pagesDesign and Fabrication of Automatic Dishwasher Machine: January 2017Ajit KalasaitNo ratings yet

- CFD Analysis of Swept and Leaned Transonic Compressor RotorDocument5 pagesCFD Analysis of Swept and Leaned Transonic Compressor RotorseventhsensegroupNo ratings yet

- Design and Fabrication of Pneumatic Bar Bending MachineDocument4 pagesDesign and Fabrication of Pneumatic Bar Bending MachineAnonymous kw8Yrp0R5rNo ratings yet

- Final Report Vacuum CleanerDocument21 pagesFinal Report Vacuum CleanerDeepanraj RajakumaranNo ratings yet

- Design and Analysis of Vortex Generators: International Journal For Modern Trends in Science and TechnologyDocument7 pagesDesign and Analysis of Vortex Generators: International Journal For Modern Trends in Science and TechnologyNoumanNo ratings yet

- Design and Fabrication of Mini DC VacuumDocument7 pagesDesign and Fabrication of Mini DC VacuumArhyel IshakuNo ratings yet

- Food - Forage - Potential - and - Carrying - Capacity - Rusa Kemampo - MedKonDocument9 pagesFood - Forage - Potential - and - Carrying - Capacity - Rusa Kemampo - MedKonRotten AnarchistNo ratings yet

- S.V. Kulkarni, S.A. Khaparde Transformer and Inductor Design Handbook 2004Document532 pagesS.V. Kulkarni, S.A. Khaparde Transformer and Inductor Design Handbook 2004Gianpiero Boccato0% (1)

- ManufactureDocument2 pagesManufactureRahima Akter RakhiNo ratings yet

- Mechanics of MaterialsDocument11 pagesMechanics of MaterialsPeter MwangiNo ratings yet

- Sotero 05activity EnvironmetnDocument3 pagesSotero 05activity Environmetnbernadette soteroNo ratings yet

- Present Arlypon VPCDocument1 pagePresent Arlypon VPCErcan Ateş100% (1)

- Stokerchapter25lipidmetabolism 160320032037Document29 pagesStokerchapter25lipidmetabolism 160320032037Dawlat SalamaNo ratings yet

- Indigo Airlines - Final ReportDocument22 pagesIndigo Airlines - Final Reportanand_lihinarNo ratings yet

- Into The Unknown 21 Doc PDFDocument9 pagesInto The Unknown 21 Doc PDFFernando AlbuquerqueNo ratings yet

- Certified: Steelfab of VirginiaDocument1 pageCertified: Steelfab of VirginiaRamume188No ratings yet

- Coca ColaDocument50 pagesCoca Colamariyha PalangganaNo ratings yet

- Assignment On Cholera: Submitted ToDocument17 pagesAssignment On Cholera: Submitted ToEhesanulHaqueSaifNo ratings yet

- AC350 Specs UsDocument18 pagesAC350 Specs Uskloic1980100% (1)

- Case-Study - Decision Making Under UncertaintyDocument21 pagesCase-Study - Decision Making Under UncertaintyMari GhviniashviliNo ratings yet

- Estimation of Fire Loads For An Educational Building - A Case StudyDocument4 pagesEstimation of Fire Loads For An Educational Building - A Case StudyEditor IJSETNo ratings yet

- Nammiaca 000032Document5,323 pagesNammiaca 000032gangadhark196No ratings yet

- Mwangi, Thyne, Rao - 2013 - Extensive Experimental Wettability Study in Sandstone and Carbonate-Oil-Brine Systems Part 1 - Screening ToDocument7 pagesMwangi, Thyne, Rao - 2013 - Extensive Experimental Wettability Study in Sandstone and Carbonate-Oil-Brine Systems Part 1 - Screening ToMateo AponteNo ratings yet

- Collage Lab PDFDocument145 pagesCollage Lab PDFmaa siddhi92% (12)

- Chuyên Đề ConjunctionDocument5 pagesChuyên Đề ConjunctionKhánh Linh TrịnhNo ratings yet

- Gcat Threathorizons Full Jan2023Document26 pagesGcat Threathorizons Full Jan2023josbjsNo ratings yet

- KZPOWER Perkins Stamford Genset Range CatalogueDocument2 pagesKZPOWER Perkins Stamford Genset Range CatalogueWiratama TambunanNo ratings yet

- Afectiuni Si SimptomeDocument22 pagesAfectiuni Si SimptomeIOANA_ROX_DRNo ratings yet

- Ac 521 007Document10 pagesAc 521 007JacquesNo ratings yet

- TOP233YDocument24 pagesTOP233YJose BenavidesNo ratings yet

- Annual Report 2022-23 (Eng.)Document326 pagesAnnual Report 2022-23 (Eng.)Gaurav DurejaNo ratings yet

- NURS1108 Lecture 10 - Nervous System ENHANCEDDocument40 pagesNURS1108 Lecture 10 - Nervous System ENHANCEDJacia’s SpaceshipNo ratings yet

- Resource Access ControlDocument19 pagesResource Access Controlusamadar707No ratings yet

- 2014 An125hkl4Document69 pages2014 An125hkl4El Turco ChalabeNo ratings yet

- 1 28701-FGC+101+3441+Router+6471+Datasheet+Rev+FDocument2 pages1 28701-FGC+101+3441+Router+6471+Datasheet+Rev+FВладимир ЕгоровNo ratings yet