Professional Documents

Culture Documents

The Full Underground Distribution Transformer in Practice: Cired Cired Cired Cired

Uploaded by

des1982Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Full Underground Distribution Transformer in Practice: Cired Cired Cired Cired

Uploaded by

des1982Copyright:

Available Formats

CIRED 21st International Conference on Electricity Distribution Frankfurt, 6-9 June 2011

Paper 0197

THE FULL UNDERGROUND DISTRIBUTION TRANSFORMER IN PRACTICE

Frank de Groot Maarten van Riet Gerard Buisman

Liandon – The Netherlands Liandon – The Netherlands Liandon – The Netherlands

frank.de.groot@alliander.com maarten.van.riet@alliander.com gerard.buisman@alliander.com

An additional advantage is the great liberty of allocating this

ABSTRACT kind of station. Feeding the low voltage grid can be

optimized so that investments in the LV grid can be

DSO’s have difficulties allocating new distribution stations minimized.

in city centres.

In response Liandon is developing a fully underground Capacity

compartment for distribution transformers. This paper Part of the development is determining the ideal capacity of

describes the development including the design, thermal this kind of distribution station. An analysis of the capacity

testing and the results of testing in a real live environment and load of several distribution stations in an average

that is being executed at this moment. community has given the following conclusion: In 88

percent of the stations a 10/0,4 kV transformer no larger

INTRODUCTION than 400 kVA is used. The maximum capacity that is used

In large city centres Distribution System Operators are for supplying the LV grid is 630 kVA. The ideal capacity

encountering difficulties finding suitable locations for for the underground station is set at 400 kVA, a possibility

distribution stations. New stations are necessary because of for 630 kVA is attractive but no more than a wish.

new customers and a rising demand on power. Local

authorities are becoming less tolerant about allocating DESIGN

distribution stations in public space and stations inside The following issues need to be taken into consideration

buildings are often less economic. A solution is using when placing a transformer in an underground structure.

compact underground stations.

Liandon is working on a small size underground distribution Weak soil

station with no parts, like ventilation shafts, above ground The western part of the Netherlands consists of weak soil

level. The station will not be a traditional man-accessible under sea level. For underground compartment risks are

underground room but consists of a compartment for a possible sinking due to extensive mass and floating due to

transformer and one for the low voltage switchgear. The LV upward forces from groundwater.

compartment is a standard product. Design and construction

of the transformer compartment is fully new. Measures against sinking

Two measures have been taken to ensure that the

GRID CONFIGURATION AND CAPACITY compartment and surrounding pavement will not sink:

• The compartment has been equipped with several

Fitting in the grid mounting eyes which make it possible to attach the

This type of station is designed to be operated without object to a concrete foundation. In the live test a

medium voltage switchgear. The goal is supporting the concrete structure with piles was made, which gives the

existing grid. In the existing grid there are a lot of stations in advantage that the foundation can be made location

which it is possible to connect the MV-cable that feeds the specific.

underground transformer station. • Around the outer cover a tongue-construction ensures

that the pavement directly next to the cover can’t sink.

Measures against floating

A calculation was made to determine the risk of floating in

case of no foundation.

There is a risk of floating when the upward force

(Archimedes) from the groundwater exceeds the

gravitational force due to the mass of the compartment with

or without the transformer. The upward force depends on

the water displacement causing it to be proportional to the

volume of the part of the compartment that is inside the

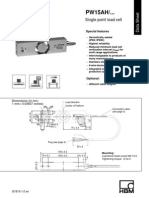

Figure 1: Grid connection groundwater.

Paper No 0197 1/4

CIRED 21st International Conference on Electricity Distribution Frankfurt, 6-9 June 2011

Paper 0197

The outcome of the calculations is that with a high level of important ones are:

groundwater there is a small remaining upward force when • Transformer specifications

no transformer is present. The adhesive force from the • Transformer load and loading curve

surrounding soil will be amplified by the cooling fins so the • Time constants

risk of floating is minimal. • Air temperature

Attaching the object to a foundation is also a solution to • The conductivity of the soil

prevent floating. • The temperature of the surrounding soil

Water tightness

Transformer specifications

Groundwater is often present in weak soil with varying from

When it comes to distribution transformers there is one

just under the pavement till much deeper. Resistance against

mayor choice:

groundwater is accomplished by using a diving bell

• Oil immersed transformers

principle that is explained in the next figure.

• Casting resin transformers (“dry transformers”)

Casting resin transformers produce more heat due to higher

losses, are more sensitive to overloading and are more

sensitive for moisture than oil immersed transformers. The

choice in this case is clear. The presence of oil and the

higher weight of an oil immersed transformer are not a

problem for use in an underground compartment.

There is a strong urge to use a standard transformer because

of interchange ability, low cost and other advantages.

Figure 2: Diving bell principle In the Netherlands the bigger part of distribution

transformers, purchased and operated by the DSO’s, are

The compartment in fact consists of a bottom compartment built according to a joint standard.

which is covered by an airtight inner cover. Because of the An extract of the Dutch standard concerning the maximum

air that is present underneath the inner cover the ground losses of three types of transformers is shown in the table.

water is kept outside.

Apart from the diving bell principle the compartment has 250 kVA 400 kVA 630 kVA

been equipped with a possibility for connecting it to a sewer No load losses (W) 365 515 745

system. Load losses (W) 2640 3750 5200

Table 1: Maximum losses of standard transformers

Thermal behaviour

Probably the biggest challenge is dealing with the heat Another important parameter from the Dutch standard

generated by the transformer due to losses. This heat has to transformers is the choice for “A class” isolation. Conform

be drained, otherwise temperatures will rise to unacceptable the IEC 60076-7 (loading guide for transformers) this type

values. We want to be in control of temperatures because of isolation allows hot spot temperatures of a maximum of

temperature is the limiting factor for transformers. The 98°C. Above this temperature aging of the transformer

demand “no ventilation shafts” means that the heat mainly rapidly rises.

has to be transferred through the surrounding soil. Perhaps a On a number of distribution transformers, in service in the

little heat can be transferred by the cover of the grid, measurements have been performed to determine the

compartment but this will only be a small contribution. relation between the hot spot and the top oil temperatures.

Concluded is that the hot spot temperature is about 9 °C

Processes and parameters higher than the top oil, for calculations 10 °C difference will

The process of heat draining is complex and consists of be used. This is in accordance with the IEC 60076-7.

several sub processes, the main ones are:

• Production of heat Calculations and size

• Conducting heat from transformer to the wall of the Calculations have more or less shown that the design like

compartment presented will accomplish the goal of housing a 400 kVA

• Transferring heat from compartment to surrounding soil transformer under normal loading conditions within

• Transferring heat to the air above the compartment or temperature limits. To take into account are that the

extra heating by sunlight processes of heat transferring are complex and might not be

completely modelled. Also a number of parameters is not

The processes depend on a number of parameters, the most fully known or might vary in an unknown pattern, causing

the outcome of the calculations to contain an amount of

Paper No 0197 2/4

CIRED 21st International Conference on Electricity Distribution Frankfurt, 6-9 June 2011

Paper 0197

uncertainty and probably a deviation from practice.

The presented design has a somehow maximum acceptable

size. When the size increases the allocating possibilities and

the economic value would decrease gravely.

On these grounds a decision was made to build the

compartment and perform extensive thermal testing to

decrease the calculation uncertainty and come closest to

practice.

Final design

The demands and other issues have led to the final design of

the transformer compartment as shown in the next figure.

Figure 4: Heating elements in transformer tank

Also the maximum load in the day pattern varies. For the

day pattern losses the chosen time distribution of the losses

is represented in the next table.

Time 7:00 - 10:00 - 16:00 - 19:00 -

interval (hr) 10:00 16:00 19:00 7:00

Figure 3: Compartment overview Losses (W) max 0,67 max max 0,33 max

Table 2: Losses with day pattern load

The compartment has been made from sheet iron with a cast

iron outer top cover. Clearly visible are the cooling fins. Heating with a constant load was done to determine the

The outer cover is divided into four parts so manually lifting system time constant. The measured time constant is 20

is possible. For lifting the inner cover a crane is needed. The hours, calculated was 21,5 hours.

outside dimensions are 3,3 x 1,5, x 2,2 m (l x w x h). The Like predicted, next to the simulated losses, the outside

inner compartment, the transformer room, stands 1,75 x temperature has a great influence at the oil temperature

1,00 x 1,94 m. This makes it possible to use a transformer inside the transformer tank. Clearly visible is that the

of a maximum of 800 kVA. highest oil temperatures are reached on hot sunny days. Top

oil temperatures are higher than calculated, probably

THERMAL TESTING because of extra heat production due to incident sunlight on

the outer cover. When the limit for the top oil temperature is

After constructing the transformer compartment, it was set on 100 ° C the maximum losses may not exceed 2500 W

installed on the test site. It was placed in so called back-fill at the given loading curve. Consequence of choosing 100 °

sand to ensure a good transfer of heat. After installing a C is that extra aging will occur; this effect will be focussed

number of tests were performed during a 10 months period. upon later.

Imitation transformer Transformer choice

Performing a long term test with a real 10/0,4 kV The limit of 2500 W obliges us to review the transformer

transformer is hard. Besides working with live medium before further testing.

voltage a controllable load is necessary. To produce The following options where considered:

realistic losses the load should be adjustable up to 400 kVA. • Using a standard 630 kVA transformer at max 366 kVA

Instead of using a real transformer the tank of an old one • Special low loss transformer

was used. A number of heating elements with different • Transformer with a higher isolation class

capacities was installed in the oil filled tank. The advantage • Limiting the capacity by using a 250 kVA transformer

of this combination is that only the relatively small losses

have to be controlled for. The first option was chosen. This option is based upon the

Thermal testing results and analyses fact that the load losses of a transformer are proportional

with the quadrate of the load. Although the no load losses of

In general two test types are performed: heating with a

a 630 kVA transformer are higher than those of a 400 kVA

constant capacity and heating with a varying capacity

one, the total losses are smaller due to the lower copper

matching the losses of a transformer with a day pattern load.

resistance.

Paper No 0197 3/4

CIRED 21st International Conference on Electricity Distribution Frankfurt, 6-9 June 2011

Paper 0197

IN PRACTICE hottest part of the day so this is a sort of worst case test.

With the knowledge, obtained from the thermal tests, live Negligible effect from thermal overloading

testing has started. Especially in July and August the transformer is thermally

For the live test a location is chosen next to a conventional overloaded. The top oil temperature reaches a maximum of

man-accessible 10/0,4 kV station with a load of 99 °C at August 20th which means the hot spot temperature

approximately 350 kVA. The underground transformer is was about 108 °C. To prevent aging according to the

connected redundantly with the grid so that at all times its IEC60076-7 the hotspot temperature is limited to 98 °C.

function can be taken over by the existing station. The Combined with the 10 °C difference concluded from other

station is placed at a spot where it is lighted by the tests, this means that when top oil temperatures exceed 88°C

afternoon sun. extra aging takes place.

A large number of variables is measured and logged. This

provides great opportunities for analysing. Also a number of

alarms are installed. The main measurements are:

• LV loading current(s)

• Top oil temperature

• Air temperature

• Groundwater level

Thermal testing results and analyses

Live testing is performed since 2007. At this moment we Figure 6: Top oil and outside temperatures

have complete data over the years 2007- 2010. Analysing

the data shows the following results: In 2009 the top oil temperatures exceeded the limit of 88 °C

• At this location the groundwater level is of no during 278 quarters of an hour. The high limit of 105 °C,

significance. mentioned in the IEC60076-7, has never been exceeded.

• No water leakages or equivalent have occurred. Calculated according the IEC60076-7, the overload causes a

• Oil temperatures peak in the months July and August yearly aging of 109 hour in a period of 69,5 hours (278

and mainly depend on the transformer load and outside quarters). This means that, in the given circumstances, the

temperature in combination with the sunlight. transformer gets an extra aging of 40 hours each year. This

• The highest temperatures have occurred in the long hot is less than 0,5% loss of lifetime and is therefore

summer of 2009, in the other seasons top oil considered acceptable.

temperatures are much lower. Focus is on the year

2009. CONCLUSIONS

The form of the daily and weekly load curves are shown in

the next figures. • Building a totally underground distribution transformer

is possible using the “diving bell principle” system.

• The load curve and ambient temperature during

summer are the decisive parameters for the maximum

acceptable load.

• Using a 630 kVA “standard” transformer at a maximum

load of 400 kVA gave a good performance but this is

near the limit of possibilities. When a higher capacity is

Figure 5: Two week load and top oil temperature curves needed a special transformer becomes necessary.

• Due to the special compartment and the over

proportioned transformer this kind of solution is clearly

more expensive than a traditional station. So this

solution is only suited for special situations.

REFERENCES

Figure 2: One day load and top oil temperature curves

[1] G. Buisman, 2005, thesis, college of technology

Clearly visible is that this is a so called “day load” pattern, Arnhem and Nijmegen.

rising from early morning and dropping in late afternoon. [2] A.F. Mills, 1999, Heat Transfer 2nd edition, Prentice

This is typical for a business area. Also visible is that the Hall, New Jersey, USA.

maximum load is about 600 A equalling 400 kVA. The load

is at its maximum at the hottest day of the year and at the

Paper No 0197 4/4

You might also like

- LeakageLayer FerreiraDocument7 pagesLeakageLayer FerreiraNeha RajputNo ratings yet

- Online Transformer Drying System - June2021 (Enlit-Africa)Document7 pagesOnline Transformer Drying System - June2021 (Enlit-Africa)Yogesh SoodNo ratings yet

- IAEI News Grounding of Wind PowerDocument4 pagesIAEI News Grounding of Wind PowerMIUWWW12100% (1)

- Automatic cable fault locator using GSMDocument6 pagesAutomatic cable fault locator using GSMHari KishorNo ratings yet

- Designing of HV Power Substation and LayoutDocument6 pagesDesigning of HV Power Substation and LayoutRagavanNo ratings yet

- Ampacity Calculations For Deeply InstallDocument10 pagesAmpacity Calculations For Deeply InstallsajuaanalsaNo ratings yet

- EMC - Kerala Distribution Transformer Loss Study - 175-208Document34 pagesEMC - Kerala Distribution Transformer Loss Study - 175-208Santanu MandalNo ratings yet

- GTD ElDocument30 pagesGTD ElVaishali KharpuseNo ratings yet

- Power Below The Waves: Transformers at Depths of 3 KMDocument4 pagesPower Below The Waves: Transformers at Depths of 3 KMSathishkumar PragasamNo ratings yet

- Transformer dimensions MATLAB codeDocument30 pagesTransformer dimensions MATLAB codesenthilkumarNo ratings yet

- Dimmers: by Andrew PenfoldDocument4 pagesDimmers: by Andrew PenfoldDimitrios TriantafyllidisNo ratings yet

- A New Type of Oil-Free Power Transformer With Low Environmental ImpactDocument6 pagesA New Type of Oil-Free Power Transformer With Low Environmental ImpactOSAMANo ratings yet

- The Pluggable Transformer: Flexibility For Future GridsDocument8 pagesThe Pluggable Transformer: Flexibility For Future GridsChumporn SaraphatmarkyingNo ratings yet

- Topic No. 5 Distribution LinesDocument15 pagesTopic No. 5 Distribution Linesburnermike011323No ratings yet

- AC Mitigation Case Histories: Nebraska Pipeline Safety Seminar Mike Ames March 26, 2013 Grand Island, NEDocument32 pagesAC Mitigation Case Histories: Nebraska Pipeline Safety Seminar Mike Ames March 26, 2013 Grand Island, NEMattNo ratings yet

- SUPPLEMENT 09/2019: DescriptionDocument1 pageSUPPLEMENT 09/2019: Descriptionnoel beloyNo ratings yet

- Testing Distribution Switchgear For Partial DischargeDocument5 pagesTesting Distribution Switchgear For Partial DischargeJordan MontemayorNo ratings yet

- Paper No OP003 Draft 1 enDocument10 pagesPaper No OP003 Draft 1 enNagaraj NeradhalaNo ratings yet

- WS OperatingInstructions GEAFOL enDocument12 pagesWS OperatingInstructions GEAFOL enNguyen Trung DungNo ratings yet

- Ingenieria Electrica 3Document4 pagesIngenieria Electrica 3Antonela MasottaNo ratings yet

- Practical Problems with Substation EarthingDocument6 pagesPractical Problems with Substation Earthingshawnr7376No ratings yet

- EARTHING PresentationDocument15 pagesEARTHING PresentationsemajamesNo ratings yet

- Protection of HT & L T TransformerDocument33 pagesProtection of HT & L T TransformerMrunal SalveNo ratings yet

- X'merDocument13 pagesX'mervatsalNo ratings yet

- Vs1 en 150dpiDocument13 pagesVs1 en 150dpiPatrik PulungNo ratings yet

- Research Paper Transformer PDFDocument5 pagesResearch Paper Transformer PDFUsmanNo ratings yet

- REFCL Trial FINAL Report CH 8 Appendices 140804Document28 pagesREFCL Trial FINAL Report CH 8 Appendices 140804gayboiNo ratings yet

- Ground Bounce2Document16 pagesGround Bounce2HemantkumarNo ratings yet

- Current-Limiting Reactors: by W. M. DannDocument5 pagesCurrent-Limiting Reactors: by W. M. DannAhsn ShkNo ratings yet

- Trends in The 'Undergrounding' of Power Lines 2007 PDFDocument6 pagesTrends in The 'Undergrounding' of Power Lines 2007 PDFMantshaNo ratings yet

- Assessing The Impact of Harmonics and Interharmonics of Top and Mudpump Variable Frequency Drives in Drilling RigsDocument10 pagesAssessing The Impact of Harmonics and Interharmonics of Top and Mudpump Variable Frequency Drives in Drilling RigsHydra ZineNo ratings yet

- LC-4.5 User ManualDocument11 pagesLC-4.5 User ManualJUAN FRANCISCO PINEDONo ratings yet

- BusBar LiteratureDocument4 pagesBusBar LiteratureschaktenNo ratings yet

- Effective Methods For Power Systems Grounding OkDocument10 pagesEffective Methods For Power Systems Grounding OkAditya AstariNo ratings yet

- Electrical DesignDocument5 pagesElectrical DesignMahmoud ElboraeNo ratings yet

- Subsea High Voltage Power DistributionDocument9 pagesSubsea High Voltage Power DistributionSeun Sam AdetolaNo ratings yet

- Earthing & Protective DevicesDocument26 pagesEarthing & Protective DevicesShreeja mayyaNo ratings yet

- CH 5 CoronaDocument21 pagesCH 5 CoronaZerihun PaulosNo ratings yet

- Oil-Filled Terminals Maintain Safety for High Voltage Underground CablesDocument8 pagesOil-Filled Terminals Maintain Safety for High Voltage Underground CablesGabriel SantiagoNo ratings yet

- Making sense of risk: What is a TransformerDocument6 pagesMaking sense of risk: What is a TransformerShiaTVfanNo ratings yet

- MAGS ArticleDocument5 pagesMAGS ArticlesatishmuggulaNo ratings yet

- SEMICONDUCTOR APPLICATION NOTE: Order this document by AN1542/DDocument14 pagesSEMICONDUCTOR APPLICATION NOTE: Order this document by AN1542/Dskyfoggy4799No ratings yet

- Cable Selection Guide For TelecommunicationsDocument3 pagesCable Selection Guide For TelecommunicationsDaniel AkinyoyenuNo ratings yet

- A Case Study of Voltage Transformer FailuresDocument12 pagesA Case Study of Voltage Transformer Failuresafru2000No ratings yet

- ELA1075 Maximise Pulley Service Life V7Document12 pagesELA1075 Maximise Pulley Service Life V7nicolas quispe bNo ratings yet

- Calculating Stray Losses in Power Transformers Using Surface Impedance With Finite ElementsDocument4 pagesCalculating Stray Losses in Power Transformers Using Surface Impedance With Finite ElementsMatejComelNo ratings yet

- EDOC-Practical Considerations in Surge ProtectionDocument15 pagesEDOC-Practical Considerations in Surge ProtectionEl Comedor BenedictNo ratings yet

- Guideline For Adoption of CMEN Earthing System: Purpose and ScopeDocument14 pagesGuideline For Adoption of CMEN Earthing System: Purpose and ScopeTerex14253No ratings yet

- Grounding: Egbodor Peter UwhubetineDocument18 pagesGrounding: Egbodor Peter UwhubetineEgbodor Peter100% (1)

- Neutral Earthing in HV NetworksDocument12 pagesNeutral Earthing in HV Networksmiksa samuNo ratings yet

- Grounding-Back To BasicsDocument5 pagesGrounding-Back To BasicsUsman TariqNo ratings yet

- Analysis of Integral Snubber Circuit Design For Transformers in Urban High Rise Office BuildingDocument17 pagesAnalysis of Integral Snubber Circuit Design For Transformers in Urban High Rise Office BuildingLuis ÁtilaNo ratings yet

- Case Studies on Grid Substation Operation and Control SchemesDocument6 pagesCase Studies on Grid Substation Operation and Control SchemesDeeptanshu TripathyNo ratings yet

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringFrom EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Gallium Nitride-enabled High Frequency and High Efficiency Power ConversionFrom EverandGallium Nitride-enabled High Frequency and High Efficiency Power ConversionGaudenzio MeneghessoNo ratings yet

- Practical Transformer Handbook: for Electronics, Radio and Communications EngineersFrom EverandPractical Transformer Handbook: for Electronics, Radio and Communications EngineersRating: 4 out of 5 stars4/5 (16)

- Capacitor Discharges - Magnetohydrodynamics - X-Rays - UltrasonicsFrom EverandCapacitor Discharges - Magnetohydrodynamics - X-Rays - UltrasonicsRating: 5 out of 5 stars5/5 (1)

- Impulse Breakdown On Lighting Protection Device at Distribution LinesDocument13 pagesImpulse Breakdown On Lighting Protection Device at Distribution Linesdes1982No ratings yet

- 1210 Nis Petrovic 263-267 PDFDocument5 pages1210 Nis Petrovic 263-267 PDFSalNo ratings yet

- Evaluation of Substation Bus Schemes Considering ReliabilityDocument6 pagesEvaluation of Substation Bus Schemes Considering Reliabilitydes1982No ratings yet

- Condition-Based MaintenanceDocument4 pagesCondition-Based Maintenancedes1982No ratings yet

- Managing The Risk of Protection Relay Failure: Project Specification Consultation ReportDocument42 pagesManaging The Risk of Protection Relay Failure: Project Specification Consultation Reportdes1982No ratings yet

- Transformer Failure Due To Circuit Breaker Induced SwitchingsDocument13 pagesTransformer Failure Due To Circuit Breaker Induced Switchingsdes1982No ratings yet

- Electrical Interferences in SFRA Measurements Article 2016 ENUDocument15 pagesElectrical Interferences in SFRA Measurements Article 2016 ENUykh92167No ratings yet

- Harmonic Emission Limits For Customers Connected To MV HV EHVDocument4 pagesHarmonic Emission Limits For Customers Connected To MV HV EHVdes1982No ratings yet

- Improved Electrical Safety Through High Resistance GroundingDocument6 pagesImproved Electrical Safety Through High Resistance Groundingdes1982No ratings yet

- A View On Internal Arc Testing of LV SwitchgearDocument8 pagesA View On Internal Arc Testing of LV Switchgeardes1982No ratings yet

- A New Criterion Needed To Evaluate Reliability of Digital Protective RelaysDocument5 pagesA New Criterion Needed To Evaluate Reliability of Digital Protective Relaysdes1982No ratings yet

- Estimation of Replacement of Numerical Relay SystemsDocument6 pagesEstimation of Replacement of Numerical Relay Systemsdes1982No ratings yet

- IEEE Vol 23 No 3 June 2016 - Guarding MV Cables On-LineDocument8 pagesIEEE Vol 23 No 3 June 2016 - Guarding MV Cables On-Linedes1982No ratings yet

- Reliability Measures: Failure and Root Cause Analysis (FRCA) For GIS Early FailureDocument5 pagesReliability Measures: Failure and Root Cause Analysis (FRCA) For GIS Early Failuredes1982No ratings yet

- Energies: Classical Failure Modes and E Context of Smart Grid Cyber-Physical SystemsDocument26 pagesEnergies: Classical Failure Modes and E Context of Smart Grid Cyber-Physical SystemssrobayocNo ratings yet

- 2014 CEPSI - On-Line PD and Fault Location With SCGDocument8 pages2014 CEPSI - On-Line PD and Fault Location With SCGdes1982No ratings yet

- A Maintenance Strategy of Improving The Reliability of Relay ProtectionDocument7 pagesA Maintenance Strategy of Improving The Reliability of Relay Protectiondes1982No ratings yet

- CIRED2007 0779 Paper PDFDocument6 pagesCIRED2007 0779 Paper PDFdes1982No ratings yet

- 2016 Cepsi - On-Line Fault Detection and Localization in Medium Voltage NetworkDocument6 pages2016 Cepsi - On-Line Fault Detection and Localization in Medium Voltage Networkdes1982No ratings yet

- Jicable2015 LiraDocument6 pagesJicable2015 Lirades1982No ratings yet

- 2015 Jicable - Risk On Failure Based On PD Measurements in Actual MV PILC and XLPE Cables.Document3 pages2015 Jicable - Risk On Failure Based On PD Measurements in Actual MV PILC and XLPE Cables.des1982No ratings yet

- Reliability Measures: Failure and Root Cause Analysis (FRCA) For GIS Early FailureDocument5 pagesReliability Measures: Failure and Root Cause Analysis (FRCA) For GIS Early Failuredes1982No ratings yet

- 2016 Cepsi - On-Line Fault Detection and Localization in Medium Voltage NetworkDocument6 pages2016 Cepsi - On-Line Fault Detection and Localization in Medium Voltage Networkdes1982No ratings yet

- 2007 Jicable - Permanent On-Line Monitoring of MV Cables - An Update PDFDocument6 pages2007 Jicable - Permanent On-Line Monitoring of MV Cables - An Update PDFdes1982No ratings yet

- 2014 CEPSI - On-Line PD and Fault Location With SCGDocument8 pages2014 CEPSI - On-Line PD and Fault Location With SCGdes1982No ratings yet

- Online PD Monitoring System Detects Cable Defects Before FailureDocument4 pagesOnline PD Monitoring System Detects Cable Defects Before Failuredes1982No ratings yet

- 2007 Jicable - Permanent On-Line Monitoring of MV Cables - An Update PDFDocument6 pages2007 Jicable - Permanent On-Line Monitoring of MV Cables - An Update PDFdes1982No ratings yet

- Cired 2015 - 1044 - SCGDocument5 pagesCired 2015 - 1044 - SCGdes1982No ratings yet

- Cigre 2016 - B1-205Document9 pagesCigre 2016 - B1-205des1982No ratings yet

- Apar Transformer Oil PDS - To 1020 60 U PDFDocument1 pageApar Transformer Oil PDS - To 1020 60 U PDFmaa vaishnavi ventureNo ratings yet

- B 1815Document4 pagesB 1815Angelo MachadoNo ratings yet

- Decoder/Encoder ImplementationDocument6 pagesDecoder/Encoder ImplementationLoers AntarioNo ratings yet

- Chapter 3 Notes NBCAS511Document18 pagesChapter 3 Notes NBCAS511Zilly cocoNo ratings yet

- Coleco Av Mod HowtoDocument9 pagesColeco Av Mod HowtoOscar Arthur KoepkeNo ratings yet

- Edec Question Paper-IDocument8 pagesEdec Question Paper-IarunfriendsNo ratings yet

- Typical Questions Rev1Document8 pagesTypical Questions Rev1hbgdiatmNo ratings yet

- VERIFICATION OF TRUTH TABLES OF LOGIC GATES AND CIRCUITSDocument40 pagesVERIFICATION OF TRUTH TABLES OF LOGIC GATES AND CIRCUITSRockRahil100% (3)

- FAN7387 SMDDocument17 pagesFAN7387 SMDHung KdNo ratings yet

- Manual Mk7Document111 pagesManual Mk7Fernando NazarethNo ratings yet

- XPRO Manual Complete PDFDocument2 pagesXPRO Manual Complete PDFGibran Medina CardosoNo ratings yet

- Full Thesis ZBP-New 663157Document145 pagesFull Thesis ZBP-New 663157KaustubhDabeerNo ratings yet

- AH 480 DeviceList 20210719Document456 pagesAH 480 DeviceList 20210719Yu FelixNo ratings yet

- Cas CL3000 Service Manual PDFDocument94 pagesCas CL3000 Service Manual PDFPritam Joisar100% (1)

- Whirlpool PWA 830 A Service ManualDocument14 pagesWhirlpool PWA 830 A Service ManualIoana Ancuța MoiseNo ratings yet

- PhotodetectorsDocument46 pagesPhotodetectorsShivam AgarwalNo ratings yet

- Lecture17 PDFDocument19 pagesLecture17 PDFSuriya SkariahNo ratings yet

- Feed 304 M12 - M13, Feed 484 M12 - M13 R 0459 161 990 PDFDocument22 pagesFeed 304 M12 - M13, Feed 484 M12 - M13 R 0459 161 990 PDFMadalina LazarNo ratings yet

- Mercedes (DTC) 968590102650 20210422094641Document4 pagesMercedes (DTC) 968590102650 20210422094641Wtennessee GoesNo ratings yet

- Thessaloniki EstablishmentDocument220 pagesThessaloniki Establishmentzedbolete6704No ratings yet

- DF11 CatalogDocument14 pagesDF11 Catalogscualoboy2006No ratings yet

- Elsewedy EgyptDocument7 pagesElsewedy EgyptshenshNo ratings yet

- Plant specification and bill of quantityDocument4 pagesPlant specification and bill of quantitylewgne08No ratings yet

- Ece Smart QuillDocument21 pagesEce Smart QuillRajanikant UpadhyeNo ratings yet

- RangeLink UHF LRS Manual v1.3Document17 pagesRangeLink UHF LRS Manual v1.3lgenniferNo ratings yet

- HT2300 Satellite Router Installation GuideDocument64 pagesHT2300 Satellite Router Installation GuideT Bag100% (1)

- Afc 1563Document10 pagesAfc 1563Eugene FlexNo ratings yet

- Bus Bar Size CalculatorDocument6 pagesBus Bar Size CalculatorPrashanth RajuNo ratings yet

- Signals and Systems for Electrical EngineersDocument119 pagesSignals and Systems for Electrical EngineersJay MehtaNo ratings yet

- Nichiyu Fb10 30p Dc70 Series TrsDocument83 pagesNichiyu Fb10 30p Dc70 Series TrsJuli Nugroho SuSanto100% (1)