Professional Documents

Culture Documents

Magotteaux Braunverfrb ENDOC

Uploaded by

Selwyn MunatsiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magotteaux Braunverfrb ENDOC

Uploaded by

Selwyn MunatsiCopyright:

Available Formats

R. Härdtl, G.

Bolte, Heidelberg Cement Technology Center

A suitable measuring process for assessing the potential for brown

discoloration?

Magotteaux test for cement analysis

Yellowish to brownish discolorations restrict the quality of concrete products. These undesirable

discolorations are caused by small quantities of soluble iron ions brought to the concrete surface

through the pore system. There they can be bonded into the lime efflorescences that begins to form,

where already traces of them will cause yellowish to brownish discolorations of the crystal.

Discolorations of this kind that can be visually detected are triggered by a complex interaction of

numerous constitutive and process parameters. This begins with the choice of suitable constituent

materials of the concrete: cement, additions, admixtures and aggregate. Type, content and

granulometric distribution of the components play here a decisive role. The dense pore structure

required for the finished products can only be obtained with the proper mix and with appropriately

adjusted compaction. Temperature and air humidity, in particular during curing in the hours following

production and subsequent storage, significantly influence the type of discoloration as well as the time

at which they may occur.

Significance of the Magotteaux tests

Cement, as a possible source of water-soluble, divalent iron (FeO), is an essential constituent of

concrete. The Magotteaux Test [1] is recommended as a rapid and easy to perform analysis method

for semi-quantitative determination of the FeO content [2]. For the test, droplets of two defined

chemical solutions are applied to a cement or ground clinker specimen. The FeO content in the

specimen is then determined based on the resulting pink coloration of the solution (Table). The test

procedure is described in detail in [2]. In order to verify the precision of this test method for

determining the FeO content, various clinkers and cements were investigated. For this purpose,

clinkers were obtained from different cement plants as well as different types of cement. This provided

a representative cross-section of specimen materials. In parallel to the Magotteaux test, the exact FeO

contents in the specimens were ascertained by wet processing, using the typical titration of potassium

manganate solution.

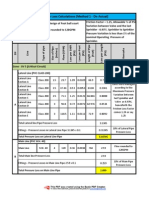

Table 1. Assessment of the FeO content based on theMagotteaux test

Figure 1: Color reaction in the Magotteaux test

A comparison of the test results from the two methods of analysis shows that no or only very small

quantities of FeO are contained in a sample when no color reaction occurs. On the other hand,

however, no reliable conclusion on the magnitude of the FeO content can be derived based on the

coloration. In an extreme case, for example, virtually no FeO was detected by the wet process, despite

a very strong color reaction (FeO content implicating > 0.16 M.-%). Looking at the results of the tests

in which slight color reactions occurred in the Magotteaux test, for example, a substantial number of

specimens were found to be within the relevant range of 0.04 to 0.08 M.-% FeO. On the other hand,

however, there was also a relatively great number of specimens where the actual FeO content was

found to be less or even clearly above (Figure).

Assessment of results

What are the possible causes for the poor conformity of the results? For the Magotteaux test, a

subjective classification of color reaction is required for conducting a simple test. Here, errors are

possible. But this alone can be no plausible explanation for the discrepancies determined. The

Magotteaux test was initially designed for obtaining oriented conclusions on the conditions prevailing

in the burning zone of a cement kiln. Its application therefore focused on the investigation of clinkers or

pure portland cements. During reaction with the test solutions not only divalent iron can be fused, but

other ferriferous constituents as well. Modern cements, such as composite cements as (CEM II) and

Blastfurnace slag cements (CEM III) contain in addition to clinker further constituents of cement. In

particular in cements containing granulated blast-furnace slag, strong color reactions are almost

invariably observed with the Magotteaux test, although the measured FeO contents are much lower.

Here, quite obviously, the Magotteaux test reacts strongly to the ferriferous constituents. A

dependence of the amount of granulated blast furnace slag contained in the cement could not be

established. Even the prescribed removal of the ferriferous constituents by magnets prior to the

analysis, did not change the results.

Summary

The conclusion that a strong reaction of the Magotteaux test in cements indicates an increased

potential for brown discoloration, is clearly not in line with verified practical experience. It is for

example a well known fact that in particular the use of cements containing granulated blast-furnace

slag is an effective measure for reducing the risk of brown discoloration. More recent findings show

moreover that the FeO content of a cement is a rather unsuitable parameter for assessing the

potential for brown discoloration in a cement [3]. The amount of FeO that is as a rule required for

causing brown discoloration is very low and virtually always present in concrete. Of much greater

significance is how the iron ions are dissolved and are transported to the surface of the concrete.

Against this background, the Magotteaux test, from our point of view, appears to be an unsuitable

measuring process for assessing the potential for brown discoloration in cement, both for reason of the

imprecise measuring results and the lack of lack of significance of the parameters determined.

Literature

[1] American Magotteaux Corporation: A rapid test for detecting reducing conditions in the kiln. Test

discription. Brentwood 1992 [2] Manns, W.: Zur Braunverfärbung von Betonwaren – Möglichkeit der

frühzeitigen Erkennung. Betonwerk + Fertigteil- Technik 68 (2002) Heft 11, S. 32–47

[3] Härdtl, R.; Bolte, G.; Tax, M.; Dienemann, W.: Das Braunverfärbungpotenzial von Zementen.

Cement International, Heft 4/2003 (erscheint in Kürze)

You might also like

- Lucky Internship ReportDocument29 pagesLucky Internship Reportسید عاصم علی شاہNo ratings yet

- Distribution of Sulfate Between Phases in Portland Cement ClinkersDocument7 pagesDistribution of Sulfate Between Phases in Portland Cement ClinkersNocifLyesNo ratings yet

- CementDocument59 pagesCementkamal21No ratings yet

- PILLARD AKTUEL Progressive BurningDocument3 pagesPILLARD AKTUEL Progressive BurningSteveih100% (1)

- Cement GlossaryDocument22 pagesCement GlossaryfyoveraNo ratings yet

- Epilux-78 Primer-Base (MSDS) PDFDocument4 pagesEpilux-78 Primer-Base (MSDS) PDFAkhtar aliNo ratings yet

- Clinker CoolerDocument5 pagesClinker CoolerManish VermaNo ratings yet

- Cement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Document20 pagesCement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Abay ShiferaNo ratings yet

- influenceofclinkerSO3onthecementcharacteristics PDFDocument9 pagesinfluenceofclinkerSO3onthecementcharacteristics PDFKeshab BasnetNo ratings yet

- A TEC Leaflet HURRICLON PDFDocument2 pagesA TEC Leaflet HURRICLON PDFthanh100% (1)

- Cement - Snapshot PackDocument9 pagesCement - Snapshot PackAnkit MishraNo ratings yet

- Alkali Activation of Natural Pozzolan For Geopolymer Cement ProductionDocument10 pagesAlkali Activation of Natural Pozzolan For Geopolymer Cement Productionyusef_behdari100% (7)

- Advanced Heat and MassDocument58 pagesAdvanced Heat and MassJonathan LokeNo ratings yet

- Perillex Bricks PDFDocument3 pagesPerillex Bricks PDFMuntandwe georgeNo ratings yet

- 4 - Pilot Scale Manufacture of LC3-Indian ExperienceDocument7 pages4 - Pilot Scale Manufacture of LC3-Indian ExperienceSakthivel ThangavelNo ratings yet

- Analysis of Dynamic Effects in A Rotary Kiln System Used For Iron ProductionDocument9 pagesAnalysis of Dynamic Effects in A Rotary Kiln System Used For Iron ProductionLuis Gabriel L. CatalanNo ratings yet

- Cement, Slag, Pozzolan, & Silica FumeDocument60 pagesCement, Slag, Pozzolan, & Silica Fumeog_double8699No ratings yet

- Cement Industry: Handy ManualDocument44 pagesCement Industry: Handy ManualMahmoudRadiNo ratings yet

- Variation of Feed Chemical Composition and Its Effect On Clinker Formation-Simulation ProcessDocument7 pagesVariation of Feed Chemical Composition and Its Effect On Clinker Formation-Simulation Processmohamadi42No ratings yet

- Fls - Cfi SiloDocument4 pagesFls - Cfi SiloNicolás CanelliNo ratings yet

- 71 LC3 The Cuban ExperienceDocument38 pages71 LC3 The Cuban ExperienceMirza BasitNo ratings yet

- Portland CementDocument40 pagesPortland CementMuhammad AreebNo ratings yet

- Cement Composition and Special Cements - Part 2Document14 pagesCement Composition and Special Cements - Part 2Kaushal KumarNo ratings yet

- Cpi FlamesDocument43 pagesCpi FlamesRobert Brown100% (1)

- Ask DR Clark Raw MaterialsDocument11 pagesAsk DR Clark Raw Materialsmareymorsy2822No ratings yet

- Novel Cements For Low Energy and Low EmissionDocument9 pagesNovel Cements For Low Energy and Low EmissionChinchu CherianNo ratings yet

- Performance Based Durability Design of A Bored Tunnel With Concrete LiningDocument10 pagesPerformance Based Durability Design of A Bored Tunnel With Concrete LiningHarold TaylorNo ratings yet

- 2 CementDocument37 pages2 CementEman SalehNo ratings yet

- 17.00 Loïc Pottier, Fives FCBDocument11 pages17.00 Loïc Pottier, Fives FCBMohd AliNo ratings yet

- Lab Ball Mill Testing of ClinkerDocument5 pagesLab Ball Mill Testing of ClinkerPrasann R NamannavarNo ratings yet

- Cement Chemistry 2016 BL1Document41 pagesCement Chemistry 2016 BL1Tyo Deka100% (1)

- ABOUT CEMENT & ITS USE - What Is Cement?Document5 pagesABOUT CEMENT & ITS USE - What Is Cement?Prasanjeet DebNo ratings yet

- Cement Kiln CapacityDocument2 pagesCement Kiln Capacityemad sabriNo ratings yet

- Effects of Clinker Grinding Aids On Flow of Cement Based MaterialsDocument11 pagesEffects of Clinker Grinding Aids On Flow of Cement Based MaterialsJaga JayNo ratings yet

- CementDocument42 pagesCementMadhavanIceNo ratings yet

- Bestway Cement Annual 15 AccountsDocument49 pagesBestway Cement Annual 15 AccountsM Umar FarooqNo ratings yet

- Upgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L SmidthDocument7 pagesUpgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L Smidthmail2quraishi3084No ratings yet

- Operacion 44Document44 pagesOperacion 44Nelly Isabel Narvaez PachecoNo ratings yet

- Final - Metex GroupDocument37 pagesFinal - Metex GroupVeluri HemanthNo ratings yet

- Hexavalent Chromium in Portland CementDocument5 pagesHexavalent Chromium in Portland Cementyinglv100% (1)

- Design of A Cement Plant For Producing 1Document20 pagesDesign of A Cement Plant For Producing 1Shehabul Hasan MamunNo ratings yet

- 118Document9 pages118Suhail KhanNo ratings yet

- Chemical Composition of Portland Cement 9Document2 pagesChemical Composition of Portland Cement 9Jorge CabreraNo ratings yet

- Type of Monolithic Refractories PDFDocument4 pagesType of Monolithic Refractories PDFNaelNo ratings yet

- Influence of SO3 On The Hydration HeatDocument10 pagesInfluence of SO3 On The Hydration HeatPaknubkNo ratings yet

- Portland Cement: Wednesday, March 25, 2015Document35 pagesPortland Cement: Wednesday, March 25, 2015EFRA BININo ratings yet

- Cement Plant Simulation and Dynamic Data PDFDocument8 pagesCement Plant Simulation and Dynamic Data PDFUsman HamidNo ratings yet

- 13 Pasuki - HeidelbergCementDocument37 pages13 Pasuki - HeidelbergCementJohnNo ratings yet

- Chemistry and Engineering of Cement Production. State of The Art. Sorretino PDFDocument8 pagesChemistry and Engineering of Cement Production. State of The Art. Sorretino PDFrmarin_90No ratings yet

- 10 Causes For Low Strength in ConcreteDocument17 pages10 Causes For Low Strength in ConcreteTatineni RaviNo ratings yet

- Meq 01 2015 0012Document17 pagesMeq 01 2015 0012Anonymous Ja3jvaXNo ratings yet

- Influence of Clinker So 3 On The Cement CharacteristicsDocument9 pagesInfluence of Clinker So 3 On The Cement CharacteristicsShakti Singh100% (1)

- Auto Clave ExpensionDocument11 pagesAuto Clave ExpensionSyed Kazam RazaNo ratings yet

- Xu CS 2020 0020Document10 pagesXu CS 2020 0020shri ramNo ratings yet

- Effect of Curing Temperature and Type of Cement On Early-Age Shrinkage of High-Performance ConcreteDocument6 pagesEffect of Curing Temperature and Type of Cement On Early-Age Shrinkage of High-Performance ConcreteSakthivel ThangavelNo ratings yet

- Articulo 2Document14 pagesArticulo 2gustavo vegaNo ratings yet

- Compatibility Between Polycarboxylate-Based Admixtures and Blended Cement PasteDocument12 pagesCompatibility Between Polycarboxylate-Based Admixtures and Blended Cement Pasteshihab44No ratings yet

- Insoluble ResidueDocument6 pagesInsoluble Residueemreg_gs06No ratings yet

- Setting Time and Bleeding of Concrete With Binary and Ternary CementsDocument10 pagesSetting Time and Bleeding of Concrete With Binary and Ternary Cementsmehdi_hoseineeNo ratings yet

- Advances in Materials Science for Environmental and Energy Technologies VIFrom EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiNo ratings yet

- Albert DocumentDocument6 pagesAlbert DocumentSelwyn MunatsiNo ratings yet

- 1-LafargeHolcim - Production Mail - Pareto Charts Week 11 PDFDocument3 pages1-LafargeHolcim - Production Mail - Pareto Charts Week 11 PDFSelwyn MunatsiNo ratings yet

- 01 Mono Channel BurnerDocument1 page01 Mono Channel BurnerSelwyn MunatsiNo ratings yet

- Law Society of Zimbabwe General Tariff 2019Document6 pagesLaw Society of Zimbabwe General Tariff 2019Selwyn Munatsi100% (1)

- 2Document6 pages2Selwyn MunatsiNo ratings yet

- (Conectores) SandhaasC Munch-AndersenJ DietschP DesignofConnectionsinTimberStructures PDFDocument332 pages(Conectores) SandhaasC Munch-AndersenJ DietschP DesignofConnectionsinTimberStructures PDFClaudio Ignacio Zurita MillónNo ratings yet

- ANNEX 9 - FacilitationDocument62 pagesANNEX 9 - FacilitationSyahid Macheda100% (1)

- Explain The Basic Elements of A C# Program. Illustrate Every Aspect Completely Through A Simple C# Program StructureDocument6 pagesExplain The Basic Elements of A C# Program. Illustrate Every Aspect Completely Through A Simple C# Program StructureishwarsumeetNo ratings yet

- Friction Loss Calculations of Irrigation Design A Foot Ball CourtDocument13 pagesFriction Loss Calculations of Irrigation Design A Foot Ball Courtmathewmanjooran100% (2)

- WCA Time Critical: (Formerly Known As VCK Air BV)Document43 pagesWCA Time Critical: (Formerly Known As VCK Air BV)zeta100% (1)

- MECH 370 - Modeling, Simulation and Control Systems, Final Examination, 09:00 - 12:00, April 15, 2010 - 1/4Document4 pagesMECH 370 - Modeling, Simulation and Control Systems, Final Examination, 09:00 - 12:00, April 15, 2010 - 1/4Camila MayorgaNo ratings yet

- EZstrip O&M Manual PDFDocument60 pagesEZstrip O&M Manual PDFJesus S. QuijadaNo ratings yet

- Cat Reforming Part 2 3 PDF FreeDocument68 pagesCat Reforming Part 2 3 PDF FreeLê Trường AnNo ratings yet

- HN1000 HN2000Document44 pagesHN1000 HN2000Mose SodeNo ratings yet

- Flashcarder Project ProposalDocument2 pagesFlashcarder Project ProposalrydeNo ratings yet

- MEMS-Based Uncooled Infrared Bolometer Arrays - A ReviewDocument15 pagesMEMS-Based Uncooled Infrared Bolometer Arrays - A ReviewMarco LicofonteNo ratings yet

- Stanley 46 InstructionsDocument2 pagesStanley 46 Instructionsj_abendstern4688No ratings yet

- DP Misc Wnt5 x86-32 ChangelogDocument5 pagesDP Misc Wnt5 x86-32 ChangelogBrandal KalocyNo ratings yet

- Green Pin Shackles - Certificates Overview and Specifications - 0Document1 pageGreen Pin Shackles - Certificates Overview and Specifications - 0Eduardo SolanoNo ratings yet

- 24 - Article - $mbps Vs $MHZ Why Is This ImportantDocument2 pages24 - Article - $mbps Vs $MHZ Why Is This ImportantShiraz SiddiqNo ratings yet

- Ram Structural SystemDocument234 pagesRam Structural Systemlavy100% (1)

- Epanet Vs Watergems (083011)Document9 pagesEpanet Vs Watergems (083011)MABA02100% (1)

- Valtra Tractor All Model Diagnostics and Programming ManualDocument22 pagesValtra Tractor All Model Diagnostics and Programming Manualpicax1879100% (17)

- Lean Thinking Redefines O&M PracticesDocument10 pagesLean Thinking Redefines O&M PracticesAsel Juárez ViteNo ratings yet

- PPE Microproject Report.Document14 pagesPPE Microproject Report.JAMES BOND100% (2)

- Copeland Scroll Compressors For Refrigeration Zs09kae Zs11kae Zs13kae Application Guidelines en GB 4214008Document24 pagesCopeland Scroll Compressors For Refrigeration Zs09kae Zs11kae Zs13kae Application Guidelines en GB 4214008Cesar Augusto Navarro ChirinosNo ratings yet

- Diprotic Acid Titration Calculation Worked Example Sulphuric Acid and Sodium Hydroxide - mp4Document2 pagesDiprotic Acid Titration Calculation Worked Example Sulphuric Acid and Sodium Hydroxide - mp4tobiloba temiNo ratings yet

- SVT-RM10: Remote Control UnitDocument2 pagesSVT-RM10: Remote Control UnitJOGITELENo ratings yet

- Operating Systems: Credits: 4 Credits Course Coordinator: V.V.SubrahmanyamDocument4 pagesOperating Systems: Credits: 4 Credits Course Coordinator: V.V.SubrahmanyamHarendra KumarNo ratings yet

- Jeppiaar SRR Engineering College: Title: Smart Wearble Health Monitoring For Patient/Elder PeopleDocument12 pagesJeppiaar SRR Engineering College: Title: Smart Wearble Health Monitoring For Patient/Elder PeopleKurushNishanthNo ratings yet

- Planning For Procurement of Construction ContractsDocument41 pagesPlanning For Procurement of Construction ContractsJoel AlcantaraNo ratings yet

- Silhouette Training NotesDocument33 pagesSilhouette Training NotesMichael Lester67% (3)

- Ionic Equations & Redox ReactionsDocument6 pagesIonic Equations & Redox ReactionsAyaanNashidNo ratings yet

- Excel ExercisesDocument37 pagesExcel ExercisesBERNIELLE DAVE FALDASNo ratings yet

- System Theory - Model ExamDocument2 pagesSystem Theory - Model ExamrajapandiyaNo ratings yet