Professional Documents

Culture Documents

Graphene Composites for Conventional and Additive Manufacturing

Uploaded by

CHELVASEROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Graphene Composites for Conventional and Additive Manufacturing

Uploaded by

CHELVASERCopyright:

Available Formats

Graphene Based composites for conventional and additive manufacturing

Amaya Ortega, Begoña Galindo

AIMPLAS, Parque Tecnológico Gustave Eiffel 4 Aptdo Correos 51, 46980, Paterna, Valencia, Spain

aortega@aimplas.es

Abstract (Arial 10)

Graphene-based composites manufactured on a lab scale have been shown to exhibit impressive

properties over unreinforced polymers. A small percentage of graphene within a polymer matrix can

significantly improve its strength, stiffness and electrical conductivity, however the material remains

prohibitively expensive for large-scale use as a composite reinforcement. Therefore, the concept for this

project is to develop the knowledge-based processing methods required to up-scale the production of

graphene and expanded graphite reinforced thermoplastic masterbatches and compounds and,

ultimately, enable its industrial commercialisation in Europe. The work is focused on developing

processes for large scale rapid production of graphene reinforced plastic intermediate materials, which

can be integrated into current conventional and additive manufacturing processes.

Injection moulding, extrusion blow moulding and film extrusion are all well-established moulding

methods for producing parts at very high throughputs. Compounds and masterbatches are commonly

used in these processes, and the graphene reinforced thermoplastic compounds and masterbatches will

simply fit into the existing manufacturing chain, enabling the functionality of these materials to be

applied to high volume components.

Additive Manufacturing (AM) is a process of joining materials to make objects from 3D model data,

usually layer upon layer, as opposed to subtractive manufacturing methodologies such as machining.

The biggest advantage of additive manufacturing is the flexibility in the production due to a tool free

process, which also reduces the costs and the time to market of new products. Due to the layered

nature of the part generation, additive manufacturing can deliver unique materials, structures and

properties.

Graphene and expanded graphite based materials have been developed and optimise nanocomposite

processing parameters - both for conventional processes such as injection moulding and film extrusion;

and for additive manufacturing processes, including selective laser sintering and fused deposition

modelling.

The research leading to these results has received funding from the European Community's Seventh

Framework Programme FP7/2007-2013 under grant agreement n° 285718.(Nanomaster project)

References

[1] Chua Ck, Leong KF,Lim CS. Rapid Prototyping: Principles and applications.3rd Edition, World

scientific. (2003)

[2] B Galindo, S Gil Alcolea, J Gómez, A Navas, A Ortega Murguialday, M Pérez Fernandez and R C

Puelles. Effect of the number of layers of graphene on the electrical properties of TPU polymers. IOP

Conference Series: Materials Science and Engineering Volume 64 conference 1 (2014)

You might also like

- Fleet ManagementDocument8 pagesFleet ManagementDiana LorenaNo ratings yet

- 29 OPF Safety Program Manual - Welding and CuttingDocument7 pages29 OPF Safety Program Manual - Welding and CuttingMonica LeonNo ratings yet

- Technical Report PDFDocument184 pagesTechnical Report PDFSrinivasan RajenderanNo ratings yet

- Instruction Manual STR 155 RL-1Document24 pagesInstruction Manual STR 155 RL-1VENDI100% (3)

- Mass Production of High Quality Graphene An Analysis of Worldwide PatentsDocument12 pagesMass Production of High Quality Graphene An Analysis of Worldwide PatentsSrramNo ratings yet

- An Overview On Current Manufacturing Technologies: Processing Continuous Rovings Impregnated With Thermoset ResinDocument26 pagesAn Overview On Current Manufacturing Technologies: Processing Continuous Rovings Impregnated With Thermoset ResinRaif SakinNo ratings yet

- Lightning Protection System Testing & Commissioning Method StatementDocument3 pagesLightning Protection System Testing & Commissioning Method Statementvin ssNo ratings yet

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- Properties of LPGDocument33 pagesProperties of LPGmukund madhav100% (2)

- Grouting in Rock TunnellingDocument161 pagesGrouting in Rock TunnellingOanaNo ratings yet

- Evaluation of A New "Inlineprepreg" Process ApproachDocument20 pagesEvaluation of A New "Inlineprepreg" Process ApproachDmitry GrenishenNo ratings yet

- Processes and Properties of Polymer Composites Used For Additive ManufacturingDocument4 pagesProcesses and Properties of Polymer Composites Used For Additive ManufacturingSantiago OrtizNo ratings yet

- ADHESIVE BONDING Broschuere 2804 en KlebtechnikDocument8 pagesADHESIVE BONDING Broschuere 2804 en KlebtechnikRuxandra CozmanciucNo ratings yet

- Fused Deposition Modeling of Polypropylene MaterialsDocument9 pagesFused Deposition Modeling of Polypropylene MaterialsLucas VillalobosNo ratings yet

- Materials Today Communications: SciencedirectDocument8 pagesMaterials Today Communications: SciencedirectJavier MunozNo ratings yet

- Current Opinion in Solid State & Materials Science: Chao Hu, Qing-Hua QinDocument26 pagesCurrent Opinion in Solid State & Materials Science: Chao Hu, Qing-Hua Qinmohd asrofi muslimNo ratings yet

- Wear Assessment of 3-D Printed Parts of PLA (Polylactic Acid) Using Taguchi Design and Artificial Neural Network (ANN) TechniqueDocument16 pagesWear Assessment of 3-D Printed Parts of PLA (Polylactic Acid) Using Taguchi Design and Artificial Neural Network (ANN) TechniqueArturo CervantesNo ratings yet

- Abs TgaDocument10 pagesAbs TgaArtaNo ratings yet

- Additive Manufacturing: Alberto Boschetto, Luana Bottini, Francesco VenialiDocument11 pagesAdditive Manufacturing: Alberto Boschetto, Luana Bottini, Francesco VenialiAbdullah UYSALNo ratings yet

- Polymers 13 03697Document17 pagesPolymers 13 03697hykiNo ratings yet

- FDM 3D Printing Of: High Performance Composite MaterialsDocument5 pagesFDM 3D Printing Of: High Performance Composite MaterialsDigvijayNo ratings yet

- Influence of Extruder's Nozzle Diameter On The Improvement of Functional Properties of 3D-Printed PLA ProductsDocument18 pagesInfluence of Extruder's Nozzle Diameter On The Improvement of Functional Properties of 3D-Printed PLA Productsrio_sanmedNo ratings yet

- Durão2019 Article OptimizingAdditiveManufacturinDocument23 pagesDurão2019 Article OptimizingAdditiveManufacturinAlamNo ratings yet

- Carbon Fibre Manufacturing CostsDocument8 pagesCarbon Fibre Manufacturing CostsGabriel Piñana NaharroNo ratings yet

- Materials 14 01162Document16 pagesMaterials 14 01162Mihai Edward GheorgheNo ratings yet

- Optimization of FDM 3D printing using Taguchi techniqueDocument12 pagesOptimization of FDM 3D printing using Taguchi techniquekuldeep sharmaNo ratings yet

- Two ShortDocument14 pagesTwo ShortTrịnh HugoNo ratings yet

- Laminated Strong Eco-Material For Building Contruction Made of Cellulose-Strengthened WoodDocument4 pagesLaminated Strong Eco-Material For Building Contruction Made of Cellulose-Strengthened Woodportillo63No ratings yet

- 1 s2.0 S0263822318301818 MainDocument11 pages1 s2.0 S0263822318301818 MainBishal DuttaNo ratings yet

- Composites Part A: SciencedirectDocument8 pagesComposites Part A: SciencedirectRitik RajNo ratings yet

- Polymer Testing: SciencedirectDocument18 pagesPolymer Testing: SciencedirectjeanNo ratings yet

- AM of Ceramic Based MaterialsDocument26 pagesAM of Ceramic Based MaterialsGuglielmoCelleraiNo ratings yet

- Automated Layup and FormingDocument148 pagesAutomated Layup and FormingSamora Tooling EngineerNo ratings yet

- Polyethylene Painting ProcessDocument8 pagesPolyethylene Painting ProcessHotnCrispy CrispyNo ratings yet

- Additive Manufacturing of High Density Carbon Fibre Rein - 2022 - Additive ManufDocument10 pagesAdditive Manufacturing of High Density Carbon Fibre Rein - 2022 - Additive ManufGUANCI ZHUNo ratings yet

- Numerical and Experimental Study of Compression Properties of PLA Manufactured with FDMDocument17 pagesNumerical and Experimental Study of Compression Properties of PLA Manufactured with FDMsiyu chenNo ratings yet

- ExtraInfo E InternetDocument68 pagesExtraInfo E InternetLuis Alberto StanziolaNo ratings yet

- Optimization of The Diaphragm Forming Process With Regard To Product Quality and CostDocument12 pagesOptimization of The Diaphragm Forming Process With Regard To Product Quality and CostclaradwisNo ratings yet

- Graphene Oxide Overprints For Flexible and Transparent ElectronicsDocument6 pagesGraphene Oxide Overprints For Flexible and Transparent ElectronicsEwa SNo ratings yet

- 1 s2.0 S0142941823000296 MainDocument15 pages1 s2.0 S0142941823000296 Mainkumar mandyaNo ratings yet

- Fabrication of Complex 3D Composites by Fusing Automated Fiber Placement (AFP) and Additive Manufacturing (AM) TechnologiesDocument12 pagesFabrication of Complex 3D Composites by Fusing Automated Fiber Placement (AFP) and Additive Manufacturing (AM) TechnologiesAnalfabetas Vacas Pitas Do Ask e afinsNo ratings yet

- Optimization of Isotactic Polypropylene Nanocomposite Content of Tungsten Carbide For Material Extrusion 3D PrintingJournal of Composites ScienceDocument23 pagesOptimization of Isotactic Polypropylene Nanocomposite Content of Tungsten Carbide For Material Extrusion 3D PrintingJournal of Composites ScienceAris NasNo ratings yet

- Bahloul 1Document1 pageBahloul 1De TeNo ratings yet

- 3DP 2021 0304 Collado - 1P - RdoradoDocument12 pages3DP 2021 0304 Collado - 1P - RdoradoCarolina MuñizNo ratings yet

- The lab-to-fab journey of 2D materialsDocument3 pagesThe lab-to-fab journey of 2D materialsSergio Graniero EcheverrigarayNo ratings yet

- Screw Extrusion Based 3D Printing, A Novel Additive Manufacturing TechnologyDocument7 pagesScrew Extrusion Based 3D Printing, A Novel Additive Manufacturing TechnologyPaulo Canedo da SilvaNo ratings yet

- Prospectus AalenDocument12 pagesProspectus Aalenasim_ietNo ratings yet

- Materials Today: Proceedings: M. Shunmugasundaram, Maughal Ahmed Ali Baig, M. Ajay KumarDocument5 pagesMaterials Today: Proceedings: M. Shunmugasundaram, Maughal Ahmed Ali Baig, M. Ajay Kumarfatima ibrahimNo ratings yet

- A Review On Fibre Reinforced Composite Printing Via FFFDocument17 pagesA Review On Fibre Reinforced Composite Printing Via FFFAnilNo ratings yet

- Reinforcing Polypropylene With Graphene-Polylactic Acid MicrocapsulesDocument9 pagesReinforcing Polypropylene With Graphene-Polylactic Acid MicrocapsulesLucas VillalobosNo ratings yet

- Thickning OperationDocument10 pagesThickning OperationHabtamu GeremewNo ratings yet

- Application of Taguchis Experimental Design and Range Analysis in Optimization of FDM Printing Parameters For Pet G Pla and HipsDocument12 pagesApplication of Taguchis Experimental Design and Range Analysis in Optimization of FDM Printing Parameters For Pet G Pla and HipsMohammedrafficNo ratings yet

- E3sconf Eece18 02004Document5 pagesE3sconf Eece18 02004dariamonastyrevaNo ratings yet

- Brochure Composites enDocument4 pagesBrochure Composites enAnonymous r3MoX2ZMTNo ratings yet

- Manufacture of natural fiber-reinforced polyurethane composites using LFIDocument3 pagesManufacture of natural fiber-reinforced polyurethane composites using LFIAshokan KelothNo ratings yet

- Optimization of FFF Processing Parameters To Improve Geometrical Accuracy and Mechanical Behavior of Polyamide 6 Using Grey Relational Analysis (GRA)Document29 pagesOptimization of FFF Processing Parameters To Improve Geometrical Accuracy and Mechanical Behavior of Polyamide 6 Using Grey Relational Analysis (GRA)nader zirakNo ratings yet

- 1 s2.0 S0032386121003578 MainDocument9 pages1 s2.0 S0032386121003578 MainSahin CoskunNo ratings yet

- Pre Proposal: Project AcronymDocument21 pagesPre Proposal: Project AcronymCarmen PlapcianuNo ratings yet

- s00521-022-07370-7 (2)Document17 pagess00521-022-07370-7 (2)JyotisMan BorahNo ratings yet

- CIRP Annals - Manufacturing Technology: L.M. Galantucci (1), F. Lavecchia, G. PercocoDocument4 pagesCIRP Annals - Manufacturing Technology: L.M. Galantucci (1), F. Lavecchia, G. PercocoRajendra MandaNo ratings yet

- New Niche Markets: For The Pulp and Paper Industry WasteDocument4 pagesNew Niche Markets: For The Pulp and Paper Industry WasteNicolas Chacon SanchezNo ratings yet

- Introduction:-: Showed Major ProblemsDocument3 pagesIntroduction:-: Showed Major Problemsmech mech1No ratings yet

- Additive Manufacturing For Composites FDM Introduction - en EbookDocument10 pagesAdditive Manufacturing For Composites FDM Introduction - en Ebook3603985huNo ratings yet

- GrapheneDocument6 pagesGrapheneshfgakasgNo ratings yet

- 1 s2.0 S2214785323025750 MainDocument8 pages1 s2.0 S2214785323025750 MainThanusha ReddyNo ratings yet

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsFrom EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNo ratings yet

- SAMDocument38 pagesSAMCHELVASERNo ratings yet

- Gmail - RedBus Ticket - TN4C62887027Document2 pagesGmail - RedBus Ticket - TN4C62887027CHELVASERNo ratings yet

- Phase IDocument16 pagesPhase ICHELVASERNo ratings yet

- SAMDocument38 pagesSAMCHELVASERNo ratings yet

- Mastering CAD CAM PDFDocument846 pagesMastering CAD CAM PDFsureshNo ratings yet

- 2015 Ortega Amaya Aortega@Aimplas - Es TNT2015OrtegaAmayaDocument10 pages2015 Ortega Amaya Aortega@Aimplas - Es TNT2015OrtegaAmayaCHELVASERNo ratings yet

- Rapid Tooling Technologies & Industrial ApplicationsDocument267 pagesRapid Tooling Technologies & Industrial ApplicationsDenis Cabrera Anaya100% (1)

- Udroiu RDocument8 pagesUdroiu RCHELVASERNo ratings yet

- Welding Cutting ProgramDocument31 pagesWelding Cutting ProgramCHELVASERNo ratings yet

- Graphene Composites for Conventional and Additive ManufacturingDocument1 pageGraphene Composites for Conventional and Additive ManufacturingCHELVASERNo ratings yet

- Spot The Errors 300-350 QuestionsDocument4 pagesSpot The Errors 300-350 QuestionsCHELVASERNo ratings yet

- Chapter - 3 Review of LiteratureDocument17 pagesChapter - 3 Review of LiteratureCHELVASERNo ratings yet

- 193 198 PMR Jul15Document6 pages193 198 PMR Jul15Richu JoeNo ratings yet

- 03 AbstractDocument4 pages03 AbstractCHELVASERNo ratings yet

- Mastering CAD CAM PDFDocument846 pagesMastering CAD CAM PDFsureshNo ratings yet

- New India Two-Wheeler InsuranceDocument2 pagesNew India Two-Wheeler InsuranceCHELVASER100% (1)

- Spot The Errors 351-400 SolutionDocument2 pagesSpot The Errors 351-400 SolutionCHELVASERNo ratings yet

- Spot The Errors 351-400 QuestionsDocument5 pagesSpot The Errors 351-400 QuestionsCHELVASERNo ratings yet

- DartDocument4 pagesDartCHELVASERNo ratings yet

- Mastering CAD CAM PDFDocument846 pagesMastering CAD CAM PDFsureshNo ratings yet

- Spot The Errors 351-400 SolutionDocument2 pagesSpot The Errors 351-400 SolutionCHELVASERNo ratings yet

- IBPS Clerk RecruitmentDocument47 pagesIBPS Clerk RecruitmentTopRankersNo ratings yet

- M.e.cad Cam. - 3Document40 pagesM.e.cad Cam. - 3Gnaneswaran NarayananNo ratings yet

- 80 DAYS Study Plan For SBI PO Prelims 2017Document5 pages80 DAYS Study Plan For SBI PO Prelims 2017CHELVASERNo ratings yet

- Syllogisms Possibility Questions PracticeDocument3 pagesSyllogisms Possibility Questions PracticeCHELVASERNo ratings yet

- Brandt M FR Btd500blnDocument74 pagesBrandt M FR Btd500blnStéphane JoussetNo ratings yet

- Dedi Kristiawan: Personal DetailDocument5 pagesDedi Kristiawan: Personal DetaildedyNo ratings yet

- Mycom Nims ProptimaDocument4 pagesMycom Nims ProptimasamnemriNo ratings yet

- Effectiveness Ntu MethodDocument4 pagesEffectiveness Ntu MethodBen Musimane100% (1)

- Goodyear Brochure Bandas-48Document1 pageGoodyear Brochure Bandas-48DavidNo ratings yet

- Catalogo DeltaDocument2 pagesCatalogo DeltaHelena ChagasNo ratings yet

- 200E ManualDocument56 pages200E ManualManoj KrishnanNo ratings yet

- Petri Net Modeling and ApplicationsDocument13 pagesPetri Net Modeling and ApplicationsRishiraj SenguptaNo ratings yet

- Figure 6-1. Frame Accessories Battery Figure 6-1. Frame Accessories BatteryDocument31 pagesFigure 6-1. Frame Accessories Battery Figure 6-1. Frame Accessories BatteryalopezvillavicencioNo ratings yet

- Dokumen - Tips Carte Ford C Max 2007Document278 pagesDokumen - Tips Carte Ford C Max 2007Rostás MiklósNo ratings yet

- Pressure Regulators (DRV Valve) Suitable ForDocument4 pagesPressure Regulators (DRV Valve) Suitable ForNOUREDDINE BERCHAOUANo ratings yet

- PI Digital Panel Indicator - B0Document7 pagesPI Digital Panel Indicator - B0dtoxidNo ratings yet

- International Log Building StandardsDocument19 pagesInternational Log Building Standardsursind100% (1)

- GEC - Sample Resume For StudentsDocument2 pagesGEC - Sample Resume For StudentsNiketNo ratings yet

- SN 761672 ADocument19 pagesSN 761672 ANhất TríNo ratings yet

- Internship Report-1Document64 pagesInternship Report-1VIJAY SPNo ratings yet

- Catalogo - CATUDocument132 pagesCatalogo - CATUxis-zeroNo ratings yet

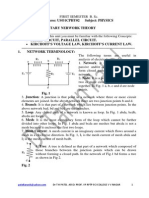

- Us01cphy02 Unit 1 2014 THPDocument18 pagesUs01cphy02 Unit 1 2014 THPapi-264723824No ratings yet

- Hybrid or Standard?: Why The Urge To "Go Green"Document20 pagesHybrid or Standard?: Why The Urge To "Go Green"Tyler McPhersonNo ratings yet

- Partitioned Data Set Extended Usage Guide Guide: Front CoverDocument364 pagesPartitioned Data Set Extended Usage Guide Guide: Front CoverCsutka PocsNo ratings yet

- Abbreviations Plumbing Symbols: Fort Worth DistrictDocument21 pagesAbbreviations Plumbing Symbols: Fort Worth DistrictDenzel NgNo ratings yet

- Genesis of Spalling in Tandem Mill Work-RollsDocument9 pagesGenesis of Spalling in Tandem Mill Work-Rolls54321qazNo ratings yet

- Baja Parts Catalog PX250S Motorcycle VIN Prefix LUAHDocument20 pagesBaja Parts Catalog PX250S Motorcycle VIN Prefix LUAHholycostNo ratings yet

- Bluskies Engineering PVT LTD: Acp Panel Inpection ReportDocument7 pagesBluskies Engineering PVT LTD: Acp Panel Inpection ReportRavi Shankar KolluruNo ratings yet