Professional Documents

Culture Documents

LS-043 HTX Spec Sheet

Uploaded by

Santo EOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LS-043 HTX Spec Sheet

Uploaded by

Santo ECopyright:

Available Formats

Separator Type & Performance

The removal of specific unwanted solids from a pumped/pressurized fluid flow

system shall be accomplished with a centrifugal-action vortex separator. Solids

removal efficiency is principally predicated on the difference in specific

gravity between the liquid and the solids. Fluid viscosity must be 100 SSU or

less.

In a single pass through the separator, given solids with a specific gravity of

2.6 and water at 1.0, performance is expected to be 98% of 74 microns and

larger. Additionally, particles finer in size, heavier by specific gravity and

some lighter by specific gravity will also be removed, resulting in an

appreciable aggregate removal of particles (up to 75%) as fine as 5 microns.

In a recirculating system, 98% performance is predictable to as fine as 40

microns (given solids with a specific gravity of 2.6), with correspondingly

higher aggregate performance percentages (up to 90%) of solids as fine as 5

microns.

Performance Requirement

Separator performance must be supported by published independent test results

from a recognized and identified test agency. Standard test protocol of

upstream injection, downstream capture and separator purge recovery is allowed

with 50-200 mesh particles to enable effective, repeatable results. Single-pass

test performance must not be less than 95% removal. Model tested must be of the

same flow-design series as specified unit.

Separator Design & Function

A tangential inlet and mutually tangential internal accelerating slots shall be

employed to promote the proper velocity necessary for the removal of the

separable solids. The internal accelerating slots shall be spiral-cut for

optimum flow transfer, laminar action and particle influence into the separation

barrel. The separator's internal vortex shall allow this process to occur

without wear to the accelerating slots.

Separated particle matter shall spiral downward along the perimeter of the inner

separation barrel, in a manner which does not promote wear of the separation

barrel, and into the solids collection chamber, located below the vortex

deflector plate.

To ensure maximum particle removal characteristics, the separator shall

incorporate a vortex-induced pressure relief line (Vortube), drawing specific

pressure and fluid from the separator's solids collection chamber via the outlet

flow's vortex/venturi effect, thereby efficiently encouraging solids into the

collection chamber without requiring a continuous underflow or excessive system

fluid loss.

System fluid shall exit the separator by following the center vortex in the

separation barrel and spiral upward to the separator outlet.

Purging & Solids Handling

Evacuation of separated solids shall be accomplished automatically, employing a

dedicated solid-state controller in a NEMA 4 housing. Available for worldwide

single-phase voltages of 24VAC to 250VAC. Programming options to include a purge

frequency range of every 60 seconds to every 23 hours, 59 minutes. Purge

duration options range from 10 seconds to 59 minutes, 59 seconds. Non-volatile

memory. Meets CSA requirements. This controller shall automatically operate one

of the following techniques:

Motorized Ball Valve - An electrically-actuated valve shall be programmed at

appropriate intervals and duration in order to efficiently and regularly purge

solids from the separator's collection chamber. Valve body shall be bronze

(optional stainless steel also available). Valve ball shall be stainless steel

with sealant seat. Valve size: ______

Pneumatic Ball Valve - A fail-safe valve shall be programmed at appropriate

intervals and duration in order to efficiently and regularly purge solids from

the separator's collection chamber. A spring-control shall provide that this

full-port valve closes in the event that compressed air or electricity is

interrupted. Valve body shall be bronze (optional stainless steel also

available). Valve ball shall be stainless steel with sealant seat. Valve size:

_______

Solids Recovery Vessel - Separated solids shall be continuously purged under

controlled flow into a vessel equipped with one (or three, depending on the

model specified) 25-micron fiberfelt solids collection bag. Solids collection

capacity: 360 cubic inches (6 liters). If larger vessel is specified: 1080 cubic

inches (18 liters). Excess liquid shall pass through the bag and return to

system flow via the separator's integral Vortube, eliminating any need for

piping return flow to the system pump's suction line.

If optional Indicator Package has been specified: System also includes manual

isolation valves for use when servicing the collection bag; sightglass for

verification of flow through the vessel; annunciator for indicating when the

collector bag needs cleaning/replacement; flow control orifice to minimize fluid

volume/velocity through the vessel and collector bag; clamps, tubing and

specialty piping for completing the system assembly.

Systemization (a specified option only)

The separator and its accessories shall be packaged as a complete system, with

all componentry from a single source. In addition to the equipment already

specified, the system shall also include pressure gauges with petcock valves for

both the inlet and outlet of the separator and an isolation valve at the purge

outlet for servicing of the automatic valve as necessary without interrupting

system flow.

A connection spool shall also be included for installation on the separator's

outlet to properly facilitate the separator's internal access feature.

Separator Details

A. Inlet & outlet shall be grooved connections, size: _______

B. Purge outlet shall be threaded with screw-on flange, size: _______

C. The separator shall operate within a flow range of: _________

D. Pressure loss shall be between 3-12 psi (.2 - .8 bar), remaining constant,

varying only when the flow rate changes.

Separator Construction

The separator shall feature the following access capabilities for either

inspection or the removal of unusual solids/debris:

--An upper-chamber full-size grooved coupling, allowing complete access to the

inlet chamber, acceleration slots and internal separation barrel

--A hand-hole port at the collection chamber (model HTX-0285 and larger only)

--A 1/2-inch inspection/drain, located at the lowest point of the upper chamber

The separator shall be constructed of A-36, A-53B or equivalent quality carbon

steel, minimum thickness of .25 inches (6.35 mm). Maximum operating pressure

shall be 150 psi (10.3 bar), unless specified otherwise.

Paint coating shall be acrylic urethane, spray-on, gloss black.

Separator Source & identification

The separator shall be manufactured by LAKOS Filtration Systems,

a division of Claude Laval Corporation in Fresno, California USA.

Specific model designation is: __________________

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- 5 Steps To A 5 AP Physics C 2017 - McGraw-HillDocument299 pages5 Steps To A 5 AP Physics C 2017 - McGraw-HillRishit Kalra100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pumps and SystemsDocument5 pagesPumps and SystemsDhi AdhiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- RA-Chlorination & Disinfectionof Water Supply SystemDocument11 pagesRA-Chlorination & Disinfectionof Water Supply SystemSanto ENo ratings yet

- Method Statement For Installation of Steam RoomDocument10 pagesMethod Statement For Installation of Steam RoomSanto E0% (1)

- Method Statement For Installation of Steam RoomDocument10 pagesMethod Statement For Installation of Steam RoomSanto E0% (1)

- Method Statement For Gi Puddle Flanges InstallationDocument1 pageMethod Statement For Gi Puddle Flanges InstallationSanto E0% (1)

- Measuring Length of Pipe in BendsDocument1 pageMeasuring Length of Pipe in Bendsamacathot06100% (1)

- MS Sanitary Ware Inst.Document12 pagesMS Sanitary Ware Inst.Santo ENo ratings yet

- Metallic Pipe Pressure Testing MethodDocument18 pagesMetallic Pipe Pressure Testing MethodEmirhan Pay100% (1)

- Fans BlowersDocument143 pagesFans BlowersRoudy J. Mhawas50% (2)

- Lacos Sweeping Basin SystemDocument18 pagesLacos Sweeping Basin SystemSanto ENo ratings yet

- Kit de Joint de Verin CaterpillarDocument2 pagesKit de Joint de Verin CaterpillarzephyrinNo ratings yet

- Method Statement for Water, Stormwater and Sewer PipelinesDocument4 pagesMethod Statement for Water, Stormwater and Sewer Pipelinesمحمد عاشورNo ratings yet

- Smokevent Calculation..Document2 pagesSmokevent Calculation..Karthy GanesanNo ratings yet

- 200 20 Pi DTS 00008Document72 pages200 20 Pi DTS 00008ritesh142No ratings yet

- Finite Element Analysis of Unreinforced Masonry Walls: MahammedDocument14 pagesFinite Element Analysis of Unreinforced Masonry Walls: MahammedSaad HneidiNo ratings yet

- 602.0 Bucket Shower - MSSDocument10 pages602.0 Bucket Shower - MSSSanto ENo ratings yet

- Method Statement For Installation of HammamDocument10 pagesMethod Statement For Installation of HammamSanto ENo ratings yet

- 2301.0 Hammam Steam - MSSDocument10 pages2301.0 Hammam Steam - MSSSanto ENo ratings yet

- Method Statement For Installation of LoungersDocument10 pagesMethod Statement For Installation of LoungersSanto ENo ratings yet

- Method Statement For Installation of Large PoolDocument9 pagesMethod Statement For Installation of Large PoolSanto ENo ratings yet

- Method Statement For Installation of HammamDocument10 pagesMethod Statement For Installation of HammamSanto ENo ratings yet

- 701.0 Plunge Pool - MSSDocument9 pages701.0 Plunge Pool - MSSSanto ENo ratings yet

- Method Statement For Installation of Whirl PoolDocument9 pagesMethod Statement For Installation of Whirl PoolSanto ENo ratings yet

- 601.0 Experience Shower - MSSDocument10 pages601.0 Experience Shower - MSSSanto ENo ratings yet

- Method Statement For Installation of Sauna RoomDocument10 pagesMethod Statement For Installation of Sauna RoomSanto ENo ratings yet

- Installation Manual for Water Intake ScreensDocument98 pagesInstallation Manual for Water Intake ScreensSanto ENo ratings yet

- DOC8517-202-Installation Quality PlanDocument17 pagesDOC8517-202-Installation Quality PlanSanto ENo ratings yet

- Vertical Turbine Canal Recirculation & CT Make-Up Water PumpDocument37 pagesVertical Turbine Canal Recirculation & CT Make-Up Water PumpSanto ENo ratings yet

- Iom Vertical Turbine PumpDocument33 pagesIom Vertical Turbine PumpSanto ENo ratings yet

- MS Boiler & CalorifierDocument14 pagesMS Boiler & CalorifierSanto ENo ratings yet

- Pn419742 Car Park O&mDocument12 pagesPn419742 Car Park O&mirfanNo ratings yet

- Multi Cell Assembly Cooling Tower PDFDocument32 pagesMulti Cell Assembly Cooling Tower PDFSanto ENo ratings yet

- Installation Manual: Air Conditioner Indoor Unit Floor/Ceiling TypeDocument15 pagesInstallation Manual: Air Conditioner Indoor Unit Floor/Ceiling TypeSanto ENo ratings yet

- York (Closed Control Unit)Document10 pagesYork (Closed Control Unit)Santo ENo ratings yet

- Design of crane runway girdersDocument4 pagesDesign of crane runway girdersHamdi AslanNo ratings yet

- Lee's Disc Apparatus (Theory) Heat & Thermodynamics Virtual LDocument3 pagesLee's Disc Apparatus (Theory) Heat & Thermodynamics Virtual LReddyvari VenugopalNo ratings yet

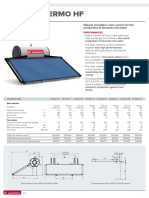

- Kairos Thermo HF Natural Circulation Solar System for Domestic Hot Water ProductionDocument4 pagesKairos Thermo HF Natural Circulation Solar System for Domestic Hot Water ProductionFILID MADNo ratings yet

- Wheatly XDocument2 pagesWheatly XElinton SarmientoNo ratings yet

- CCMC Canadian Code Compliance Evaluation - National Research Council CanadaDocument14 pagesCCMC Canadian Code Compliance Evaluation - National Research Council CanadaMark AdamsNo ratings yet

- 6100 6200 Tractors Europe Edition IntroductionDocument16 pages6100 6200 Tractors Europe Edition Introductionceli gimNo ratings yet

- Asme 314Document2 pagesAsme 314JoelHernandezGonzalezNo ratings yet

- Production and Industrial EngineeringDocument27 pagesProduction and Industrial EngineeringShivangi MishraNo ratings yet

- AMP Summer Question Paper (Msbte Study Resources)Document4 pagesAMP Summer Question Paper (Msbte Study Resources)Varad DateNo ratings yet

- Thermal Relief Valves: From The Automation List Department..Document1 pageThermal Relief Valves: From The Automation List Department..Sofyan HadiNo ratings yet

- Salford Journal of Bridge Engineering Jan-18Document24 pagesSalford Journal of Bridge Engineering Jan-18Swaminathan VivekananthamNo ratings yet

- Chemical Engg. 3rd SemDocument3 pagesChemical Engg. 3rd SemAVERAGENo ratings yet

- HW3 Spring19Document2 pagesHW3 Spring19Alex Williams0% (1)

- ME8091 Automobile Engineering1Document2 pagesME8091 Automobile Engineering1AyyanrajNo ratings yet

- Identification Markings for Fasteners GuideDocument87 pagesIdentification Markings for Fasteners GuideasdfagNo ratings yet

- Mini Fragment Implants and InstrumentsDocument13 pagesMini Fragment Implants and InstrumentsMarc KleinNo ratings yet

- Mould Ejection OptDocument50 pagesMould Ejection OptMohamed HassanNo ratings yet

- How Carburetors Work: Understanding the Six Main SystemsDocument7 pagesHow Carburetors Work: Understanding the Six Main Systemssaithea25No ratings yet

- Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ)Document2 pagesErp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ)José Ramón Devan DevanNo ratings yet

- Yfm35Fgx Yfm35Fax Yfm35Fgx Yfm35Fgx: (5UHL) (5UHM) (5UHN) (5UHP)Document0 pagesYfm35Fgx Yfm35Fax Yfm35Fgx Yfm35Fgx: (5UHL) (5UHM) (5UHN) (5UHP)Cristiano Marcelo Oliveira MelloNo ratings yet

- DE-18 Fuel Oil Injection Pump and Device Parts ListsDocument6 pagesDE-18 Fuel Oil Injection Pump and Device Parts ListsK.l. DhanaNo ratings yet

- Mechanism and Robot Kinematics: Anirvan DasguptaDocument122 pagesMechanism and Robot Kinematics: Anirvan Dasguptaसुमित शर्माNo ratings yet

- Tractor Operator AgricultureDocument9 pagesTractor Operator AgricultureConstantin CarpenNo ratings yet

- Certificado - Flange Adapter 125MM - XindaDocument3 pagesCertificado - Flange Adapter 125MM - XindaGR CarlosNo ratings yet