Professional Documents

Culture Documents

RWF40 Universal Burner Controller

Uploaded by

RamadanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RWF40 Universal Burner Controller

Uploaded by

RamadanCopyright:

Available Formats

865

7

ISO 9001

Universal Burner

Controllers RWF40...

RWF40... complete with housing

The RWF40... is a compact universal digital boiler temperature / pressure

controller providing functions designed specifically for the control of heat

generating plant.

The RWF40... and this data sheet are intended for use by OEMs which

integrate the controller in their products.

Mechanical design The RWF40... is supplied complete with housing for flush panel mounting.

The controller is matched to the controlled variable and the required setpoint range by

making parameter settings.

The control parameters can be set and optimized while the burner is running.

All settings are made with four buttons located on the unit front and are directly

displayed.

LEDs on the front indicate the following operational statuses:

– Control ON / OFF

– Positioning pulses OPEN or CLOSE for driving the burner's air damper when using

modulating burner control, or stage I / stage II when using two-stage burner control

– Position of the configurable contact «K6»

– Manual control ON / OFF

– «Two-stage» operating mode

During operation, the digital displays above the LEDs show the setpoint (green), the

actual value (red) and – when making parameter settings - the relevant parameters.

Landis & Staefa Division CC1N7865E August 03, 1999 1/6

Warning notes To avoid injury to persons, damage to property or the environment, the

following warning notes should be observed!

It is not permitted to open, interfere or modify the controller!

• When selecting the cables, when making the installation and the electrical

connections, observe the regulations of VDE 0100 «Erection of power installations

with rated voltages below AC 1000 V» and the relevant national regulations!

• The electrical connections may only be made by authorized staff!

• Provide double-pole isolation of the controller from the mains supply if there is a risk

of touching live parts while work is carried out!

Installation notes Please observe the notes given in the user documentation CC1B7865E!

Service notes • For service purposes, the controller can be removed from its housing with no need

for tools.

• The electrical connections are made via the screw terminals located at the rear of

the housing.

Type summary Controller with RWF40.000A97

– three-position output

– housing

– fixing material and seal

Controller with RWF40.001A97

– three-position output

– analog output

– housing

– fixing material and seal

Controller with RWF40.002A97

– three-position output

– analog output

– RS-485 port

– housing

– fixing material and seal

Accessory Adapter frame for replacing the RWF32... ARG40

Technical data

Mains voltage AC 100...240 V ±10 % Power consumption approx. 8 VA

Mains frequency 50...60 Hz Safety extra low voltage DC 24 V

Safety class II to DIN 0631 Perm. contact rating of the control outputs (relays

«K1...K3»)

- Up to 2 x 105 switching cycles 2 A; AC 24...240 V

Mounting orientation optional - Up to 107 switching cycles 0,1 A; AC 24...240 V

Terminals for 2 x 1.5 mm² or 1 x 2.5 mm² Weight (complete with housing) approx. 760 g

Environmental conditions Recommended actuator running time 15...60 s

Transport

Temperature range -40...70 °C Degree of protection of housing

Humidity < 75 % r.h. - Front IP65, EN 60529

Operation - Base IP20, EN 60529

Temperature range -20...50 °C

Humidity < 75 % r.h. CE conformity

Condensation, formation of ice and According to the directives of the European Union

Ingress of water are not permitted! Electromagnetic compatibility EMC

according to NAMUR recommendation

NE 21, EN 50081 Part 1 and EN 50082 Part 2

2/6 CC1N7865E August 03, 1999 Landis & Staefa Division

Function The RWF40... provides the following functions:

– One digital PID controller with a three-position or analog output (optional)

– To control two-stage burners, the RWF40... can be switched over to provide two-

position control

– Automatic thermostat (or pressurestat) function in low-flame operation

– One shift controller for weather-dependent setpoint shifting

– One minimum limiter and one maximum limiter for the boiler temperature or

the boiler pressure

– One limit thermostat to DIN 3440

– One potential-free configurable contact

– Manual operating mode

– Communication via serial port (option)

– Self-setting function

3 analog inputs Release of burner

Input 1: Output 1

Boiler temperature - Relay (N. O. contact)

for Pt100, Ni100, Pt1000,

thermocouple or standard

signals

Input 2: 3-position outout

External setpoint, O ut put 2:

setpoint shifting - Re la y ( re gulating unit op en)

for 0...1 k resistor

or standard signals O ut put 3:

without linearization - Re la y ( re gulating unit c los ed)

Input 3:

Outside tem peratur e

for Pt1000, Ni1000 Limit comparator

Output 4:

- Relay (N. O. contact)

2 binary inputs Power supply measuring

F or potential-free c ontacts transducer

DC 24 V, 30 mA

Input 1: (short-circuit-proof)

Operating m ode

c hangeover

Modulating output

Input 2:

Output 5:

Setpoint shifting /

c hangeover

DC 0...10 V, D C 2...10 V

0...20 mA, 4...20 mA

Serial port

Power supply

RS-485

AC 100...240 V MOD bus protocol

48...63 Hz ±10 % Baud rate 9600

786 5d 01 e/08 99

Type suffix / option

Block structure

Function of the

controller when used for

burner control

Low-flame operation In low-flame operation, the RWF40... operates like a control thermostat or

pressurestat.

This means that it operates as a two-position controller maintaining the required

setpoint by switching the burner on and off.

The switching differential for two-position operation can be adjusted within a wide

range.

If the demand for heat increases, the controller switches to high-flame operation only

when an adjustable limit is exceeded.

This function is aimed at optimizing the burner's switching ratio.

High-flame operation, In that case, the RWF40... operates as a two-position controller with adjustable

two-stage control switching thresholds.

Using the relays of the three-position output, the RWF40... drives the actuator to the

1st and 2nd output stage.

In this operating mode, the optional analog output switches between the minimum

signal for the 1st stage and the maximum output signal for the 2nd stage.

Landis & Staefa Division CC1N7865E August 03, 1999 3/6

High-flame operation, In that case, the RWF40... operates as a PID / PI controller with a three-position

modulating control output without position feedback signals or, optionally, with a modulating output.

By making use of its self-setting facility, the RWF40... is able to determine the PID /

PI control parameters, or the parameters can be set manually.

Binary input 1 Using a potential-free contact, the RWF40... can be switched from the modulating

(changeover of mode to two-stage operation.

operating mode)

Binary input 2 In the case of setpoint shifting, the current setpoint is shifted by an adjustable

(setpoint shifting or amount.

setpoint changeover) Setpoint changeover provides changeover between two setpoints adjusted on the

RWF40... controller.

If analog input 2 is set to the external setpoint, changeover is provided between the

setpoint adjusted on the RWF40... and an external setpoint.

Limit comparator Potential-free contact «K6» can be assigned a number of functions.

Example: limit value supervision

Operation Four buttons on the unit front are used to operate and program the RWF40...

During operation and programming, the seven-segment displays show the parameter

values and parameter names.

Weather-dependent The controller's standard configuration ex works is such that when connecting a

setpoint shifting QAC22 outside sensor, automatic changeover to weather-dependent setpoint shifting

takes place.

The signal delivered by the QAC2... outside sensor may not be fed parallel to

several RWF40...!

Analog input 1 To acquire the actual value, a number of sensors can be connected to the RWF40...

(actual value at sensor)

Measurement range

Two- or three-wire Pt100 / IEC 751 -200...+850 °C

resistance sensors Pt1000 / IEC 751 -200...+850 °C

Ni100 / DIN 43760 -60...+230 °C

Ni1000 / DIN 43760 -60...+230 °C

L&S-Ni1000 -50...+160 °C

Thermocouples NiCr-Ni / type «K» -200...+1372 °C

Cu-Cu-Ni / type «U» -200...+400 °C

NiCroSil-NiSil / type -100...+1300 °C

«N»

FeCuNi / type «J» -200...+1000 °C

Linearized 0...20 mA Scaleable -1999...+9999

standard signals 4...20 mA Scaleable -1999...+9999

DC 0...10 V Scaleable -1999...+9999

DC 0...1 V Scaleable -1999...+9999

To power provided for the measuring transducers is DC 24 V / 30 mA.

Analog input 2 Feeding a signal to analog input 2, the controller's setpoint can be influenced.

(external setpoint shift The influence can be scaled.

or external setpoint)

The following signals can be used:

– Input signals DC 0...1 V, DC 0...10 V, 0...20 mA or 4...20 mA

– 1 kΩ potentiometer in a two-wire circuit

4/6 CC1N7865E August 03, 1999 Landis & Staefa Division

Connection diagram Temperature and pressure control on a dual-fuel burner.

(basic diagram) Burner control and supervision are provided by burner control type LAL... or LFL...

Note – DC 24 V at terminals «G+» and «G-» is used for powering the QBE620... pressure

sensor!

RWF40

L N G1+ M1 B9 M9 XB6 M6 Q 13 Q14 Y1 Y2 Q D1 GND D2

LAL..., L FL...

int. ext.

4 5 18 19 9 11 10 20

ST

BS

B M B M 102

QAE... QAC...

M R

BV1

LK

N v a z m

FZA... SQ...

M

~ MIN.

0 RV

G AS

I BV 1 BV2

L OIL

N

7865a01/0799

RWF40

L N G+ U1- M1 G- XU6 M6 Q 13 Q14 Y1 Y2 Q D1 GND D2

LAL..., LFL... int. ext.

4 5 18 19 9 11 10 20

ST

BS

G B M 102

QBE620...

0...10 V BV1

LK

a z m

FZA... N v

SQ...

M

~ MIN.

0 RV

GAS

I BV 1 BV2

L OIL

N

7865a02/0799

Legend a Limit switch for air damper position QAE... Immersion temperature sensor

«OPEN» QBE... Pressure sensor

BS Operation selector RV Gas control damper

1 = «gas» S1 Internal / external setpoint switch (E)

(modulating burner control) SQ... Actuator of burner's air damper

2 = «oil» and gas control damper

(two-stage burner control) ST Connections of burner control's

BV... Fuel valve start control loop

FZA... Remote setpoint adjuster v Auxiliary switch for the release

(active when «S1» is closed) of the second fuel valve depending

L... Burner control on the air damper position

LK Burner's air damper z Limit switch for the fully «CLOSED»

m (MIN) Auxiliary switch for controlling the position of the air damper

low-flame operation

QAC... Outside sensor for weather-dependent

setpoint shifting

Landis & Staefa Division CC1N7865E August 03, 1999 5/6

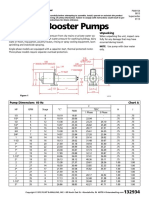

Dimensions Dimensions in mm

48

SIEMENS

91,5

96

K6

P GM E XI T

Landis& StaefaRWF40

112

43,5

Panel cutout to DIN 43700

45+0,6

127,5

92+0,8

7865m01e/0899

15,5

ARG40 adapter frame

7865m02/0799

1999 Landis & Staefa Produktion GmbH

6/6 CC1N7865E August 03, 1999 Landis & Staefa Division

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Big Five Personality TestDocument3 pagesBig Five Personality Testchandu_jjvrpNo ratings yet

- Mastercam Book 5 Axis Bai 1Document31 pagesMastercam Book 5 Axis Bai 1tuanvn76100% (3)

- Lorry AirBrakesDocument3 pagesLorry AirBrakesEnache CristinaNo ratings yet

- Monitor Transformer Temperatures with PC-414R IndicatorDocument4 pagesMonitor Transformer Temperatures with PC-414R IndicatorMKNo ratings yet

- Modern Machine Shop 262180-MAR 2014Document228 pagesModern Machine Shop 262180-MAR 20141mmahoneyNo ratings yet

- Bashar Discusses Monatomics, White Powder Gold and Ormus MineralsDocument32 pagesBashar Discusses Monatomics, White Powder Gold and Ormus MineralsFlorin V. Iagaru100% (6)

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- RWF40 N7865Document10 pagesRWF40 N7865miguel_alfonzo216314No ratings yet

- Prca S2 T 200Document6 pagesPrca S2 T 200RoxanneNo ratings yet

- TeSys Ultra - LUCM32BLDocument4 pagesTeSys Ultra - LUCM32BLNur Awwaluddin ZNo ratings yet

- ABB - Ugaoni Servomotor 100 NMDocument11 pagesABB - Ugaoni Servomotor 100 NMMiroslav ProdanaNo ratings yet

- tmg740 3Document6 pagestmg740 3tespakNo ratings yet

- PRCA S2 T - DatasheetDocument4 pagesPRCA S2 T - DatasheetaniketNo ratings yet

- ISO 9001 certified burner control box technical guideDocument6 pagesISO 9001 certified burner control box technical guideVijay BhureNo ratings yet

- Vari Level Lb3 - BrochureDocument12 pagesVari Level Lb3 - BrochureAlexNo ratings yet

- Type EA15 IOMDocument7 pagesType EA15 IOMAlan CNo ratings yet

- Rob50 221 Siemens Temperature ControllerDocument5 pagesRob50 221 Siemens Temperature ControlleradamsvillanuevaNo ratings yet

- Symphony Plus Combustion Instrument MultiDocument28 pagesSymphony Plus Combustion Instrument MultiAjinkyaNo ratings yet

- SQN 90 Dumper ActuarorDocument9 pagesSQN 90 Dumper ActuarorRomica CiorneiNo ratings yet

- LD-B10-10 Temperature Controller User GuideDocument22 pagesLD-B10-10 Temperature Controller User GuideFareh KhanNo ratings yet

- ELCOS CAM-120/10 Manual for Firmware Version 1.31Document12 pagesELCOS CAM-120/10 Manual for Firmware Version 1.31محمد باسل100% (2)

- 95C 10939efsDocument40 pages95C 10939efsBobNo ratings yet

- Usph 2011Document3 pagesUsph 2011Victor AdamitaNo ratings yet

- Technical specifications and data sheet for BELIMO basic rotary actuator AG230Document3 pagesTechnical specifications and data sheet for BELIMO basic rotary actuator AG230Trai Nhà NôngNo ratings yet

- Pana40+ Controller DatasheetDocument3 pagesPana40+ Controller DatasheetRadoNo ratings yet

- Fenwal 35-65 & 35-66Document8 pagesFenwal 35-65 & 35-66salquintero74No ratings yet

- Linear Actuator La25 Data Sheet EngDocument40 pagesLinear Actuator La25 Data Sheet EngEdgarjavier Loor SolorzanoNo ratings yet

- Actuator LA25: Data SheetDocument24 pagesActuator LA25: Data SheetMohamedKecibaNo ratings yet

- MODEL PC-252 - Transformer Temperature IndicatorDocument6 pagesMODEL PC-252 - Transformer Temperature IndicatorMKNo ratings yet

- Es60 26 ND9000 SMC ValmetDocument20 pagesEs60 26 ND9000 SMC ValmetJosé Angel ZabaletaNo ratings yet

- Electric Actuator EPI2Document6 pagesElectric Actuator EPI2ilkinNo ratings yet

- MANUAL Electronic Controls and Valves (RWR462)Document19 pagesMANUAL Electronic Controls and Valves (RWR462)Cezary50% (2)

- DS8792 Standard EU enDocument17 pagesDS8792 Standard EU enItss Mee HadiNo ratings yet

- 7SF/7SC Temperature Controllers for Applications Requiring Autotuning, RS-485 & DisplayDocument10 pages7SF/7SC Temperature Controllers for Applications Requiring Autotuning, RS-485 & DisplayZul FaijarNo ratings yet

- Sensitive Hall-Effect Switches For High-Temperature OperationDocument8 pagesSensitive Hall-Effect Switches For High-Temperature Operationesmailee1400No ratings yet

- Caterpillar XQ30 Towable Diesel Generator SetDocument5 pagesCaterpillar XQ30 Towable Diesel Generator SetMacAllister Machinery100% (1)

- Actuating DXR2Document7 pagesActuating DXR2Mark Izsm AmersonNo ratings yet

- MODEL PC-171 - Transformer Temperature IndicatorDocument6 pagesMODEL PC-171 - Transformer Temperature IndicatorMKNo ratings yet

- XQ30Document5 pagesXQ30NimaNo ratings yet

- SQNDocument22 pagesSQNare_reeNo ratings yet

- Controlador para Calderetea de Motores Lmo44.255 - 38ld0015Document10 pagesControlador para Calderetea de Motores Lmo44.255 - 38ld0015Pablo AllosiaNo ratings yet

- Comparador de Temperatura AcDocument24 pagesComparador de Temperatura Acjose alberto nava martinezNo ratings yet

- W7212 Honeywell EconomiserDocument24 pagesW7212 Honeywell EconomiserSean ByrneNo ratings yet

- DLG 974/976 Gas Burner Safety ControlDocument6 pagesDLG 974/976 Gas Burner Safety ControlPodaruNo ratings yet

- 95C 10939Document12 pages95C 10939Cvijic DejanNo ratings yet

- Superheat Controller RWR462.10Document23 pagesSuperheat Controller RWR462.10Pep FiguerasNo ratings yet

- Direct-Coupled Damper Actuators for Modulating and Floating ControlDocument8 pagesDirect-Coupled Damper Actuators for Modulating and Floating ControlLindEtjulietcapulet KplesetmontagueNo ratings yet

- Rotary limit switch controls industrial machine movementDocument16 pagesRotary limit switch controls industrial machine movementAhmad DagamsehNo ratings yet

- MVH3K Valve Actuator Specifications and Technical DetailsDocument3 pagesMVH3K Valve Actuator Specifications and Technical DetailsSyed Mohammad NaveedNo ratings yet

- Eight-Channel, Digital Input Terminals, 24 VDocument2 pagesEight-Channel, Digital Input Terminals, 24 VtadiganeshNo ratings yet

- Manual de ValvulaDocument16 pagesManual de ValvulaRene CalliriNo ratings yet

- Manual Honeywell DLG 976 (En)Document6 pagesManual Honeywell DLG 976 (En)Fernando M. AlaveNo ratings yet

- Satronic DKO 970 - 972Document6 pagesSatronic DKO 970 - 972legion ptomonttNo ratings yet

- Geothermal EnergyDocument9 pagesGeothermal EnergyRafael FloresNo ratings yet

- NM24A-MF-TP 1 0 enDocument8 pagesNM24A-MF-TP 1 0 enJuanNo ratings yet

- Fuji Electric PXZ Series PID Autotune ControllersDocument78 pagesFuji Electric PXZ Series PID Autotune ControllersByron Maximiliano Vargas UrbinaNo ratings yet

- Rotary Limit Switch GF4CDocument16 pagesRotary Limit Switch GF4CIvan PimentelNo ratings yet

- Servomotor Cu Arc de RevenireDocument3 pagesServomotor Cu Arc de Revenirestefan_c_petreNo ratings yet

- (TER) Pendant Control Station AlphaDocument12 pages(TER) Pendant Control Station AlphaCristi LazarNo ratings yet

- Roadheader Starter 2.0 Smart Switchgear Boosts Mining SafetyDocument4 pagesRoadheader Starter 2.0 Smart Switchgear Boosts Mining SafetyYousef AlipourNo ratings yet

- Technical Data Sheet Nrfa-S2Document3 pagesTechnical Data Sheet Nrfa-S2Dave PotterNo ratings yet

- Integritas Industrial Battery Charger: Application Industries FeaturesDocument4 pagesIntegritas Industrial Battery Charger: Application Industries Featurescelimo0710No ratings yet

- Quemador BrahmaDocument4 pagesQuemador BrahmaClaudio VerdeNo ratings yet

- Rittal Chiller Blue e - Targeted Cooling Output With Exce 5 4813Document12 pagesRittal Chiller Blue e - Targeted Cooling Output With Exce 5 4813Madhura MaheshNo ratings yet

- FWPB Booster Pumps InstructionsDocument15 pagesFWPB Booster Pumps InstructionsRamadanNo ratings yet

- RWF40 Universal Burner ControllerDocument6 pagesRWF40 Universal Burner ControllerRamadanNo ratings yet

- 749 PDFDocument1 page749 PDFRamadanNo ratings yet

- RWF40 Technical LiteratureDocument57 pagesRWF40 Technical LiteratureRamadanNo ratings yet

- RWF40 Technical LiteratureDocument57 pagesRWF40 Technical LiteratureRamadanNo ratings yet

- How To Review A Book in Up To 5,000 Words: First StepsDocument3 pagesHow To Review A Book in Up To 5,000 Words: First StepsAnnaNo ratings yet

- LD Lab ManualDocument92 pagesLD Lab ManualSunil BegumpurNo ratings yet

- What Is Creole Language - Definition & PhrasesDocument2 pagesWhat Is Creole Language - Definition & PhrasesGabriel7496No ratings yet

- Practical File Class XDocument5 pagesPractical File Class XJaiNo ratings yet

- Product PlanningDocument23 pagesProduct PlanningGrechen CabusaoNo ratings yet

- Porter's Five Forces: Submitted by Subham Chakraborty PGDMDocument5 pagesPorter's Five Forces: Submitted by Subham Chakraborty PGDMSubham ChakrabortyNo ratings yet

- Operator Interface SERIES 300 Device Platform EAGLE OS ET-316-TXDocument6 pagesOperator Interface SERIES 300 Device Platform EAGLE OS ET-316-TXDecoNo ratings yet

- Adjustment: - Electronic Modulated Air SuspensionDocument2 pagesAdjustment: - Electronic Modulated Air SuspensionThar KyiNo ratings yet

- Bachelor of Science in Tourism Management: Iloilo City Community College Ge 1. Understanding The SelfDocument4 pagesBachelor of Science in Tourism Management: Iloilo City Community College Ge 1. Understanding The SelfPaula Danielle HachuelaNo ratings yet

- Memory Slim CBLT PDFDocument4 pagesMemory Slim CBLT PDFMichell ben ManikNo ratings yet

- Chlorine (Free or Total) Manual For Test Kits CN-70, CN-70F, CN-70TDocument6 pagesChlorine (Free or Total) Manual For Test Kits CN-70, CN-70F, CN-70TDemétrius Ivo FernandesNo ratings yet

- MECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Document10 pagesMECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Wan Mohd AfnanNo ratings yet

- Usg Sheetrock® Brand Acoustical SealantDocument3 pagesUsg Sheetrock® Brand Acoustical SealantHoracio PadillaNo ratings yet

- ĐỀ CƯƠNG ÔN TẬP HỌC KÌ 1-LỚP 12Document15 pagesĐỀ CƯƠNG ÔN TẬP HỌC KÌ 1-LỚP 12Anh Duc VuNo ratings yet

- Load of Pedstrain On FobDocument26 pagesLoad of Pedstrain On FobPOOJA VNo ratings yet

- Tutorial Quartus II Simulation VHDLDocument27 pagesTutorial Quartus II Simulation VHDLHeitor B. S. BezerraNo ratings yet

- Meinrad 2018 All Symbols With NumbersDocument4 pagesMeinrad 2018 All Symbols With NumbersXer N. AcostaNo ratings yet

- KL 8052N User ManualDocument33 pagesKL 8052N User ManualBiomédica HONo ratings yet

- CSC309 Extra Credit 1Document5 pagesCSC309 Extra Credit 1Fluffy BagelzNo ratings yet

- Vision and Mission Analysis ChapterDocument15 pagesVision and Mission Analysis Chapterzaza bazazaNo ratings yet

- Ethics UNAM IsakDocument74 pagesEthics UNAM IsakIsak Isak IsakNo ratings yet

- Starting and Configuring Crontab in CygwinDocument2 pagesStarting and Configuring Crontab in CygwinSamir BenakliNo ratings yet

- Open Newel StaircaseDocument4 pagesOpen Newel StaircaseSujan Dhoj KhadkaNo ratings yet

- DHP UM 015 IHP24 HART User ManualDocument70 pagesDHP UM 015 IHP24 HART User Manualkumar ambujNo ratings yet