Professional Documents

Culture Documents

WB56S E7016-1

Uploaded by

cwiksjCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WB56S E7016-1

Uploaded by

cwiksjCopyright:

Available Formats

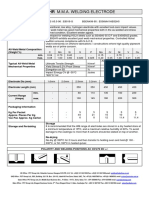

WB56S M.M.A.

WELDING ELECTRODE

Classifications & Approvals AWS A5.1-04 : E7016-1

Approvals LRS : 3YCMnLT40 ABS 4Y

Product Description Thinly coated low hydrogen electrode for all-positional welding, yielding metal of very

high impact values. Especially suitable for making full penetration welds in all

positions such as pipe and overhead butt welds. Excellent de-slag & re-strike.

Applications Recommend for the welding of unalloyed, micro-alloyed and low alloy steels within the

medium tensile class. Excellent impact values down to -40°C, it is widely used for

offshore fabrications. Eminently suitable for root pass welding on TKY Joints.

All-Weld Metal Composition

(Weight %) C Mn Si S P Mo Cr Ni V Cu

min. 0.05 1.40 0.20 - - - - - - -

max. 0.10 1.60 0.50 0.015 0.020 0.05 0.05 0.10 0.02 0.08

Typical All-Weld Metal Ultimate Tensile Strength N/mm² 524

Mechanical Properties Yield Stress/0.2% Proof Stress N/mm² 424

Elongation on 5D % 31

Impact Energy CV @ -46°C Joules 164

As-welded

Electrode Dia (mm) 1.6mm 2.0mm 2.5mm 3.2mm 4.0mm 5.0mm 6.0mm

Electrode Length (mm) - - 350 450 450 450 450

min. - - 60 105 140 160 220

Current Range

(Amps) max. - - 90 140 170 200 250

Packaging Information

Kg Per Vac-Pac - - 2 2 2 2 2

Approx. Pieces Per Kg - - 50 26 17 11 8

Vac Pac Approx. Kg Carton - - 20 20 20 20 20

Storage and Re-Drying Storage

It is recommended that the WB range of electrodes are stored in a dry heated store at

a minimum temperature of 18°C, and a maximum relative humidity of 60%. To avoid

damage to the coatings no more than 6 cartons should be staked on top of another.

Re-drying if standard packaging

Re-dry @ 350°C for 2 hours and then transfer to holding oven and hold @ 100 -

200°C, or 50-100°C in heated quiver.

Current Conditions AC OCV70 DC +/- and Welding Positions

You might also like

- Ams 5596K PDFDocument8 pagesAms 5596K PDFadiNo ratings yet

- Metal Z PurlinsDocument4 pagesMetal Z PurlinstonyNo ratings yet

- Metrode WPS SuperduplexDocument4 pagesMetrode WPS SuperduplexClaudia Mms100% (3)

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Sandvik Coromant2011Document64 pagesSandvik Coromant2011Trần Huỳnh Hoàng KhangNo ratings yet

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganNo ratings yet

- All Materials DocumentsDocument1 pageAll Materials DocumentsHarnish BariaNo ratings yet

- Aluminium Rail CoachDocument7 pagesAluminium Rail CoachdselvakuuNo ratings yet

- IIW IWE SyllabusDocument27 pagesIIW IWE SyllabusAnonymous hNpF6INo ratings yet

- Shrinkage in Ductile IronDocument5 pagesShrinkage in Ductile Ironkarthikkanda100% (1)

- Pre - Painted Color Steel Sheet (PCM) & (VCM)Document4 pagesPre - Painted Color Steel Sheet (PCM) & (VCM)Shahariar Sabbir0% (1)

- End MillsDocument140 pagesEnd MillsGuru PrasadNo ratings yet

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78No ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb2000e E6013Document1 pageWb2000e E6013cwiksjNo ratings yet

- Wb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2Document1 pageWb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2lathasri78No ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Shielded Power Inductors - MOS6020Document2 pagesShielded Power Inductors - MOS6020mauricio alfonsoNo ratings yet

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Maxflux SAF-8 (LS) : Agglomerated Basic Flux For Submerged Arc WeldingDocument1 pageMaxflux SAF-8 (LS) : Agglomerated Basic Flux For Submerged Arc WeldingPrashant KumarNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Electrode Booklet F Web 20Document1 pageElectrode Booklet F Web 20satnamNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Document1 pageL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Az 850Document2 pagesAz 850Aravindh RaNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- American - Zettler AZ732 053 52 DatasheetDocument2 pagesAmerican - Zettler AZ732 053 52 DatasheetZoro DNo ratings yet

- 253 MA-NF AC/DC: Covered ElectrodesDocument1 page253 MA-NF AC/DC: Covered ElectrodesElMacheteDelHuesoNo ratings yet

- 12a DPST Miniature Power RelayDocument2 pages12a DPST Miniature Power RelaykarkeraNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- α α α α CBH CBV Cbr-V / Cbr-H: AlphaDocument2 pagesα α α α CBH CBV Cbr-V / Cbr-H: AlphaCecep MarfuNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- Electrode Booklet F Web 22Document1 pageElectrode Booklet F Web 22satnamNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- Az847 5Document2 pagesAz847 5SarathBattaNo ratings yet

- Primacore MW 71Document2 pagesPrimacore MW 71rjan7peNo ratings yet

- Da2319 AldDocument1 pageDa2319 Aldjawali supriyoNo ratings yet

- Wire Wound Fixed Resistors: FeaturesDocument7 pagesWire Wound Fixed Resistors: FeaturesteoilcaNo ratings yet

- 70cuni TigDocument3 pages70cuni TigGiannhs SeitaridhsNo ratings yet

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembeNo ratings yet

- T90 A230xsmdDocument2 pagesT90 A230xsmdhgfgffgfggffgNo ratings yet

- Technical Report (CSF-81TM)Document5 pagesTechnical Report (CSF-81TM)matiasg.sanchezv95No ratings yet

- 02112015000000B - Boehler FOX EASN 25 M - CeDocument1 page02112015000000B - Boehler FOX EASN 25 M - CeABNo ratings yet

- Tri-Rated Rev005Document2 pagesTri-Rated Rev005Jean Pierre Goossens100% (1)

- Duplex MetrodeDocument6 pagesDuplex Metrodeandresrojas25No ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- N004 - Daiko Strip 625Document1 pageN004 - Daiko Strip 625cwiksjNo ratings yet

- K034 - Daikoflux 940Document1 pageK034 - Daikoflux 940cwiksjNo ratings yet

- Robo TiPTiG Data Sheet FinalDocument2 pagesRobo TiPTiG Data Sheet FinalcwiksjNo ratings yet

- Carboklad Cr36 Data SheetDocument1 pageCarboklad Cr36 Data SheetcwiksjNo ratings yet

- Hardfacing Wood Chipper KnivesDocument1 pageHardfacing Wood Chipper KnivescwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- IN150 ProHeat 35 WaterCooled Induction System EnglishDocument4 pagesIN150 ProHeat 35 WaterCooled Induction System EnglishCARLOSNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Utp 068 HHDocument1 pageUtp 068 HHRoberto_PrrNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- Meeting Minutes Roberts RulesDocument1 pageMeeting Minutes Roberts RulessaeedNo ratings yet

- A Max WearplateDocument1 pageA Max WearplatecwiksjNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb2000e E6013Document1 pageWb2000e E6013cwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- SS-000-15200-0106 - 02 General Welding RequirementsDocument37 pagesSS-000-15200-0106 - 02 General Welding RequirementsNima SharifiNo ratings yet

- 18 Octt MetallurgyDocument13 pages18 Octt MetallurgyAmit KumarNo ratings yet

- A789 PDFDocument4 pagesA789 PDFmahmoud hanafiNo ratings yet

- Denso Paste S105Document2 pagesDenso Paste S105sattar12345No ratings yet

- Surface Hardening of SteelDocument50 pagesSurface Hardening of SteelTeptep GonzalesNo ratings yet

- Galvanising ProcessDocument13 pagesGalvanising ProcesschepurthiNo ratings yet

- Corus Tinplate Packaging Products Range 2006Document8 pagesCorus Tinplate Packaging Products Range 2006gtorre77No ratings yet

- Carbon Alloy Steel Stainless SteelDocument4 pagesCarbon Alloy Steel Stainless Steelaswar_mhNo ratings yet

- CHM031L - Experiment 3 - Group 6Document5 pagesCHM031L - Experiment 3 - Group 6Prince KJNo ratings yet

- Avesta 316L-SKRDocument1 pageAvesta 316L-SKRIuliu HurducaciNo ratings yet

- SAEJ404v001 Aço LigaDocument6 pagesSAEJ404v001 Aço LigaRenato MassanoNo ratings yet

- MT Powder MetallurgyDocument74 pagesMT Powder MetallurgyAhad RazzNo ratings yet

- SchlageDocument11 pagesSchlageapi-262447022No ratings yet

- Sapa Thermal ManagementDocument8 pagesSapa Thermal Managementwww.profilalouminio.comNo ratings yet

- Teromatec Eo 8355: Description Procedure of UseDocument1 pageTeromatec Eo 8355: Description Procedure of UseAravind rajNo ratings yet

- XLER International CompareDocument22 pagesXLER International Comparefuransu777No ratings yet

- Diagram EllinghamDocument9 pagesDiagram EllinghamcindycinpengNo ratings yet

- Pilani Campus: Practice, EDD, BITS PilaniDocument3 pagesPilani Campus: Practice, EDD, BITS PilaniRitik GuptaNo ratings yet

- Waterman - Stop Gates Spec SheetDocument3 pagesWaterman - Stop Gates Spec SheetbatataNo ratings yet

- Aalco Metals LTD - Copper and Copper Alloys CW508L Sheet - 114Document2 pagesAalco Metals LTD - Copper and Copper Alloys CW508L Sheet - 114Mihai ChitibaNo ratings yet