Professional Documents

Culture Documents

Wb2000e E6013

Uploaded by

cwiksjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wb2000e E6013

Uploaded by

cwiksjCopyright:

Available Formats

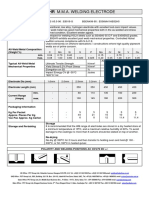

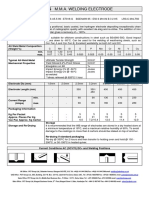

WB2000E M.M.A.

WELDING ELECTRODE

Classifications / Approvals AWS A5.1-04 : E6013 BSEN 499-95 : E42 A R 1 2 LRS :GRADE 1

Product Description Easy to use all purpose contact electrode, recommended where a neat weld

appearance and high finish is required. Excellent de-slag with little or no spatter.

Applications Mild and medium C-Mn steels up to 15mm thick with a UTS of 500 N/mm² max.

Typical grades - BS1449 plate and steel - BS4360 grades 43A, 43C - Lloyds grade A

and D ship steel - BS4360 grade 50B - Lloyds grade AH and DH - BS3059 and

BS3601 grade 320-420 - AP15L and AP15L 42.

All-Weld Metal Composition

(Weight %) C Mn Si S P Ni Cr Mo V Cu

min. 0.05 0.40 0.20 - - - - - - -

max. 0.11 0.70 0.70 0.020 0.025 0.05 0.05 0.03 0.050 0.050

Typical All-Weld Metal Ultimate Tensile Strength N/mm² 610

Mechanical Properties Yield Stress/0.2% Proof Stress N/mm² 520

Elongation on 5D % 22

Impact Energy CV @ +20°C Joules 60

Electrode Dia (mm) 1.6mm 2.0mm 2.5mm 3.2mm 4.0mm 5.0mm 6.0mm

Electrode Length (mm) 300 300 350 450 450 450 450

min 30 40 70 90 130 160 190

Current Range

(Amps) max. 50 60 100 135 165 200 250

Packaging Information

Kg Per Packet 5 5 5 5 5 5 5

Approx. Pieces Per Kg 134 92 55 25 16 11 7

Storage

Storage and Re-Drying It is recommended that the WB range of electrodes are stored in a dry heated store at

a minimum temperature of 18C, and a maximum relative humidity of 60%. To avoid

damage to the coatings no more than 6 cartons should be stacked on top of another.

Re-drying

If these electrodes become excessively damp re-dry @ 100C for 1 hour.

Current Conditions AC OCV70 DC +/- and Welding Positions

You might also like

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78No ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocument1 pageSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Quality 102Cr6: Lucefin GroupDocument1 pageQuality 102Cr6: Lucefin GroupPaulo ZechinNo ratings yet

- Standard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Document7 pagesStandard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Bhagoo HatheyNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- Wb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2Document1 pageWb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2lathasri78No ratings yet

- SL20GDocument2 pagesSL20Gridho_48No ratings yet

- 70cuni TigDocument3 pages70cuni TigGiannhs SeitaridhsNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- E 7016 Spezial electrode-oerlikon-en-TN110089Document2 pagesE 7016 Spezial electrode-oerlikon-en-TN110089Khhg AgddsNo ratings yet

- E 6013 Fincord M electrode-oerlikon-en-TN110429Document1 pageE 6013 Fincord M electrode-oerlikon-en-TN110429Khhg AgddsNo ratings yet

- Basic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660Document1 pageBasic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660mohamed AdelNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Autopeso - PA6140 - 6240Document1 pageAutopeso - PA6140 - 6240Yeison DurangoNo ratings yet

- Prysmian - BS5467 PDFDocument5 pagesPrysmian - BS5467 PDFReginald D. De GuzmanNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- LINCOLN Nicromo 60-16Document2 pagesLINCOLN Nicromo 60-16AbdülHak ÖZkaraNo ratings yet

- 1 3243hs652513 PDFDocument1 page1 3243hs652513 PDFmarko9292No ratings yet

- Conarc 49C: Basic ElectrodeDocument2 pagesConarc 49C: Basic ElectrodeMark Williams100% (1)

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- N2XKB (AL) Y 1 X (16-800) MM 0.6/1 KVDocument5 pagesN2XKB (AL) Y 1 X (16-800) MM 0.6/1 KVmuhammad wafiNo ratings yet

- Böhler Fox CM 2 KB: Classifi CationsDocument1 pageBöhler Fox CM 2 KB: Classifi CationsBranko FerenčakNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- CLC4003 HardnessDocument5 pagesCLC4003 Hardnessarif.haddieNo ratings yet

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- CLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)Document4 pagesCLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)PeterWayNo ratings yet

- 1 3207hs104310Document1 page1 3207hs104310marko9292No ratings yet

- Resistor DatacsheetDocument4 pagesResistor DatacsheetNhan NguyenNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- 4140 High Tensile Steel PDFDocument3 pages4140 High Tensile Steel PDFFikri SiplhoNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Carboklad Cr36 Data SheetDocument1 pageCarboklad Cr36 Data SheetcwiksjNo ratings yet

- K034 - Daikoflux 940Document1 pageK034 - Daikoflux 940cwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- Robo TiPTiG Data Sheet FinalDocument2 pagesRobo TiPTiG Data Sheet FinalcwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- N004 - Daiko Strip 625Document1 pageN004 - Daiko Strip 625cwiksjNo ratings yet

- Metrode WPS SuperduplexDocument4 pagesMetrode WPS SuperduplexClaudia Mms100% (3)

- Utp 068 HHDocument1 pageUtp 068 HHRoberto_PrrNo ratings yet

- Hardfacing Wood Chipper KnivesDocument1 pageHardfacing Wood Chipper KnivescwiksjNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- Meeting Minutes Roberts RulesDocument1 pageMeeting Minutes Roberts RulessaeedNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- A Max WearplateDocument1 pageA Max WearplatecwiksjNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- IN150 ProHeat 35 WaterCooled Induction System EnglishDocument4 pagesIN150 ProHeat 35 WaterCooled Induction System EnglishCARLOSNo ratings yet

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- OrganocatalysisDocument42 pagesOrganocatalysisHifsa HussainNo ratings yet

- Hypochlorite Bleach Catalyst-ALQUAT BBA - Garment Processing ChemicalDocument9 pagesHypochlorite Bleach Catalyst-ALQUAT BBA - Garment Processing ChemicalL.N.CHEMICAL INDUSTRYNo ratings yet

- Structural Steel FabricationDocument14 pagesStructural Steel FabricationClarkFedele27No ratings yet

- Housekeeping ChemicalsDocument13 pagesHousekeeping ChemicalsRahul Jaiswar87% (31)

- Atlas Grade Datasheet 316 Rev Jan 2011 PDFDocument2 pagesAtlas Grade Datasheet 316 Rev Jan 2011 PDFmarklaforestNo ratings yet

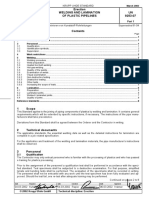

- Erection Welding and Lamination of Plastic Pipelines UN 9253-07Document8 pagesErection Welding and Lamination of Plastic Pipelines UN 9253-07Ahmed GomaaNo ratings yet

- Meijer Grand Chute Building Packages BiddersDocument33 pagesMeijer Grand Chute Building Packages BiddersAlex RayNo ratings yet

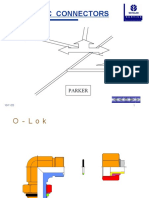

- P14 CX Hydr NippelsDocument11 pagesP14 CX Hydr NippelsasdfNo ratings yet

- Lab Sheet CNC TurningDocument4 pagesLab Sheet CNC TurningSeiichi HaruhiNo ratings yet

- Crosscut Sled PlanDocument6 pagesCrosscut Sled PlanRj NamffohNo ratings yet

- AHNO ProfileDocument26 pagesAHNO ProfilePavel PavelkaNo ratings yet

- Astm A266Document4 pagesAstm A26609122912680No ratings yet

- PCN廢水處理原理簡介 WWTPDocument67 pagesPCN廢水處理原理簡介 WWTPosmar winaldaNo ratings yet

- Introduction To Merichem TechnologyDocument16 pagesIntroduction To Merichem TechnologyNgoVietCuongNo ratings yet

- Flamex S: Constructive SolutionsDocument4 pagesFlamex S: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- RT Report Format Rev.1 17-3-19Document6 pagesRT Report Format Rev.1 17-3-19mohd as shahiddin jafriNo ratings yet

- Powder Metallurgy ProjectDocument54 pagesPowder Metallurgy ProjectDhruv Raj33% (3)

- Asme Section Ii A-2 Sa-995Document4 pagesAsme Section Ii A-2 Sa-995Anonymous GhPzn1xNo ratings yet

- MEROXDocument16 pagesMEROXai_25109275% (4)

- Asian Heat Resisting Aluminium PaintDocument1 pageAsian Heat Resisting Aluminium Paintrumi_2kNo ratings yet

- Logan Fishing Bumper Sub (English)Document26 pagesLogan Fishing Bumper Sub (English)Gianfranco Exequiel Sebastian GarciaNo ratings yet

- Application of PaintsDocument2 pagesApplication of PaintsfaithNo ratings yet

- En Penetrant Test ProcedureDocument6 pagesEn Penetrant Test ProcedureAdham AhmedNo ratings yet

- Epoxy HR PDFDocument5 pagesEpoxy HR PDFJayaraman KamarajNo ratings yet

- Vaccum Heat TretmentDocument2 pagesVaccum Heat TretmentNITIN0% (1)

- Zem CoatDocument1 pageZem Coatjcedricaquino0% (1)

- Touchwood NC Thinner: Architectural CoatingsDocument2 pagesTouchwood NC Thinner: Architectural CoatingsmuthukumarNo ratings yet

- Cemwet SP 3000 (Pce 3)Document2 pagesCemwet SP 3000 (Pce 3)Angry BoyNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- Gatekeeper Inert Gas Purifier EsiteDocument4 pagesGatekeeper Inert Gas Purifier EsiteMarcos MedranoNo ratings yet