Professional Documents

Culture Documents

Article Low Cost and Reliable Sulphur Recovery PDF

Uploaded by

psnmurthy333Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Article Low Cost and Reliable Sulphur Recovery PDF

Uploaded by

psnmurthy333Copyright:

Available Formats

CLAUS TAIL GAS TREATING

Low cost and reliable

sulphur recovery*

By combining a selective oxidation process with a wet gas scrubber technology, Jacobs and

MECS have developed a cost effective alternative to amine-based Claus tail gas treating.

Sulphur recovery and SO2 emission reduction requirements can be met at significantly lower

capital and operating costs. This article compares the capital and operating costs of a typical

140 t/d SRU with an amine-based TGTU versus a SUPERCLAUS® /DynaWave®.

election of an appropriate and cost

S effective tail gas treatment process

to follow existing Claus plants is a

challenge facing refiners and natural gas

Fig 1: SUPERCLAUS® process

reheater Claus reactor

selective

oxidation reactor incinerator

plant owners around the world. New emis-

sion regulations, interest in increasing sul- steam

phur recovery and processing of higher stack

sulphur crudes are the main drivers.

waste heat H2S

The most common approach is to boiler steam

install an amine-based Tail Gas Treatment QC

Unit (TGTU) however lower installed cost

combustion

and higher reliability can be achieved by chamber

combining two well established processes,

Jacobs SUPERCLAUS® selective oxidation condenser

S S S S

process and MECS’ DynaWave® wet gas

scrubber technology. Owners can lower ABC control

capital and operating costs significantly system

with this solution. +

SUPERCLAUS® FC

The SUPERCLAUS® process was developed

H2S + 1/2 O2 →

to catalytically recover elemental sulphur air

from H2S containing Claus tail gases to 2H2S + SO2 3S + 2H2O

feed gas S + H2O

improve the overall sulphur recovery level

of the sulphur recovery facility. The process

was commercially demonstrated in 1988,

and today more than 160 units are under enters the SUPERCLAUS® reactor for selec- Unlike the conventional Claus process,

license and over 140 are in operation. tive oxidation of the H2S to elemental sul- the SUPERCLAUS® process controls to a set

The SUPERCLAUS® process achieves phur. The formed sulphur is then condensed H2S concentration entering the SUPER-

high sulphur recovery levels by suppressing and recovered by the SUPERCLAUS® con- CLAUS® stage. This is achieved by imple-

SO2 formation in the Claus stages, and denser. Tail gas from the SUPERCLAUS® mentation of Jacobs proprietary control

selectively oxidising H2S in the presence of stage is typically routed to an incinerator for system called the Advanced Burner Control

oxygen over a proprietary catalyst (see Fig. thermal oxidation of the residual sulphur (ABC system), which controls the thermal

1). Claus tail gas from the last Claus con- components and venting of the flue gas to stage combustion air through combined

denser is reheated, mixed with air and then atmosphere via the incinerator stack. feedforward and feedback logic. The

*Authors: Dennis Koscielnuk and Frank Scheel of Jacobs Comprimo® Sulphur Solutions, Steven F. Meyer and Andrea Trapet of MECS, Inc. DynaWave®

and B. Gene Goar of Goar Sulphur Services & Assistance.

Sulphur 326 | January -February 2010 1

CLAUS TAIL GAS TREATING

required quantity of combustion air is cal- with high L/G ratios. In general, higher liq- SO2 (v) + NaOH (l) → NaHSO3

SO2 (v) + 2NaOH (l) → Na2SO3 + H2O

culated by measuring the amine acid gas uid-to-gas ratios will result in higher SO2

and the sour water acid gas (SWS) flows. removal efficiencies.

The total air demand is then compared with The DynaWave® achieves high L/G and

the feedback signal from the air demand infinite turndown using reverse jet technol- In most cases, the sodium sulphite/

analyser (located upstream of the SUPER- ogy. Tail gas from the SRU incinerator, or sodium bisulphite salts formed in the

CLAUS® reactor) to adjust air supply to the waste heat boiler, enters the scrubber inlet above reactions must be further oxidised

thermal stage. The ABC system ensures duct and collides with the circulating scrub- to sodium sulphate in order to reduce the

that the required H2S content is achieved at ber liquor (see Fig. 2). The liquor is injected COD of the scrubber effluent to acceptable

the inlet of the SUPERCLAUS® stage for opti- countercurrent to the gas flow through a levels. The reactions are as follows:

NaHSO3(soluble salt) + 0.5O2 + NaOH →

mum sulphur recovery efficiency of the unit. large bore, open throat nozzle known as

SUPERCLAUS® catalyst is not sensitive the reverse jet nozzle. The contact zone

Na2SO4 (soluble salt) + H2O

Na2SO3 (soluble salt) + 0.5O2 → Na2SO4

to excess O2, nor the presence of SO2 or where the gas and liquor collide is referred

H2O because the selective oxidation reac- to as the froth zone.

tion is not equilibrium based like the Claus The froth zone is an area of high mass (soluble salt)

reaction: transfer and turbulence where quench and

Claus reaction acid gas absorption take place simultane- After the gas exits the inlet duct, it flows

2H2S + SO2 ↔ 3S + 2H2O

ously. The amount of recirculation liquid through the top portion of the vessel and

required to develop the froth zone is cal- exits to atmosphere through an integral

SUPERCLAUS® reaction culated based on the maximum process stack. Before exiting the vessel, the clean,

H2S + 1/2 O2 → S + H2O

conditions. The liquid flow is constant, saturated gas flows through a set of

which means that when the inlet gas flow chevrons which maximise liquid droplet

SUPERCLAUS® is compatible with conven- decreases, the L/G increases and acid gas removal from the gas stream.

tional SRU designs that properly destroy removal efficiency increases. The scrubbing liquor falls to the bottom

ammonia present in the SWS feed gases Compared to packed towers, where of the scrubber vessel which is used as a

with no added risk to ammonia salt deposi- high liquid flow rates can cause flooding, reservoir for continuous feed to the recir-

tion. Close to 50% of the SUPERCLAUS® the DynaWave® can operate at liquid circu- culation pumps. The vessel also provides

installations in the world are effectively oper- lation rates which are 5 to 7 times normal the oxidation zone for in-situ oxidation of

ating in ammonia processing Claus units. packed tower flow rates. This allows the sulphite salts to sulphate salts.

SUPERCLAUS® is a non-cyclic process DynaWave® to handle extremely high levels The DynaWave® wet gas scrubber has

that has repeatedly shown simplicity of of SO2, present at SSM when a portion of been installed in over 300 applications

operation, high online reliability, and sul- the SRU must be bypassed. worldwide. The DynaWave® has been designed

phur recovery guarantees up to 99.3%. To react with SO2, owners prefer to use for 11 SRU tail gas treatment projects in the

sodium based reagents such as caustic United States, and installed in seven. The

DynaWave® reverse jet scrubber (NaOH). The reaction between SO2 and caus- DynaWave® is leading all other SO2 absorption

tic is a strong acid-base reaction and is prac- technologies in total SRU installations.

DynaWave® is a unique wet gas scrubber tically instantaneous. Once the SO2 is in

technology which offers a number of advan- solution, the reaction proceeds as follows: SUPERCLAUS®/DynaWave® process

tages in the SRU application. The most

important challenges in the SRU scrubber Fig 2: DynaWave® reverse jet scrubber By combining the SUPERCLAUS® and

application are turndown, the need for a high DynaWave® technologies, the overall system

liquid to gas (L/G) ratio, and the requirement dirty gas in can achieve greater than 99.9% sulphur

for oxidation. An SRU tail gas scrubber must removal at compelling capital and operating

be able to handle a varying range of inlet costs. Approximately 99.0% of the H2S is

flow conditions and inlet SO2 concentrations captured and recovered as elemental sul-

which occur during the critical stages of phur by the SUPERCLAUS® and the remain-

startup, shutdown and malfunction (SSM). ing sulphur is scrubbed and converted to

Oxidation of the liquid effluent may be Na2SO4 by the DynaWave®. Figure 3 is a

required in order to reduce chemical oxygen clean gas out schematic of the combined technologies:

demand (COD) to levels acceptable to waste-

water treatment facilities. Technology comparison

Wet gas scrubbers circulate a liquid

reagent which absorbs SO2. The liquid-to- When comparing SUPERCLAUS®/DynaWave®

gas (L/G) ratio is a key process parameter with an amine-based TGTU, one must fully

for a scrubber, and must be high enough in assess the advantages or disadvantages

the SRU application to fully quench the hot of each factor, e.g. capital costs, operating

process gas and absorb the SO2 without pump costs, number of equipment items, plot

make-up

suppressing the pH in the absorber reac- foot-print, liquid discharges, chemical

tion/contact zone. Momentary pH depres- effluent requirements, achievable sulphur recovery

sion in the contact zone can be avoided rate and operability/reliability.

2 Sulphur 326 | January -February 2010

CLAUS TAIL GAS TREATING

Fig 3: Combined SUPERCLAUS® / DynaWave® process

Claus reactor selective oxidation reactor

reheater incinerator

steam

waste heat H2S

boiler steam outlet

QC

combustion

chamber

condenser

S S S S

make-up

ABC control caustic

system

+

FC

air blowdown

feed gas SUPERCLAUS® DynaWave®

SO2 emissions all auxiliary equipment such as waste heat SUPERCLAUS®/DynaWave® process will

boilers, incinerators, stacks, amine/ hold for a wide range of sulphur loads.

The basis of the comparison assumes an caustic storage tanks, drain tanks, pumps,

EPA stack SO2 outlet limit of 50 ppm. Both scrubbers, etc. Costs for catalyst, Operational/equipment complexity

technology offerings can achieve greater chemicals, royalties, etc. were also Simplicity of operation and equipment

than 99.9% removal of the sulphur and dis- included for a more comprehensive complexity are key considerations when

charge less than 50 ppm SO2 at their comparison. No costs were included for choosing a process to install. Compared to

respective outlets. sulphur storage or handling facilities. an amine-based TGTU, the SUPERCLAUS®/

To achieve this low SO2 outlet value, Table 1 provides a comparison of the DynaWave® process has 35% less

the amine-based TGTU normally requires an relative capital costs. In each case a grass equipment and fewer complex equipment

amine additive to allow for very lean roots installation is assumed and a ther- items because complex towers with

solvent stripping. Also required are additional mal stage followed by a two-stage Claus pumparound systems are not required.

trays in the towers, as well as increased unit is included. Normalising the SRU plus The SUPERCLAUS®/DynaWave® process

solvent circulation and reboiler duties. amine-based TGTU system cost to a rela- essentially requires a reheater, reactor,

The SUPERCLAUS®/DynaWave® option tive value of 185, the combined SUPER- sulphur condenser and caustic scrubber.

achieves low SO2 emission levels simply CLAUS®/DynaWave® process cost is only This translates into less maintenance costs,

through the combination of the two tech- 140. This indicates an overall 24% capital less operational attention and manhours

nologies. The SUPERCLAUS® process uses cost savings when choosing the SUPER- and the probability of a higher on-stream

proprietary selective oxidation catalyst to CLAUS®/DynaWave® process. factor if equipment redundancy is equivalent.

reduce tail gas SO2 levels to 1,600 ppm. When a two-stage Claus unit already

The DynaWave® scrubber takes the incin- exists and a TGTU is to be added, the eval- Plot footprint

erated tail gas and reduces its SO2 content uation shows that the SUPERCLAUS®/ A factor that is sometimes overlooked

from 1,600 ppm to 50 ppm or less. DynaWave® process provides approxi- when comparing technologies is the plot

mately 53% savings on the capital cost of footprint required of the installation.

Comparative capital costs an amine-based TGTU. Most of the savings The SUPERCLAUS® /DynaWave® process

A capital cost analysis was per formed are realised through a simpler flow requires approximately 40% less plot

based on a 140 t/d sulphur recovery scheme, less complex equipment (fewer space than the amine-based TGTU. The

facility processing acid gas containing 77 towers and pumparounds) and approxi- equipment count is 24 for an amine-based

mol-% H2S and 8 mol-% NH3. For both the mately 35% less equipment count. TGTU compared to 16 for SUPERCLAUS®/

amine-based TGTU and SUPERCLAUS®/ Savings will depend on the size of the DynaWave®. The SRU section with two reac-

DynaWave® process, costs were calculated SRU system, however, it is reasonable to tors common to both process schemes

on a “turnkey” installed basis and include assume that the cost advantage of the has 23 pieces of equipment.

Sulphur 326 | January -February 2010 3

CLAUS TAIL GAS TREATING

Comparative operating costs

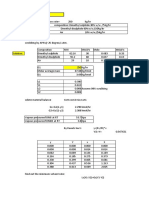

Table 1: Technology capital cost comparison (140 t/d SRU)

Comparative operating costs, i.e. utilities,

can be broken down into several cate- Item Unit description Relative Approximate Comparison

gories; power, steam, fuel gas, water, and cost savings (%) basis

chemicals. For a 140 t/d SRU, Table 2 pro-

1 2-Stage Claus SRU 100

vides a utility cost comparison between an

2 2-Stage Claus SRU + amine-based TGTU 185

amine-based TGTU and a SUPERCLAUS®/

3 2-Stage Claus SRU + 140 24% Item 3 vs 2

DynaWave®.

SUPERCLAUS® /DynaWave®

As Table 2 illustrates, there is approxi-

4 Amine-based TGTU alone 85

mately 20% operating cost savings with the

5 SUPERCLAUS® / DynaWave® alone 40 53% Item 5 vs 4

SUPERCLAUS®/DynaWave® Process.

The SUPERCLAUS®/DynaWave® process

typically does not require cooling water Unique SRU solutions ing startup, shutdown and malfunction

because the only cooling needed is to (SSM). Emission levels during SSM are

condense the steam from the final sulphur Sometimes an owner does not require a potentially unpredictable. In the case of

condenser. The amine-based TGTU requires complete TGTU. This might be the case SRUs with TGTUs, normal emissions can be

2,050 gpm of cooling water for a 140 t/d SRU. when the Claus SRU is small or another between 200-1000 ppm SO2. During SSM,

With regards to overall fresh water TGTU technology is already installed. Both emissions can reach 4,000 to 10,000 ppm

make-up, the SUPERCLAUS®/DynaWave® SUPERCLAUS® and DynaWave® offer solu- SO2 or even higher, and gas flow rates can

process will consume 18.5 gpm. This is tions even in this situation. fluctuate as well. The technology that follows

the amount of water required to quench the the SRU must be able to handle this wide

gas from the incinerator waste heat boiler Reducing Claus unit operating costs range of process variables. As explained pre-

plus any effluent discharged from the For example, some owners have installed viously, one of the major advantages of the

scrubber system. The amine-based TGTU caustic scrubbers, such as the DynaWave®, DynaWave® scrubber is its capability to han-

does not require direct fresh water make- directly after their Claus units. This has dle very wide turndown operations.

up, but Table 2 takes into consideration allowed them to meet air permit require-

water evaporated in the cooling tower. ments without installing complete amine- New requirements for very low SO2

The SUPERCLAUS®/DynaWave® process based TGTUs. emissions

requires caustic to react with the 1,600 When caustic is expensive, the operating Typical emission requirements for SRUs in

ppm SO2 from the incinerator waste heat costs of an inefficient Claus unit followed by the United States range between 50 to 250

boiler. The amount of caustic required by a caustic scrubber can be high. The SUPER- ppm. The Air Quality Management District

the SUPERCLAUS®/DynaWave® process is CLAUS® process offers a solution with the in Los Angeles, California is investigating

in the order of 3.5 long t/d, dry basis for a simple retrofit addition of SUPERCLAUS® cat- the feasibility of limiting SO2 emissions to

140 t/d sulphur processing facility. The alyst into the third Claus reactor and possi- below 10 ppm. The DynaWave® is a robust

reaction products result in a 10 gpm liquid bly a new sulphur condenser for the and reliable wet gas scrubbing process

effluent stream that contains 10% sodium additional heat load generated by SUPER- which can meet these future emission

sulphate which is typically sent to the CLAUS®. If the 3rd Claus stage does not requirements at a reasonably low operating

waste water treatment plant. exist, then the addition of a new SUPER- cost. In addition, since many owners will be

The amine-based TGTU process effluent CLAUS® stage would be required. required to retrofit a wet gas scrubber into

is a 17 gpm waste water stream, contain- an existing facility, the small footprint of the

ing 20-50 ppm H2S, which requires further SRU process unit redundancy DynaWave® provides the possibility to

treatment before being sent to the waste In the future, process units may no longer install this technology where real estate is

water treatment plant. be able to exempt emissions excesses dur- at a premium. ■

Table 2: Utility comparison (140 t/d SRU)

Amine-based TGTU SUPERCLAUS® /DynaWave®

Utility type $/Unit cost Consumption $/Day cost Consumption $/Day cost

Electric power $.08/kWh 499 kW 958 485 kW 931

60 psig steam consumed $4/1000 lb 10,200 lb/hr 979 none 0

60 psig steam produced $4/1000 lb none 0 7,500 lb/hr (produced) -720 (credit)

Fuel gas (incinerator) $3.50/1000 SCF 14,800 SCFH 1,243 16,600 SCFH 1,394

Fuel gas (heater or RGG) $3.50/1000 SCF 3,500 SCFH 294 1,340 SCFH 113

Cooling water $0.10/1000 gal 2050 gpm 295 none 0

Fresh water $1.30/1000 gal 22 gpm 42 18.5 gpm 35

Amine make-up $1.40/ lb 55 lb/day 77 none 0

Caustic make-up $0.175/lb ($350/ton) none 0 7,721 lb/day 1,351

Total $3,888/day $3,104/day

4 Sulphur 326 | January -February 2010

You might also like

- Phys 1Document5 pagesPhys 1Sandra Phan50% (2)

- Experimental Lab Report 1Document10 pagesExperimental Lab Report 1api-274857931100% (10)

- Air Treatment WaterleauDocument28 pagesAir Treatment WaterleauSankar CdmNo ratings yet

- PMP Formulas v4 PDFDocument1 pagePMP Formulas v4 PDFsh1n0b1klNo ratings yet

- Topsoe Wsa Process Principles 0Document4 pagesTopsoe Wsa Process Principles 0Carlos de la TorreNo ratings yet

- Hazop StudyDocument7 pagesHazop StudyAnderson JoeNo ratings yet

- BCH 2202 Chemical Thermodynamics ModuleDocument84 pagesBCH 2202 Chemical Thermodynamics Modulefrancis100% (5)

- 8th Sem Project ReportDocument55 pages8th Sem Project ReportPrathmeshBhokari100% (2)

- Low Cost Reliable Sulfur RecoveryDocument11 pagesLow Cost Reliable Sulfur RecoveryiboNo ratings yet

- CMMIDocument4 pagesCMMIclinden5802No ratings yet

- PV Elite 2016Document6 pagesPV Elite 2016RizhwanNo ratings yet

- Manhour StandardsDocument6 pagesManhour StandardsErick EnriquezNo ratings yet

- Q Vive PMP Formulas v4 PDFDocument1 pageQ Vive PMP Formulas v4 PDFmasudrana7300No ratings yet

- PMP Certification Study Plan, (Days)Document1 pagePMP Certification Study Plan, (Days)Tarek YehiaNo ratings yet

- SCRCostManualchapter Draftforpubliccomment6!5!2015Document101 pagesSCRCostManualchapter Draftforpubliccomment6!5!2015Mustika Putri PertiwiNo ratings yet

- Pressure Vessel, Boiler, Storage Tanks and Heat Exchanger in Oil, Gas Project. Storage Tanks Heat ExchangerDocument1 pagePressure Vessel, Boiler, Storage Tanks and Heat Exchanger in Oil, Gas Project. Storage Tanks Heat ExchangerValli RajuNo ratings yet

- Plant SpecificationsDocument4 pagesPlant SpecificationsjnmanivannanNo ratings yet

- FUELSDocument15 pagesFUELSJohn Archie MendozaNo ratings yet

- Xebec Hydrogen BrochureDocument24 pagesXebec Hydrogen BrochureJoshNo ratings yet

- Mix Sulphuric AcidDocument69 pagesMix Sulphuric AcidjaiminNo ratings yet

- Spent Acid OverviewDocument2 pagesSpent Acid OverviewacckypenrynNo ratings yet

- Scale-Up Chemical Engineering ProcessesDocument12 pagesScale-Up Chemical Engineering ProcesseskayeNo ratings yet

- Conversion of MT To Inch DiaDocument4 pagesConversion of MT To Inch DianikunjNo ratings yet

- Flue Gas Process - ScrubbingDocument8 pagesFlue Gas Process - ScrubbingR_M_M_No ratings yet

- Nps Table Welded Seamless Stainless Steel PipeDocument3 pagesNps Table Welded Seamless Stainless Steel PipeOmar HasounNo ratings yet

- Clean Fuels: QuestionsDocument6 pagesClean Fuels: QuestionsErika de la RosaNo ratings yet

- Comparison of Several Packings For CO2 Chemical Absorption in A Packed ColumnDocument7 pagesComparison of Several Packings For CO2 Chemical Absorption in A Packed ColumnianphilanderNo ratings yet

- Emergency Scrubber DesignDocument36 pagesEmergency Scrubber DesignSurajit das0% (1)

- Distillation Tower Design PresentationDocument2 pagesDistillation Tower Design PresentationAlmotsemNo ratings yet

- Materials Selection Modeling & SimulationDocument21 pagesMaterials Selection Modeling & Simulationleila hanjani hanantoNo ratings yet

- Random PackingDocument4 pagesRandom PackingAadam AryanNo ratings yet

- Is 14164 2008Document45 pagesIs 14164 2008Pukhraj DagaNo ratings yet

- RASCHIG-JAEGER Reactor Internals - BulletinDocument8 pagesRASCHIG-JAEGER Reactor Internals - BulletinapitbhuNo ratings yet

- Packed Towers: 12.1 Device TypeDocument10 pagesPacked Towers: 12.1 Device TypeSagar BhavsarNo ratings yet

- Sulfuric Acid - Wikipedia PDFDocument94 pagesSulfuric Acid - Wikipedia PDFrajesh indukuriNo ratings yet

- Tank Volume CalculatorDocument5 pagesTank Volume Calculatoridforemon6898No ratings yet

- Ammonium 2520sulphate Material 2520balance.Document9 pagesAmmonium 2520sulphate Material 2520balance.AgadmatorNo ratings yet

- Chemical Plant Utility - Nitrogen System DesignDocument10 pagesChemical Plant Utility - Nitrogen System DesignIJRASETPublicationsNo ratings yet

- Pumping TrapsDocument36 pagesPumping TrapsjonathanyflorenciaNo ratings yet

- P&ID Cooling System (PHE 1 Set)Document1 pageP&ID Cooling System (PHE 1 Set)Moon JaehyunNo ratings yet

- Farmatic PresentationDocument27 pagesFarmatic Presentationtaufiq ihsanNo ratings yet

- Steam Tracing Specification ChartDocument1 pageSteam Tracing Specification Chartgpskumar22No ratings yet

- Ammonia B PDFDocument9 pagesAmmonia B PDFmehrdad_k_rNo ratings yet

- Ellipsoidal Head Tank - Volume-Height CalculationDocument4 pagesEllipsoidal Head Tank - Volume-Height Calculationdadz mingiNo ratings yet

- G Me 160 PDFDocument70 pagesG Me 160 PDFHamid AbbasiNo ratings yet

- Lecture Notes On Equipment SizingDocument48 pagesLecture Notes On Equipment SizingMarge SantacruzNo ratings yet

- Cálculo de Eficiencia de Un HornoDocument29 pagesCálculo de Eficiencia de Un HornoFranklin Santiago Suclla PodestaNo ratings yet

- AspenCapitalCostEstimatorV7 2-UsrDocument795 pagesAspenCapitalCostEstimatorV7 2-UsrMcn SergNo ratings yet

- Viva Master SlideDocument36 pagesViva Master Slidethivya keasavanNo ratings yet

- Scientific Glass EquipmentDocument28 pagesScientific Glass EquipmentJuan P RuizNo ratings yet

- Low-Emission NOx Reduction RefineriesDocument5 pagesLow-Emission NOx Reduction Refinerieslaiping_lumNo ratings yet

- Sodium Bicarbonate For Flue Gas TreatmentDocument12 pagesSodium Bicarbonate For Flue Gas Treatmentblabla21No ratings yet

- Flowrate and Pressure CalculationsDocument3 pagesFlowrate and Pressure Calculationsgonvic7411No ratings yet

- Chap 34 PDFDocument16 pagesChap 34 PDFnelson escuderoNo ratings yet

- Korf BrochureDocument1 pageKorf Brochurelhphong021191No ratings yet

- ENMAS ANDRITZ Document Date CalculationsDocument3 pagesENMAS ANDRITZ Document Date CalculationsPablo ApasionadoNo ratings yet

- Aspen ZyqadDocument4 pagesAspen ZyqadsckanyiNo ratings yet

- SuperClaus Dynawave Sulphur MagazineDocument4 pagesSuperClaus Dynawave Sulphur Magazinemc_tempNo ratings yet

- Sulfur Magazine Ideas For Better Clean Up Jan 09Document0 pagesSulfur Magazine Ideas For Better Clean Up Jan 09Bharat VaajNo ratings yet

- Lurgi Sulfur ManagementDocument8 pagesLurgi Sulfur ManagementRamon IglesiasNo ratings yet

- Handout Jacobs Css - Superclaus ProcessDocument1 pageHandout Jacobs Css - Superclaus ProcessJose Juan ViopNo ratings yet

- Hermes Claus ProcessDocument3 pagesHermes Claus ProcessShyam YadavNo ratings yet

- Topsoe Wsa Meet Industry DemandsDocument6 pagesTopsoe Wsa Meet Industry DemandsBobie C. KurniawanNo ratings yet

- Desiccants PDFDocument9 pagesDesiccants PDFjesus_manrique2753No ratings yet

- Article Low Cost and Reliable Sulphur RecoveryDocument6 pagesArticle Low Cost and Reliable Sulphur Recoverypsnmurthy333No ratings yet

- (API) Steels For Hydrogen Service at Elevated Temp (B-Ok - Xyz) PDFDocument59 pages(API) Steels For Hydrogen Service at Elevated Temp (B-Ok - Xyz) PDFpsnmurthy333No ratings yet

- Journal of Controlled ReleaseDocument4 pagesJournal of Controlled Releasepsnmurthy333No ratings yet

- Conversion of Glycerol To AcroleinDocument7 pagesConversion of Glycerol To AcroleinShahzaib IftikharNo ratings yet

- Aluminium OxideDocument8 pagesAluminium Oxidepsnmurthy333No ratings yet

- Bisphenol-A and The Great Divide: A Review of Controversies in The Field of Endocrine DisruptionDocument21 pagesBisphenol-A and The Great Divide: A Review of Controversies in The Field of Endocrine Disruptionpsnmurthy333No ratings yet

- Ammonia SolutionDocument17 pagesAmmonia Solutionpsnmurthy333No ratings yet

- Iron SulfateDocument10 pagesIron Sulfatepsnmurthy333No ratings yet

- 2010 - Closures For Coarse-Grid Simulation of Fluidized Gas-Particle FlowsDocument261 pages2010 - Closures For Coarse-Grid Simulation of Fluidized Gas-Particle Flowspsnmurthy333No ratings yet

- Acidic Character of Metal-Loaded Amorphous and Crystalline Silica-Aluminas Determined by XPSDocument11 pagesAcidic Character of Metal-Loaded Amorphous and Crystalline Silica-Aluminas Determined by XPSpsnmurthy333No ratings yet

- Acidic NatureDocument14 pagesAcidic Naturepsnmurthy333No ratings yet

- Evaporation CalculationsDocument57 pagesEvaporation CalculationsHarsha94% (101)

- Acidic NatureDocument14 pagesAcidic Naturepsnmurthy333No ratings yet

- Cellular Automaton Model For Fluid Flow in Porous MediaDocument23 pagesCellular Automaton Model For Fluid Flow in Porous Mediapsnmurthy333No ratings yet

- How To Write A Great Research Paper by Simon Peyton JonesDocument46 pagesHow To Write A Great Research Paper by Simon Peyton JonesrazorazNo ratings yet

- Distillation Handbook 10004 01-08-2008 USDocument52 pagesDistillation Handbook 10004 01-08-2008 USSumit SinghNo ratings yet

- Ammonia and Urea ProductionDocument10 pagesAmmonia and Urea Productionwaheed_bhattiNo ratings yet

- Mixed Fertilizer PlantsDocument15 pagesMixed Fertilizer Plantspsnmurthy333No ratings yet

- I-Chem Solution SDN BHD: Bmsolution Safety Data SheetDocument5 pagesI-Chem Solution SDN BHD: Bmsolution Safety Data SheetAmirHakimRusliNo ratings yet

- TIGAS Haldor TopsoeDocument25 pagesTIGAS Haldor TopsoeGabriele CentiNo ratings yet

- Full Download Engineering Applications in Sustainable Design and Development 1st Edition Striebig Solutions ManualDocument12 pagesFull Download Engineering Applications in Sustainable Design and Development 1st Edition Striebig Solutions Manualjherallapizm100% (38)

- Welding Defects and PreventionDocument2 pagesWelding Defects and PreventionVicky SinghNo ratings yet

- Convection and Conduction Heat TransferDocument406 pagesConvection and Conduction Heat Transfertfemilian100% (2)

- TB3 Water Quality Analysis Emergency SituationsDocument8 pagesTB3 Water Quality Analysis Emergency Situationsনিস্তব্ধতার প্রহরেNo ratings yet

- Powder Metallurgy: Crushing and Milling Method To Form PowderDocument12 pagesPowder Metallurgy: Crushing and Milling Method To Form Powder050678No ratings yet

- Heat loss and fluid temperature calculation for buried insulated and non-insulated oil pipelinesDocument34 pagesHeat loss and fluid temperature calculation for buried insulated and non-insulated oil pipelinesselisenNo ratings yet

- 06 Chapter 1Document16 pages06 Chapter 1Maharaja PlacementNo ratings yet

- Revision Kimia f4Document6 pagesRevision Kimia f4Abdul ManafNo ratings yet

- Ganoderma laccase optimizationDocument9 pagesGanoderma laccase optimizationRajeshKumarNo ratings yet

- Coconut Shell Based Activated Carbon W No Greeen House Gas EmissionDocument4 pagesCoconut Shell Based Activated Carbon W No Greeen House Gas Emissionmragul22No ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-35 PDFDocument1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-35 PDFahmed shakerNo ratings yet

- Comenius - CodDocument13 pagesComenius - CodsridharancNo ratings yet

- Reservoir Drive Mechanisms PDFDocument28 pagesReservoir Drive Mechanisms PDFWassef MB100% (1)

- ROCKWOOL© Technical InsulationDocument36 pagesROCKWOOL© Technical InsulationHaytham ElsayedNo ratings yet

- Thermoplastic Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForDocument20 pagesThermoplastic Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForAndres Camilo BenitezNo ratings yet

- Mazahar Publication PDFDocument18 pagesMazahar Publication PDFNur Aini IktikhafsariNo ratings yet

- Airborne Oil and Gas TCP Flowline Brochure 2017Document4 pagesAirborne Oil and Gas TCP Flowline Brochure 2017Aaron Vazquez MartinezNo ratings yet

- B705 Acpt1003Document3 pagesB705 Acpt1003taya1401No ratings yet

- HPLCDocument22 pagesHPLCKafi Mahmood NahinNo ratings yet

- Probing The Mott Physics in - (BEDT-TTF) 2X Salts Via Thermal ExpansionDocument28 pagesProbing The Mott Physics in - (BEDT-TTF) 2X Salts Via Thermal ExpansionFelipeSilveiraNo ratings yet

- Ellc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneDocument9 pagesEllc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneAlvin PaboresNo ratings yet

- Feasibility Study of Cumene ProductionDocument4 pagesFeasibility Study of Cumene ProductionIntratec SolutionsNo ratings yet

- HRSG1 (终版)Document120 pagesHRSG1 (终版)Atif KhanNo ratings yet