Professional Documents

Culture Documents

Wb2318e E9018-M

Uploaded by

cwiksjOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wb2318e E9018-M

Uploaded by

cwiksjCopyright:

Available Formats

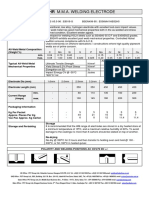

WB2318E M.M.A.

WELDING ELECTRODE

Classifications AWS A5.5 : E9018-M

Approvals ABS : 4YQ460

All positional, basic coated, low hydrogen electrode depositing exceptionally clean

Product Description metal of radiographic quality. Excellent de-slag with good welder appeal. The addition

of iron powder gives a recovery of ∼ 110%.

Widely used for the welding of low alloy steel of a tensile strength 600/700 N/mm²

Applications such as RQT600, HY80, NAXTRA 70. Frequently used for tack welding steels of

higher tensile strength.

All-Weld Metal Composition

(Weight %) C Mn Si S P Mo Cr Ni V

min. 0.03 0.80 0.20 - - 0.20 - 1.60 -

max. 0.05 1.25 0.50 0.020 0.025 0.35 0.05 1.80 0.05

Typical All-Weld Metal Ultimate Tensile Strength N/mm² 660

Mechanical Properties Yield Stress/0.2% Proof Stress N/mm² 580

Elongation on 5D % 24

Impact Energy CV @ -51°C Joules 65

As-welded

Electrode Dia (mm) 1.6mm 2.0mm 2.5mm 3.2mm 4.0mm 5.0mm 6.0mm

Electrode Length (mm) - - 350 450 450 450 450

min. - - 70 90 130 160 230

Current Range

(Amps) max. - - 90 130 180 220 280

Packaging Information

Kg Per Packet (Vac-Pac) - - 2 2 2 2 2

Approx. Pieces Per Kg - - 44 21 15 10 7

Vac Pac Approx. Kg Carton - - 20 20 20 20 20

Storage

Storage and Re-Drying It is recommended that the WB range of electrodes are stored in a dry heated store at

a minimum temperature of 18°C, and a maximum relative humidity of 60%. To avoid

damage to the coatings no more than 6 cartons should be staked on top of another.

Re-drying if standard packaging

Re-dry @ 350°C for 2 hours and then transfer to holding oven and hold @ 100 -

200°C, or 50-100°C in heated quiver.

Current Conditions AC OCV70 DC +/- and Welding Positions

You might also like

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- WB56S M.M.A. Welding Electrode for Offshore FabricationsDocument1 pageWB56S M.M.A. Welding Electrode for Offshore FabricationscwiksjNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- M.M.A. welding electrode for Martensitic stainless steelsDocument1 pageM.M.A. welding electrode for Martensitic stainless steelscwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- WB56S M.M.A. welding electrode specificationsDocument1 pageWB56S M.M.A. welding electrode specificationslathasri78No ratings yet

- All-position stainless steel electrode for difficult weldsDocument1 pageAll-position stainless steel electrode for difficult weldscwiksjNo ratings yet

- WB88SHR M.M.A. welding electrode propertiesDocument1 pageWB88SHR M.M.A. welding electrode propertieslathasri78No ratings yet

- WB35S welding electrodeDocument1 pageWB35S welding electrodelathasri78No ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- WB5525E MMA Welding Electrode Spec SheetDocument1 pageWB5525E MMA Welding Electrode Spec SheetcwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78No ratings yet

- All-Purpose Welding ElectrodeDocument1 pageAll-Purpose Welding ElectrodecwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- WB9009E M.M.A. Welding Electrode Product InformationDocument1 pageWB9009E M.M.A. Welding Electrode Product Informationlathasri78No ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- TT - Electronics 898 3 R100K Datasheet PDFDocument4 pagesTT - Electronics 898 3 R100K Datasheet PDFelnegritoheberNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosNo ratings yet

- 12a DPST Miniature Power RelayDocument2 pages12a DPST Miniature Power RelaykarkeraNo ratings yet

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERNo ratings yet

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- T90 A230xsmdDocument2 pagesT90 A230xsmdhgfgffgfggffgNo ratings yet

- Tenalloy 120G: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 120G: LOW ALLOY STEEL (High Strength)Devender NegiNo ratings yet

- Low alloy electrodes for welding high-strength steels with OK 75.75Document1 pageLow alloy electrodes for welding high-strength steels with OK 75.75corsini999No ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- Wire Wound Resistors GuideDocument7 pagesWire Wound Resistors GuideteoilcaNo ratings yet

- ASM Material Data Sheet 304Document2 pagesASM Material Data Sheet 304.xNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembeNo ratings yet

- Low alloy steel electrode for high strength weldingDocument1 pageLow alloy steel electrode for high strength weldingsatnamNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- ER-410NiMo MIG Wire Data SheetDocument2 pagesER-410NiMo MIG Wire Data SheetAnonymous skBAwexNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- Electrode Booklet F Web 20Document1 pageElectrode Booklet F Web 20satnamNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- American - Zettler AZ732 053 52 DatasheetDocument2 pagesAmerican - Zettler AZ732 053 52 DatasheetZoro DNo ratings yet

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganNo ratings yet

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDocument2 pagesGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranNo ratings yet

- Werkstoff 1.5217 (20MnV6)Document2 pagesWerkstoff 1.5217 (20MnV6)alextentwentyNo ratings yet

- Shielded Power Inductors GuideDocument2 pagesShielded Power Inductors Guidemauricio alfonsoNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Robo TiPTiG Data Sheet FinalDocument2 pagesRobo TiPTiG Data Sheet FinalcwiksjNo ratings yet

- N004 - Daiko Strip 625Document1 pageN004 - Daiko Strip 625cwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- Daikoflux 940 ESW cladding flux data sheetDocument1 pageDaikoflux 940 ESW cladding flux data sheetcwiksjNo ratings yet

- Carboklad Cr36 Data SheetDocument1 pageCarboklad Cr36 Data SheetcwiksjNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- A Max WearplateDocument1 pageA Max WearplatecwiksjNo ratings yet

- Hardfacing Wood Chipper KnivesDocument1 pageHardfacing Wood Chipper KnivescwiksjNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- Meeting Minutes Roberts RulesDocument1 pageMeeting Minutes Roberts RulessaeedNo ratings yet

- NiCrFe alloy welding electrodeDocument1 pageNiCrFe alloy welding electrodeRoberto_PrrNo ratings yet

- Superduplex Welding Procedure Specification (WPSDocument4 pagesSuperduplex Welding Procedure Specification (WPSClaudia Mms100% (3)

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- All-position stainless steel electrode for difficult weldsDocument1 pageAll-position stainless steel electrode for difficult weldscwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- IN150 ProHeat 35 WaterCooled Induction System EnglishDocument4 pagesIN150 ProHeat 35 WaterCooled Induction System EnglishCARLOSNo ratings yet

- WB5525E MMA Welding Electrode Spec SheetDocument1 pageWB5525E MMA Welding Electrode Spec SheetcwiksjNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- All-Purpose Welding ElectrodeDocument1 pageAll-Purpose Welding ElectrodecwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Porosity and Wear Resistance of Flame Sprayed TungstenDocument7 pagesPorosity and Wear Resistance of Flame Sprayed Tungstenlacoste11111No ratings yet

- Passive Block Foundation DrawingDocument1 pagePassive Block Foundation Drawingapi-426990805100% (1)

- CASHCLA DESIGN DRAWINGS FOR CALIFORNIA GOLD PROPERTIES RESIDENCEDocument7 pagesCASHCLA DESIGN DRAWINGS FOR CALIFORNIA GOLD PROPERTIES RESIDENCEAngelo MoralNo ratings yet

- Terminal CabinetDocument66 pagesTerminal CabinetChristine May CagaraNo ratings yet

- CANTEX Fitting Brochure 200809Document48 pagesCANTEX Fitting Brochure 200809Kim Ill JeongNo ratings yet

- Blocklaying Bricklaying and ConcretingDocument6 pagesBlocklaying Bricklaying and ConcretingOkeke Paschal UdochukwuNo ratings yet

- Syntho-Glass FX Datasheet (Rev 1. - 12.31.09)Document2 pagesSyntho-Glass FX Datasheet (Rev 1. - 12.31.09)Masood KhanNo ratings yet

- C200-Roadworks Notes and Details-C210Document1 pageC200-Roadworks Notes and Details-C210Don WangNo ratings yet

- 1 Kanal Boundary Wall Est v2 (20150602)Document1 page1 Kanal Boundary Wall Est v2 (20150602)Farhat DurraniNo ratings yet

- Withdrawn ReportsDocument5 pagesWithdrawn ReportsRohimNo ratings yet

- Grade 500 SteelDocument3 pagesGrade 500 SteelNathan LakaNo ratings yet

- Plastic Injection MoldingDocument24 pagesPlastic Injection MoldingelectroternalNo ratings yet

- 2.ferrous & Non Ferrous Metal & AlloysDocument14 pages2.ferrous & Non Ferrous Metal & AlloysMuhammad TanweerNo ratings yet

- Rewari PIPE ERECTION SpecificationDocument71 pagesRewari PIPE ERECTION Specificationkselvan_1100% (1)

- 577roof Bolt TypesDocument15 pages577roof Bolt TypesOmar HelalNo ratings yet

- Chemical Composition AluminiumDocument3 pagesChemical Composition AluminiumEmreNo ratings yet

- REBARS - IK - ManufacturersDocument528 pagesREBARS - IK - ManufacturersTheoNo ratings yet

- Midterm ExamDocument2 pagesMidterm ExamNissan UyNo ratings yet

- TDS MACMAT R Steel - Eng - Rev 15Document1 pageTDS MACMAT R Steel - Eng - Rev 15mili gamer roro game ROBLOX YESNo ratings yet

- Strip Seal Expansion JointDocument13 pagesStrip Seal Expansion JointsmithNo ratings yet

- Astm B209-06Document29 pagesAstm B209-06tuongNo ratings yet

- Plumbing Plans ComparisonDocument1 pagePlumbing Plans ComparisonEnriqueta VelazquezNo ratings yet

- Sika Rustoff 100-Rust RemoverDocument2 pagesSika Rustoff 100-Rust Removerraahul_nNo ratings yet

- Intro to Concrete Structures DesignDocument42 pagesIntro to Concrete Structures DesignTanvirH.ChowdhuryNo ratings yet

- K-60 MQAP Rev 1.01Document6 pagesK-60 MQAP Rev 1.01Tyler CurryNo ratings yet

- 1B PPT Roughing in IIllustDocument50 pages1B PPT Roughing in IIllustRochelleNo ratings yet

- Knjiga 3 - CUPOV Divulje - Hyperbolic Mixers PartDocument2 pagesKnjiga 3 - CUPOV Divulje - Hyperbolic Mixers PartDicle KarabiberNo ratings yet

- Polymer Processing TechniquesDocument9 pagesPolymer Processing TechniquesShalini VirdiNo ratings yet

- Module 1 Asst PDFDocument10 pagesModule 1 Asst PDFJay ReyesNo ratings yet

- Sikalatex Pds enDocument2 pagesSikalatex Pds ennidandiniNo ratings yet