Professional Documents

Culture Documents

WB5525E ENiCrMo-5

Uploaded by

cwiksjCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WB5525E ENiCrMo-5

Uploaded by

cwiksjCopyright:

Available Formats

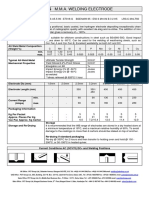

WB5525E M.M.A.

WELDING ELECTRODE

Classifications AWS A5.11 : ENiCrMo-5

Product Description Basic coated, high recovery electrode, having excellent deslag and bead profile.

Manufactured from pure nickel core wire with a very rapid rate of work hardening.

Applications Used mainly for welding and repairing nickel base castings such as Alloy C-276 which

are solution heat treated.

All-Weld Metal Composition

(Weight %) C Mn Si S P Ni Cr Cu Fe W

min. - - - - - 50.0 14.5 - 4.0 3.0

max. 0.10 1.0 1.0 0.030 0.040 - 16.5 0.50 7.0 4.5

Co V Mo

min. - - 15.0

max. 2.5 0.35 17.0

Typical All-Weld Metal Ultimate Tensile Strength N/mm² 690 min.

Mechanical Properties Yield Stress/0.2% Proof Stress N/mm² -

Elongation on 4D % 25 min.

Impact Energy CV @ Joules -

PWHT - solution treated @

1120C+WQ

Electrode Dia (mm) 1.6mm 2.0mm 2.5mm 3.2mm 4.0mm 5.0mm 6.0mm

Electrode Length (mm) - - 350 350 350 - -

min. - - 60 80 100 - -

Current Range

(Amps) max. - - 90 120 150 - -

Packaging Information

Kg Per Vac-Pac Packet - - 2 2 2 - -

Approx. Pieces Per Kg - - 28 19 12 - -

Storage

Storage and Re-Drying It is recommended that the WB range of electrodes are stored in a dry heated store at

a minimum temperature of 18C, and a maximum relative humidity of 60%. To avoid

damage to the coatings no more than 6 cartons should be staked on top of another.

Re-drying

Re-dry @ 350C for 2 hours and then transfer to holding oven and hold @ 100 -

200C, or 50-100C in heated quiver.

Current Conditions AC OCV70 DC + and Welding Positions

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78No ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- Wb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2Document1 pageWb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2lathasri78No ratings yet

- Wb2000e E6013Document1 pageWb2000e E6013cwiksjNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- 12a DPST Miniature Power RelayDocument2 pages12a DPST Miniature Power RelaykarkeraNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERNo ratings yet

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- Datasheet 507446 Zettler Electronics Az9571 1c 3de PCB Relay 3 V DC 1 A 1 Change Over 1 PcsDocument2 pagesDatasheet 507446 Zettler Electronics Az9571 1c 3de PCB Relay 3 V DC 1 A 1 Change Over 1 PcsAitorNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- 02112015000000B - Boehler FOX EASN 25 M - CeDocument1 page02112015000000B - Boehler FOX EASN 25 M - CeABNo ratings yet

- TDS - Nimrod C276KSDocument1 pageTDS - Nimrod C276KSImmalatulhusnaNo ratings yet

- Az847 5Document2 pagesAz847 5SarathBattaNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- Wire Wound Fixed Resistors: FeaturesDocument7 pagesWire Wound Fixed Resistors: FeaturesteoilcaNo ratings yet

- Shielded Power Inductors - MOS6020Document2 pagesShielded Power Inductors - MOS6020mauricio alfonsoNo ratings yet

- RO4400 PrepregDocument2 pagesRO4400 Prepreggcohen03No ratings yet

- SP 32Document1 pageSP 32Henry VillavicencioNo ratings yet

- 253 MA-NF AC/DC: Covered ElectrodesDocument1 page253 MA-NF AC/DC: Covered ElectrodesElMacheteDelHuesoNo ratings yet

- Az 850Document2 pagesAz 850Aravindh RaNo ratings yet

- P91 - Modified 9crmo: Data SheetDocument7 pagesP91 - Modified 9crmo: Data SheetpbanerjeeNo ratings yet

- S690 RQT701 High Strength Steel - Murray PlateDocument2 pagesS690 RQT701 High Strength Steel - Murray PlateAak Gayo100% (1)

- S690 RQT701 High Strength Steel - Murray PlateDocument2 pagesS690 RQT701 High Strength Steel - Murray PlateAydın DemiralNo ratings yet

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocument1 pageThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanNo ratings yet

- Electrode ComparisionDocument1 pageElectrode ComparisionAnilNo ratings yet

- American - Zettler AZ732 053 52 DatasheetDocument2 pagesAmerican - Zettler AZ732 053 52 DatasheetZoro DNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- DataSheet Rele12VDocument2 pagesDataSheet Rele12Vemp007No ratings yet

- AZ951/AZ952: Subminiature Power RelayDocument3 pagesAZ951/AZ952: Subminiature Power RelayvssabinNo ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- 03112015000000B - Boehler FOX NiCr 70 NB - CeDocument1 page03112015000000B - Boehler FOX NiCr 70 NB - CeFlori MovNo ratings yet

- Werkstoff 1.5217 (20MnV6)Document2 pagesWerkstoff 1.5217 (20MnV6)alextentwentyNo ratings yet

- Product Data Sheet: Afrox 7018-1Document2 pagesProduct Data Sheet: Afrox 7018-1Gervasio AndradeNo ratings yet

- KW H2l531.te - en 2Document24 pagesKW H2l531.te - en 2fredtranNo ratings yet

- Non Ferrous MaterialsDocument8 pagesNon Ferrous MaterialsSH1961No ratings yet

- Boehler FOX CN 25 9 CuT - CeDocument1 pageBoehler FOX CN 25 9 CuT - CeNiranjan Fakirchand YadavNo ratings yet

- Electrode Booklet F Web 73Document1 pageElectrode Booklet F Web 73satnamNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Robo TiPTiG Data Sheet FinalDocument2 pagesRobo TiPTiG Data Sheet FinalcwiksjNo ratings yet

- Specifications: Product TypeDocument1 pageSpecifications: Product TypecwiksjNo ratings yet

- K034 - Daikoflux 940Document1 pageK034 - Daikoflux 940cwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- A Max WearplateDocument1 pageA Max WearplatecwiksjNo ratings yet

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsDocument3 pagesRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb2000e E6013Document1 pageWb2000e E6013cwiksjNo ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- FEEG1002 Formula Sheet S1 and S2 2015-16Document5 pagesFEEG1002 Formula Sheet S1 and S2 2015-16GeorgeNo ratings yet

- Equivalent Single Wheel LoadDocument12 pagesEquivalent Single Wheel LoadRajesh Khadka100% (1)

- Phys 16 21 Module 2 Thermal ExpansionDocument15 pagesPhys 16 21 Module 2 Thermal ExpansionLarkTrebligNo ratings yet

- Chapter 1Document27 pagesChapter 1نزار الدهاميNo ratings yet

- Structure Factor PDFDocument28 pagesStructure Factor PDFAndrea EspinosaNo ratings yet

- Appendix A Example 1 3 PDFDocument142 pagesAppendix A Example 1 3 PDFBramanti Ari P100% (1)

- Jurnal Internasional Tentang Material FosforDocument4 pagesJurnal Internasional Tentang Material FosforBebeh Wahid NuryadinNo ratings yet

- CM 425 - Properties of Fresh Concrete PDFDocument14 pagesCM 425 - Properties of Fresh Concrete PDFTran Huynh NamNo ratings yet

- EGM 5653 Advanced Mechanics of Materials: Theories of Stress and StrainDocument34 pagesEGM 5653 Advanced Mechanics of Materials: Theories of Stress and StrainBrajesh kumarNo ratings yet

- Anchorage DesignDocument47 pagesAnchorage DesignbeeNo ratings yet

- ELEC315 Intro 2017 SeptDocument25 pagesELEC315 Intro 2017 SeptTonyNo ratings yet

- CE6302-Mechanics of Solids PDFDocument15 pagesCE6302-Mechanics of Solids PDFsarre mamoudouNo ratings yet

- Application of Electron Back Scatter DiffractionDocument108 pagesApplication of Electron Back Scatter DiffractionascgyNo ratings yet

- Metal MumpsDocument27 pagesMetal Mumpsapi-3748599No ratings yet

- Mechanical Properties of Astm A572 Grade 65 SteelDocument123 pagesMechanical Properties of Astm A572 Grade 65 Steelcesarceron2003No ratings yet

- Notes Chapter 6 (6.6)Document12 pagesNotes Chapter 6 (6.6)rushdiNo ratings yet

- Structural and Magnetic Properties of Fe Co System: M. Sorescu, A. GrabiasDocument5 pagesStructural and Magnetic Properties of Fe Co System: M. Sorescu, A. GrabiasBensebaaNo ratings yet

- Metals HandbookDocument33 pagesMetals HandbookAlexandre Sp50% (4)

- Class Notes For Making RugsDocument2 pagesClass Notes For Making RugsdakNo ratings yet

- Polymer Processing With Super Critical Fluids by SG KazarianDocument24 pagesPolymer Processing With Super Critical Fluids by SG KazarianLia NashNo ratings yet

- Scantlings Cal 1000TEU (Midship)Document85 pagesScantlings Cal 1000TEU (Midship)bhuktha100% (1)

- Francis Runner Analysis Using FEM PDFDocument6 pagesFrancis Runner Analysis Using FEM PDFAnonymous AkzeMHNTUyNo ratings yet

- Flexural Analysis and Design - Doubly Reinforced BeamsDocument23 pagesFlexural Analysis and Design - Doubly Reinforced BeamsJhe Taguines100% (1)

- Mems AssignmentDocument6 pagesMems AssignmentsrishagNo ratings yet

- 2017-03-09 - Nature Materials Deg - Materials and Corrosion Challenges in O&g ProductionDocument47 pages2017-03-09 - Nature Materials Deg - Materials and Corrosion Challenges in O&g ProductionSyarief NahdiNo ratings yet

- Exponent of HardeningDocument5 pagesExponent of HardeningneilNo ratings yet

- MAE 156A Analysis of StressDocument46 pagesMAE 156A Analysis of StressAudrey TuNo ratings yet

- Chapter 5Document6 pagesChapter 5tabloid07No ratings yet

- Magnetic Properties and Retained Austenite Quantification in SAE 4340 SteelDocument7 pagesMagnetic Properties and Retained Austenite Quantification in SAE 4340 SteelMonica Sands0% (1)

- Bearing Design Method BDocument3 pagesBearing Design Method BDhurai KesavanNo ratings yet